Large-size AlON transparent ceramic preparation method

A technology of transparent ceramics and large size, applied in the field of preparation of large size AlON transparent ceramics, can solve the problems that it is not easy to prepare large size AlON transparent ceramics, the time required for ultrafine particle size is long, and it is difficult to meet industrialization requirements. Improved refinement efficiency, short refinement processing time, and efficient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

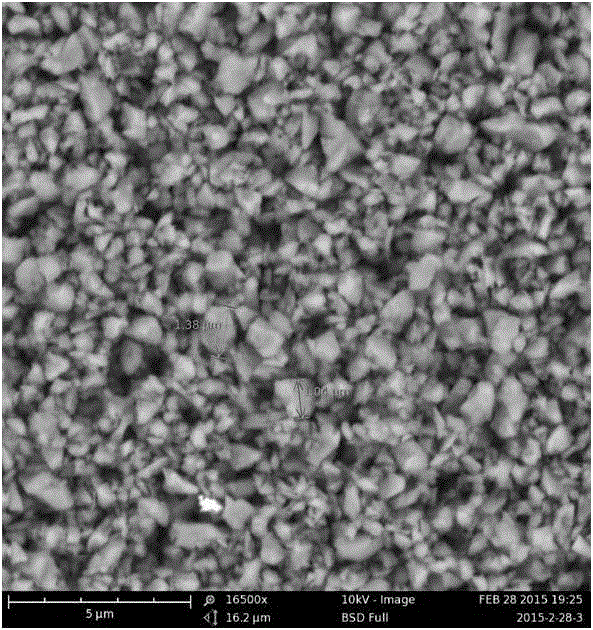

[0020] Using high-purity self-made AlON powder as raw material, adding 0.25wt% Y 2 o 3 As a sintering aid, the two mixed powders were added with absolute ethanol to form a slurry with a solid content of 50% and stirred evenly. The resulting slurry was put into a sand mill for sand grinding for 5 hours, and dried. 200-mesh sieve, carbon removal at 600°C, holding time 4h, such as figure 1 As shown, the average particle size of the obtained powder after sand milling is <1 μm;

[0021] Press the obtained carbon-removing powder body on a hydraulic press at a pressure of 10 MPa to form a Φ5cm*5mm disc, and then further increase the density of the green body on a cold isostatic press at a pressure of 200 MPa;

[0022] Place the obtained green body in a high-purity graphite crucible, fill it with high-purity AlON powder, and sinter it in a high-temperature graphite furnace at 1930°C for 6 hours under a high-purity nitrogen atmosphere to obtain a high-density AlON ceramic sintered b...

Embodiment 2

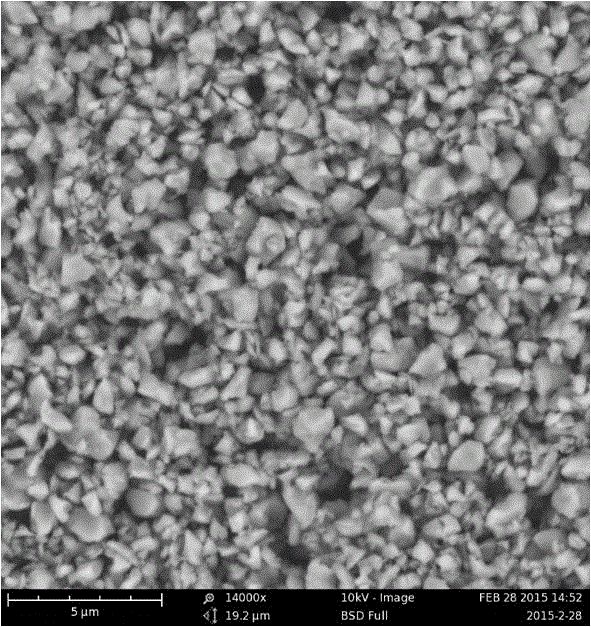

[0025] Using high-purity self-made AlON powder as raw material, adding 0.25wt% Y 2 o 3 As a sintering aid, use absolute ethanol to make the mixed powder into a slurry with a solid content of 40% and stir evenly. The resulting slurry is put into a sand mill for sanding for 8 hours, dried, and the dried powder passes through 200 Mesh sieve, remove carbon at 600°C, holding time is 6h, such as figure 2 As shown, the average particle size of the obtained powder after sand milling is <1 μm;

[0026] Press the obtained carbon-removing powder at a pressure of 10 MPa to form a disc with a thickness of Φ10 cm and a thickness of 1 cm, and then perform cold isostatic pressing at a pressure of 200 MPa;

[0027] The obtained green body was placed in a high-purity graphite crucible, buried and fired with high-purity AlON powder, the sintering temperature was 1930 ° C, and the holding time was 8 hours to obtain a high-density AlON ceramic sintered body;

[0028] The obtained ceramic sinte...

Embodiment 3

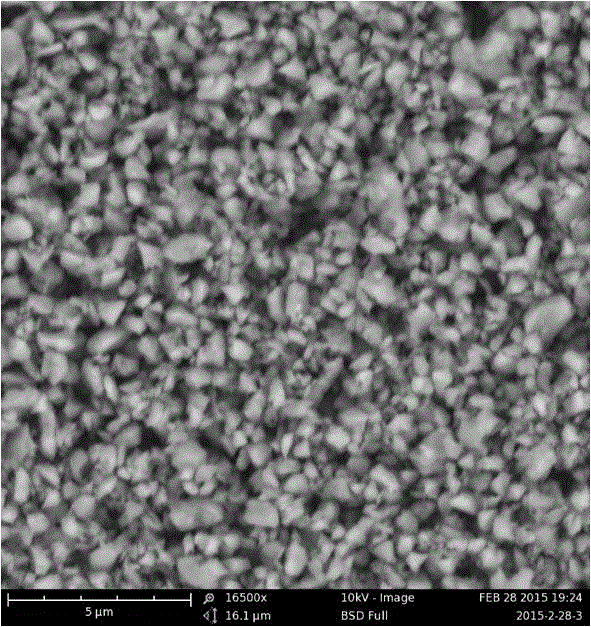

[0030] Using high-purity self-made AlON powder as raw material, adding 0.35wt% Y 2 o 3 As a sintering aid, use absolute ethanol to make a slurry with a solid content of 45% and stir evenly, then put it into a sand mill for sanding for 10 hours, and dry it. The dried powder is passed through a 200-mesh sieve. In addition to carbon, the holding time is 10h, such as image 3 As shown, the average particle size of the obtained powder is below 1 μm;

[0031] Press the obtained carbon-removing powder body on a hydraulic press with a pressure of 30 MPa to form a disc with a thickness of Φ20 cm and a thickness of 2 cm, and then further increase the density of the green body on a cold isostatic press with a pressure of 250 MPa;

[0032] Place the obtained green body in a high-purity graphite crucible, bury and sinter it with high-purity AlON powder, and sinter at 1940°C for 10 hours under a high-purity nitrogen atmosphere to obtain a high-density AlON ceramic sintered body;

[0033]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com