Chemical raw material crushing and refining device

A technology of chemical raw materials and crushing boxes, which is applied in chemical instruments and methods, solid separation, filtration and screening, etc. It can solve the problems of poor crushing effect and insufficient crushing and refining of chemical raw materials, so as to improve the refining efficiency, Promoting flipping action, full effect of crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

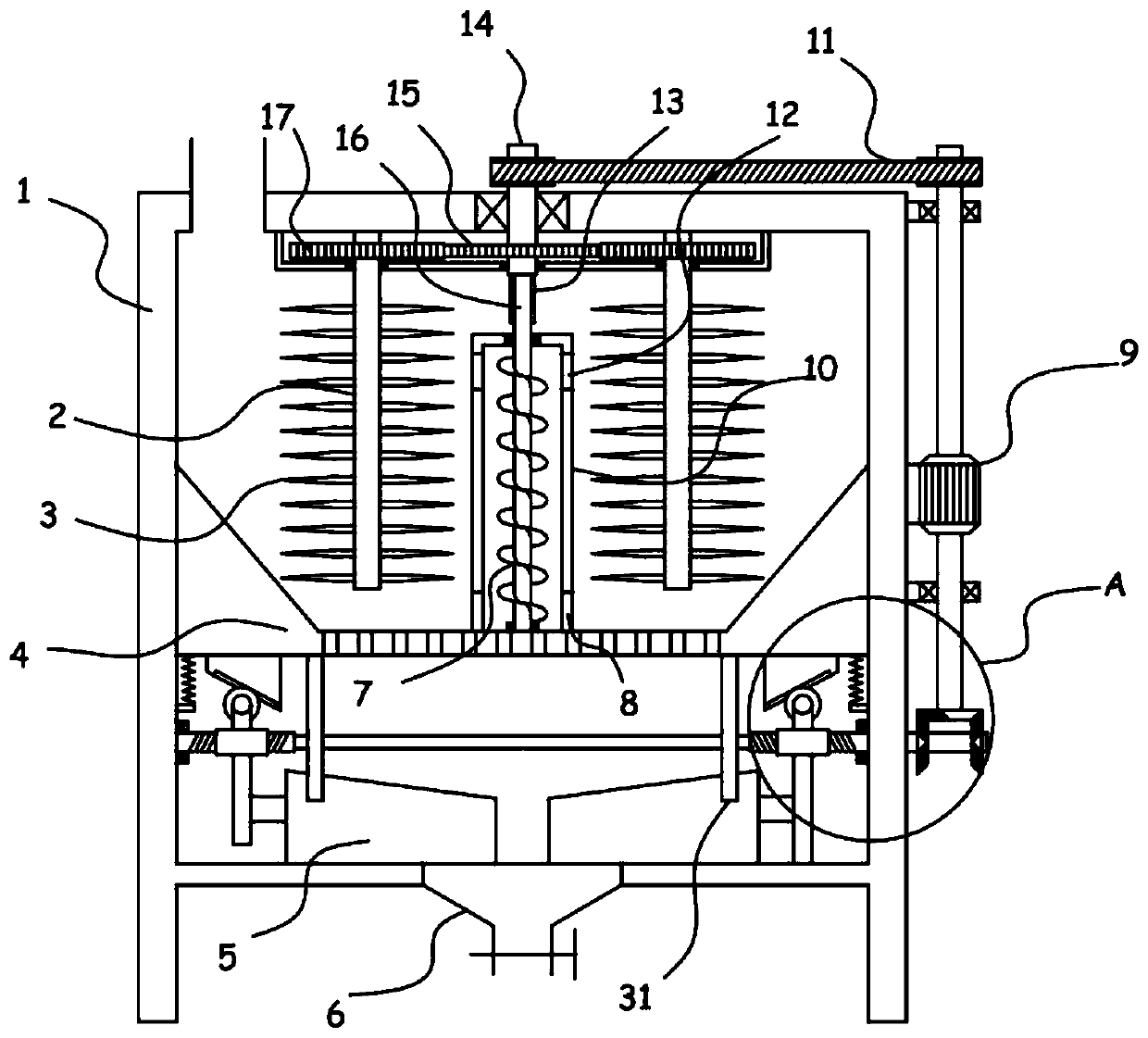

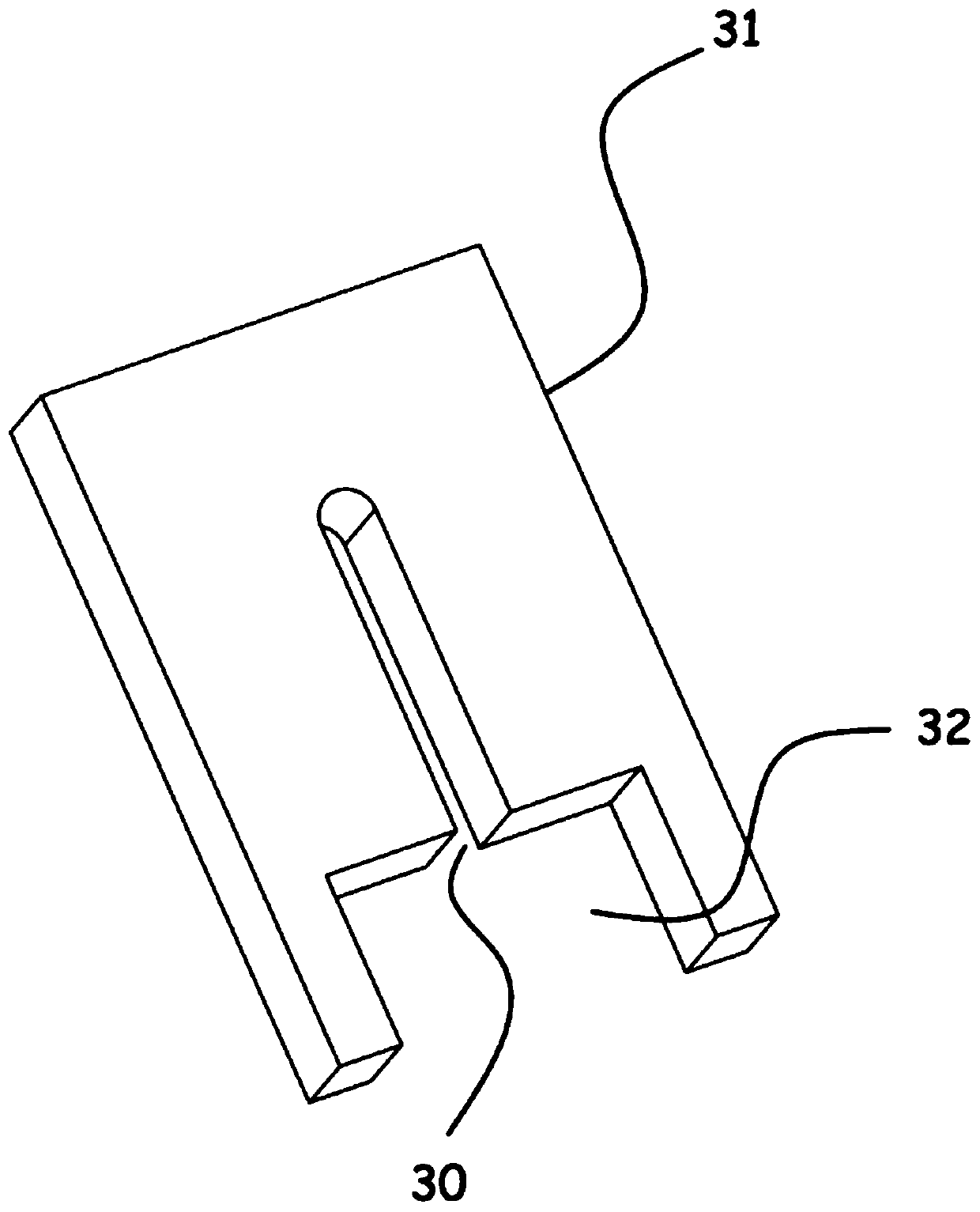

[0024] see Figure 1-3 , a chemical raw material crushing and refining device, comprising a crushing box 1, a load-bearing mesh plate 4 is fixed horizontally in the crushing box 1, and a vertically arranged driven shaft 2 and a driving shaft 16 are driven and rotated by a transmission mechanism in the crushing box 1, A number of pairs of crushing blades 3 are fixed at equal intervals on the side wall of the driven shaft 2. A lifting mechanism for lifting chemical raw materials is vertically provided in the crushing box 1. A lifting mechanism for vertical lifting, the lifting mechanism is provided with a crushing mechanism for impact crushing chemical raw materials, and a discharge hopper 6 is vertically installed at the bottom of the crushing box 1 .

[0025] The crushing box 1 set in this device is used to place the chemical raw materials to be crushed. The transmission mechanism is set to drive the driven shaft 2 to rotate, so that the driven shaft 2 drives the crushing blad...

Embodiment 2

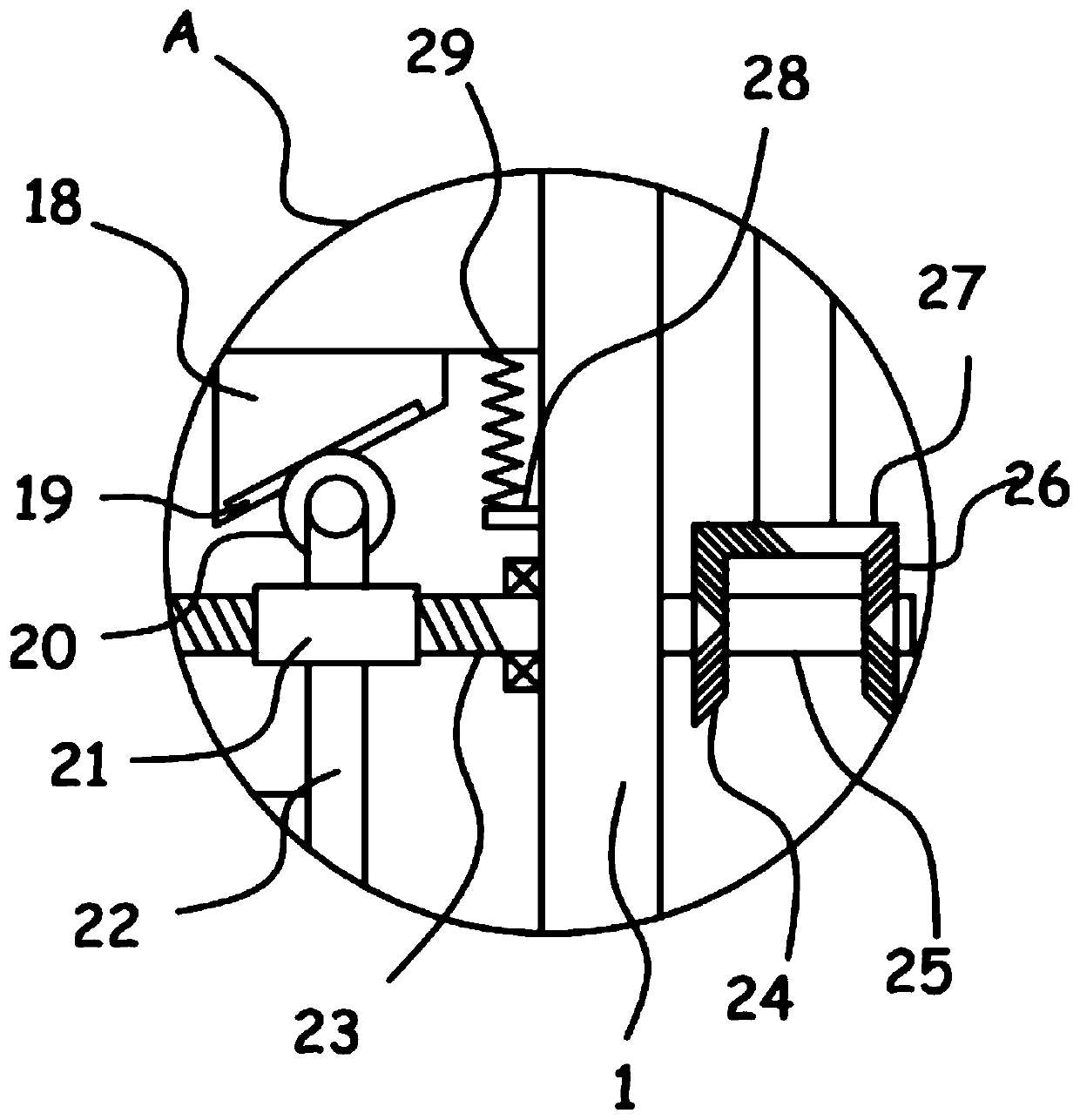

[0031] On the basis of Embodiment 1, in addition, the elevating mechanism includes a reversing mechanism connected to the biaxial motor 9 in transmission, the reversing mechanism includes a threaded rod 23 that is rotated, and a threaded sleeve 21 is threaded on the threaded rod 23, and A runner 20 is rotatably installed on the cover block 21 , and a wedge 18 fixed on the bottom of the carrying grid 4 abuts against the runner 20 . The bottom surface of the wedge block 18 is a wedge surface, and the wedge surface is provided with a locking groove 19 for the runner 20 to be embedded in. The reversing mechanism includes an incomplete bevel gear 27 coaxially fixed with the other output shaft of the biaxial motor 9, and the incomplete bevel gear 27 is alternately meshed with a bevel gear I24 and a bevel gear II26 sleeved and fixed on the transmission shaft 25. , Transmission shaft 25 and threaded rod 23 are coaxially fixed.

[0032] Through the above settings, the biaxial motor 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com