Lithium-ion power battery tab

A power battery, lithium-ion technology, applied in the field of lithium-ion power battery tabs, can solve the problems of inconsistent welding strength of battery packs, increase investment capital, hidden dangers of battery safety, etc., to save equipment investment, avoid false welding, and easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

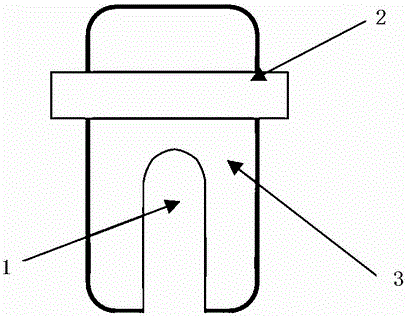

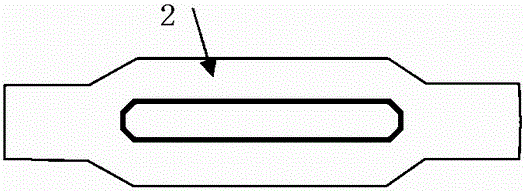

[0020] The invention provides a tab structure for a power lithium-ion power battery such as figure 1 As shown, the specific structure is:

[0021] It includes a metal conductor bar and a tab rubber block. A U-shaped hole is arranged on the edge of the longer end of the metal conductor bar. The two sides are parallel and the top end is arc-shaped. The corners of the tab metal conductor strips are rounded. In this embodiment, the width of the metal conductor strip is 25mm to 40mm, and the above-mentioned U-shaped hole is one, which is arranged in the middle of the longer end of the metal conductor strip; the distance between the edge of the U-shaped hole and the edge of the metal conductor strip Greater than 10mm.

Embodiment 2

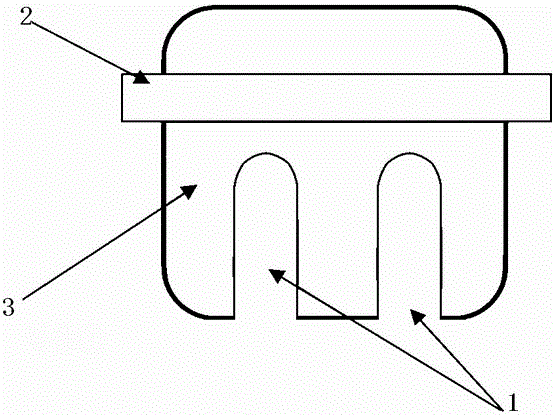

[0023] The invention provides a tab structure for a power lithium-ion power battery such as figure 2 As shown, the specific structure is:

[0024] It includes a metal conductor bar and a tab rubber block. A U-shaped hole is arranged on the edge of the longer end of the metal conductor bar. The two sides are parallel and the top end is arc-shaped. The corners of the tab metal conductor strips are rounded. In this embodiment, the width of the metal conductor strip is greater than 40mm, and there are two U-shaped holes, which are arranged in the middle of the longer end of the metal conductor strip; the distance between the edge of the above-mentioned U-shaped hole and the edge of the metal conductor strip is greater than 10mm.

[0025] In the tab of the lithium-ion power battery provided by the present invention, the U-shaped hole is used for placing screws, and the positive and negative electrodes of the battery tab are connected in series or in parallel by using the screws....

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com