Welding method and system for electrode plate of surge protector

A surge protector and welding method technology, applied in welding equipment, tin feeding devices, auxiliary devices, etc., can solve the problems of high welding defect rate, uneven heat absorption, and solder embrittlement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

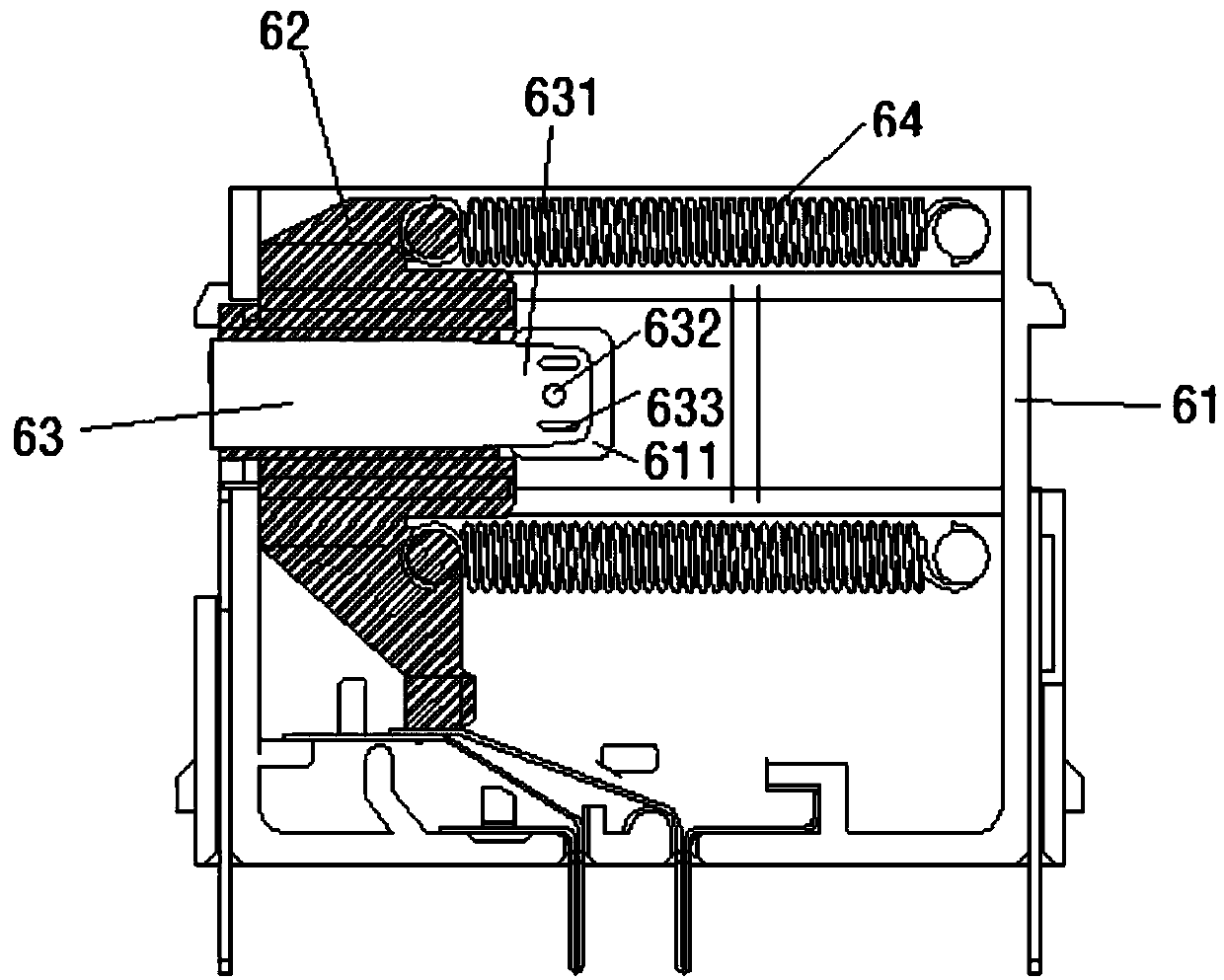

[0075] The surge protector to be welded in this embodiment includes a housing, a slider, and an electrode piece, the slider is arranged between the housing and the electrode piece, the electrode piece includes a welding end, and the housing There is a pad area for welding the electrode sheet.

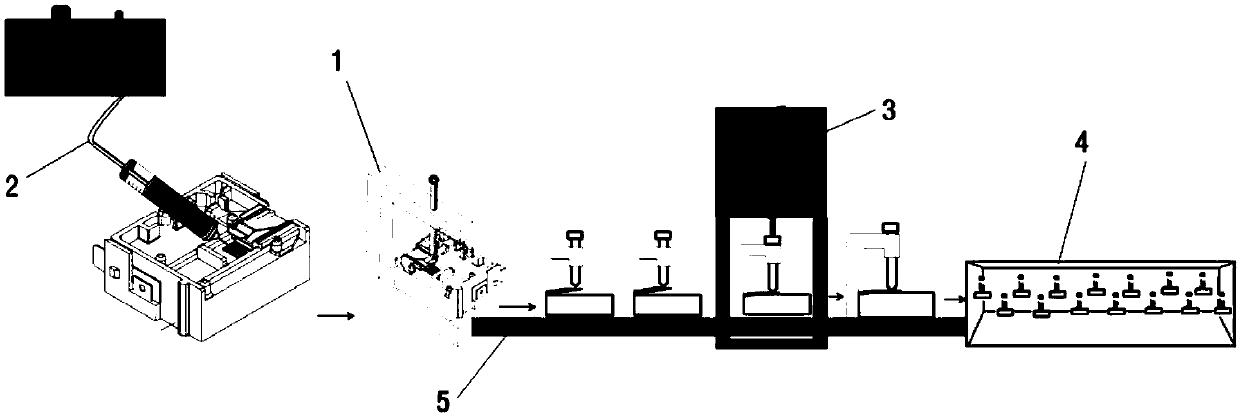

[0076] The welding process of the electrode sheet and the pad area of the surge protector specifically includes the following steps:

[0077] 1. Take the above surge protector for processing

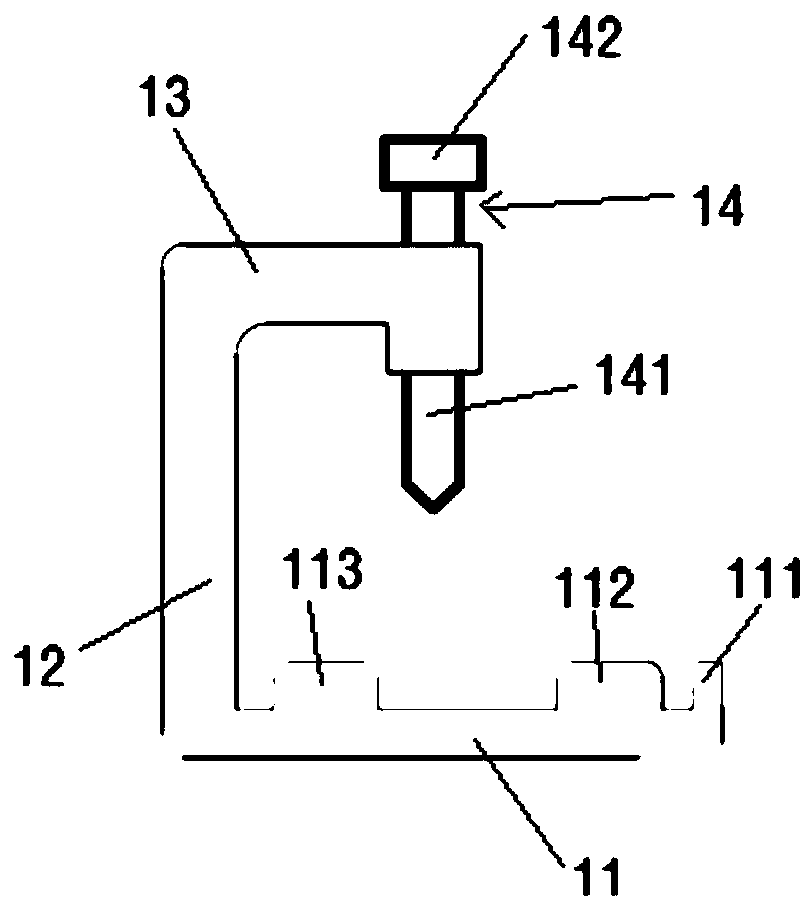

[0078] A first positioning concave platform and a second positioning concave platform are provided in the center of the welding end, and both the first positioning concave platform and the second positioning concave platform are recessed toward the pad area side, and the second positioning concave platform is arranged on the first positioning concave platform both sides of the stage.

[0079] 2. Solder paste injection

[0080] Use a dispenser to inject solder paste into the pad area, attach t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com