PCB (Printed Circuit Board) copper-containing wastewater treatment method with autocatalytic oxidation as core

A wastewater treatment and self-catalysis technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems affecting regeneration, achieve high oxidation capacity, and solve wastewater resource utilization , the effect of strong catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

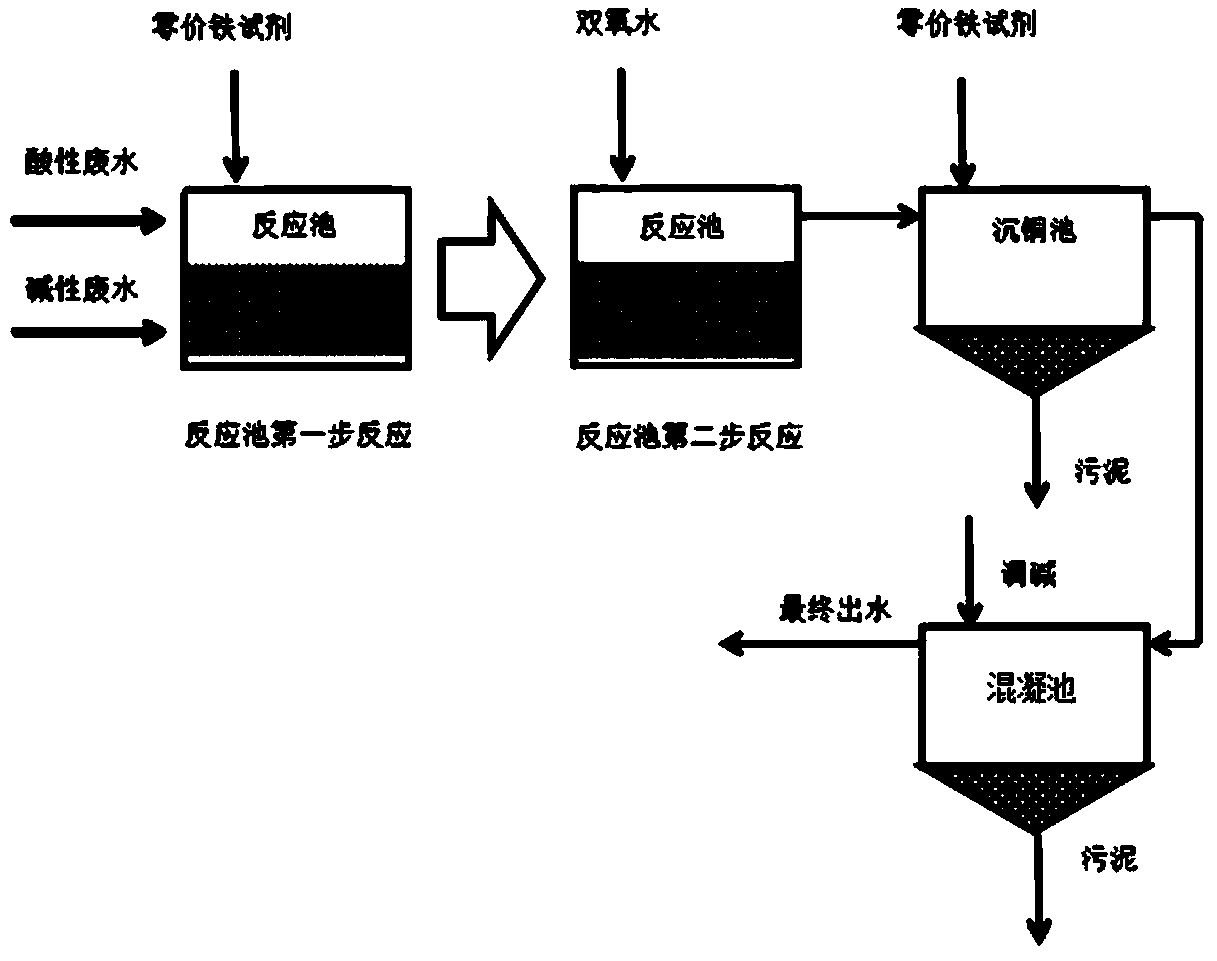

[0034] Such as figure 1 Shown, a kind of PCB copper-containing wastewater treatment method with autocatalytic oxidation as the core, its steps are:

[0035](1) 80mL acidic copper-containing wastewater (total copper is about 250mg / L, pH is about 2) and 920mL alkaline complex copper wastewater (basically EDTA complex (EDTA-Cu), total copper is about 120mg / L , the pH is about 11) mixing, the pH after mixing is 6-7;

[0036] (2) Add iron powder and Raschig ring filler to the mixed solution, the dosage of iron powder is 10mg / L, the filling ratio of Raschig ring is 5%, keep stirring, the reaction time is 30min, and the Cu in the solution is 2+ Part of it is converted into elemental copper, and the conversion rate is about 10%. The nascent elemental copper is loaded on the Raschig ring packing, and the elemental iron in the iron powder is completely converted into Fe 2+ ;

[0037] (3) Contains Fe after processing in step 2 2+ 、Cu 2+ , elemental copper and zero-valent iron reagen...

Embodiment 2

[0042] The steps of the method are the same as in Example 1, except that the iron powder added in step 2 is changed to cast iron powder (3% carbon content), the dosage is 10 mg / L, and the final effluent Fe 2+ Concentration below 10mg / L, Cu 2+ The concentration is lower than 0.5mg / L, lower than the national standard.

Embodiment 3

[0044] The method steps are the same as in Example 1, except that the iron powder added in step 2 is changed to a mixture of iron powder and carbon powder, wherein iron powder is 10 mg / L, carbon powder is 5 mg / L, and the final effluent Fe 2+ Concentration below 10mg / L, Cu 2+ The concentration is lower than 0.5mg / L, lower than the national standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com