Long-service-life aluminum-silicon alloy grain refiner and preparation method thereof

A technology of grain refiner and aluminum-silicon alloy, which is applied in the field of grain refiner for casting aluminum-silicon alloy, can solve the problems that restrict the large-scale application of Al-B alloy, accelerate the degradation process, and degrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

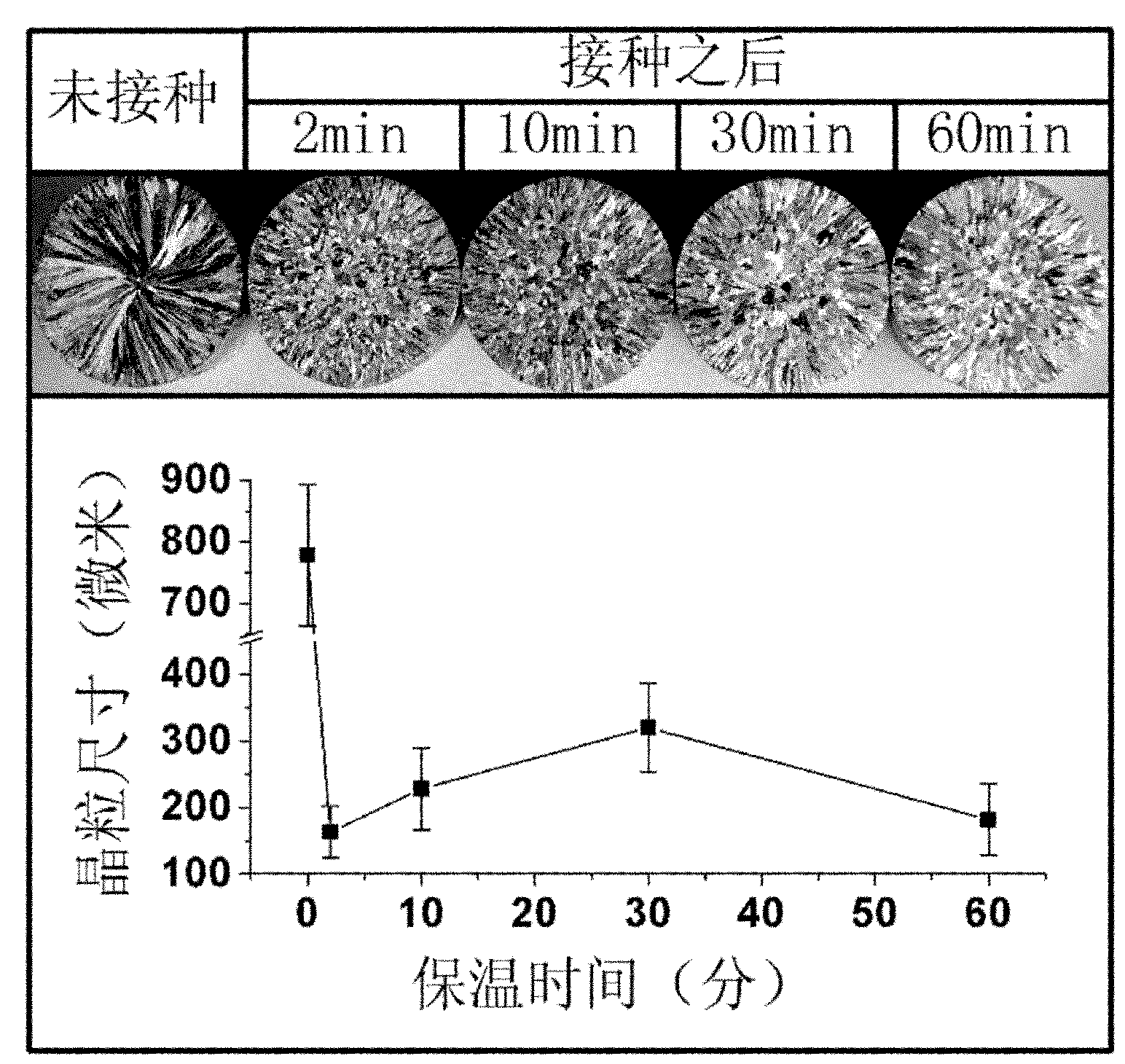

Examples

Embodiment Construction

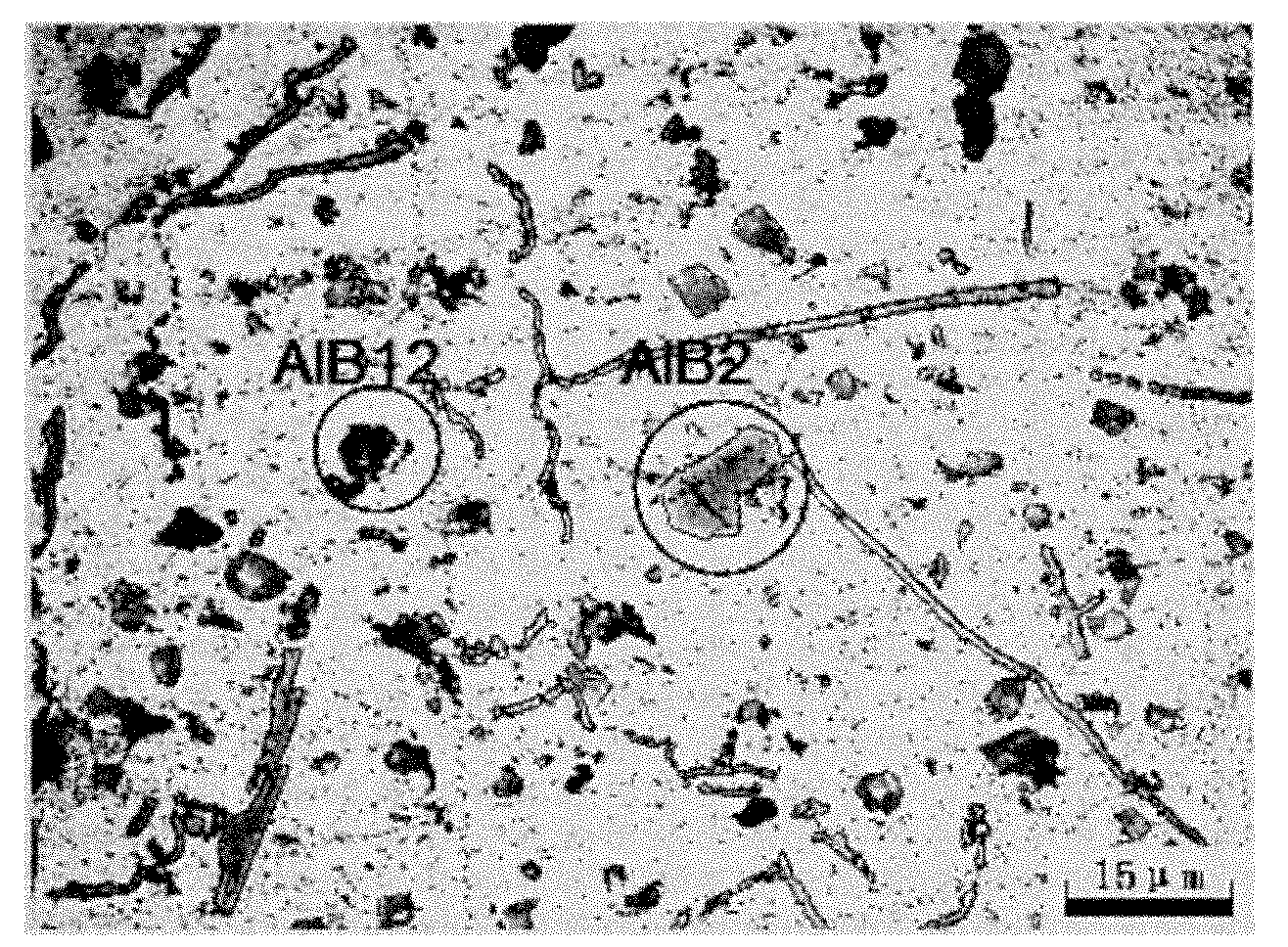

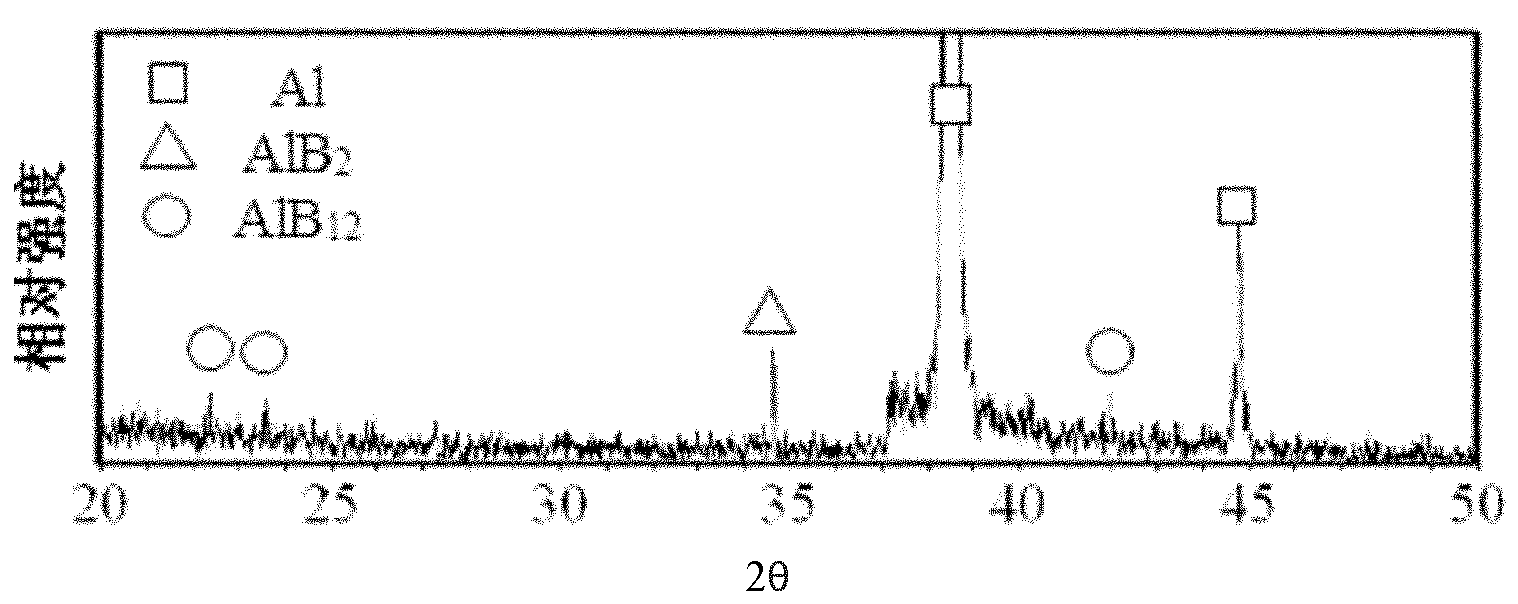

[0029] Select the composition (wt.%) of the Al-B alloy refiner: B, 3.0 (in KBF 4 given in powder form); Al, balance.

[0030] The preparation process of Al-B alloy refiner is as follows:

[0031] (1) Raw material grinding: KBF 4 Powder grinding and drying;

[0032] (2) Briquetting: use a tablet press to dry the dried KBF 4 The powder is pressed into a round cake-shaped prefabricated block with a diameter of 40mm;

[0033] (3) Melting aluminum ingots: put industrial pure aluminum in a furnace to melt, and the temperature rises to 950°C;

[0034] (4) Synthesis reaction: carefully press the prefabricated blocks below the liquid surface of the aluminum melt, without any stirring during the reaction process, and use thermocouples to measure the temperature in real time during the whole process;

[0035] (5) Heat preservation: after the temperature stops rising, keep heat for 15 minutes;

[0036] (6) Slag removal: Use a slag spoon to skim off the residual salt of the product o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com