(ScAl3+Al2O3+Sc2O3)/Al-based compound inoculant, preparation method thereof and application

A composite inoculant, S21 technology, applied in the field of aluminum alloy smelting, can solve the problems of low production efficiency and complicated preparation process of inoculants for aluminum alloys, and achieve high production efficiency, easy industrial application, and fine particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

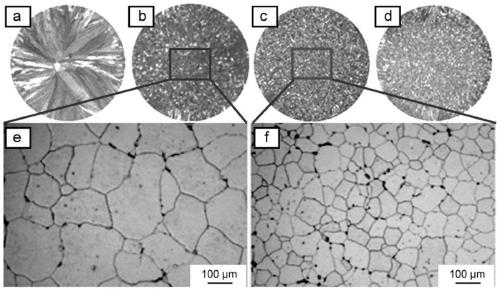

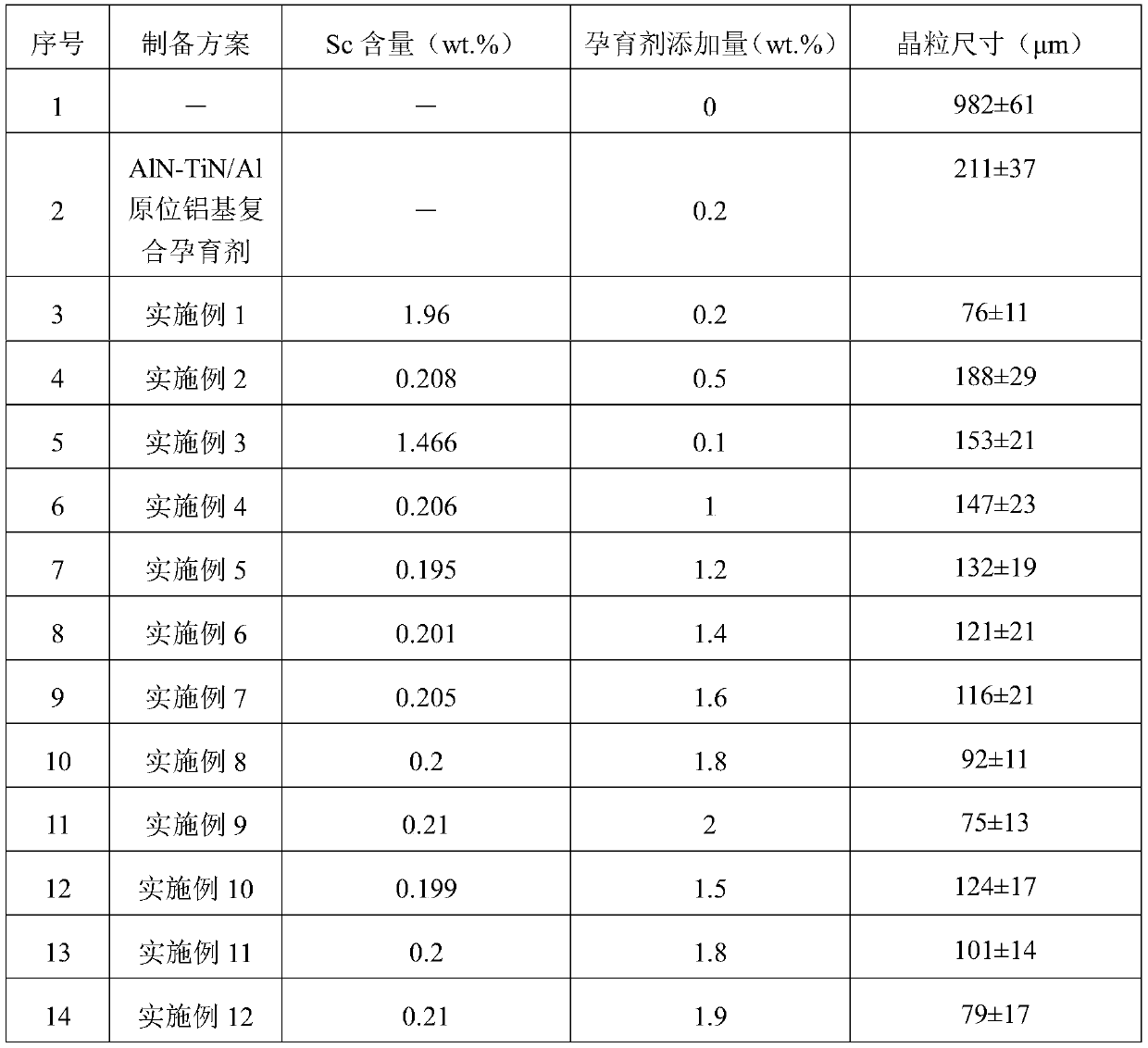

[0021] In a typical embodiment of the present application, a kind of (ScAl 3 +Al 2 o 3 +Sc 2 o 3 ) / Al-based composite inoculant preparation method, the preparation method comprising: step S1, scandium trioxide powder and pure aluminum are cast into ingots to obtain aluminum scandium oxide master alloy ingots; step S2, aluminum scandium oxide master alloy The ingot was subjected to rapid solidification treatment to obtain (ScAl 3 +Al 2 o 3 +Sc 2 o 3 ) / Al-based composite inoculant.

[0022] Using scandium trioxide powder and pure aluminum as raw materials through ingot casting and rapid solidification to form 3 、Al 2 o 3 、Sc 2 o 3 The reinforcement phase (ScAl 3 +Al 2 o 3 +Sc 2 o 3 ) / Al-based composite inoculant, the effective grain refinement and recrystallization inhibition effect of scandium on aluminum alloy can be significantly reduced (ScAl 3 +Al 2 o 3 +ScO 2 ) / Al composite material inoculant grain size, and the content of scandium element can be regu...

Embodiment 1

[0038] (1) Weigh commercial Sc 2 o 3 0.9388g of powder (100 mesh, 99.5wt.% purity) and 30g of commercially available pure aluminum (99.9wt.% purity) were mixed to form a mixture.

[0039] (2) Put the mixture into the copper crucible of WK-II non-consumable vacuum arc melting furnace for melting, specifically: vacuumize until the vacuum degree in the furnace is 5×10 -3 Pa, and then filled with high-purity argon to keep the pressure in the furnace at 0.5MPa, the whole melting process is carried out under the atmosphere of argon, adjust the current to control the melting temperature at 2200 ° C, and keep it warm for 5 minutes to melt the mixture. Under the same conditions, the smelting was repeated six times to obtain a massive Al-Sc-O master alloy ingot, and the copper crucible was cooled by circulating water during the smelting process.

[0040] (3) Put the bulk Al-Sc-O master alloy ingot into the LZK-12A vacuum quenching furnace for rapid solidification, specifically: put th...

Embodiment 2

[0042] (1) Weigh commercial Sc 2 o 3 0.0.1 g of powder (200 mesh size, 99.9 wt. % purity) and 30 g of commercially available pure aluminum (99.9 wt. % purity) were mixed to form a mixture.

[0043] (2) Put the mixture into the copper crucible of WK-II non-consumable vacuum arc melting furnace for melting, specifically: vacuumize until the vacuum degree in the furnace is 5×10 -3 Pa, and then filled with high-purity argon to keep the pressure in the furnace at 0.5MPa, the whole melting process is carried out under the atmosphere of argon, adjust the current to control the melting temperature at 2000°C, and keep it warm for 8 minutes to melt the mixture. Under the same conditions, the smelting was repeated six times to obtain a massive Al-Sc-O master alloy ingot, and the copper crucible was cooled by circulating water during the smelting process.

[0044] (3) Put the bulk Al-Sc-O master alloy ingot into the LZK-12A vacuum quenching furnace for rapid solidification, specifically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com