Reduced graphene oxide and preparation method thereof

A graphene and graphene technology, applied in the field of reduced graphene oxide and its preparation, can solve the problems of low efficiency, high energy consumption, high temperature, etc., and achieve the effects of simple preparation process, reduced production cost, and high reduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

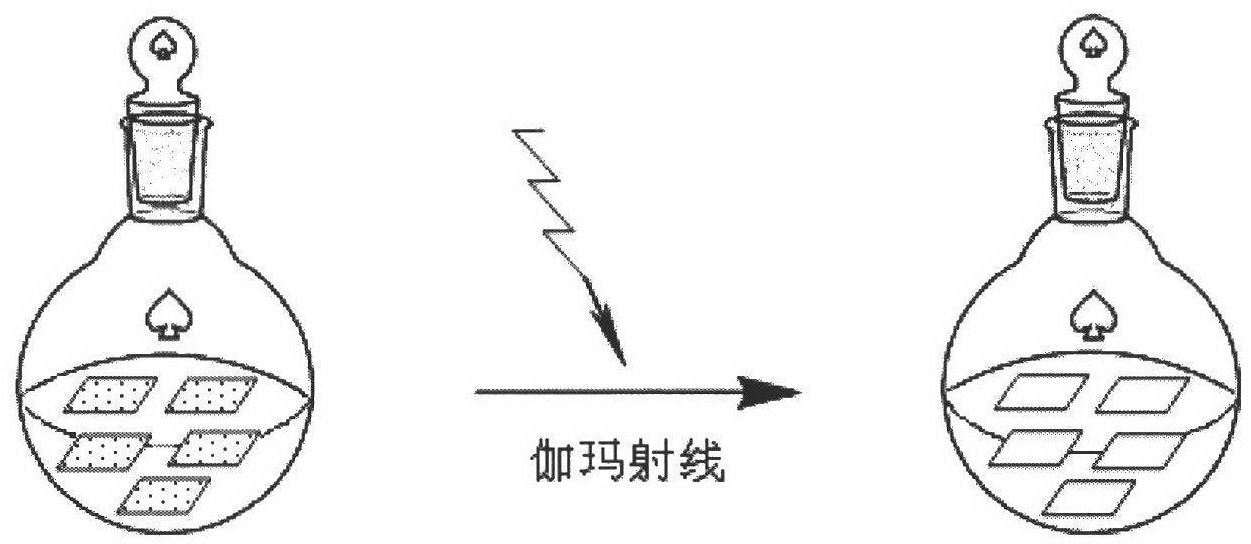

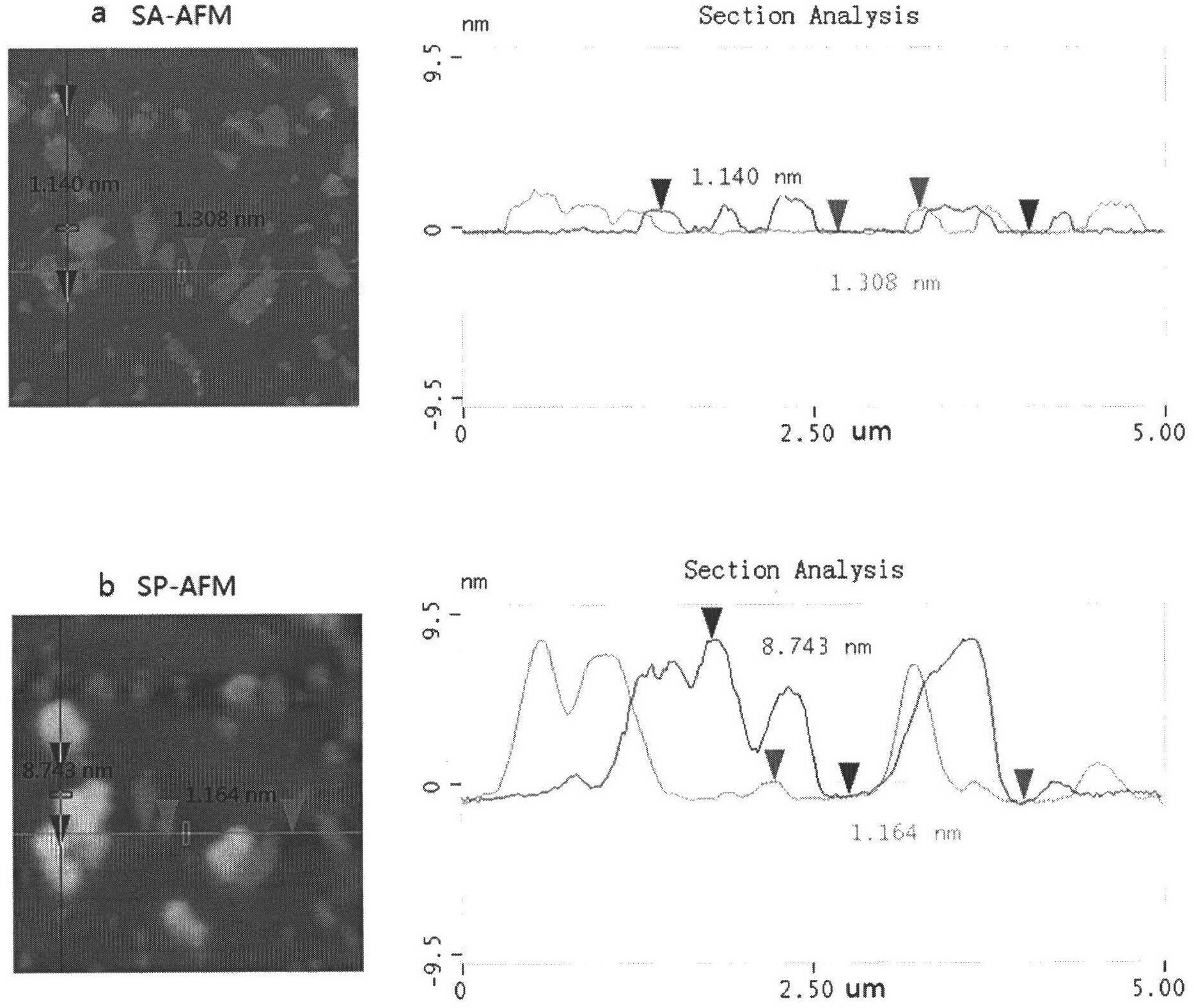

Method used

Image

Examples

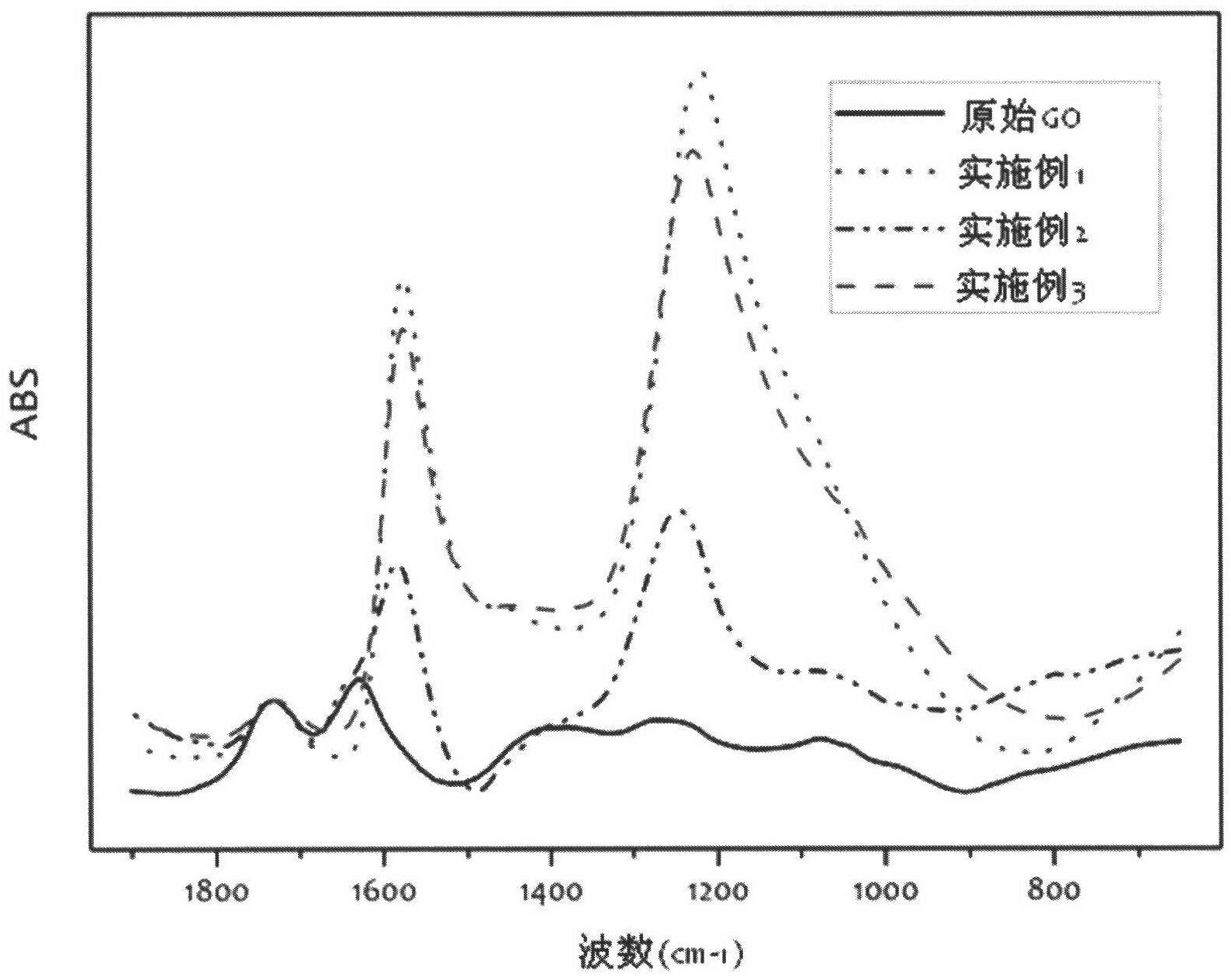

Embodiment 1

[0042] (1) Add a certain amount of methanol in the graphene oxide aqueous solution (1mg graphene oxide / mL water), shake and mix for 2min to obtain a mixed solution; the concentration of graphene oxide in the mixed solution is 0.5mg / mL, and the concentration of methanol is 50% (v / v%);

[0043] (2) Nitrogen gas bubbling for 10 minutes to remove the oxygen in the mixed solution, sealed and sent to cobalt-60 irradiation chamber, dose rate 0.882kGy / h, irradiated for 17h, to obtain the mixture;

[0044] (3) After the irradiation is completed, the resulting mixture is filtered through a PVDF microporous membrane with a pore size of 0.22 μm, and the filter cake is collected and dried to obtain reduced graphene oxide.

Embodiment 2

[0046] (1) Add a certain amount of ethanol to the graphene oxide aqueous solution (1mg graphene oxide / mL water), shake and mix for 2min to obtain a mixed solution; the concentration of graphene oxide in the mixed solution is 0.5mg / mL, and the concentration of methanol is 50 % (v / v%); the concentration of ethanol is 50% (v / v%);

[0047] (2) Nitrogen gas bubbling for 10 minutes to remove the oxygen in the mixed solution, sealed and sent to cobalt-60 irradiation chamber, dose rate 0.882kGy / h, irradiated for 17h, to obtain the mixture;

[0048] (3) After the irradiation is completed, the resulting mixture is filtered through a PVDF microporous membrane with a pore size of 0.22 μm, and the filter cake is collected and dried to obtain reduced graphene oxide.

Embodiment 3

[0050] (1) Add a certain amount of isopropanol to the graphene oxide aqueous solution (1mg graphene oxide / mL water), shake and mix for 2min to obtain a mixed solution; the concentration of graphene oxide in the mixed solution is 0.5mg / mL, isopropanol The concentration is 50% (v / v%);

[0051] (2) Nitrogen gas bubbling for 10 minutes to remove the oxygen in the mixed solution, sealed and sent to cobalt-60 irradiation chamber, dose rate 0.882kGy / h, irradiated for 17h, to obtain the mixture;

[0052] (3) After the irradiation is completed, the resulting mixture is filtered through a PVDF microporous membrane with a pore size of 0.22 μm, and the filter cake is collected and dried to obtain reduced graphene oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com