Welding structure and semiconductor part

A technology for welding structures and semiconductors, which is applied in semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., and can solve problems such as poor welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

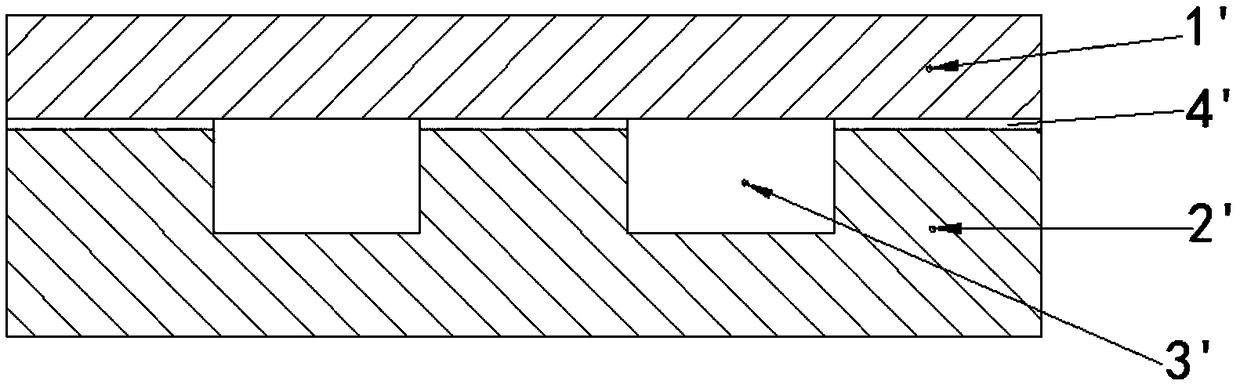

Problems solved by technology

Method used

Image

Examples

Embodiment 1

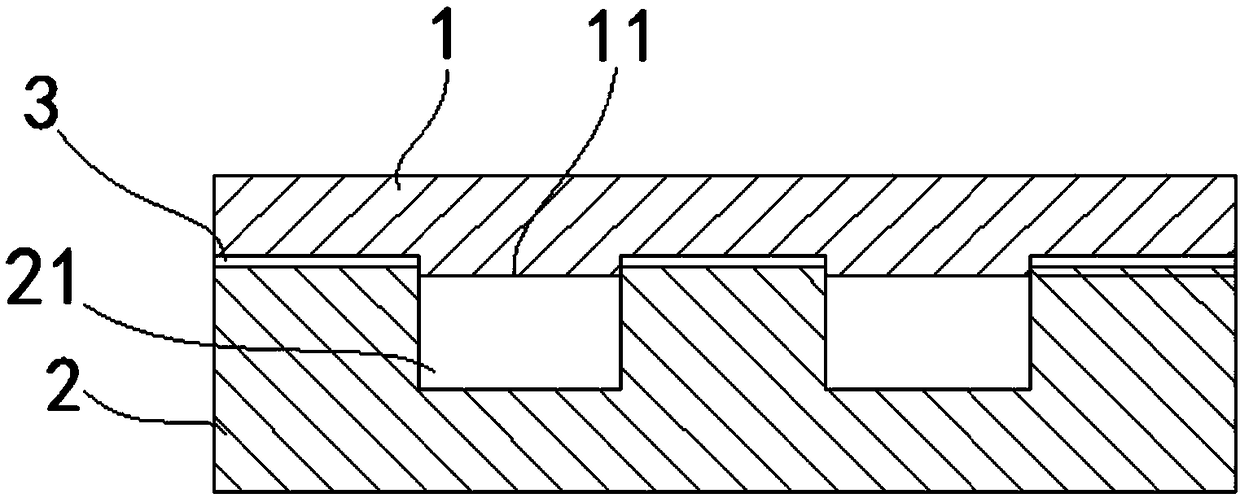

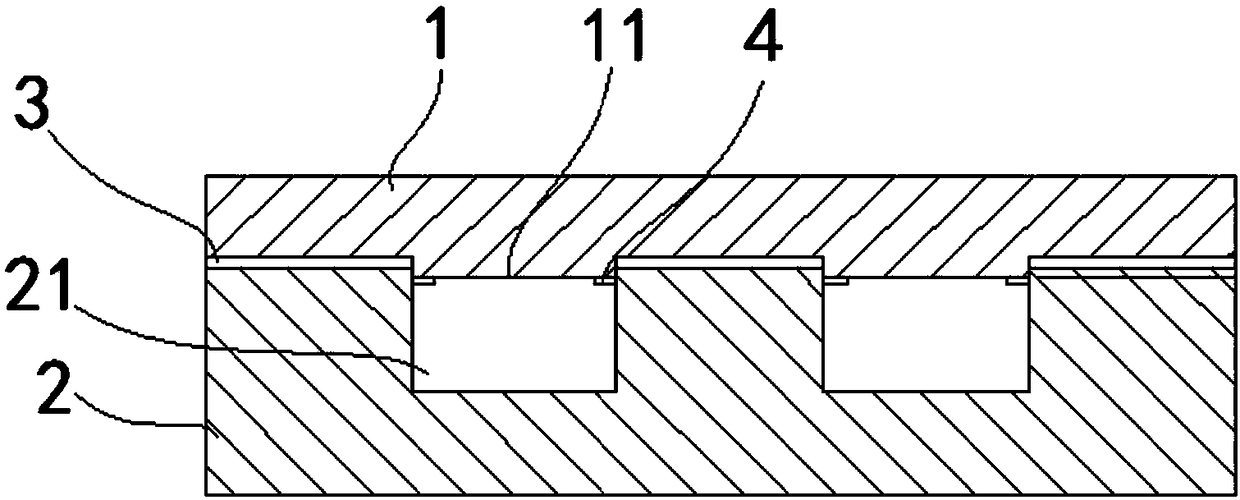

[0030] The welded structure provided by this embodiment, such as Figure 2 to Figure 3 As shown, it includes a cover plate 1 and a bottom plate 2; Through the arrangement, the groove 21 forms an opening with the first end surface; the cover plate 1 has a second end surface, the first end surface is opposite to the second end surface, and the second end surface is provided with a convex 11, the protrusion 11 can close the opening, and there is a gap between the first end surface and the second end surface, the gap is used to set the solder layer 3, the cover plate 1 and the bottom plate 2 soldered through said solder layer 3.

[0031] When welding the cover plate 1 and the bottom plate 2, the solder layer 3 is heated, the pressure is applied to the cover plate 1 toward the bottom plate 2, and the pressure is applied to the bottom plate 2 toward the cover plate 1, so that the two are welded together. The protrusion 11 and the groove 21 can form a channel. Since the protrusion...

Embodiment 2

[0049] The semiconductor component provided in this embodiment includes the soldering structure described in Embodiment 1.

[0050] The welding structure includes a cover plate 1 and a bottom plate 2; the bottom plate 2 has a first end surface, a groove 21 is provided on the first end surface, and the two ends of the groove 21 are respectively connected to the side walls of the bottom plate 2 Through the arrangement, the groove 21 forms an opening with the first end surface; the cover plate 1 has a second end surface, the first end surface is opposite to the second end surface, and the second end surface is provided with a convex 11, the protrusion 11 can close the opening, and there is a gap between the first end surface and the second end surface, the gap is used to set the solder layer 3, the cover plate 1 and the bottom plate 2 soldered through said solder layer 3.

[0051] When welding the cover plate 1 and the bottom plate 2, the solder layer 3 is heated, the pressure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com