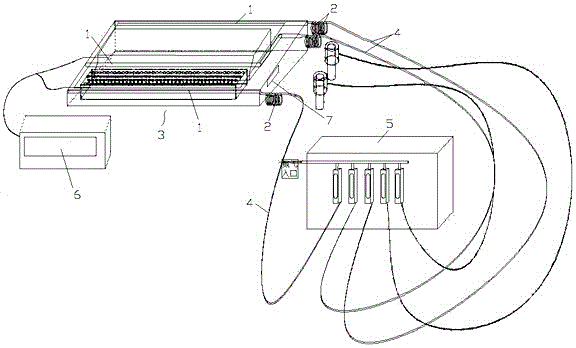

Wave-soldering nitrogen protection equipment

A technology of nitrogen protection and wave soldering, which is applied in welding equipment, metal processing equipment, auxiliary devices, etc., can solve problems such as limited amount of nitrogen, limited anti-oxidation effect of solder, and poor quality of solder joints, so as to reduce nitrogen consumption and improve The effect of anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

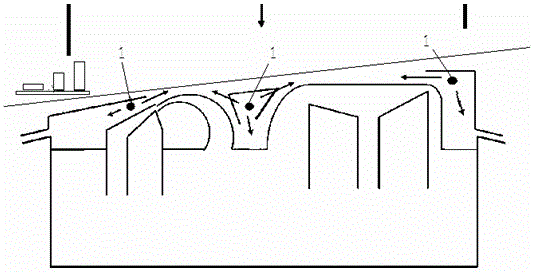

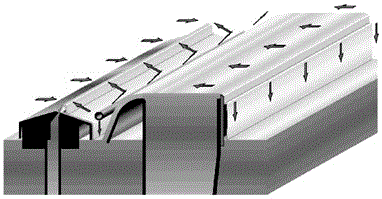

[0019] In view of the defects of the prior art: 1. The nitrogen filling method is changed. The top-down nitrogen filling method of the existing equipment does not conform to the principle of gravity. 2. The reduction of gas consumption. The existing equipment adopts the method of stainless steel drilling. Due to the large hole diameter, the nitrogen consumption is large and uneven. 3. The preheating problem of blowing out nitrogen gas. The existing equipment directly blows nitrogen gas below normal temperature into the welding surface, which may easily cause quality problems such as cold welding of solder joints. 4. The problem of automatic control. The nitrogen inlet pipe of the existing equipment is controlled by a manual switch valve, and the equipment operator often forgets to switch it. The invention provides technical solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com