Low-compressive-deformation and high-conductivity rubber composite material and preparation method thereof

A composite material and high conductivity technology, applied in the production of bulk chemicals, etc., can solve the problems of small elasticity affecting the sealing effect, and achieve the effects of good elasticity and sealing, improved dispersion, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

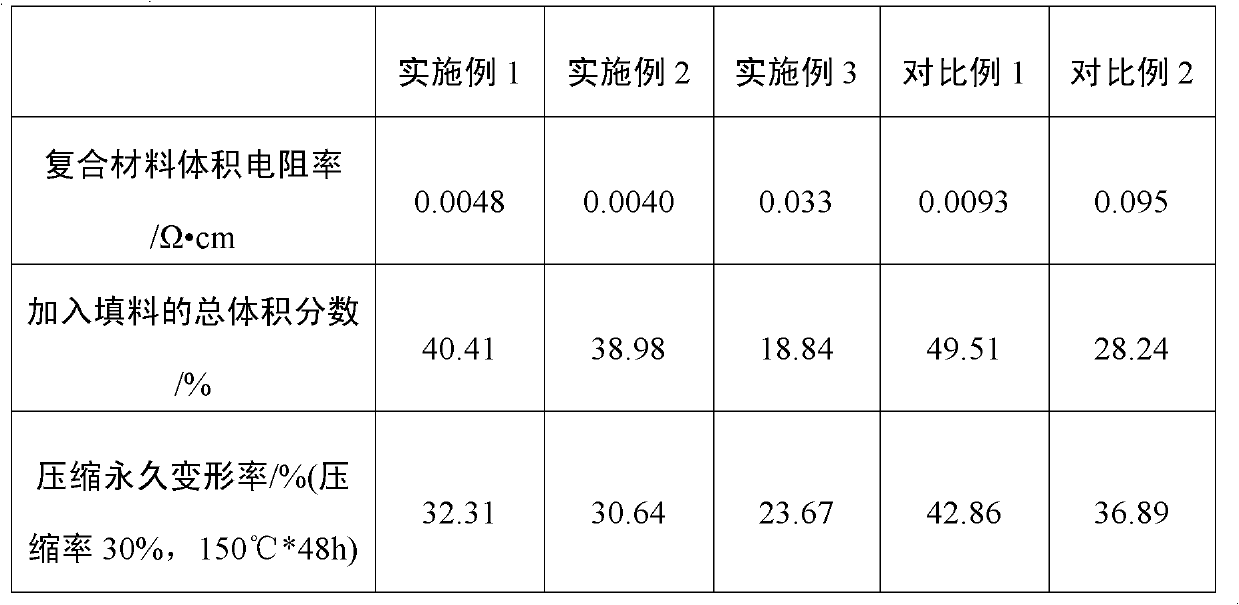

Embodiment 1

[0028] Low compression deformation and high conductive rubber composite material, its raw material components and mass parts are:

[0029] Methyl vinyl silicone rubber 100g

[0030] Conductive filler 202g

[0031] Vulcanizing agent double 2,5 2g

[0032] The conductive filler is a mixture of modified silver-plated glass beads and modified silver-plated glass fibers, and the mass ratio of the modified silver-plated glass beads to the modified silver-plated glass fibers is 14:5.

[0033] Filler modification method: 140g of silver-plated glass microspheres (S-3000-S3N from Porter, USA, particle size 20-50μm, real density 2.5g / cm 3 ), 50g of silver-plated glass fiber (SF82TF8 from Porter, USA, aspect ratio 5-50, length 50-175μm, real density 2.7g / cm 3 ), 12g of vinyltriethoxysilane A151 were added to the reaction kettle, then dry ice was added, and a magnetic stirring bar was put in at the same time, the reaction kettle was sealed and heated in a constant temperature oil bath a...

Embodiment 2

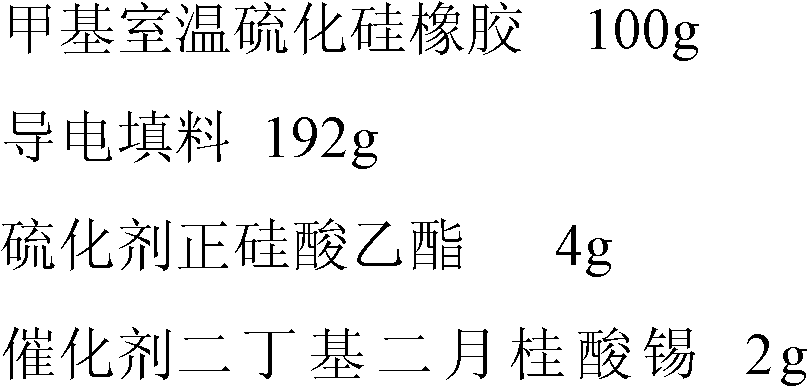

[0036] Low compression deformation and high conductive rubber composite material, its raw material components and mass parts are:

[0037]

[0038]The conductive filler is a mixture of modified silver-plated copper and modified silver-plated glass fiber, and the mass ratio of the modified silver-plated copper to the modified silver-plated glass fiber is 8:1.

[0039] Filler modification method: 160g of silver-plated aluminum (SA270S20, American Porter Company, particle size 44-88μm, real density 3.2g / cm 3 ), 20g silver-plated glass fiber (with embodiment 1), 12g coupling agent octyltriethoxysilane A137 add in the reactor, then add dry ice, put into magnetic stirring bar simultaneously, the reactor is airtight and in constant temperature oil bath Heat at medium temperature at 100°C until the pressure reaches 13.5MPa, turn on the magnetic stirrer, stir for 1.5 hours, close the valve after the reaction and slowly reduce the pressure to normal pressure, wait for the reaction ke...

Embodiment 3

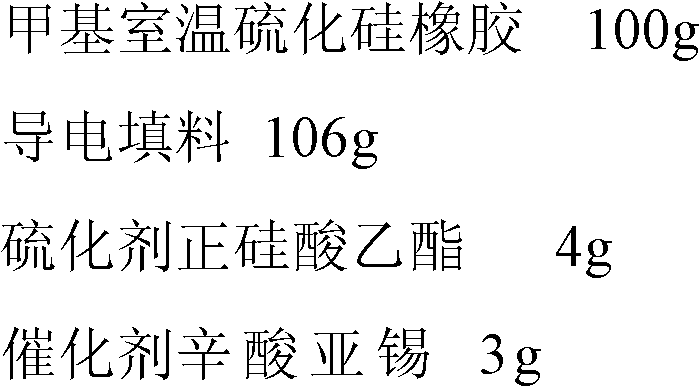

[0042] Low compression deformation and high conductive rubber composite material, its raw material components and mass parts are:

[0043]

[0044] The conductive filler is a mixture of modified nickel-plated graphite and modified nickel-plated carbon fiber, and the mass ratio of modified silver-plated copper to modified silver-plated glass fiber is 4:1.

[0045] Filler modification method: 80g nickel-plated graphite (E-FILL2701 from Sulzer, Canada, particle size 60-165μm, true density 4.0g / cm 3 ), 20g nickel-plated carbon fiber (Sulzer Canada E-FILL2901, aspect ratio 5-50, length 60-250μm, true density 3.8g / cm 3 ), 6g of coupling agent vinyltriethoxysilane A151 were added to the reaction kettle, then dry ice was added, and a magnetic stirring bar was placed at the same time, the reaction kettle was sealed and heated in a constant temperature oil bath at a temperature of 40°C until the pressure reached 10MPa , turn on the magnetic stirrer, stir for 1 hour, close the valve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com