Al-Ti-B-Er refiner and preparation method thereof

An al-ti-b-er, refiner technology, applied in the field of aluminum alloy rare earth refiner, can solve the problems of loss of refinement ability, easy aggregation of particles, loss of refinement ability, etc. Solve the effect of easy aggregation, improve morphology and distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

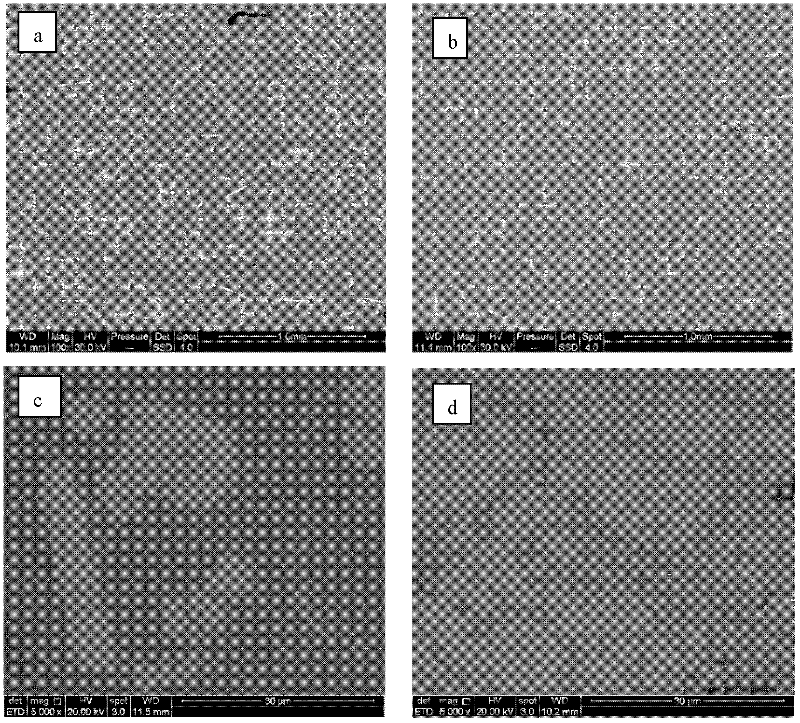

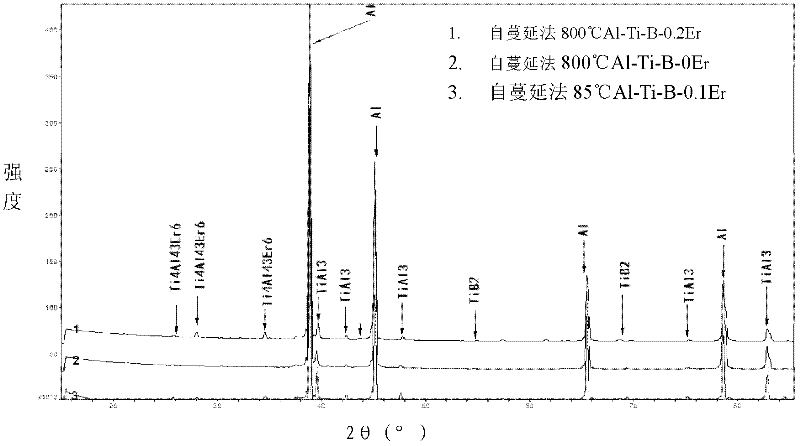

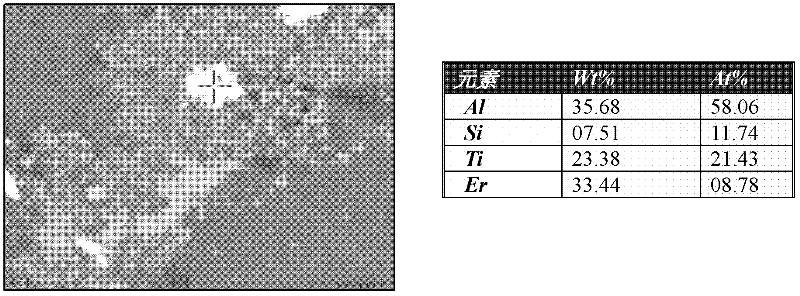

[0020] The process of preparing Al-5Ti-1B-0.1Er refiner by self-propagating reaction method is as follows:

[0021] 1. Raw material preparation, refiner consists of aluminum ingot, aluminum powder, titanium powder, boron powder, Al-Er master alloy, C 2 Cl 6 and cryolite covering agent preparation. Among them, the purity of the aluminum ingot is 99.9%, and the powder particle size is 325 mesh for Ti powder and 300 mesh for B powder.

[0022] 2. Prepare 1Kg of refiner, weigh boron powder, titanium powder, aluminum powder, Al-Er master alloy, aluminum ingot as required, and the aluminum burning loss rate is 3%. It is required that Ti / B=5 (wt%); the molar ratio of aluminum powder to titanium powder is 3.

[0023] 3. Mix titanium powder, aluminum powder, and boron powder evenly, place the evenly mixed powder in a mold, apply a pressure of 10MPa, and press it into a cylindrical powder block of φ40×50.

[0024] 4. Cryolite and C 2 Cl 6 Heat at 100°C for 1h to remove moisture. ...

Embodiment 2

[0028] Preparation of Al-5Ti-1B-0.2Er refiner by self-propagating reaction at 800℃

[0029] The aluminum ingot, aluminum powder, titanium powder, boron powder, and Al-Er master alloy will be proportioned according to the composition requirements. Press the required powder into a cylindrical powder block of φ40×50.

[0030] Heat the cleaned aluminum ingot to 780°C with a well-type resistance furnace. After the aluminum ingot is completely melted, cover it with a layer of cryolite to prevent the oxidation and gas absorption of aluminum; first wrap the Al-Er intermediate alloy with aluminum foil, and graphite clock Press the cover into the molten aluminum and let it stand for 5 minutes until the intermediate alloy is completely dissolved and spreads evenly; raise the furnace temperature to 800°C, press the cylindrical powder block that has been pressed in advance into the molten aluminum with the graphite bell, and stir the graphite rod evenly. Make it a combustion reaction, rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com