A battery cell and cover plate assembly structure and assembly method thereof

An assembly structure and cover plate technology, which is applied in the direction of battery assembly, secondary battery manufacturing, sustainable manufacturing/processing, etc., can solve the problem of easily scratched diaphragm, achieve convenient operation, simple manufacturing process, and high utilization rate of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

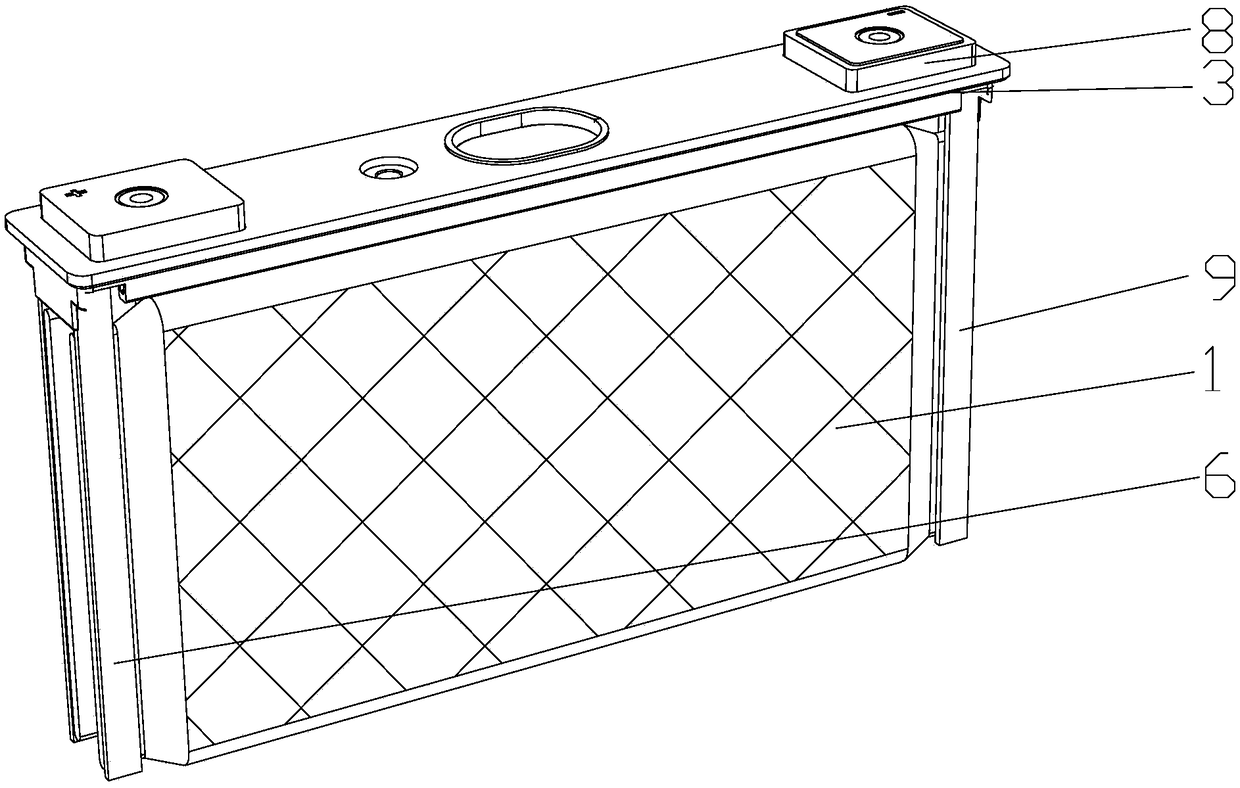

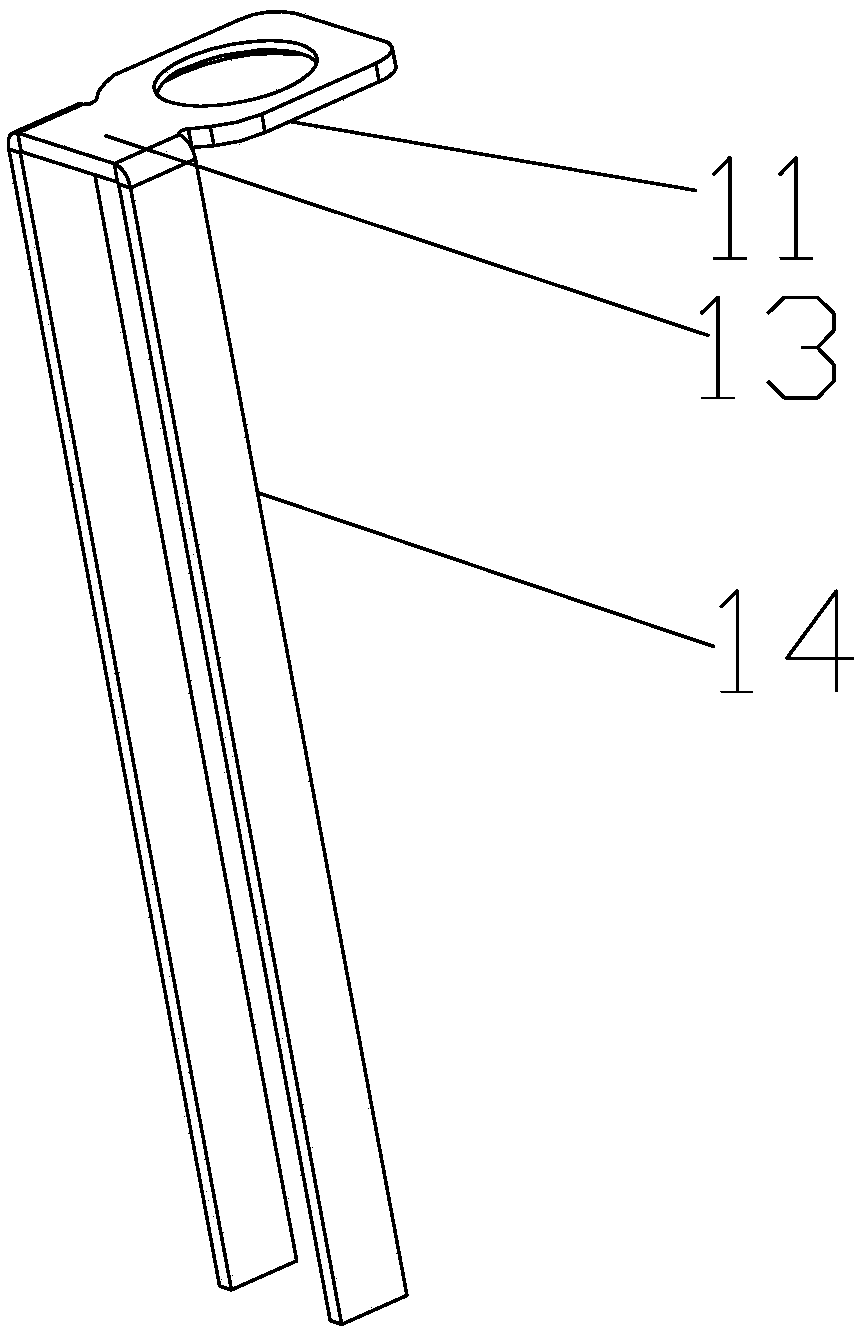

[0032] See figure 1 , 3 ~6, a battery cell and cover plate assembly structure, including two bare battery cells 1, a cover plate structure 2, and the cover plate structure 2 includes a top cover 3, a lower plastic 4, a positive conductive block 5, and a positive pole claw structure 6, Positive pole 7, negative electrode conductive block 8, negative electrode plastic 19, negative pole claw structure 9, negative pole 10, sealing ring 22, sealing ring two 23, positive electrode conductive block 5, negative electrode conductive block 8, and negative electrode plastic 19 are all installed On the upper surface of the top cover 3, the negative conductive block 8 is located in the negative upper plastic 19, the lower plastic 4 is located under the top cover 3, and the sealing ring 22 and the second sealing ring 23 are both located between the top cover 3 and the lower plastic 4. .

[0033] The positive pole claw structure 6 and the negative pole claw structure 9 are respectively located ...

Embodiment 2

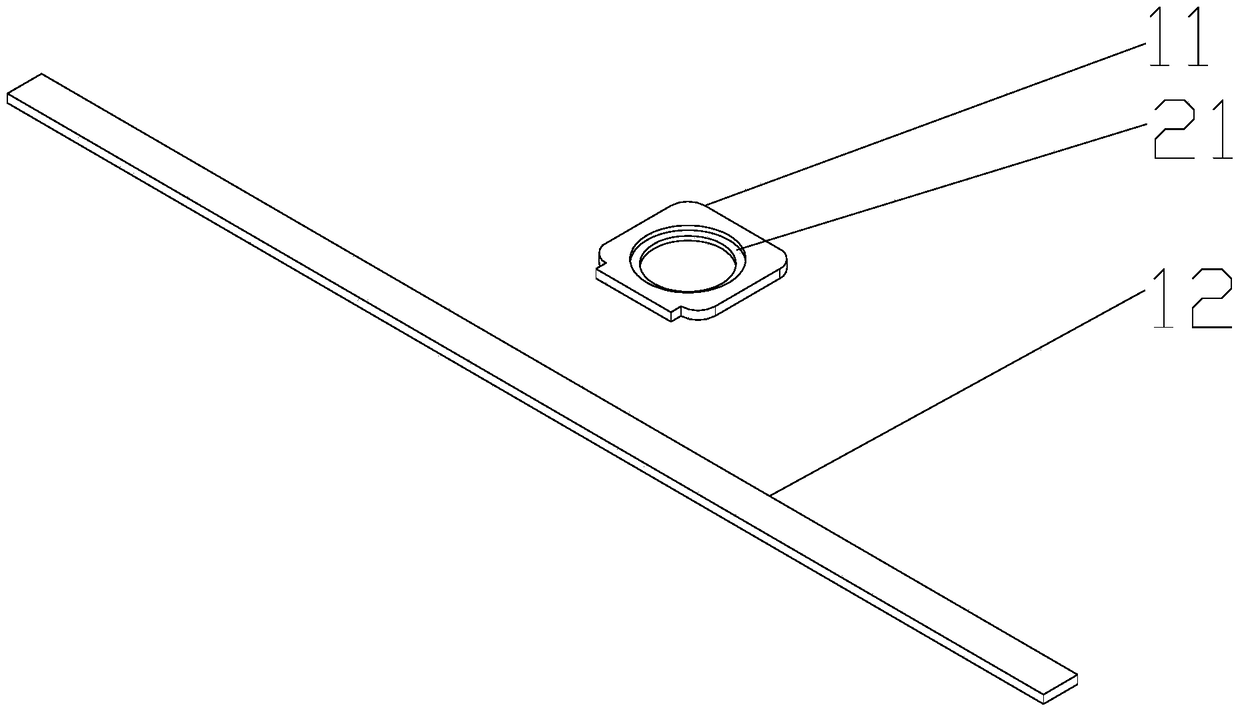

[0044] See Picture 9 The difference between this embodiment and embodiment 1 is that the connecting piece 11 and the positive pole claw 12 are integrally formed, the connecting piece two and the negative pole claw are integrally formed, and the positive pole claw structure and the negative pole claw structure are stamped separately be made of.

Embodiment 3

[0046] The difference between this embodiment and Embodiment 1 is that in this embodiment, the bending pressure of the positive pole claw is 10.2 MPa, the bending pressure of the negative pole claw is 5.2 MPa, and the bending time is 5.8 s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com