Smoke desulfurization and denitrification integration method and special device thereof

A technology for desulfurization, denitrification, and flue gas, which is applied to chemical instruments and methods, separation methods, air quality improvement, etc., and can solve problems such as low concentration, difficult recovery, and single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

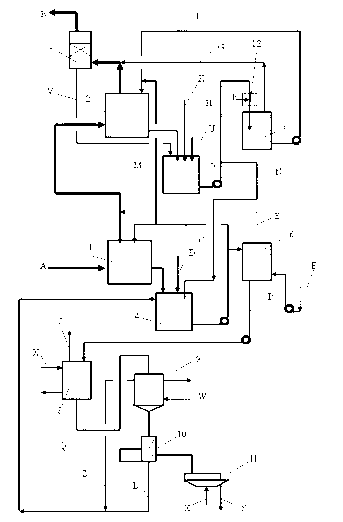

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with specific examples.

[0071] An integrated method for flue gas desulfurization and denitrification, the process flow is as follows figure 1As shown, the flue gas A is pre-passed through the bag filter to remove the solid particle ash. When the temperature is around 150°C, a heat exchange is performed to about 100°C and enters the flue gas desulfurizer 1. The desulfurizer 1 adopts a supergravity bed or a tower absorber. Ammonia water D is added to the middle tank 4 of the desulfurization liquid, ammonium salt solution is used as the desulfurization solution, and the desulfurization liquid C is circulated and pressed into the desulfurizer 1 by a pump to absorb sulfur dioxide gas to generate ammonium bisulfite or ammonium sulfite. After the desulfurization solution washes the flue gas to absorb sulfur dioxide, it flows from the desulfurizer 1 into the middle tank 4 of the desulfurization liquid. Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com