Clamping equipment for LED display screen box body welding

A technology of LED display and clamping equipment, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as low welding efficiency, unstable clamping, and clamping offset, and achieve high welding efficiency High, firm welding quality, stable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

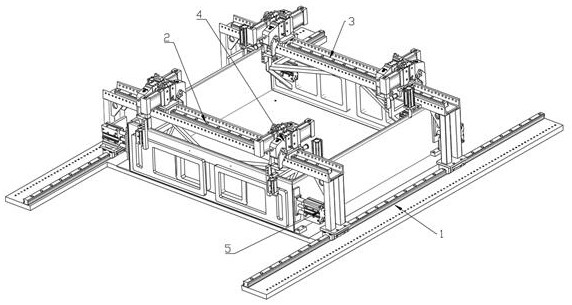

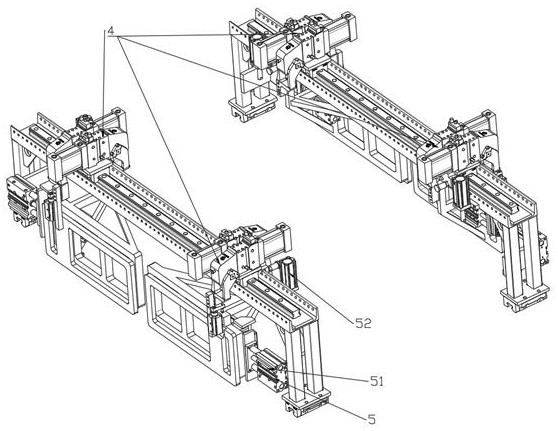

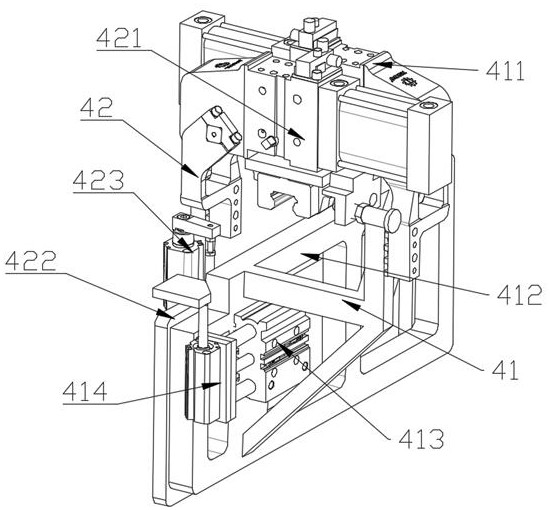

[0025] like Figure 1 to Figure 3 As shown, Embodiment 1 of the present invention: a clamping device for LED display box welding, including a tooling platform 1, a first gantry 2, a second gantry 3, a clamping mechanism 4 and a pusher Mechanism 5, the first gantry 2 and the second gantry 3 are arranged in parallel on the tooling platform 1, and the bottoms of the first gantry 2 and the second gantry 3 are both slidably connected to the tooling platform On the platform 1, the clamping mechanisms 4 are evenly distributed on the first gantry 2 and the second gantry 3, and the pushing mechanism 5 is respectively arranged on the first gantry 2 and the second gantry. On the inner side of the column and the beam of the second gantry frame 3, the first gantry frame 2 and the second gantry frame 3 are used to install the clamping mechanism 4, and the tooling platform 1 is used to place the boxes to be welded The clamping mechanism 4 is used to firmly and stably clamp the box to be wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com