PCB packaging design and welding method of TQFP chip

A welding method and chip technology, applied in welding equipment, metal processing equipment, metal processing and other directions, can solve the problems of poor grounding of chips, virtual welding, easy tin leakage from pad welding holes, etc., so as to reduce the defective welding rate and improve product quality. Quality, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

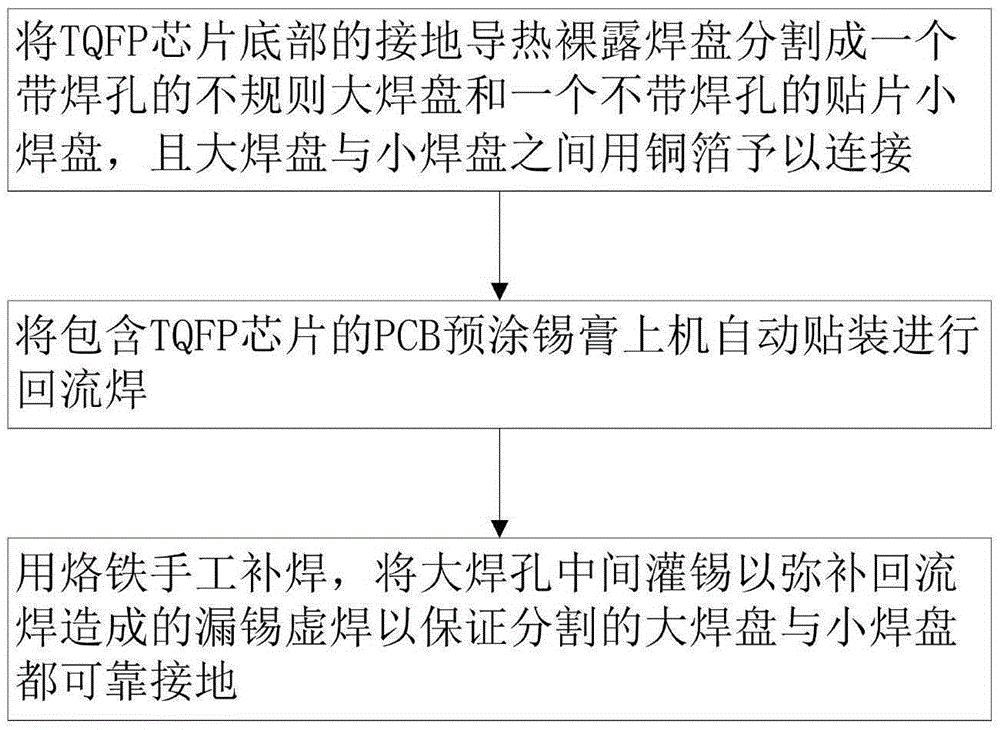

[0013] Please refer to figure 1 , the present invention provides a kind of PCB encapsulation design and soldering method of a TQFP chip, comprising the following steps:

[0014] Divide the ground heat conduction exposed pad at the bottom of the TQFP chip into an irregular large pad with a solder hole and a small patch pad without a solder hole, and connect the large pad and the small pad with copper foil ;

[0015] Automatically mount the PCB pre-coated solder paste containing the TQFP chip on the machine for reflow soldering;

[0016] Use a soldering iron to manually repair the soldering, and fill the middle of the large soldering hole with tin to make up for the solder leakage caused by reflow soldering, so as to ensure that the divided large pads and small pads are reliably grounded.

[0017] The defective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com