Method for separating V-Ti-Fe concentrate fines

A vanadium-titanium iron and fine powder technology, which is applied in the field of titanium and vanadium, and iron extraction, can solve the problems of no large-scale industrial application, and achieve the effects of easy production, energy saving and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The basic content of the present invention will be described below in conjunction with specific embodiments. The described embodiments are for better illustrating the basic content of the present invention, and should not be construed as limiting the claims of the present invention.

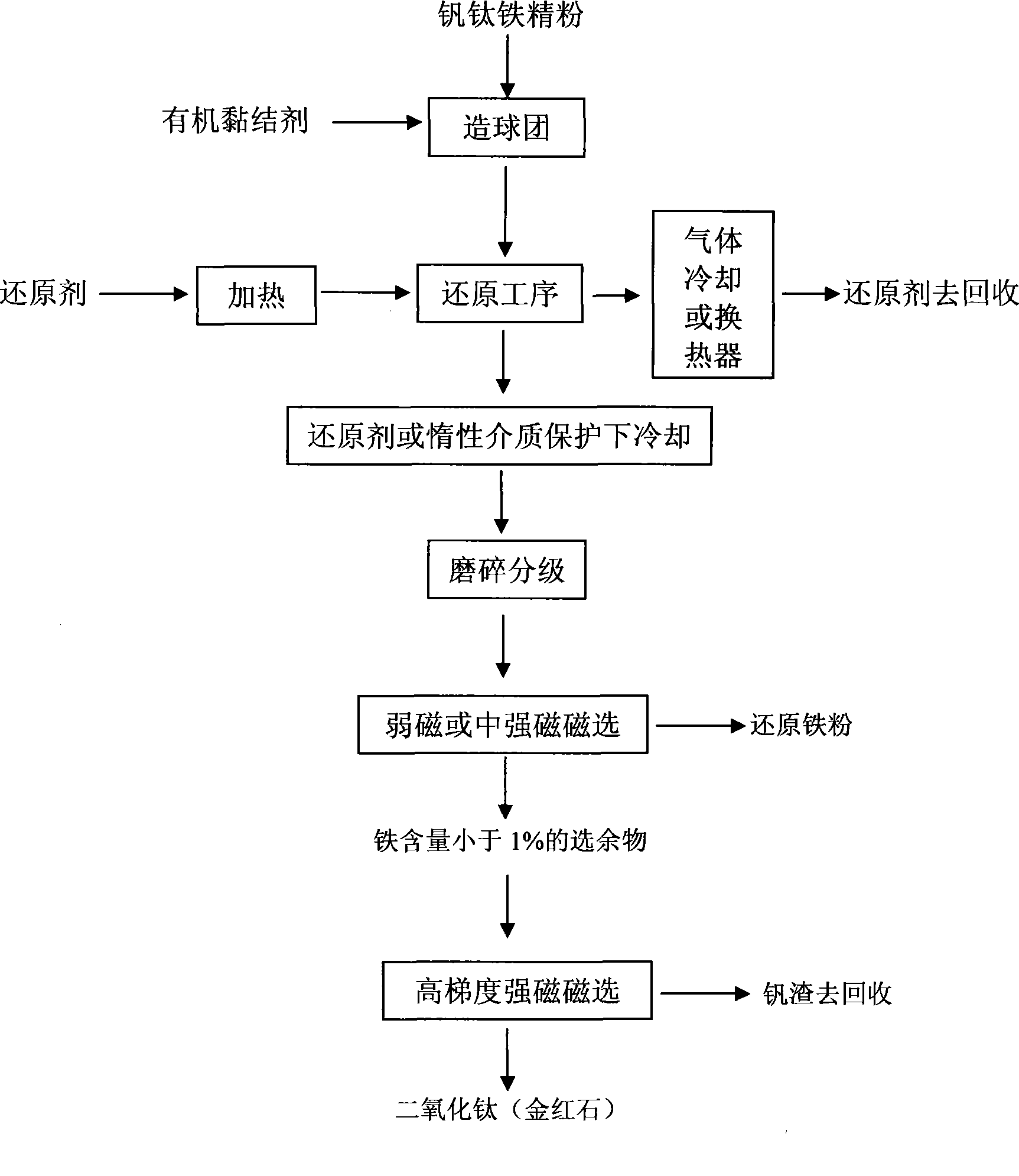

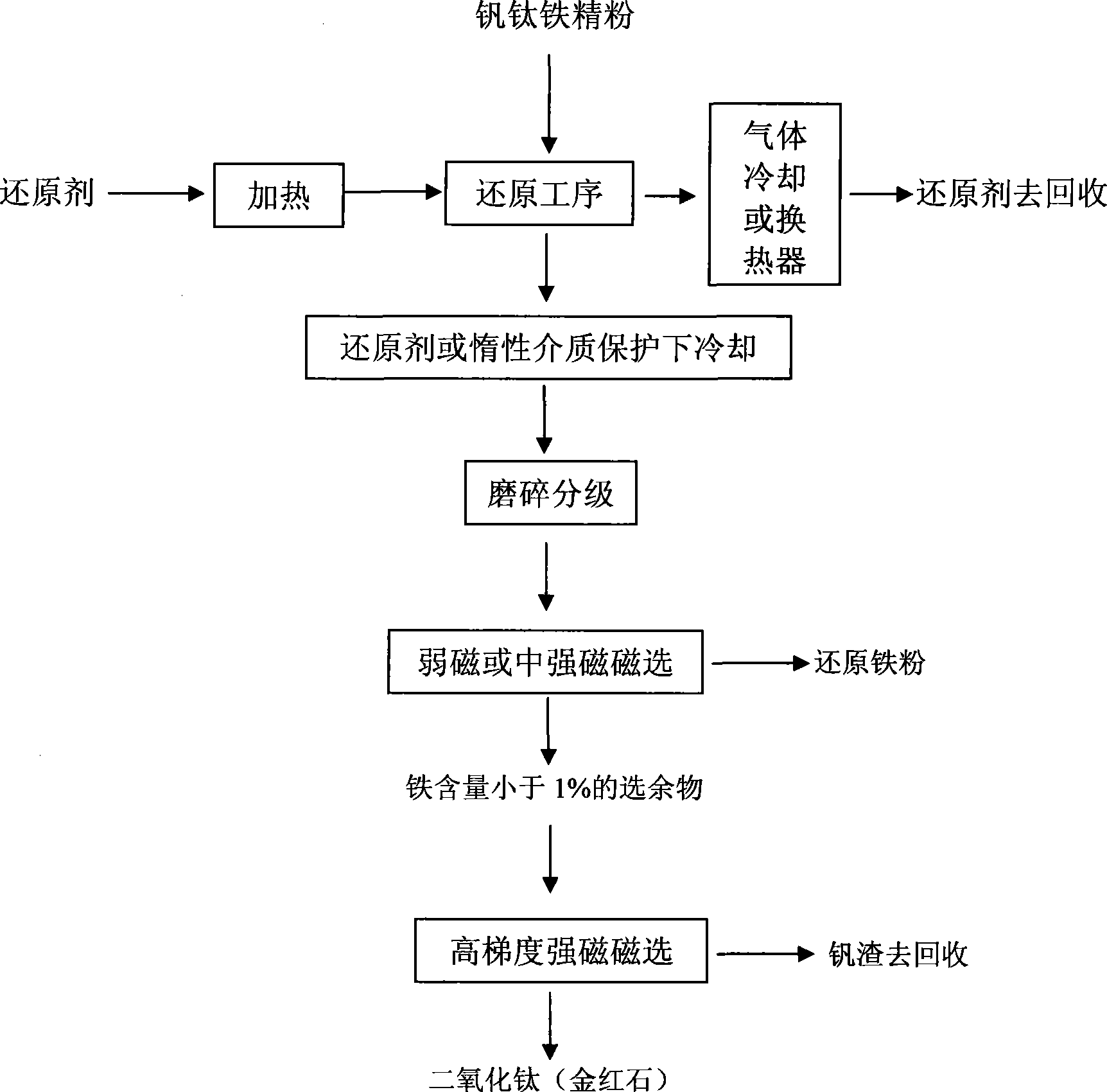

[0043] Embodiment 1 is to fully mix a small amount (0.01% to 0.1% of the total mass) of organic molecular binder and vanadium-titanium-iron fine powder, and form it into vanadium-titanium-iron fine powder pellets through pelletizing machine. The pellets are directly sent to the reduction process, and are directly contacted with a gas or liquid reducing agent for reduction, and the reduction temperature is not less than 500°C; the reduction device in the reduction process can be a continuous feeding kiln (including rotary kiln, tunnel kiln) and / or furnace (including rotary hearth furnace, electric arc furnace, submerged arc furnace), etc.; the gas reducing agent can be heated before entering...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com