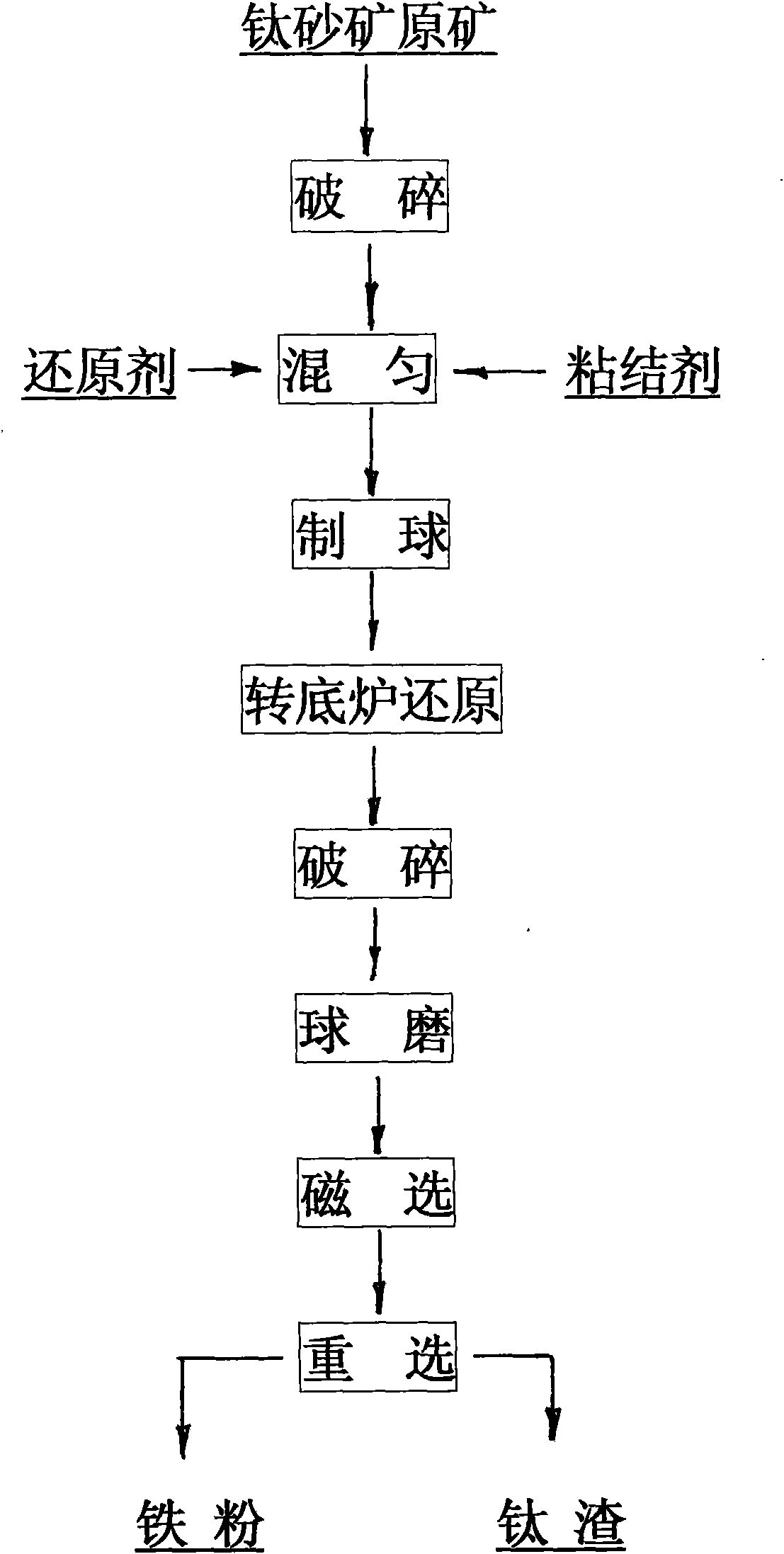

Method for producing ferrous powder and co-production titanium slag by rapidly reducing titanium placer pellets by rotary hearth furnace

A rotary hearth furnace and titanium placer technology, applied in the field of metallurgy, can solve problems such as waste of resources, backward equipment and production methods, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Embodiment 1: 1. The chemical composition of titanium placer is as follows: TFe31.56~33.74%, TiO 2 45.47~46.83, SiO 2 2.31~2.58%, Al 2 o 3 2.36-2.64%, CaO1.24-1.40%, MgO2.37-2.55%.

[0010] 2. Process conditions: 10,000g of titanium placer is crushed to -120+200 mesh, accounting for 80%, adding 20% of the original ore weight of carbon powder and adding 1% of the original ore weight of carboxymethyl cellulose binder and mixing with the titanium placer , use a spherical egg forming machine to make pellets with a diameter of 10~40mm, dry at 250°C for 4h, and use a rotary hearth furnace for rapid reduction, the temperature is controlled at 1200°C, and the time is 30min. After reduction, carry out coarse crushing (grain size is -120+200 mesh), then carry out wet ball milling, the pulp concentration is 55%, and the ball milling time is 1.5h. After ball milling, a 2500 Gauss magnetic separator is used for magnetic separation. Magnetic separation obtained The material is ...

Embodiment 2

[0011] Embodiment 2: 1. The chemical composition of vanadium-titanium iron ore concentrate is as follows: TFe32.01~34.82%, TiO 2 45.31~46.14, SiO 2 2.12~2.45%, Al 2 o 3 2.02-2.49%, CaO1.14-1.58%, MgO2.67-2.89%.

[0012] 2. Process conditions: 20,000g of titanium placer is crushed to -120+200 mesh, accounting for 80%, adding 22% of the original ore weight of carbon powder and adding 2% of the original ore weight of carboxymethyl cellulose binder and mixing with the titanium placer , use a spherical egg forming machine to make pellets with a diameter of 10-40mm, dry at 250°C for 4h, and use a rotary hearth furnace for rapid reduction, the temperature is controlled at 1250°C, and the time is 40min. After reduction, carry out coarse crushing (grain size is -120+200 mesh), then carry out wet ball milling, the pulp concentration is 65%, and the ball milling time is 1h. After ball milling, use a 3000 Gauss magnetic separator for magnetic separation, and the materials obtained by m...

Embodiment 3

[0013] Embodiment 3: 1. The chemical composition of vanadium-titanium iron ore concentrate is as follows: TFe36.54~38.01%, TiO 2 45.39~47.94%, SiO 2 2.71~2.99%, Al 2 o 3 2.64-2.97%, CaO1.54-1.77%, MgO2.64-2.98%.

[0014] 2. Process conditions: 50,000g of titanium placer is crushed to -120+200 mesh, accounting for 80%, adding 25% of the original ore weight of carbon powder and adding 3% of the original ore weight of carboxymethyl cellulose binder and mixing with the titanium placer , use a spherical egg forming machine to make pellets with a diameter of 10-40mm, dry at 250°C for 4h, and use a rotary hearth furnace for rapid reduction, the temperature is controlled at 1300°C, and the time is 50min. After reduction, carry out coarse crushing (grain size is -120+200 mesh), then carry out wet ball milling, the pulp concentration is 75%, and the ball milling time is 1.5h. After ball milling, a 3500 Gauss magnetic separator is used for magnetic separation. The material is re-sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com