Tea leaf strip tightening machine

A strip tightening machine and tea technology, applied in tea treatment before extraction, etc., can solve the problems of high labor intensity, polluted tea leaves, and tightness of finished tea strips, etc., to achieve good strip tightening effect, increased collision force, and fierce collision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

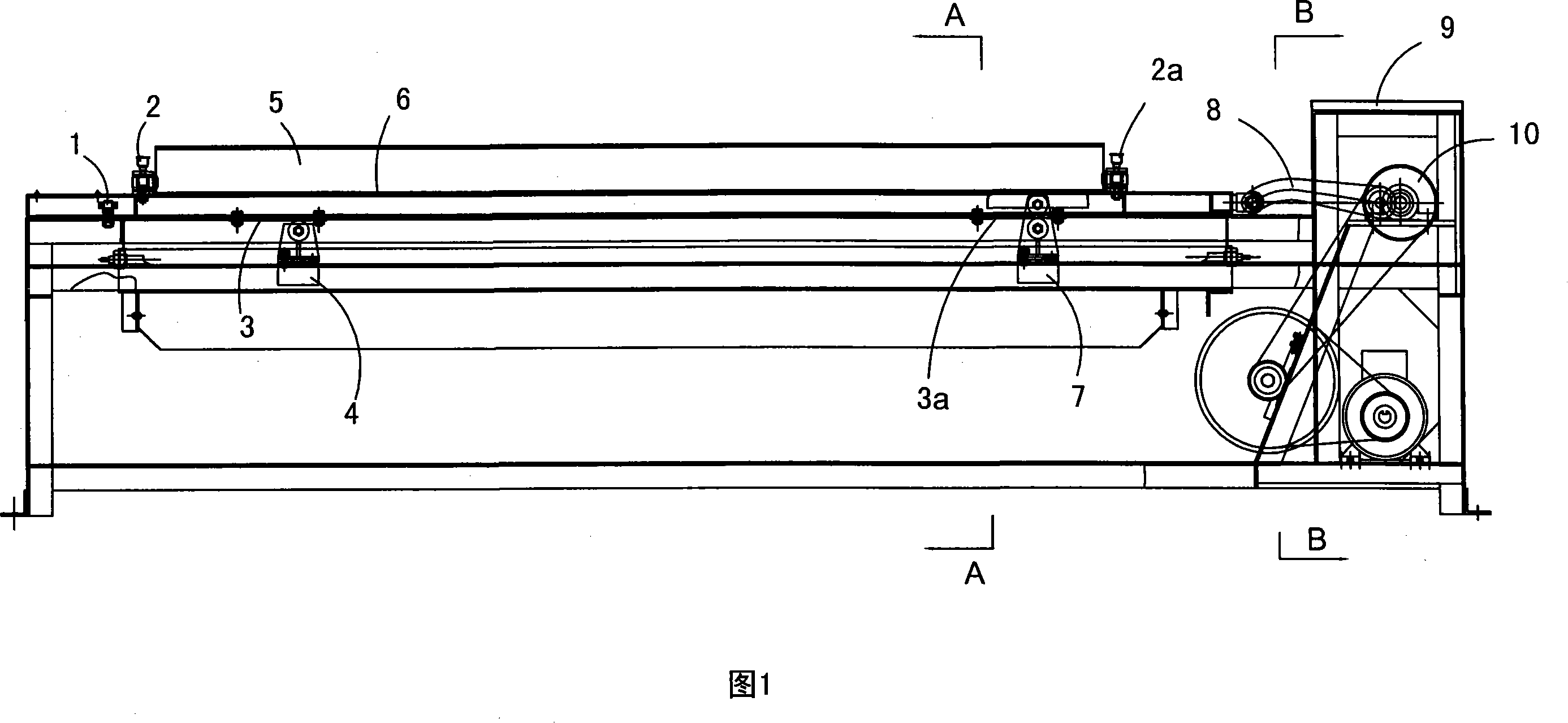

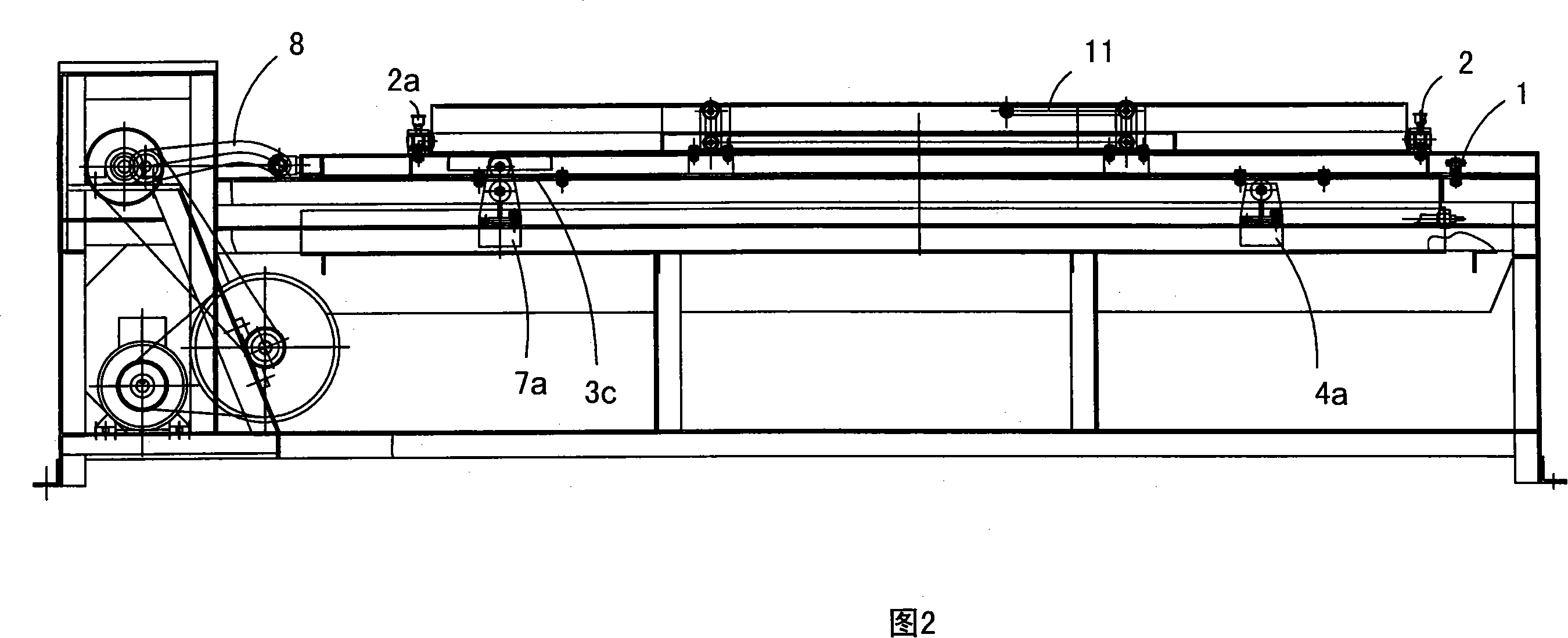

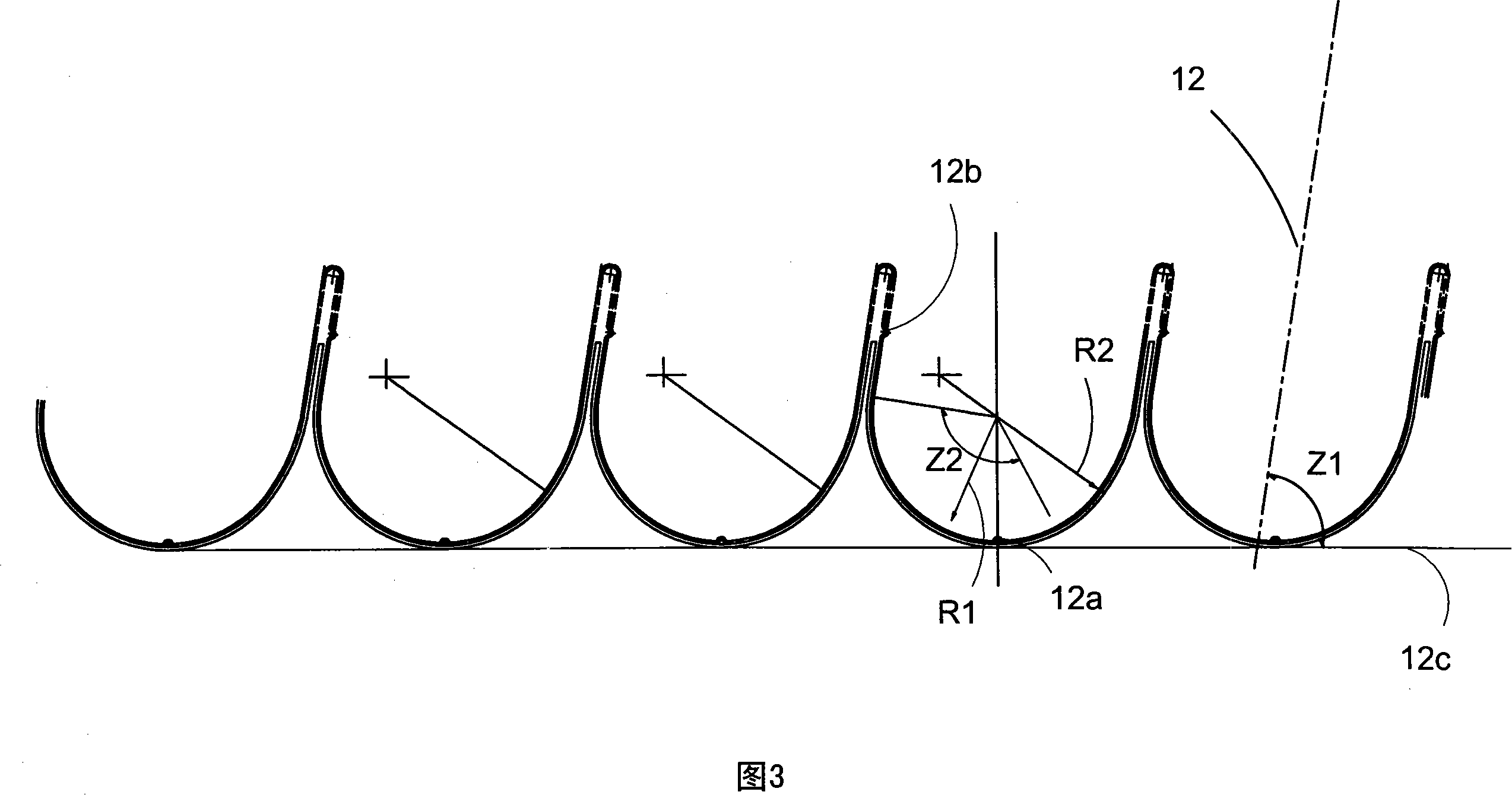

[0030] The serial numbers in the figure respectively indicate: limit clamp wheel 1, pot body hinge parts 2, 2a liner 3, rear support wheel part 4, pot body 5, pot groove 5a, pot support 6, front support wheel part 7, bearing shield 71, rolling bearing 72, rolling bearing shaft 73, shaft circlip 74, rolling bearing shaft 75, fixed seat 76, connecting rod 8, frame 9, eccentric wheel 10, pot body lifting mechanism 11, bolt 111, rocker seat 112, even Rod 113, key 114, connecting plate 115, transmission shaft 116, rocker 117, short shaft 118, long shaft 119, pressure roller 119a, rocker arm 120, handle 121, retaining ring 121a, handle shaft 121b, handle cover 121c, center Line 12, rigid convex strip 12a, rigid convex strip 12b, pot body movement plane 12c, and tea bucket 13. The angle Z1 between the center line and the motion plane, the radius R1 of the first arc, the radius R2 of the second arc, and the included angle Z2 of the first arc.

[0031] Further description will be made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com