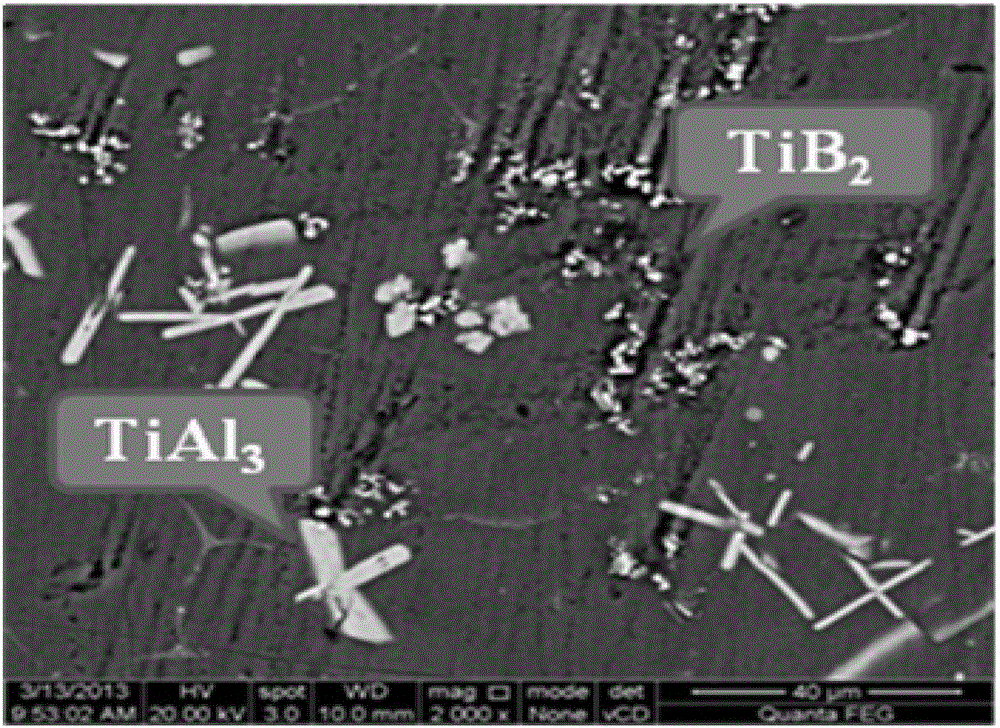

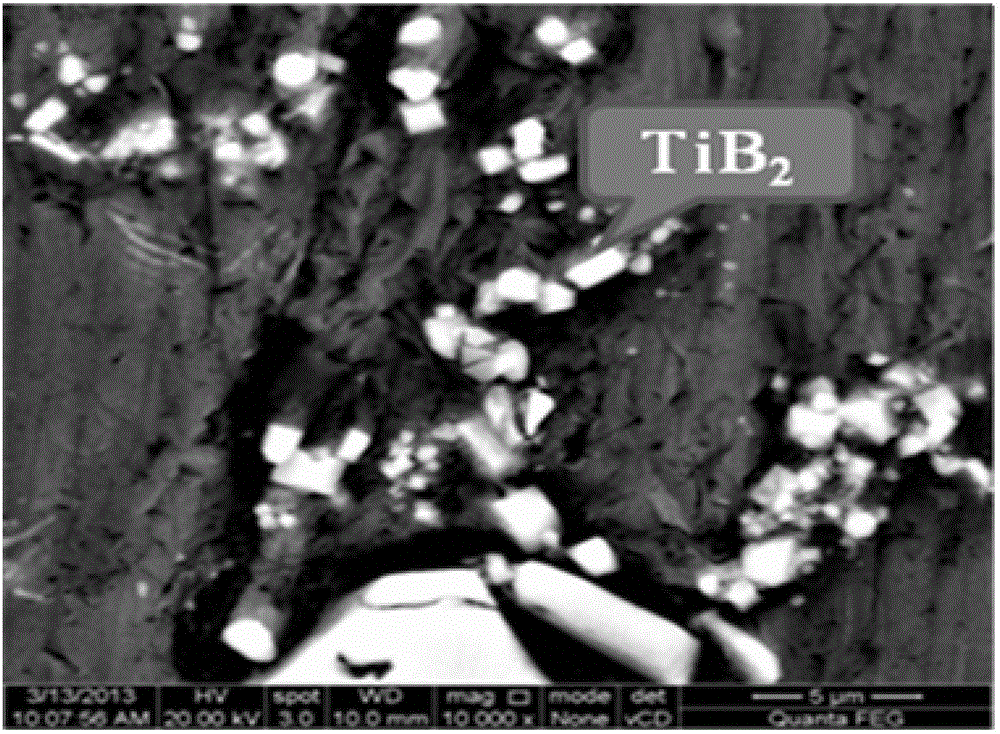

A kind of low-cost al-ti-b refiner and preparation method thereof

An al-ti-b, refiner technology, applied in the field of low-cost refiner and preparation, can solve the problems of low preparation efficiency, low refinement efficiency, low preparation cost, etc., and achieves improved refinement efficiency and distribution. Uniform, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The process of preparing Al-Ti-B refiner by contact reaction method is as follows:

[0019] 1. Raw material preparation, refiner by H 3 BO 3 、TiO 2 , aluminum powder, aluminum ingot, C 2 Cl 6 It is prepared with cryolite covering agent, in which the purity of aluminum ingot is 99.9%.

[0020] 2. Prepare 1Kg of refiner, weigh H as required 3 BO 3 、TiO 2 , aluminum powder, aluminum ingot, according to the aluminum burning rate of 3%, require TiO 2 :H 3 BO 3 : Al powder = 3: 4: 5 (mol), the rest is Al

[0021] 3 will H 3 BO 3 、TiO 2 The powder is heated at 300°C for two hours to remove the moisture.

[0022] 4. The heated TiO 2 and H 3 BO 3 Mix the mixture with aluminum powder evenly, put the evenly mixed powder in the mold, and press it into 70×Φ80mm 3 cylindrical powder block.

[0023] 5. Apply a layer of paint to tools such as molds and slag scrapers to prevent Fe impurity elements from contaminating the refiner. A graphite crucible is selected for s...

Embodiment 2

[0026] 1. Raw material preparation, refiner by H 3 BO 3 、TiO 2 , aluminum powder, aluminum ingot, C 2 Cl 6 It is prepared with cryolite covering agent, in which the purity of aluminum ingot is 99.9%.

[0027] 2. Prepare 500g of refiner, weigh H as required 3 BO 3 、TiO 2 , aluminum powder, aluminum ingots, the aluminum burning loss rate is 3%. Requires TiO 2 :H 3 BO 3 : Al powder = 1.3:2:2.5 (mol).

[0028] 3. H 3 BO 3 、TiO 2 The powder is heated at 300°C for two hours to remove the moisture.

[0029] 4. The heated TiO 2 and H 3 BO 3 Mix the mixture with aluminum powder evenly, put the evenly mixed powder in the mold, and press it into 90×Φ80mm 3 cylindrical powder block.

[0030] 5. Use a well-type resistance furnace to heat the cleaned aluminum ingot to 780°C. After the aluminum ingot is completely melted, cover it with a layer of cryolite to prevent the oxidation and gas absorption of aluminum; raise the furnace temperature to 950°C, and the graphite bell ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com