Biomass nanocellulose porous material loaded with nano transition metal oxide on surface, and preparation method thereof

A technology of nanocellulose and transition metals, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, catalyst activation/preparation, etc. small surface area etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

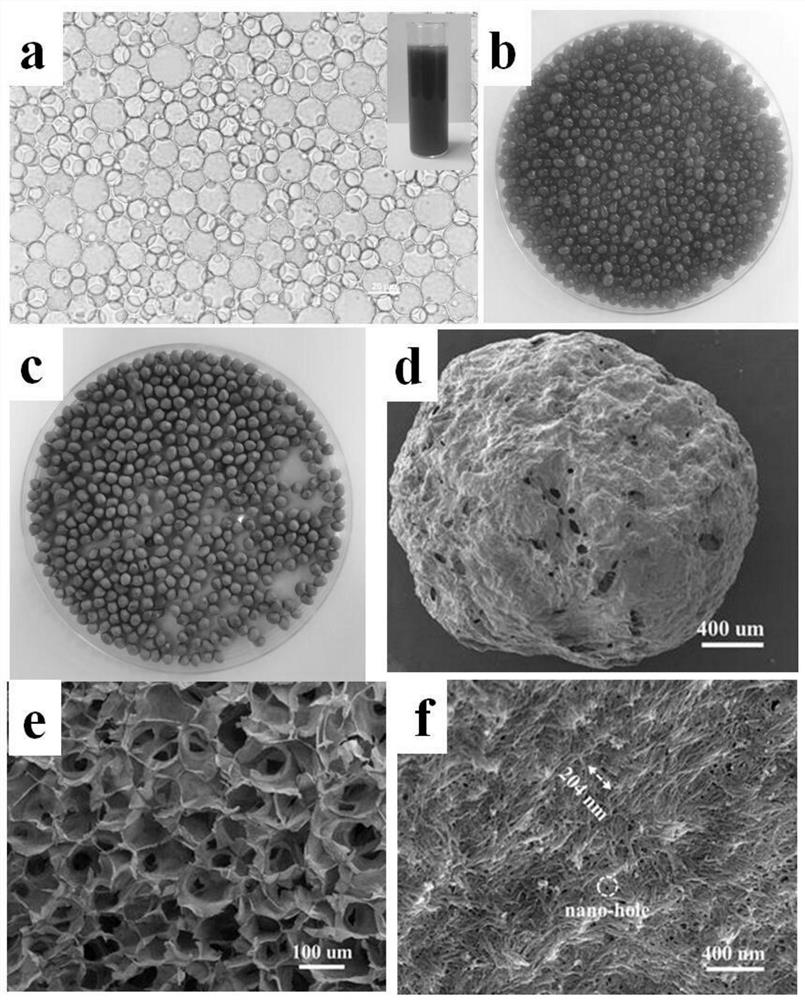

[0054] (1) Preparation of biomass nanocellulose / nanometer transition metal oxide, carboxyl organic matter, olefin monomer, olefin polymerization initiator, and surfactant mixture:

[0055] S1: Preparation of cellulose nanofibers by ammonium persulfate oxidation method: 5 g of cotton pulp cellulose was added to 150 mL of 4% sodium hydroxide dimethyl sulfoxide solution, soaked for 24 hours for swelling, and then washed with deionized water to its pH The same as deionized water, and then disperse the pretreated cellulose raw material in an aqueous solution composed of 200mL deionized water, 5g ammonium persulfate, and 8g sodium hydroxide, stir and oxidize and hydrolyze the cellulose at 50°C for 0.5h Ultrasonic treatment of liquid to obtain cellulose nanofiber suspension;

[0056] S2: In-situ generation of nano-transition metal oxides on the surface of cellulose nanofibers: heat 200 mL of 1 wt.% cellulose nanofiber suspension obtained in step S1 to 70 ° C, slowly add 1 mL of titan...

Embodiment 2

[0065] The add-on of surfactant polyvinyl alcohol is different, and the add-on of polyvinyl alcohol is 0.02g, and all the other conditions (such as: raw material type, consumption and technical process etc.) are all identical with embodiment 1, obtain the stable internal phase volume of 75% high internal phase cellulose nanofiber / nano-titanium dioxide Pickering emulsion, the emulsion droplet size is between 40-100 μm, and the average droplet size is 70 μm. Stable cellulose nanofiber / nano-titanium dioxide porous microspheres were obtained after post-treatment such as shaping and cross-linking, with a specific surface area of 12m 2 / g.

Embodiment 3

[0067] The add-on of surfactant polyvinyl alcohol is different, and the add-on of polyvinyl alcohol is 0.4g, and all the other conditions (such as: raw material type, consumption and technological process etc.) are all the same with embodiment 1, obtain the stable internal phase volume of 90% high internal phase cellulose nanofiber / nano-titanium dioxide Pickering emulsion, the emulsion droplet size is between 2-20 μm, and the average droplet size is 11 μm. Stable cellulose nanofiber / nano-titanium dioxide porous microspheres are obtained after post-treatment such as shaping and cross-linking, with a specific surface area of 20m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com