LED lamp and circuit connecting method thereof

A LED lamp and electrical connection technology, applied in printed circuit, circuit layout, printed circuit manufacturing, etc., can solve the problems of easy false welding, difficult welding, scratches and damage of wire metal substrate, etc., to avoid false welding and avoid scratches The effect that wound damage, welding are easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

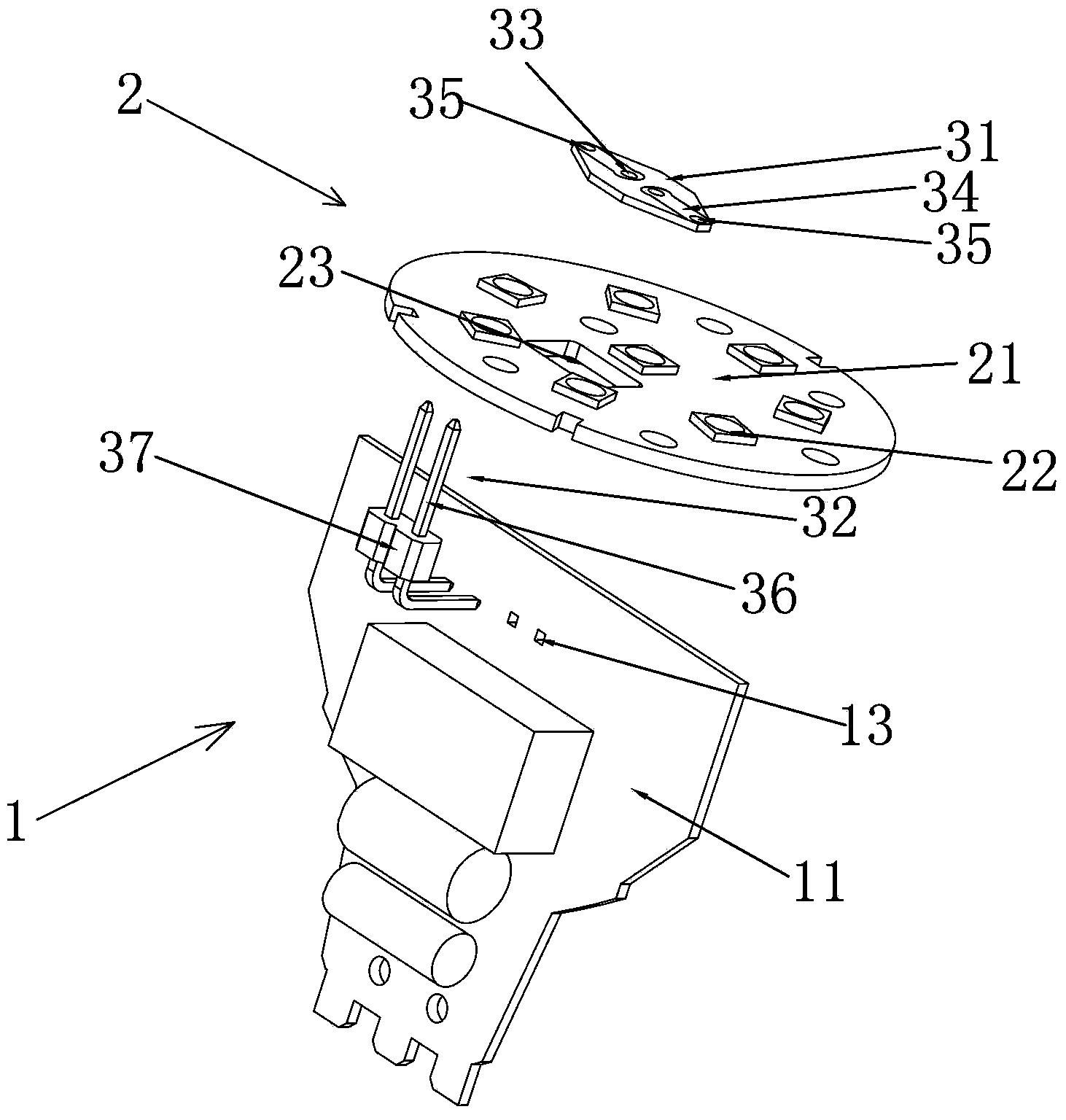

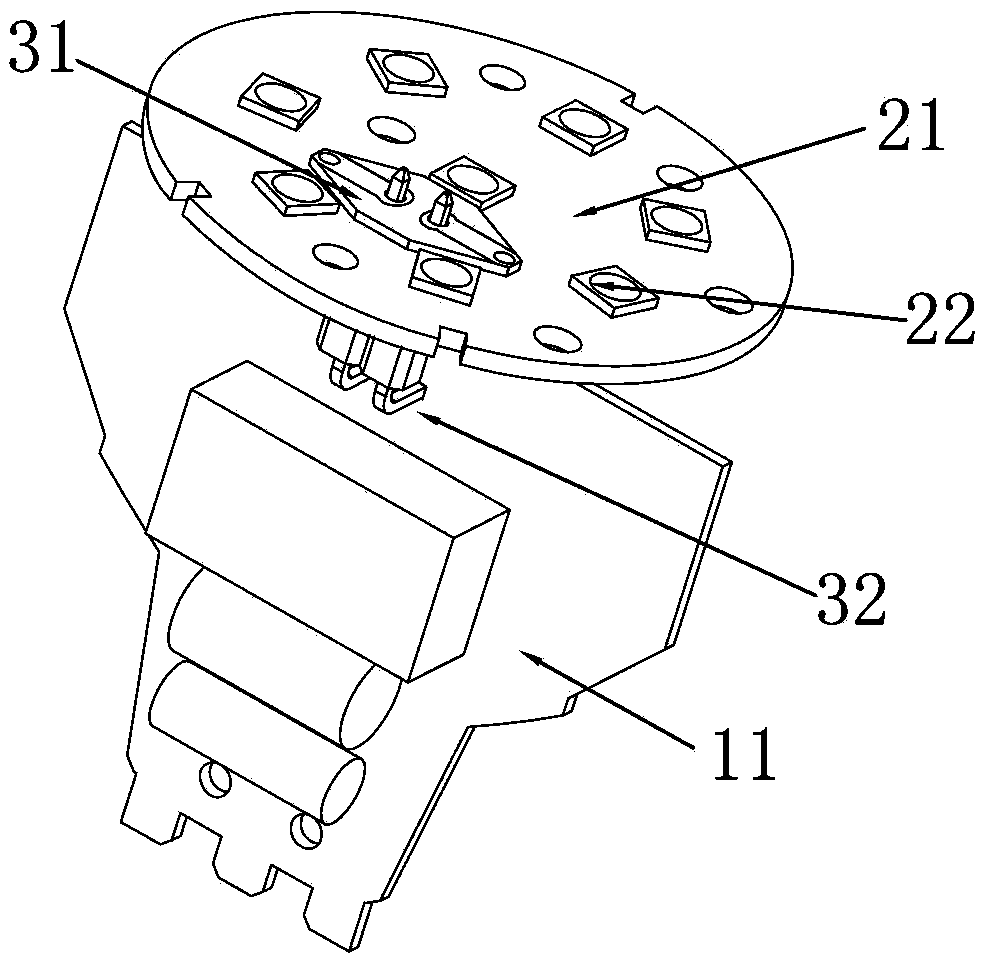

[0023] Embodiment 1: as Figure 1-3 As shown, the LED lamp of the present invention includes a power supply device 1 , an LED light source module 2 , a connection plate 31 and a connection pin 32 , and the LED light source module 2 includes a metal substrate 21 and an LED light source 22 disposed on the metal substrate 21 . The power supply device 1 of the present invention and the LED light source module 2 are connected through the connection plate 31 and the connection pin 32, and the specific connection method is as follows:

[0024] The metal substrate 21 is provided with a through hole 23, and the connection plate 31 is overlapped on the top of the through hole 23. The size of the connection plate 31 is larger than the size of the through hole 23. The connection plate 31 completely covers the through hole 23, and one end of the connection pin 32 penetrates through the hole 23. The connection plate 31 is welded and fixed through the through hole 23 , and the size of the th...

Embodiment 2

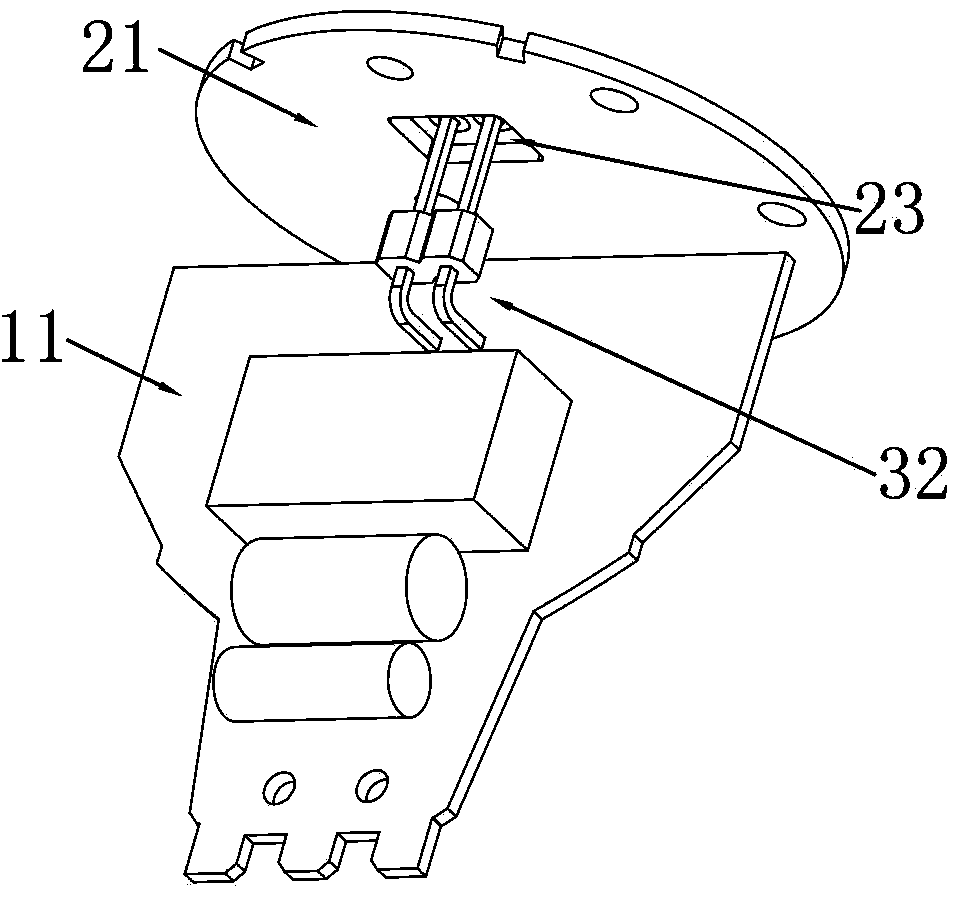

[0027] Embodiment 2: as Figure 4-6 As shown, the structure of embodiment 2 is similar to that of embodiment 1, and the structure of the connection plate 31 and the connection mode between the connection plate 31 and the metal substrate 21 are the same as those of embodiment 1, the difference is that the connection pin 32 consists of two The needles 36 in the shape of a straight bar are formed. The circuit board 11 includes a first circuit board 11a and a second circuit board 11b arranged perpendicular to each other, and the first circuit board 11a is arranged parallel to the metal substrate 21. The first circuit board 11a A third welding hole 13 is provided on it.

[0028] The specific connection method is: the connection plate 31 is arranged above the through hole 23 of the metal substrate 21 of the LED light source module 2, and one end of the connection pin 32 passes through the through hole 23 of the metal substrate 21 and the first welding hole 33 of the connection plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com