Equipment for automatically welding battery circuit board and using method of equipment

A battery circuit board and automatic welding technology, applied in welding equipment, welding equipment, resistance welding equipment, etc., can solve the problems of continuous welding, smoke generation, high cost, etc., and achieve the effects of reducing production costs, improving production efficiency, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

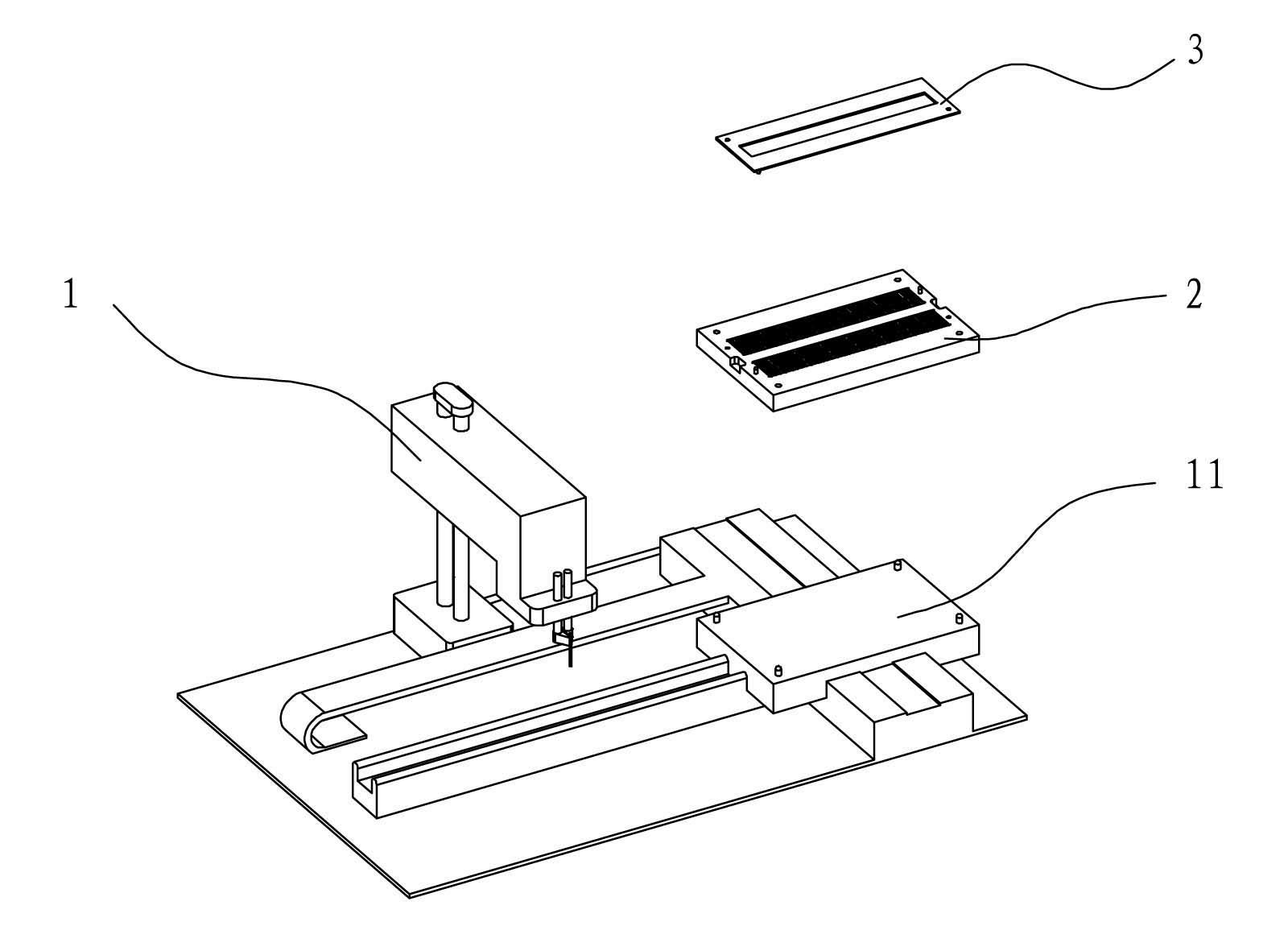

[0017] Such as figure 1 As shown, the battery circuit board automatic welding equipment proposed by the present invention includes an automatic butt welding machine 1, and the automatic butt welding machine 1 includes a two-dimensional numerical control sliding table 11, which adopts a programmable logic controller ( Programmable Logic Controller, PLC) to control, and use the touch LCD screen to display and input working parameters.

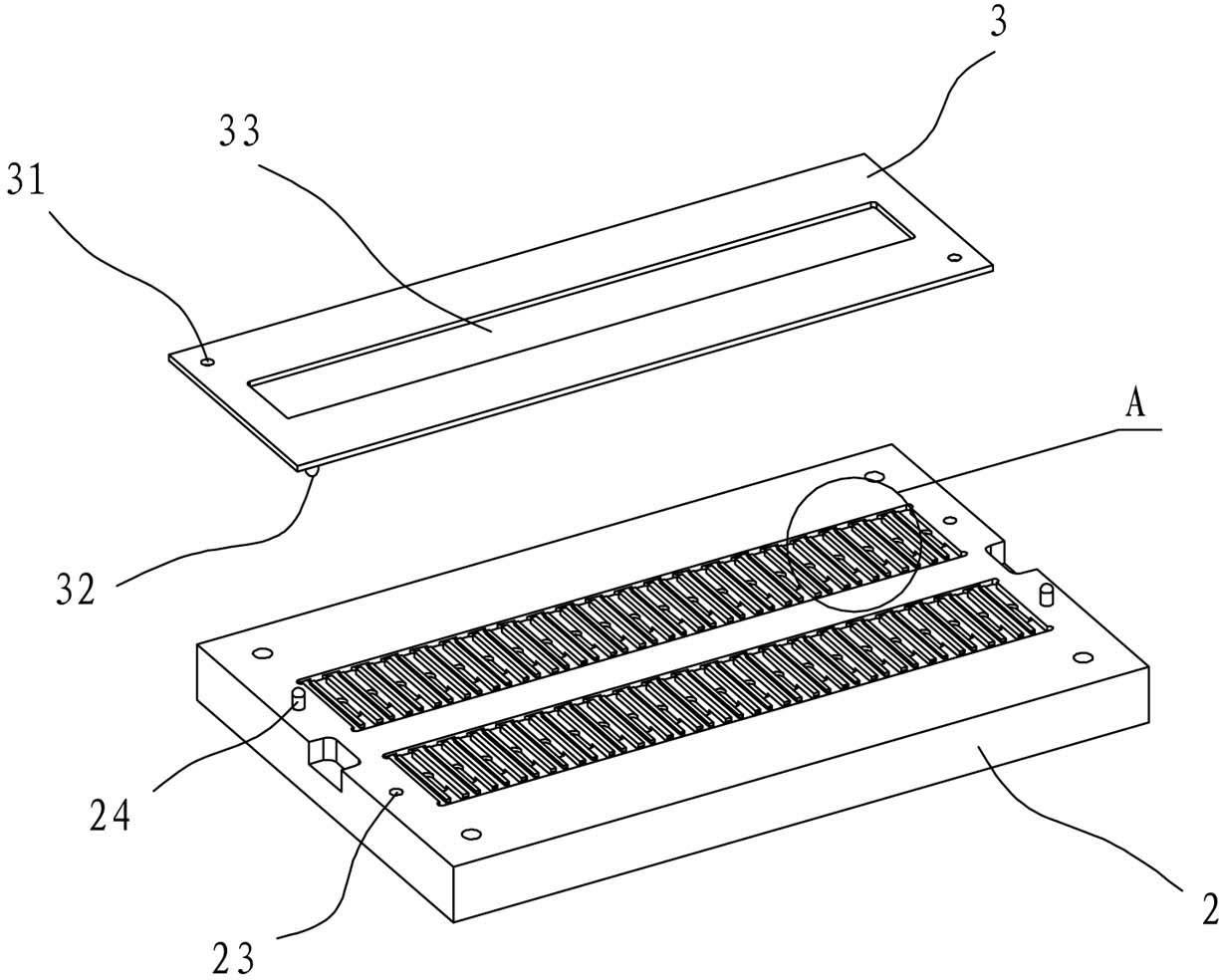

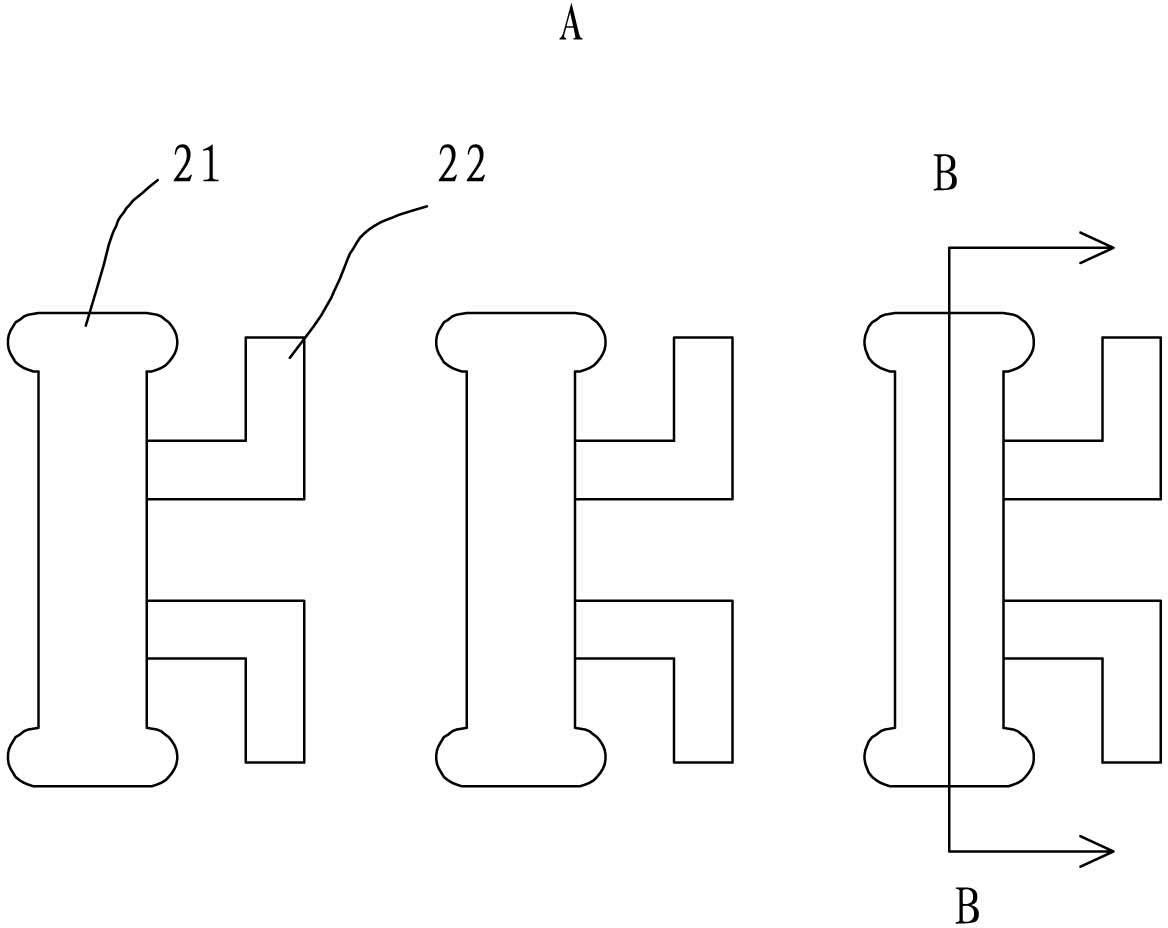

[0018] another example figure 2 , 3 As shown in and 4, a fixture 2 is installed on the two-dimensional numerical control slide table 11, and a plurality of circuit board grooves 21 for embedding circuit boards are arranged on the fixture 2, and each side of the circuit board groove 21 The corresponding position is provided with the nickel sheet groove 22 that places nickel sheet. In addition, in order to avoid the phenomenon that the circuit board bounces out of the fixture 2 due to the reaction force during the operation, the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com