Patents

Literature

72 results about "Crushing action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

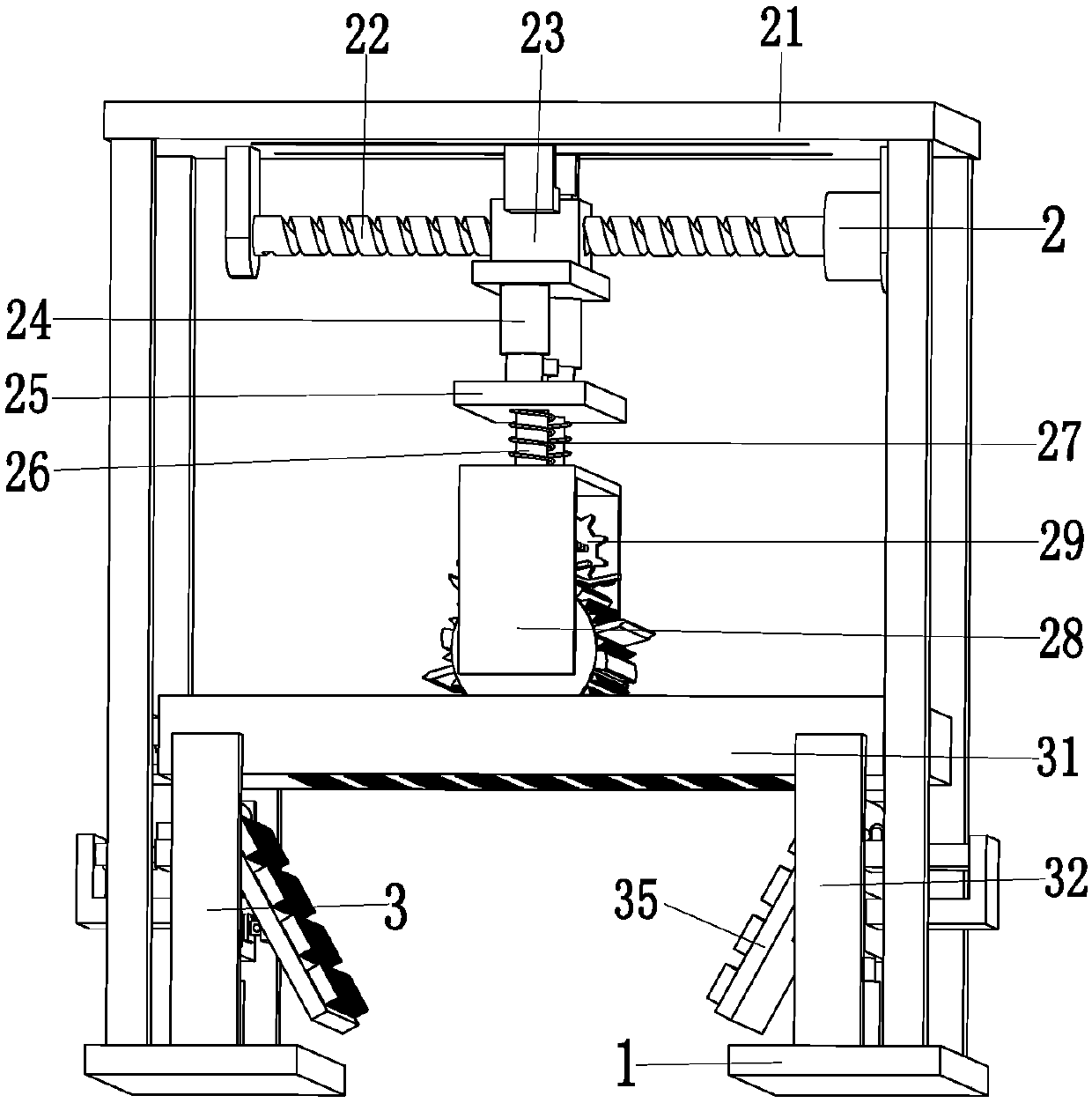

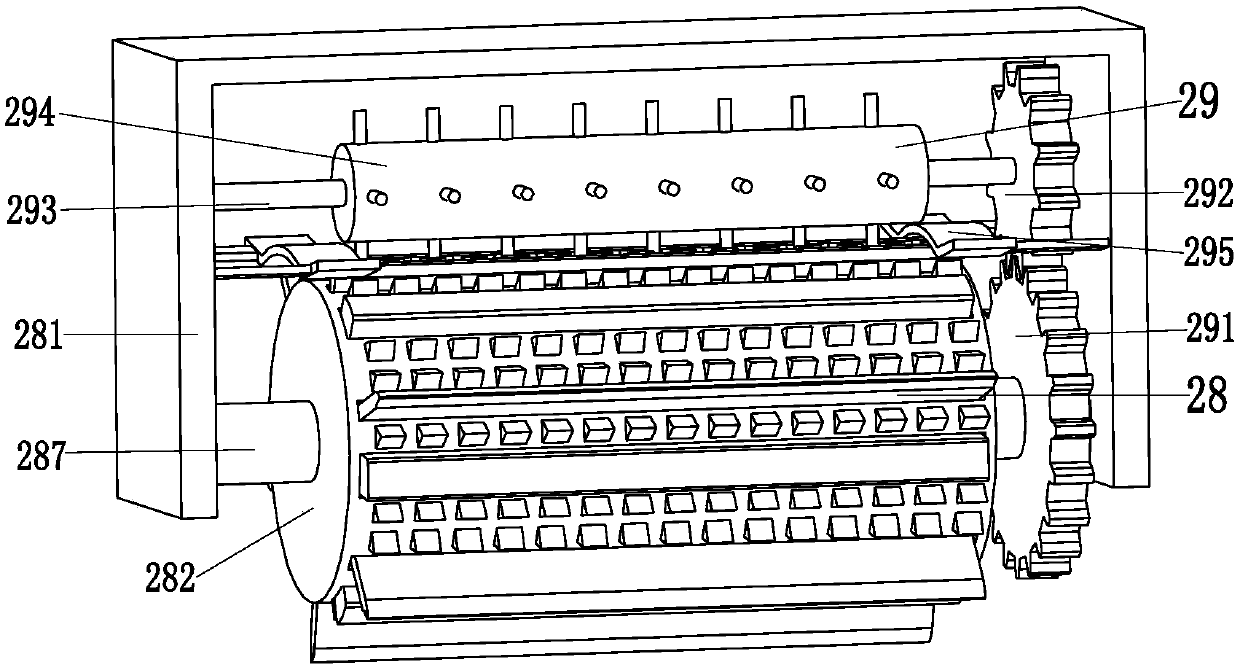

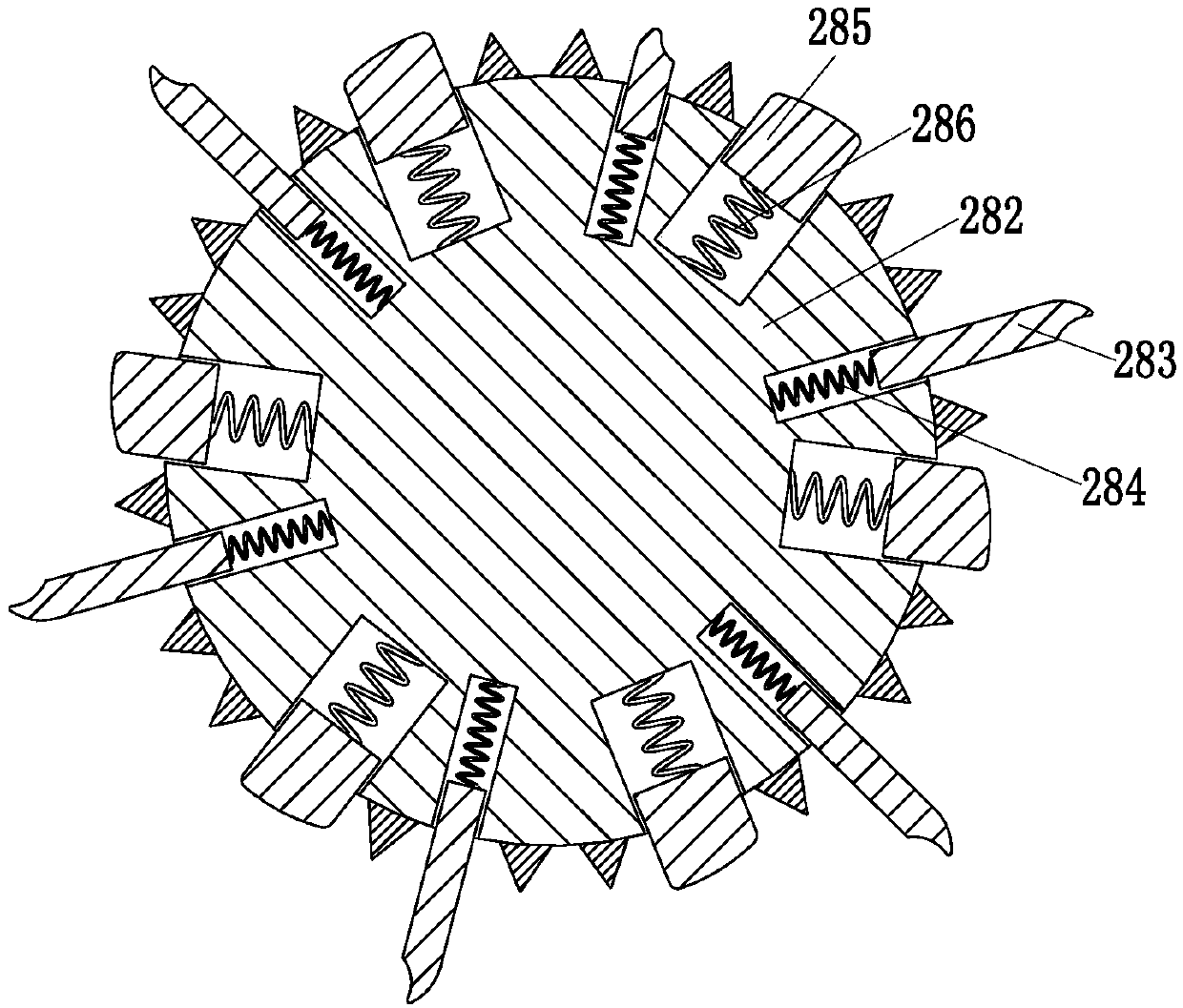

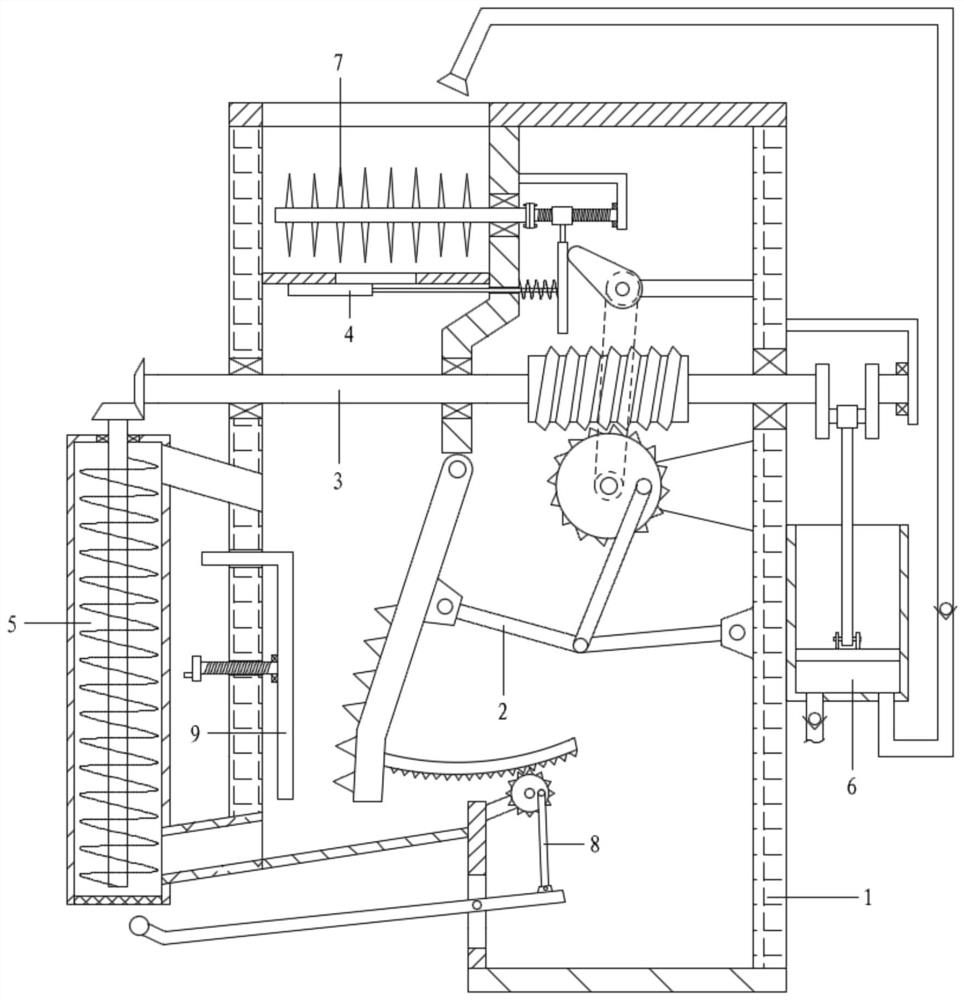

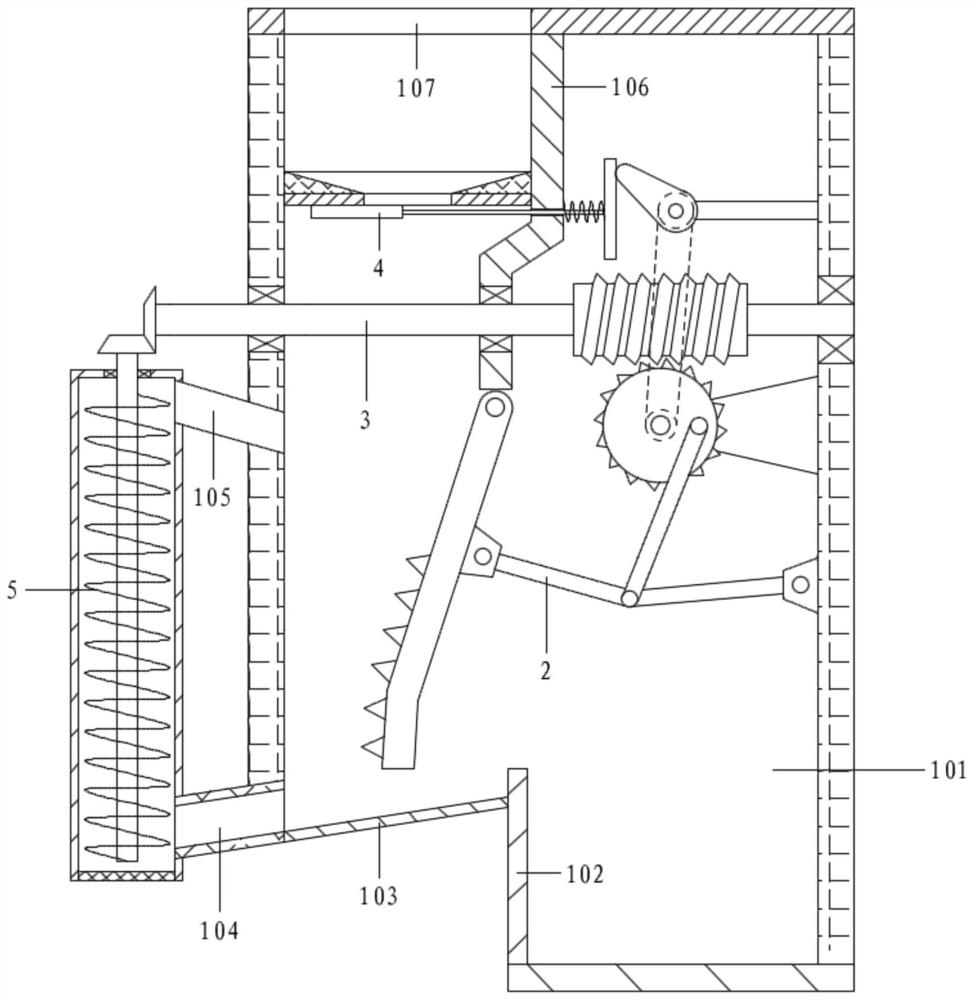

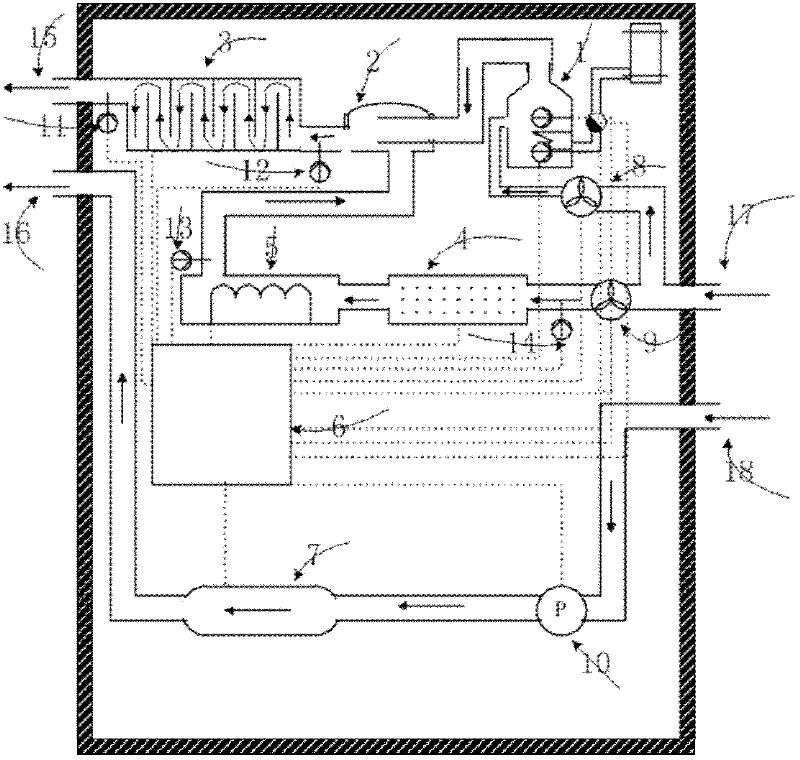

Crushed peanut processing device and processing method thereof

InactiveCN109622136AImprove crushing efficiencyFull blown actionSievingScreeningEngineeringCrushing action

The invention relates to a crushed peanut processing device and a processing method thereof. The crushed peanut processing device comprises two rolling supporting plates, a rolling device and a sieveshaking device, wherein the rolling device is mounted at the tops of the outer ends of the rolling supporting plates; the sieve shaking device is positioned below the rolling device, is mounted at thetops of the rolling supporting plates, and comprises a sieve shaking frame, sieve shaking connecting columns, gathering air cylinders, gathering plates, clamping mechanisms and pushing mechanisms; and the rolling device comprises a rolling bracket, a rolling screw rod, a rolling moving block, a rolling air cylinder, a telescopic supporting plate, a telescopic sliding column, a sliding column spring, a rolling mechanism and a clearing mechanism. By the adoption of the crushed peanut processing device provided by the invention, the problem that during the conventional peanut crushing process, the peanut crushing efficiency is low, the crushing action on peanuts cannot be performed comprehensively, the particles of crushed peanuts are relatively large, and debris on a peanut crushing cuttercannot be removed timely can be solved.

Owner:ANHUI KAILI CEREALS OILS & FOODSTUFFS

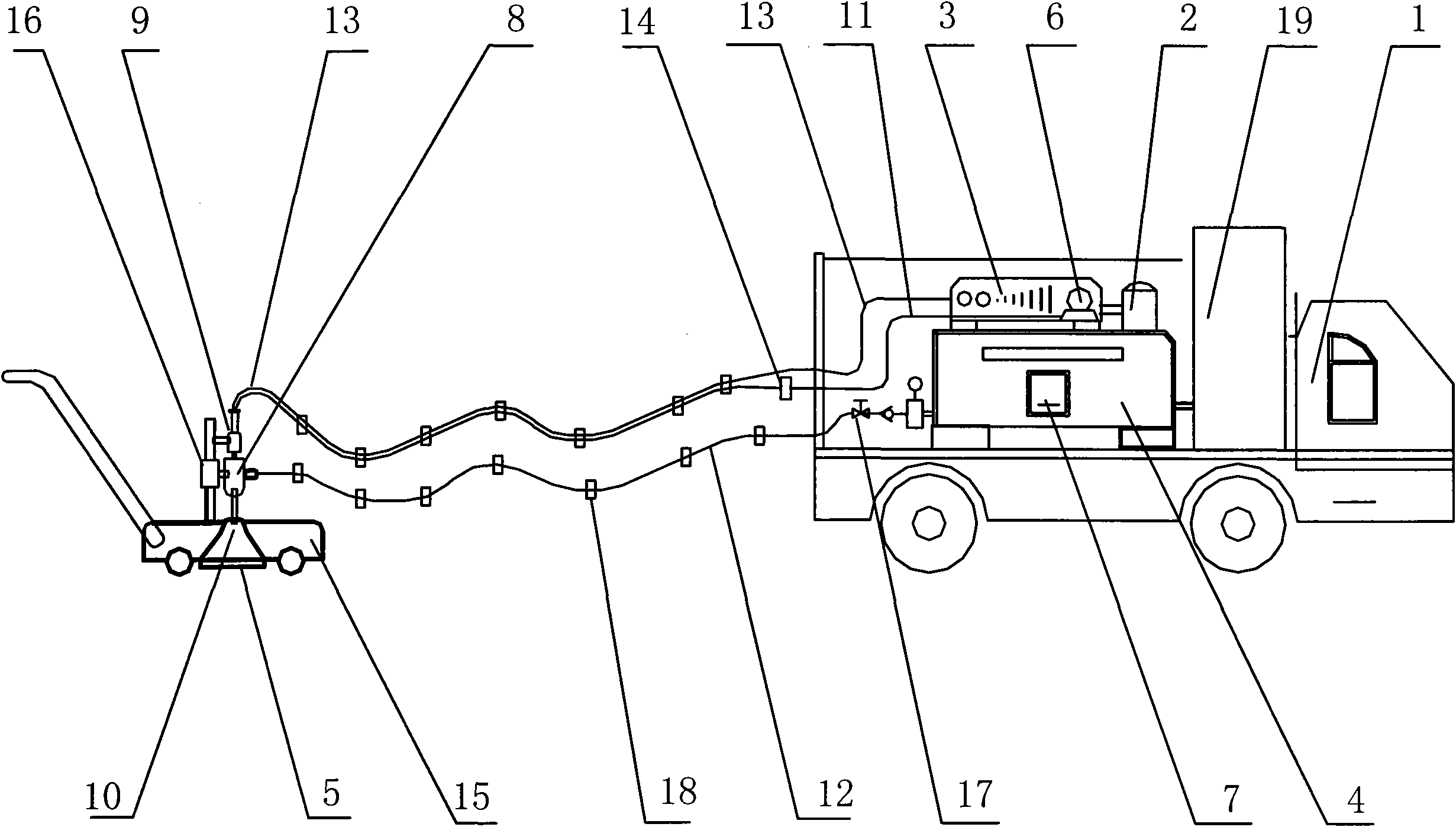

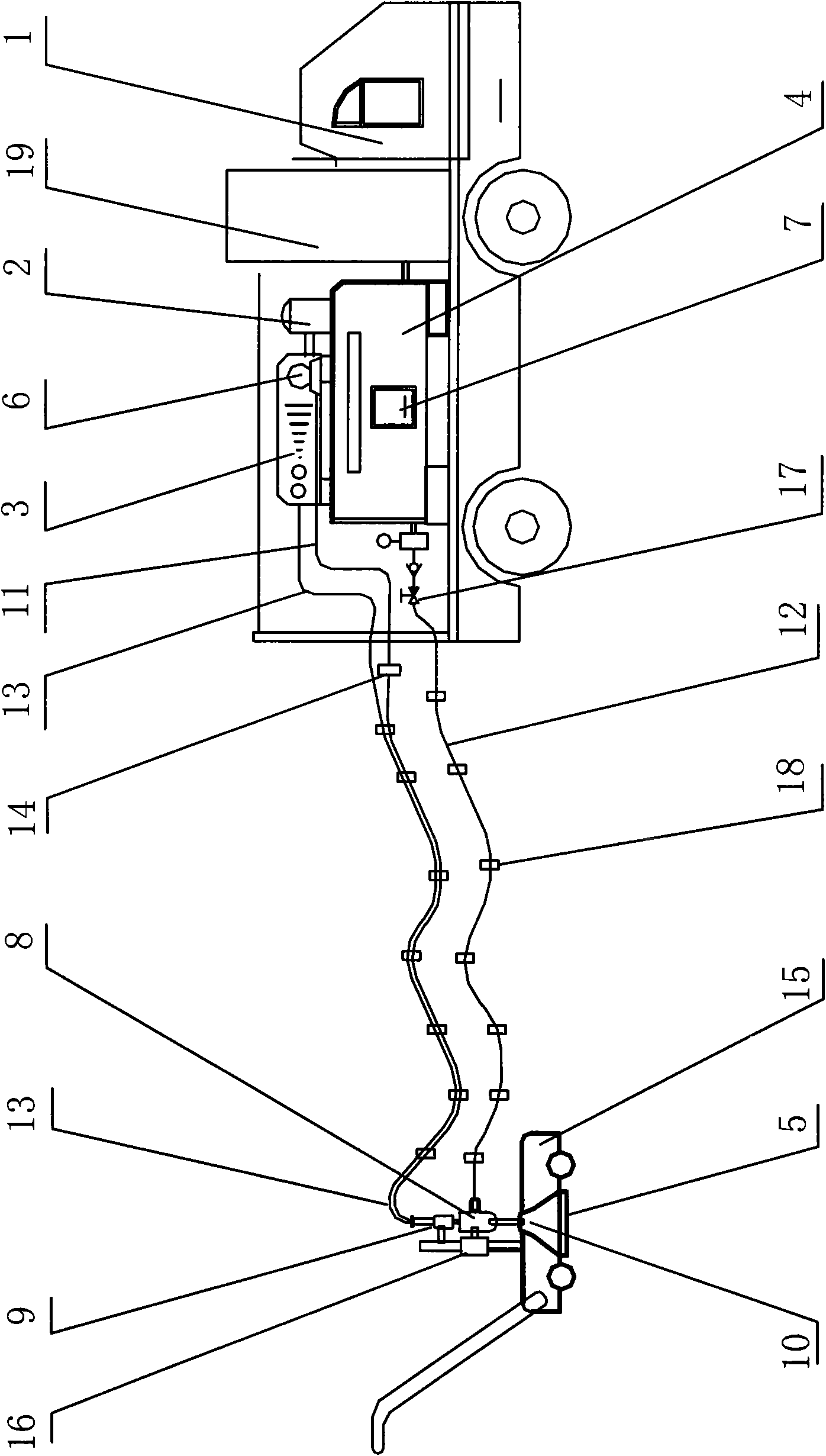

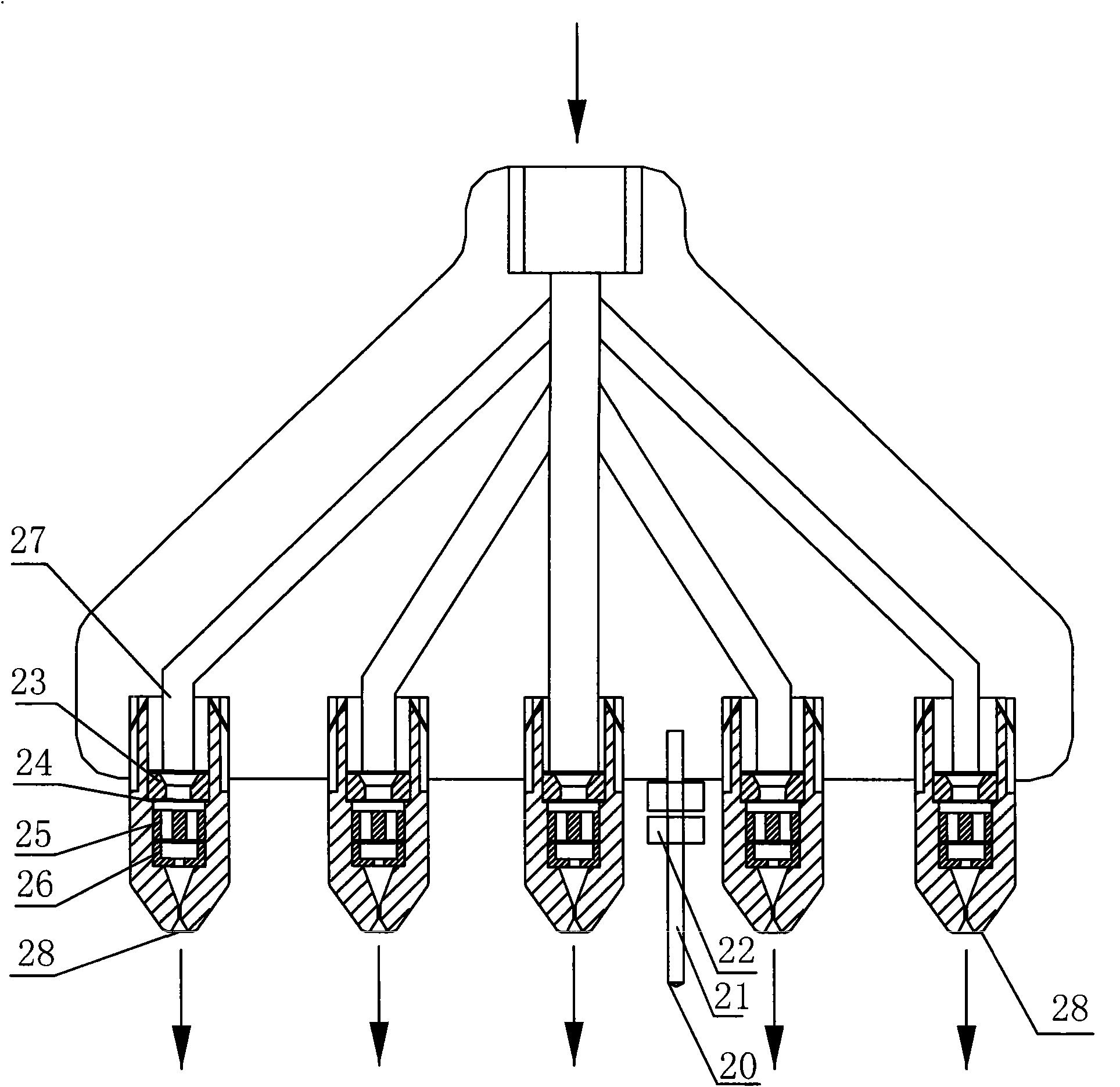

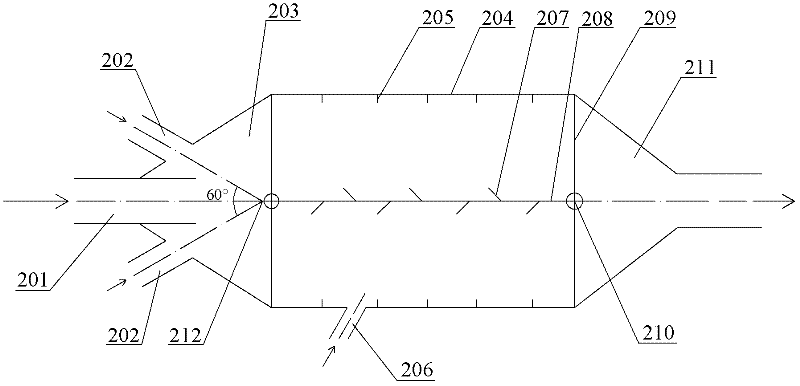

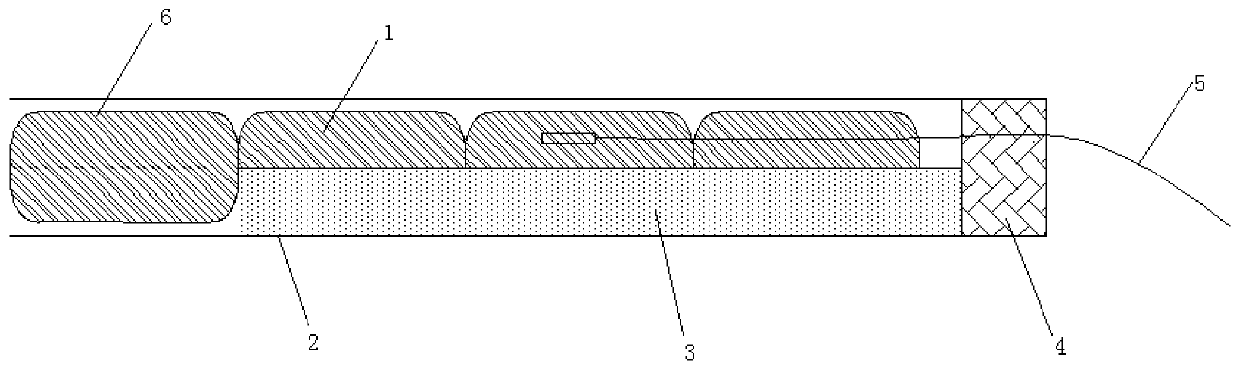

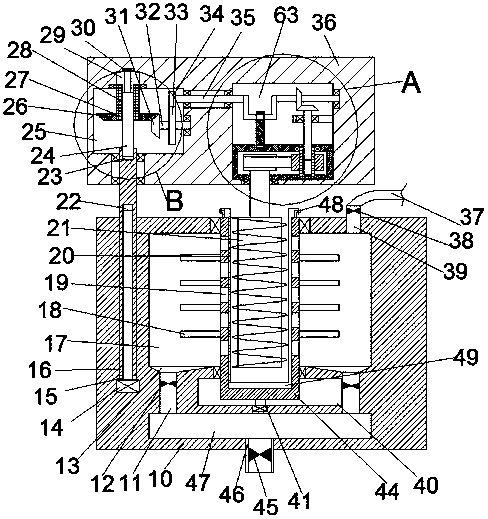

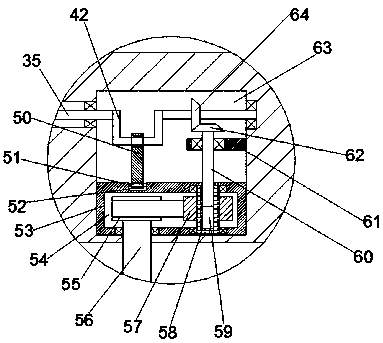

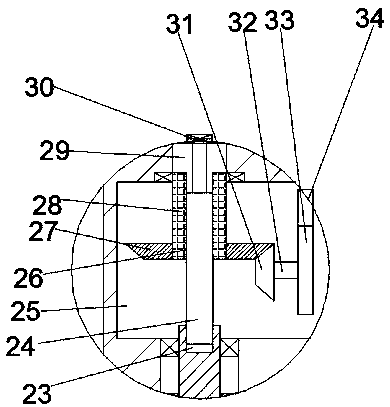

Vehicle-mounted eddy strong pulse resonant jet cleaning device

InactiveCN101811121AImprove crushing effectImprove energy efficiencySpray nozzlesCleaning using liquidsHigh pressure waterHigh pressure

The invention discloses a vehicle-mounted eddy strong pulse resonant jet cleaning device comprising a carrying vehicle 1, a power supply 2, an electrical control device 7, an ultrasonic generating device 3, an air cooling device 6, a high-pressure water jet generating device 4 and a spray head device, wherein the spray head device comprises an ultrasonic transduction vibrator 9, an amplitude transformer 10, a strong pulse vibrating chamber 8 and an eddy resonant jet spray head 5; the ultrasonic transduction vibrator 9 is connected with the ultrasonic generating device 3 by an ultrasonic transmission cable 13 and is connected with the air cooling device 6 by a cooling compressed air tube 11; and the strong pulse vibrating chamber 8 is connected with the high-pressure water jet generating device 4 by a high-pressure water inlet pipeline 12. In the invention, the energy of high-pressure water jet and eddy resonance and the energy of strong high-frequency mechanical vibration pulses generated by the ultrasonic generator are sufficiently utilized to form a stable eddy strong pulse resonant jet in the vibration chamber, which obviously improves the energy efficiency of the jet and reinforces the washing action and the crushing action generated on the surface of a material by the pulse jet; and the complete set of device does not need to be configured with additional power supply and cooling air source by customers. The cleaning device has a style of the own, convenient operation and better cleaning effect and is especially suitable for field work and maneuvering work.

Owner:任保林

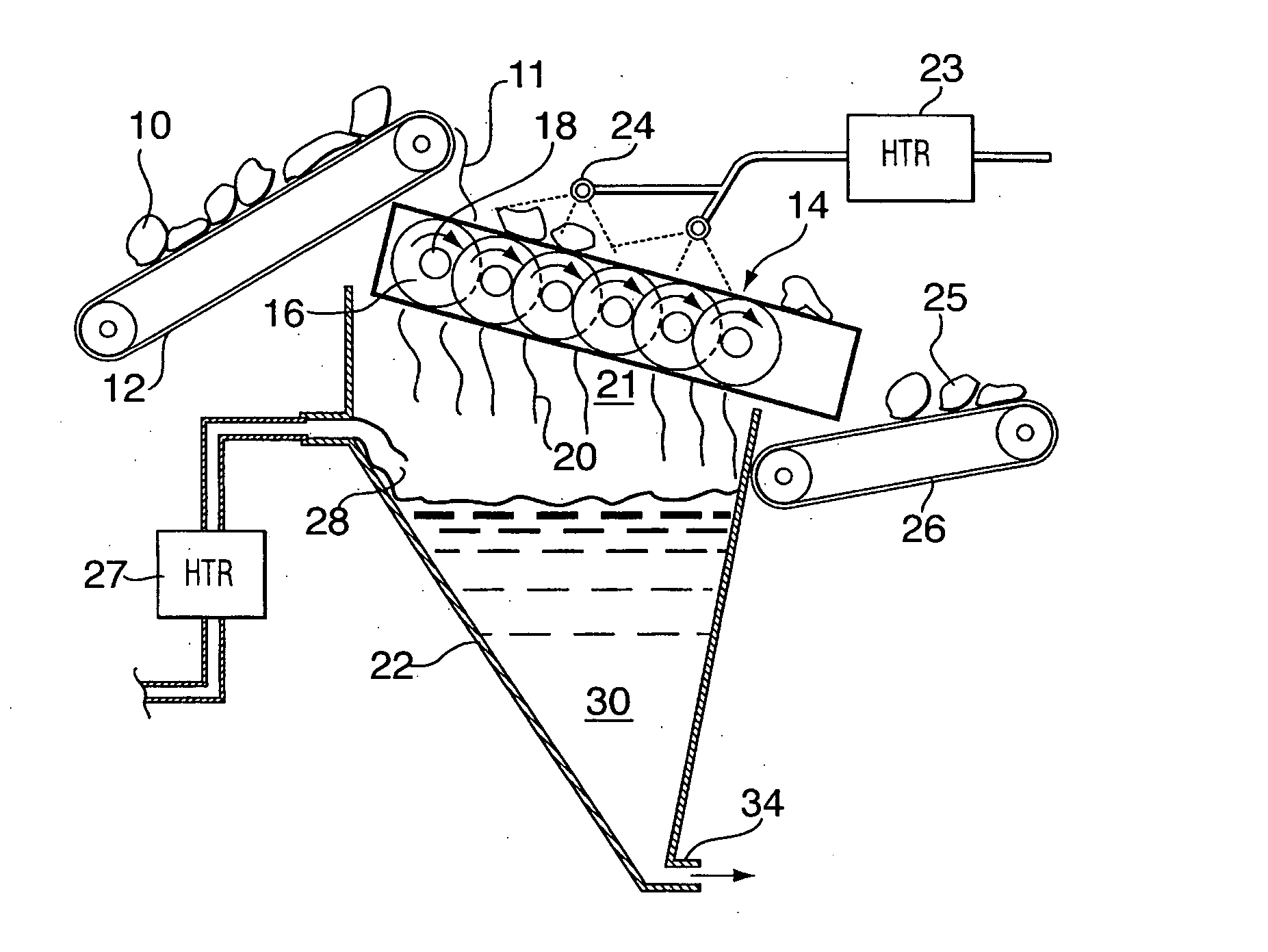

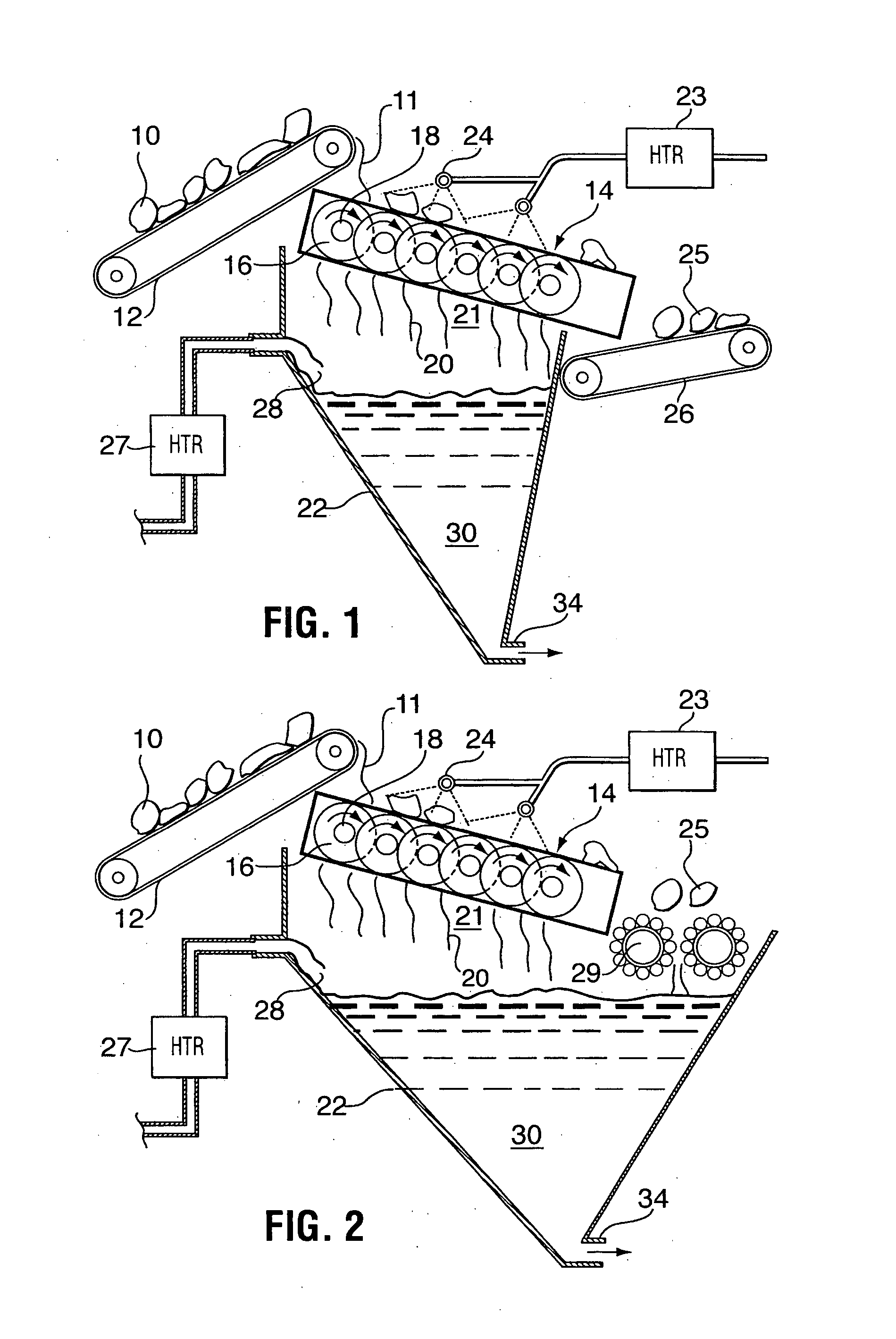

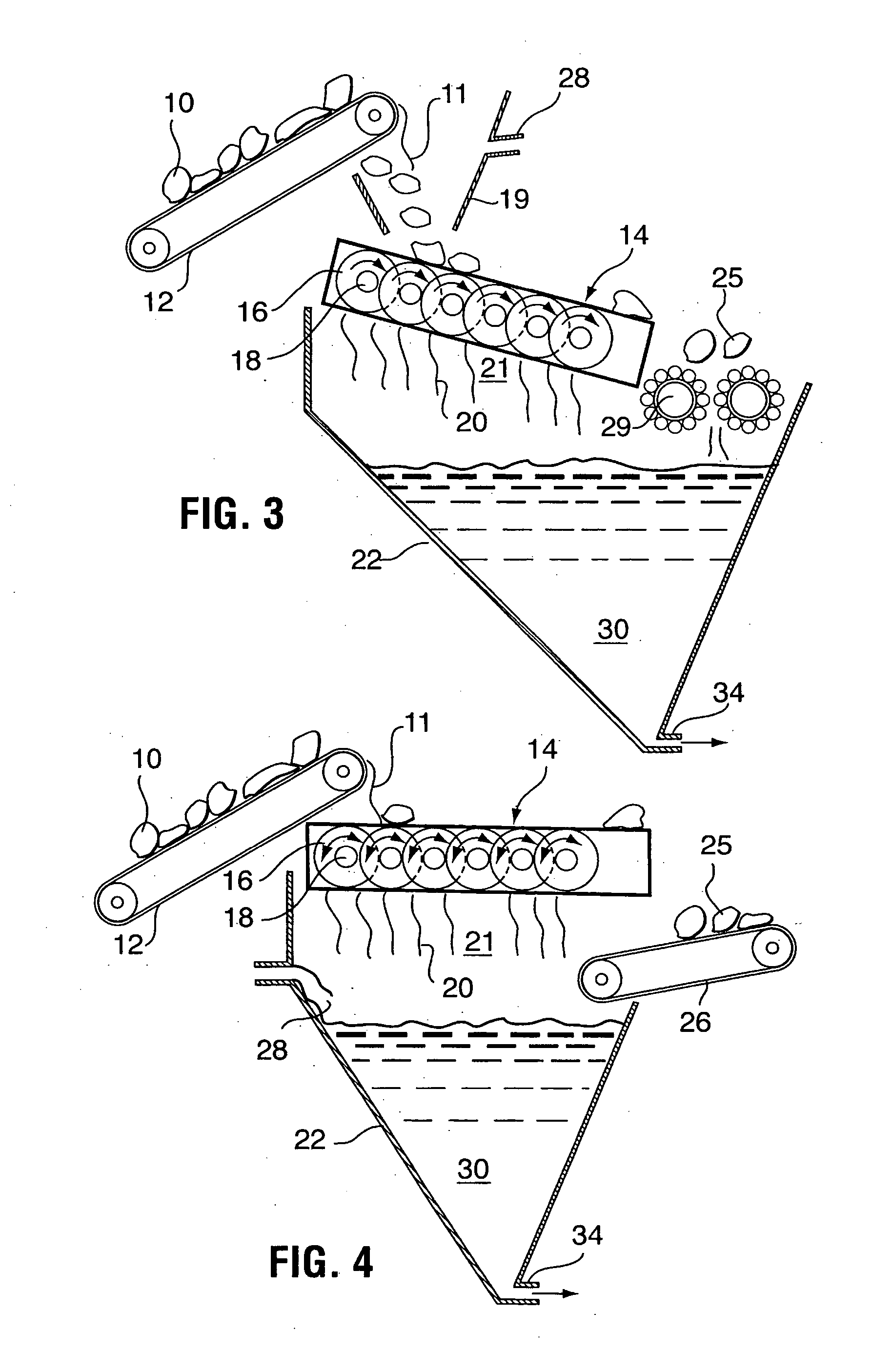

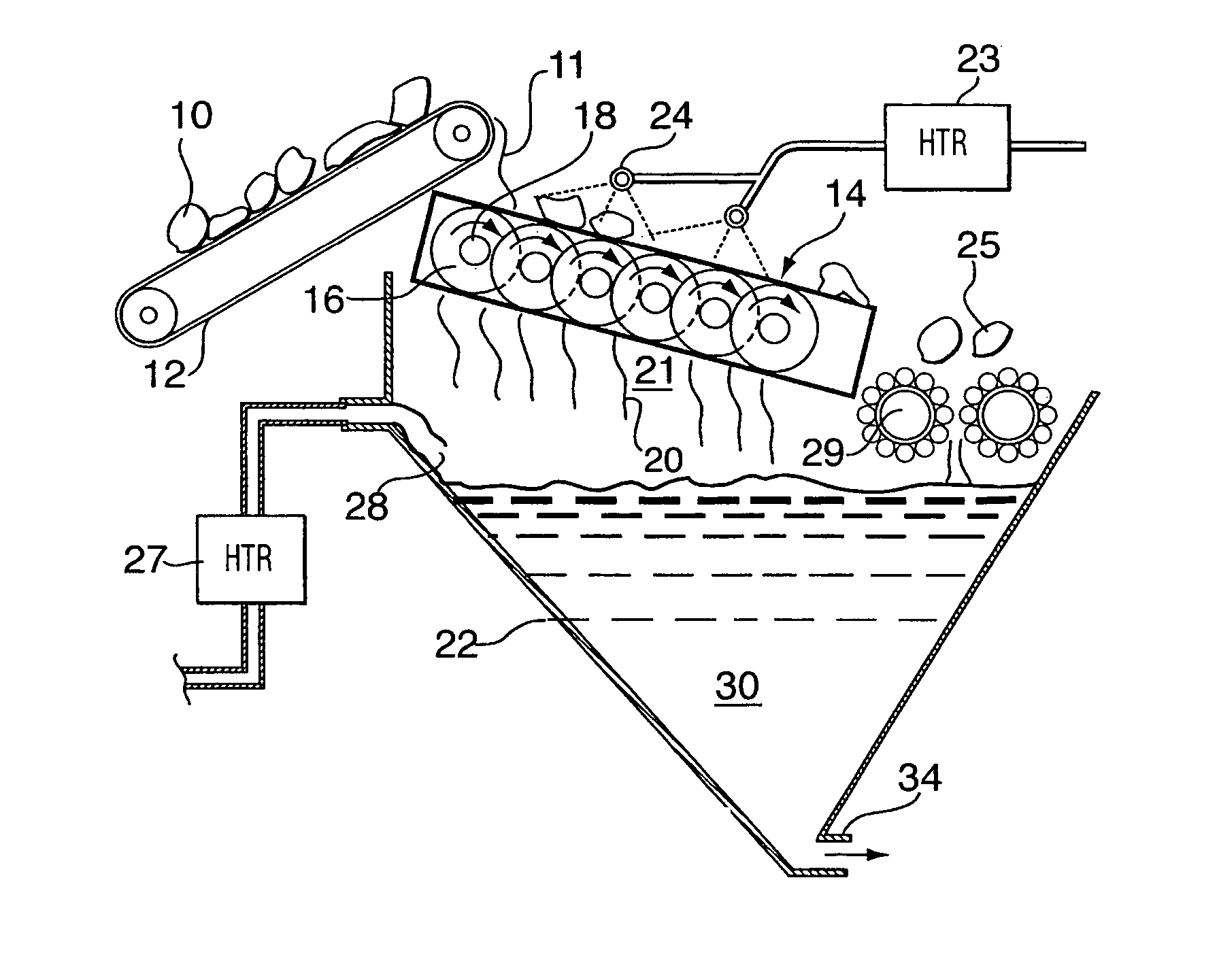

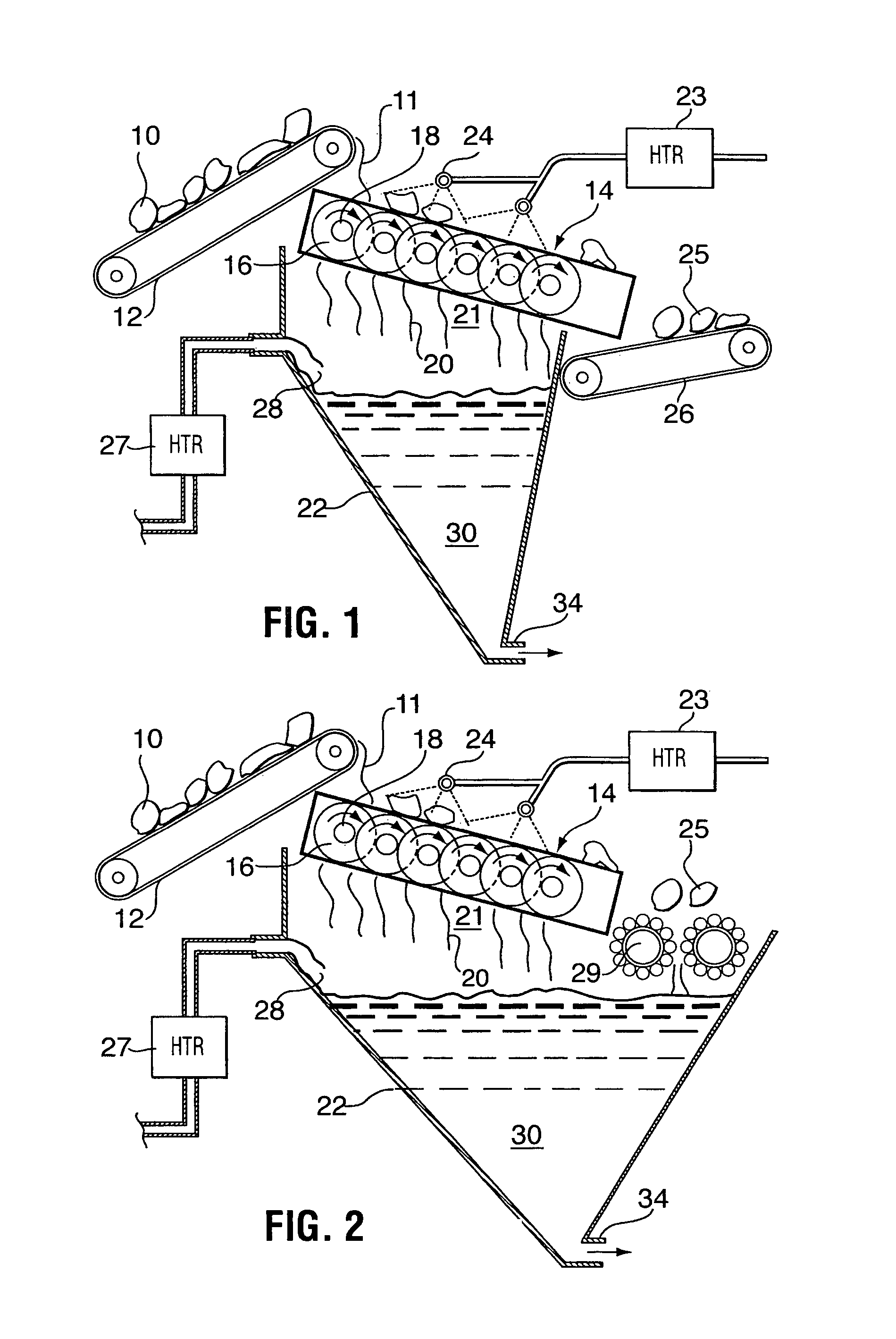

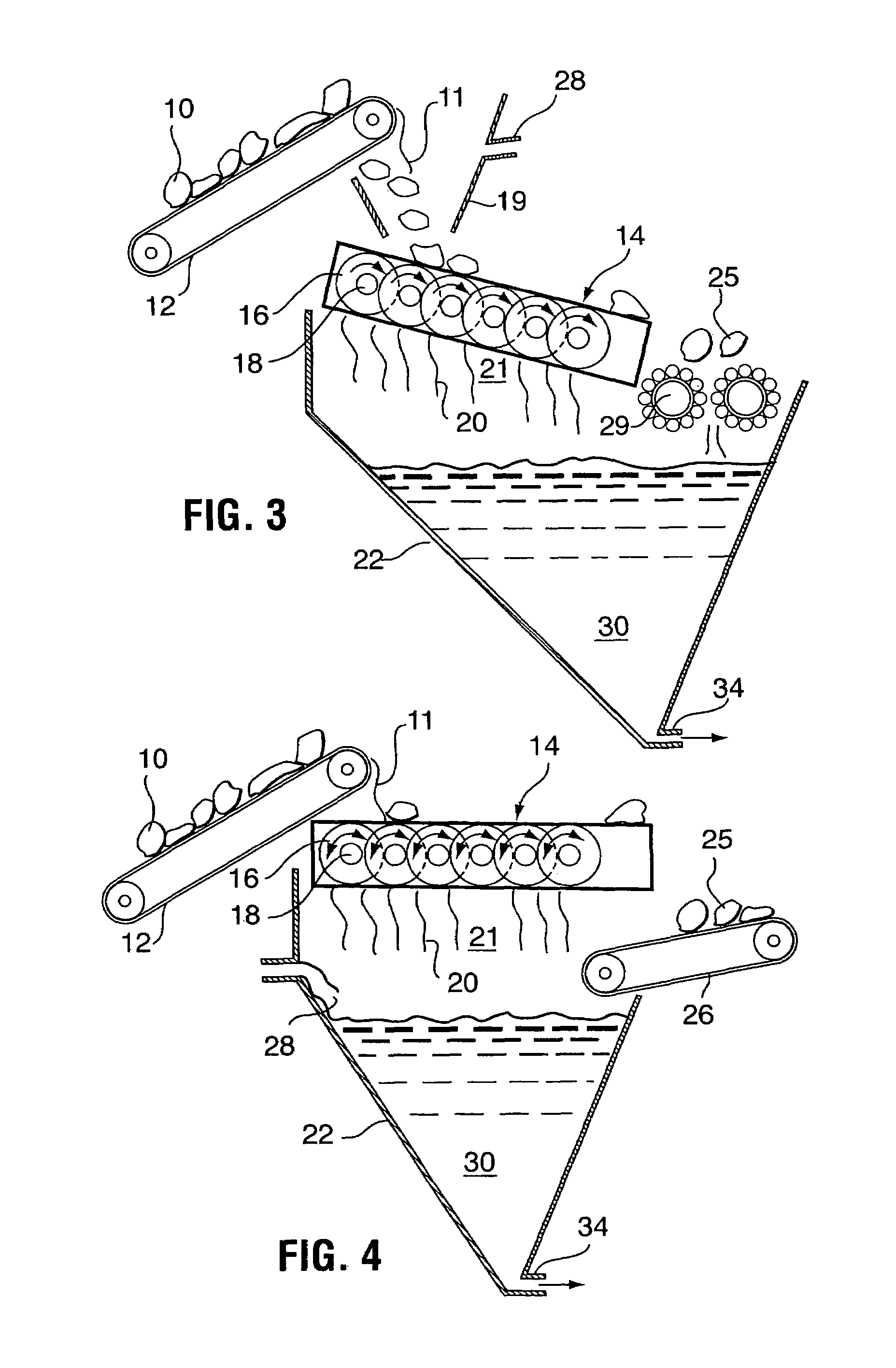

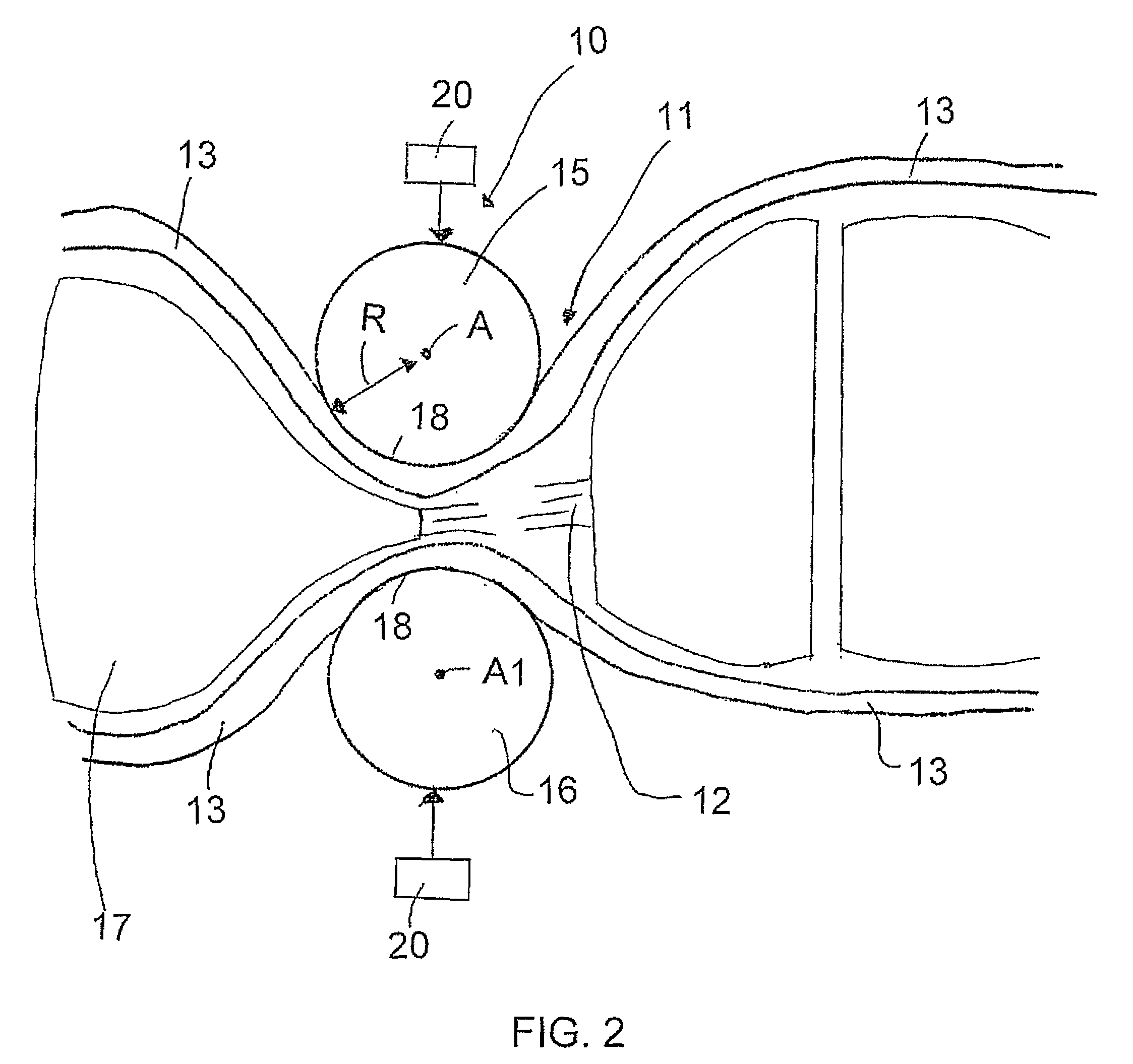

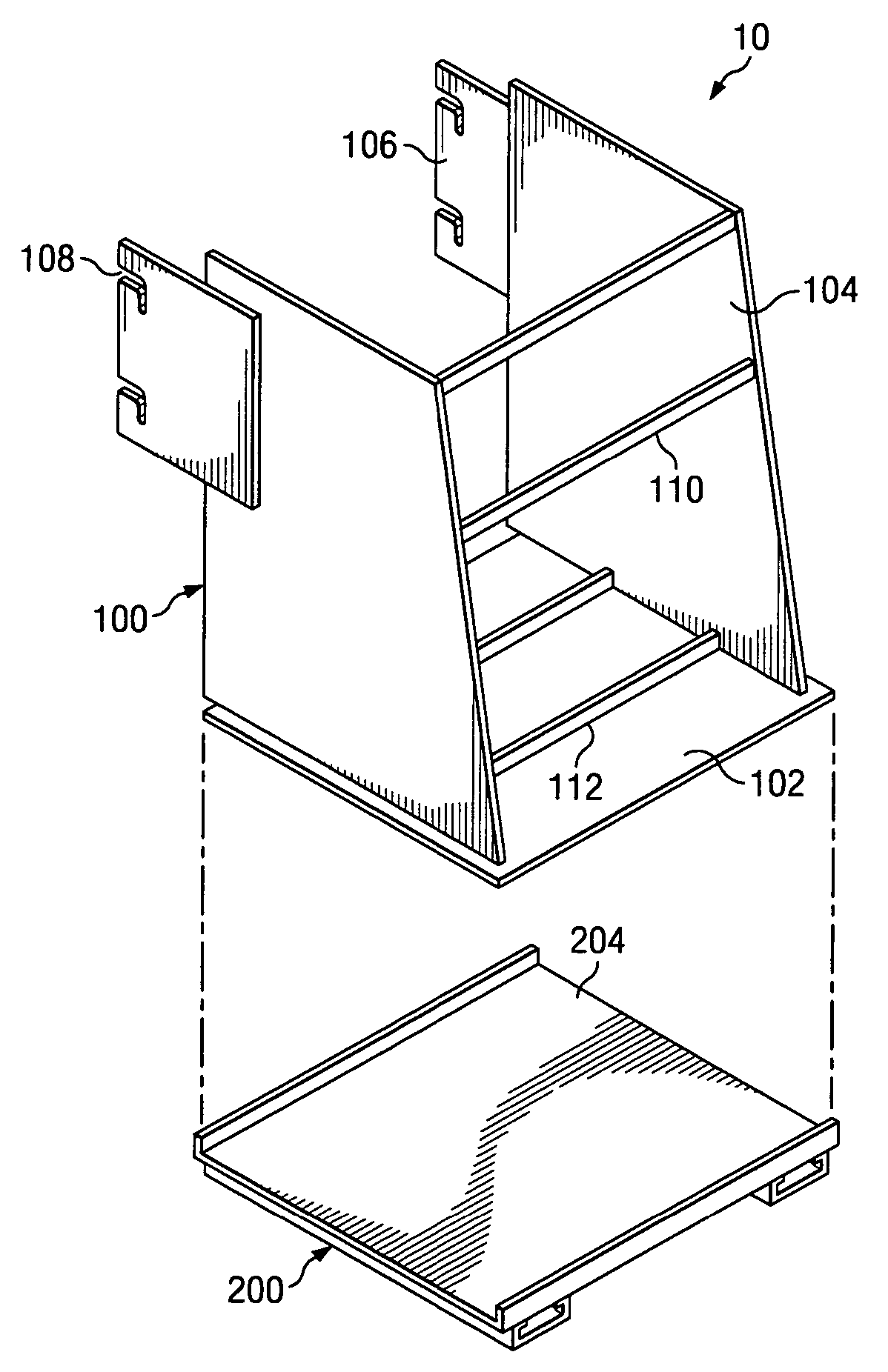

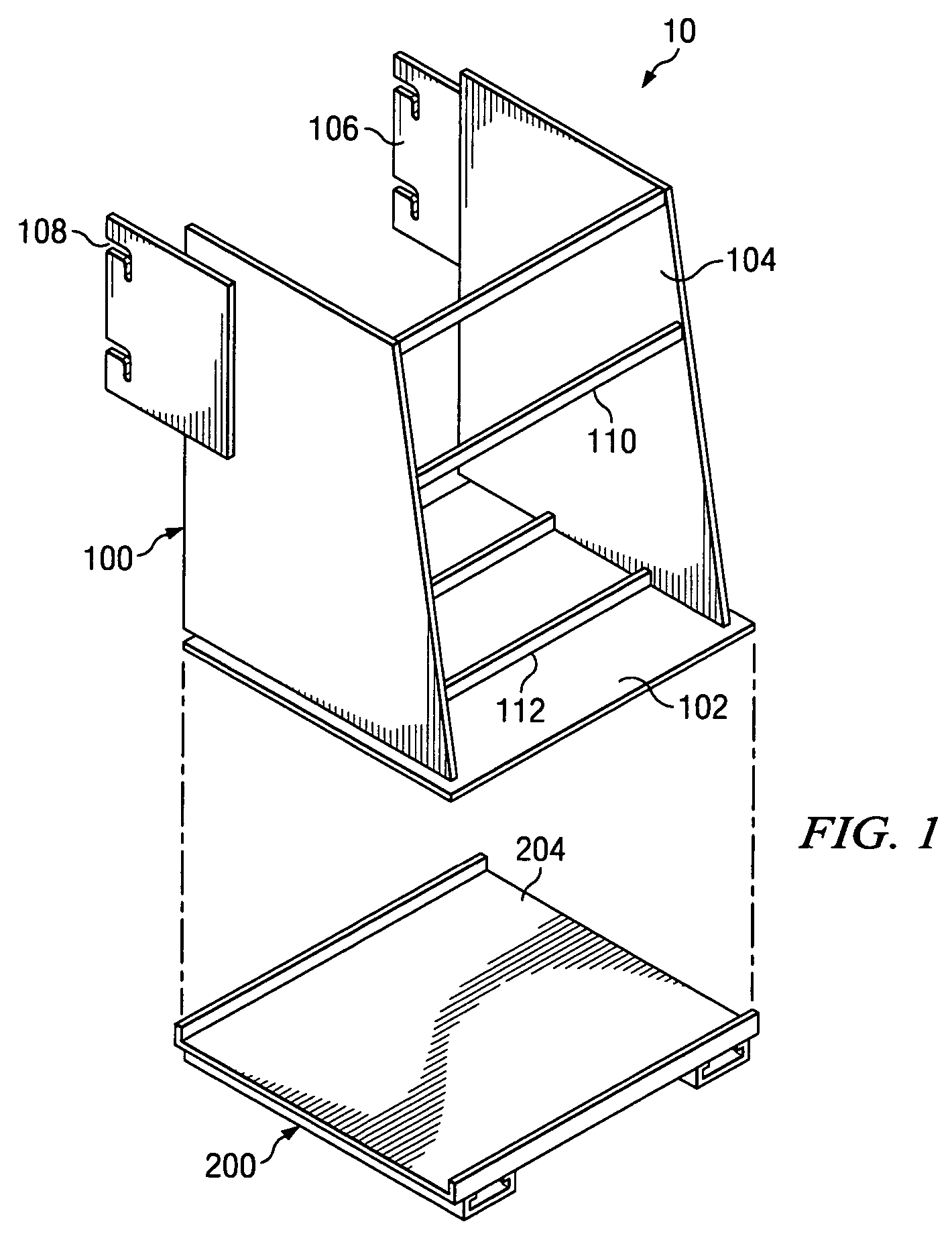

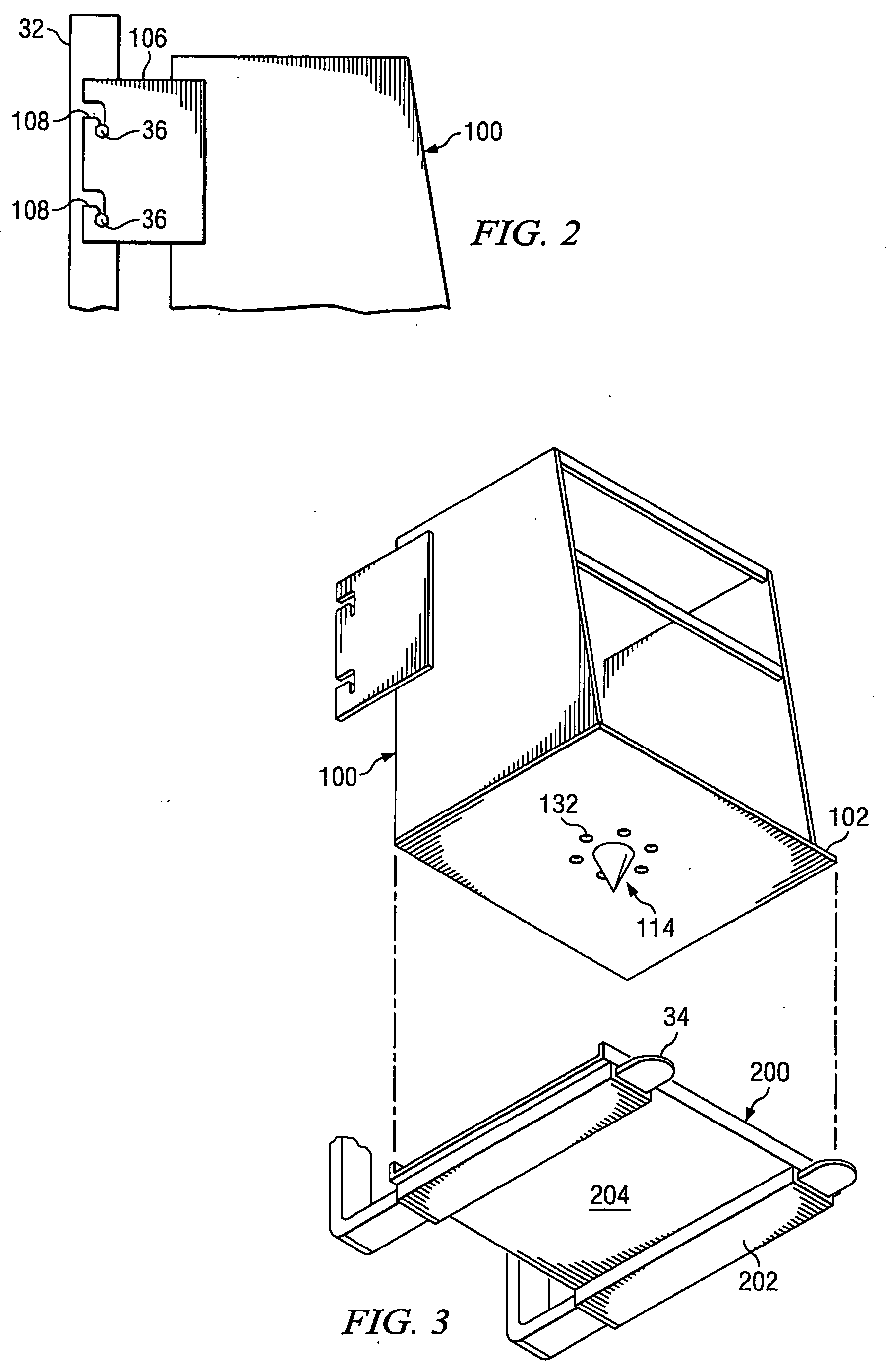

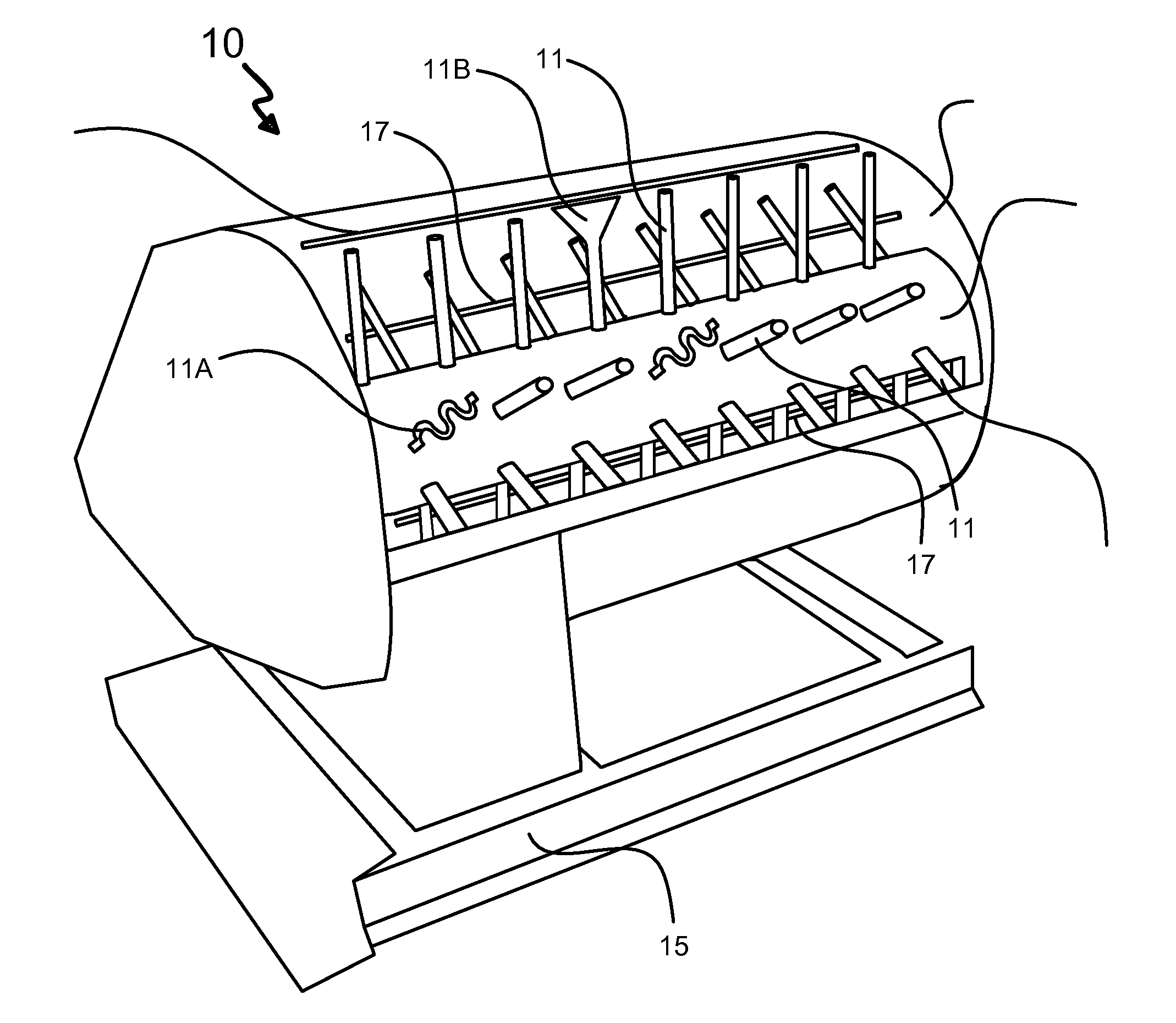

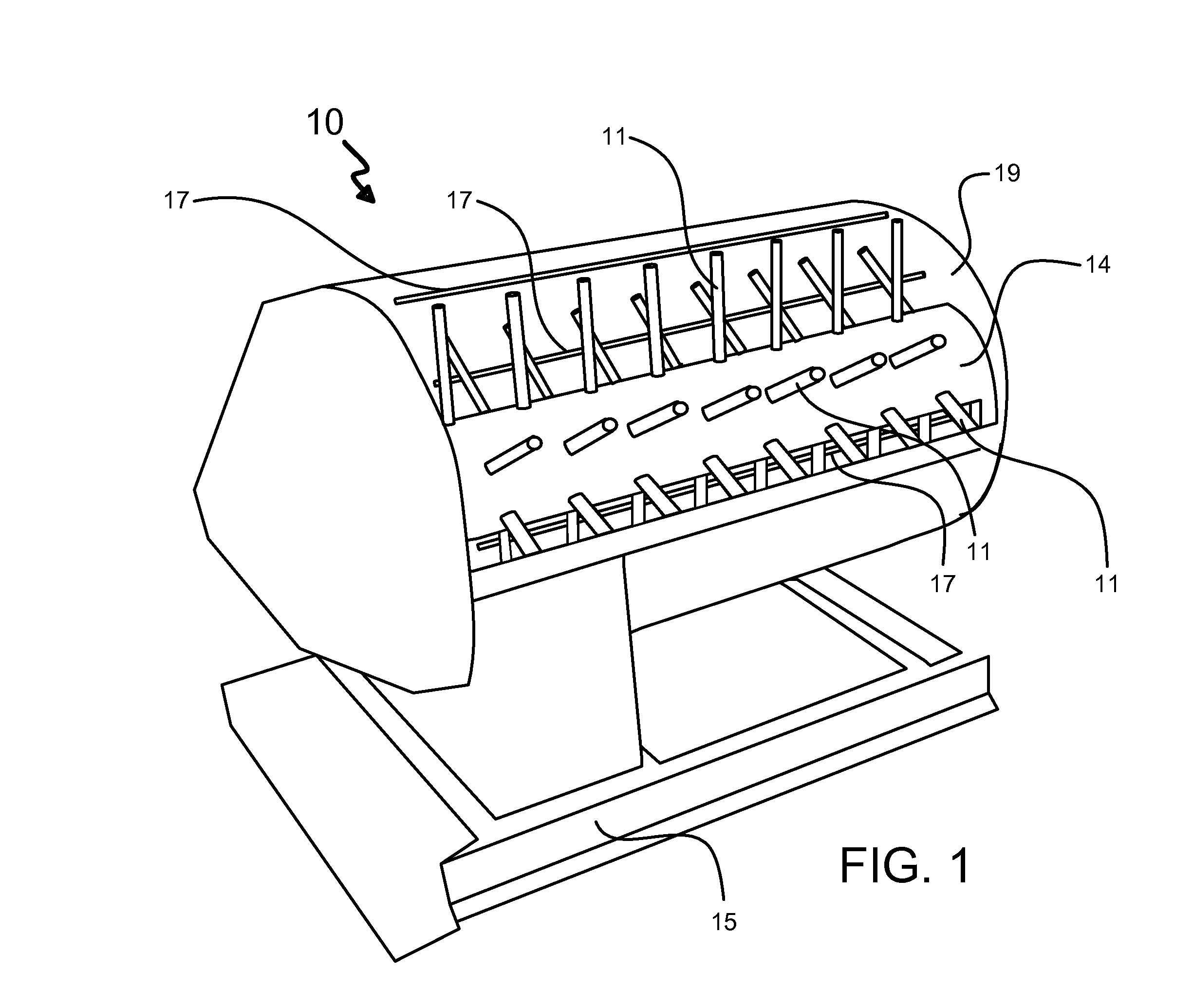

Sizing roller screen ore processing apparatus

Discloses a mined ore processing apparatus to process mined ores, such as oil sands ore, into granular material. An ore processor bed receives the ore to be processed. The ore processor bed has a frame supporting several rotating elements each separately driven to provide independent rotation rate and direction from the other. The ore processing bed is operable as a sizing device to decimate mined ore supply into granular material and separating it from rocks and other large lump mineral materials found in situ. The ore processing bed may be oriented to provide an upward inclination, which, when combined with alternating rotating element rotation directions, provides a crushing action to the ore material to crush larger rock. Alternately, a rock crusher is also provided to disintegrate oversized materials.

Owner:SUNCOR ENERGY INC

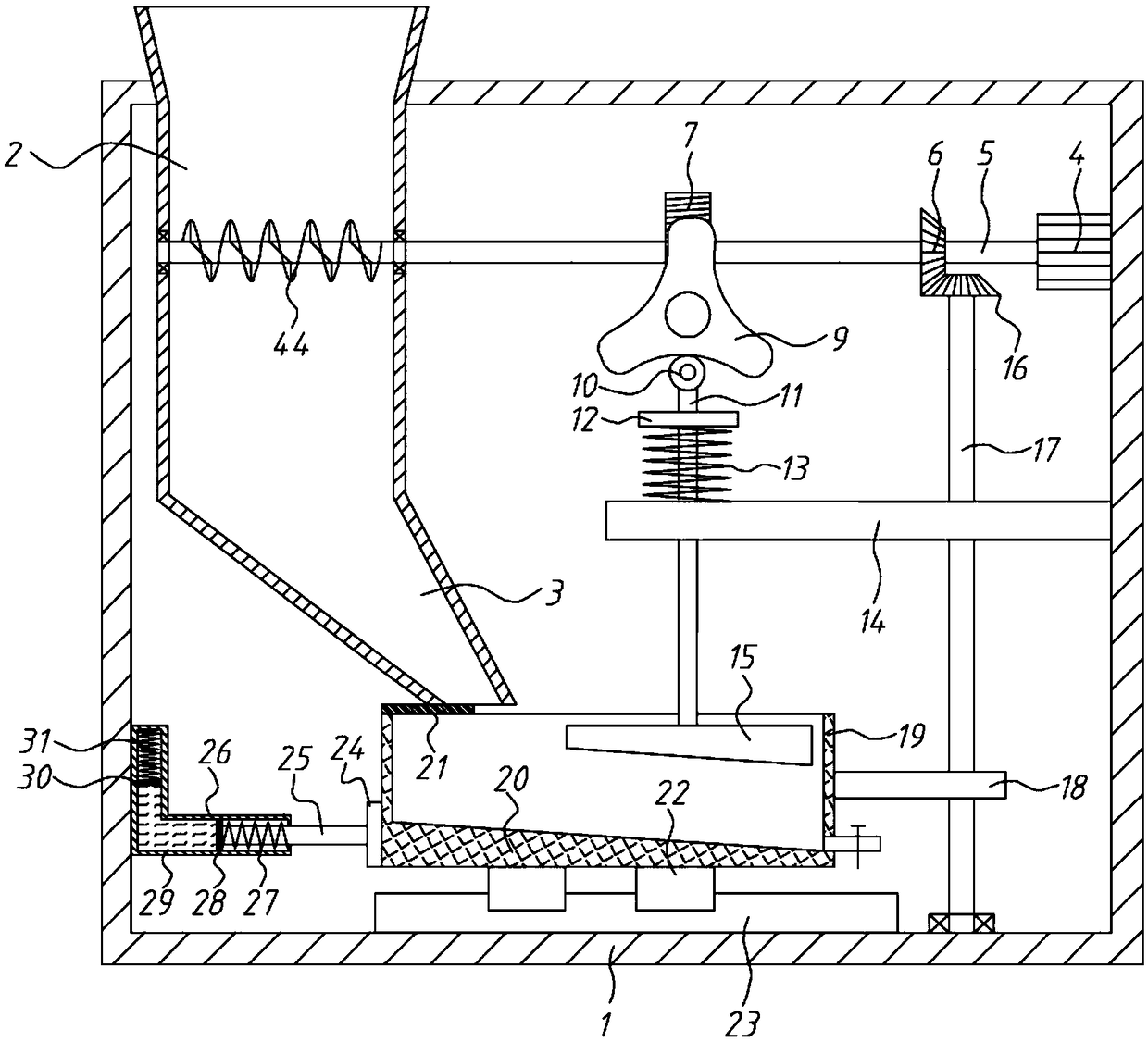

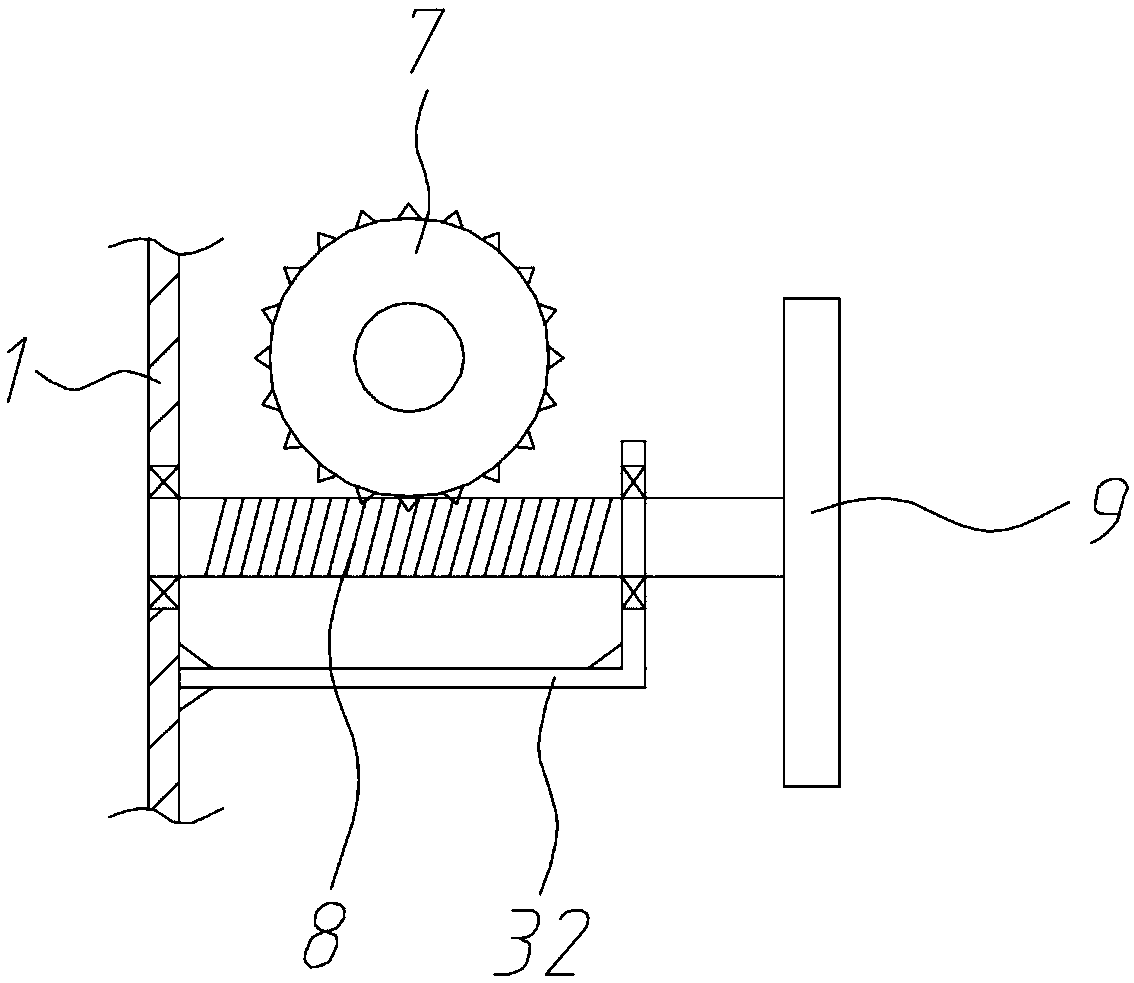

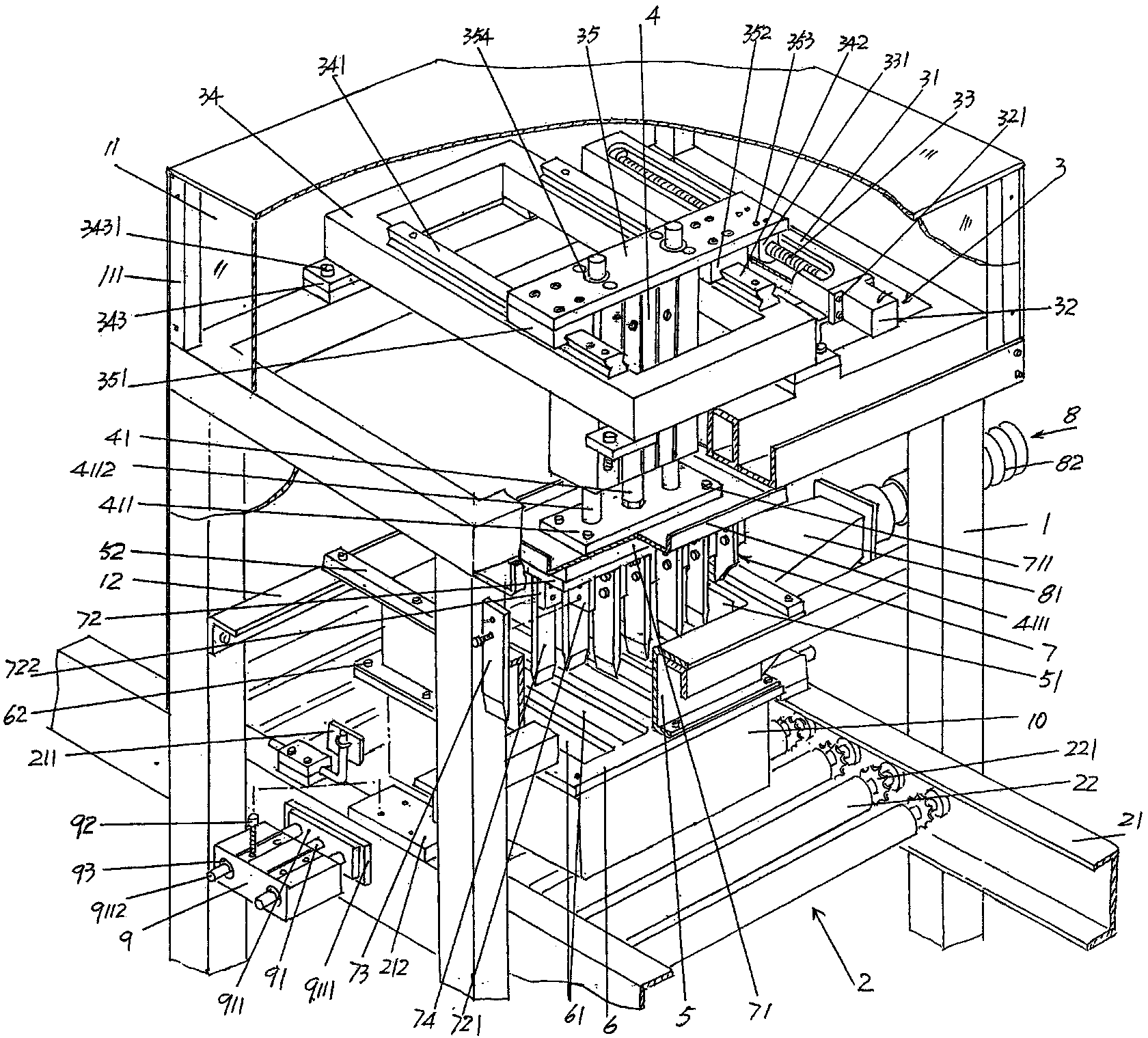

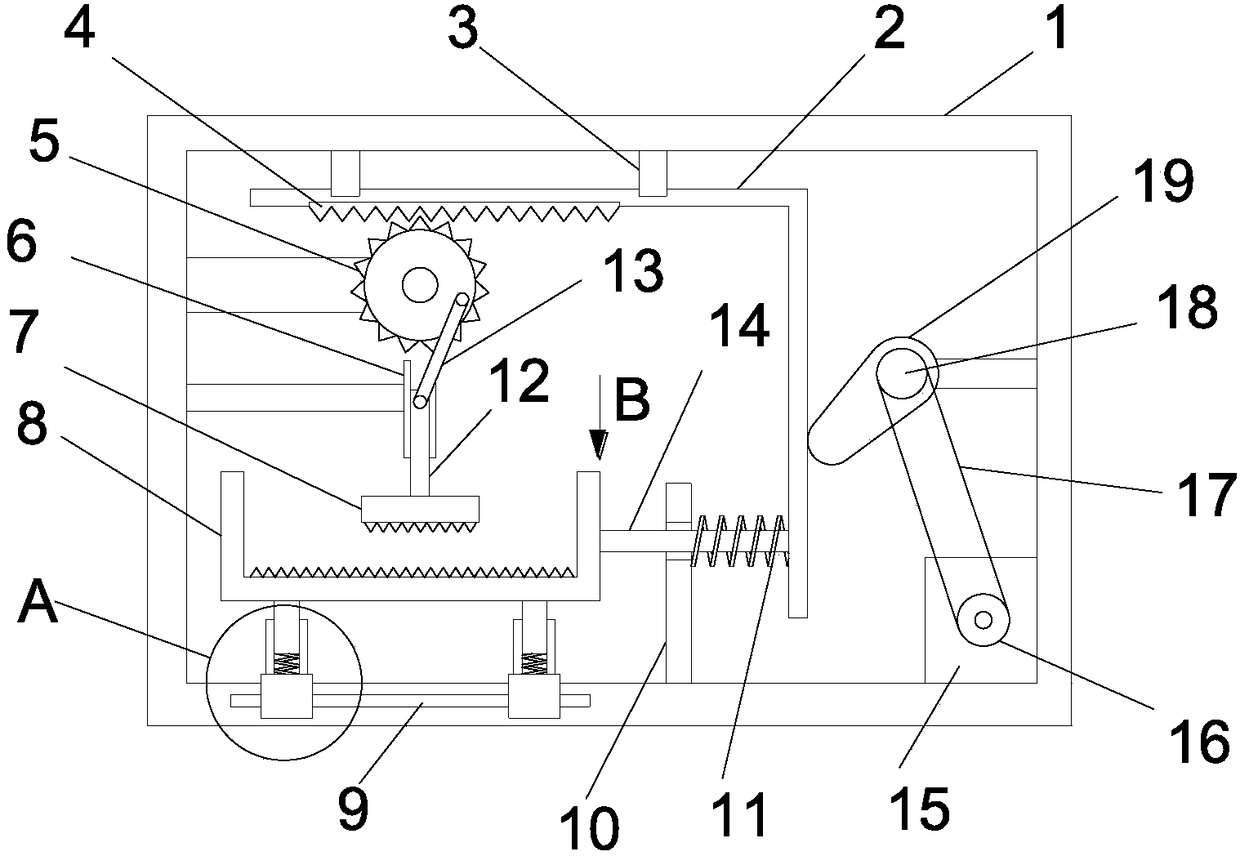

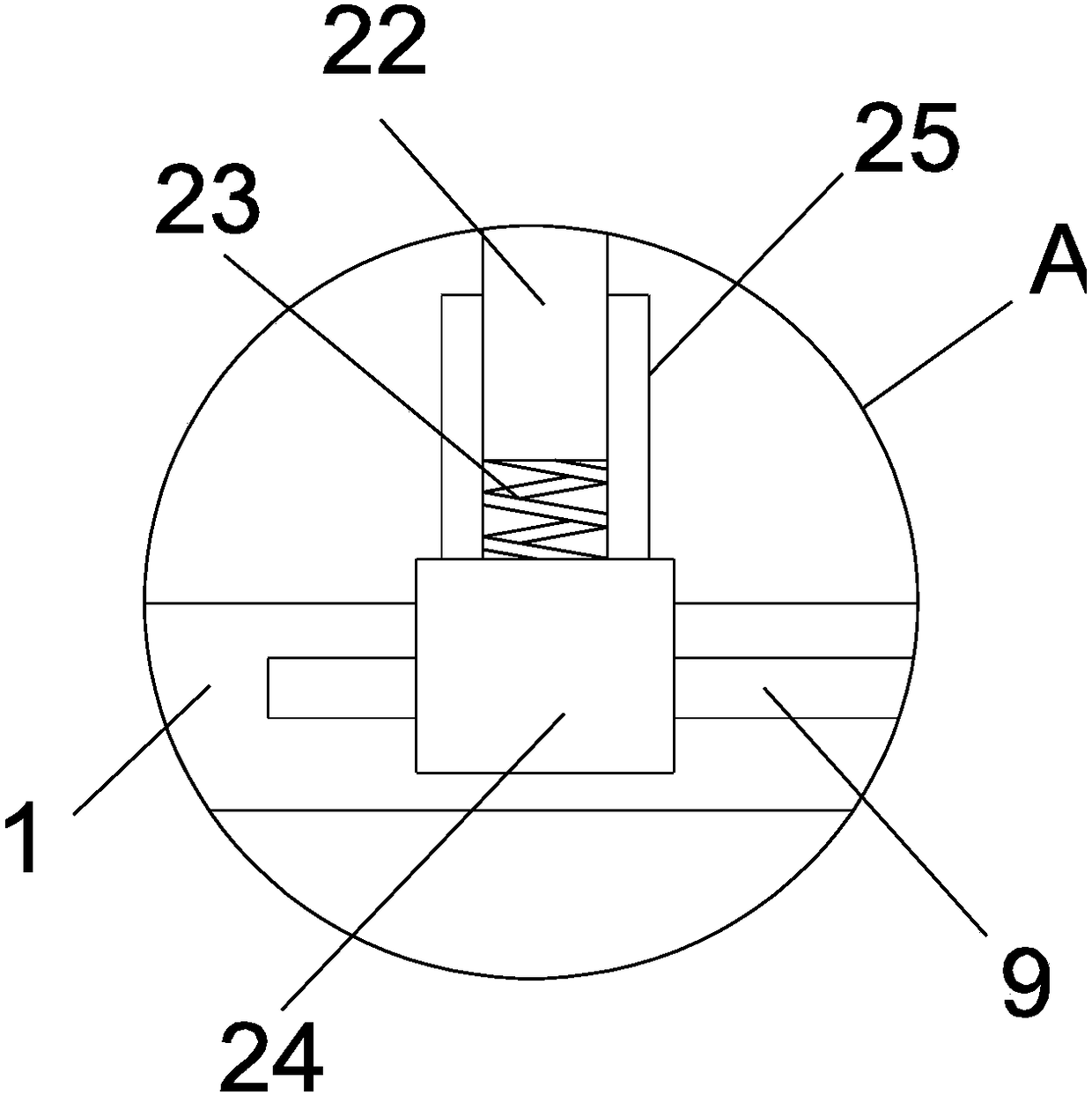

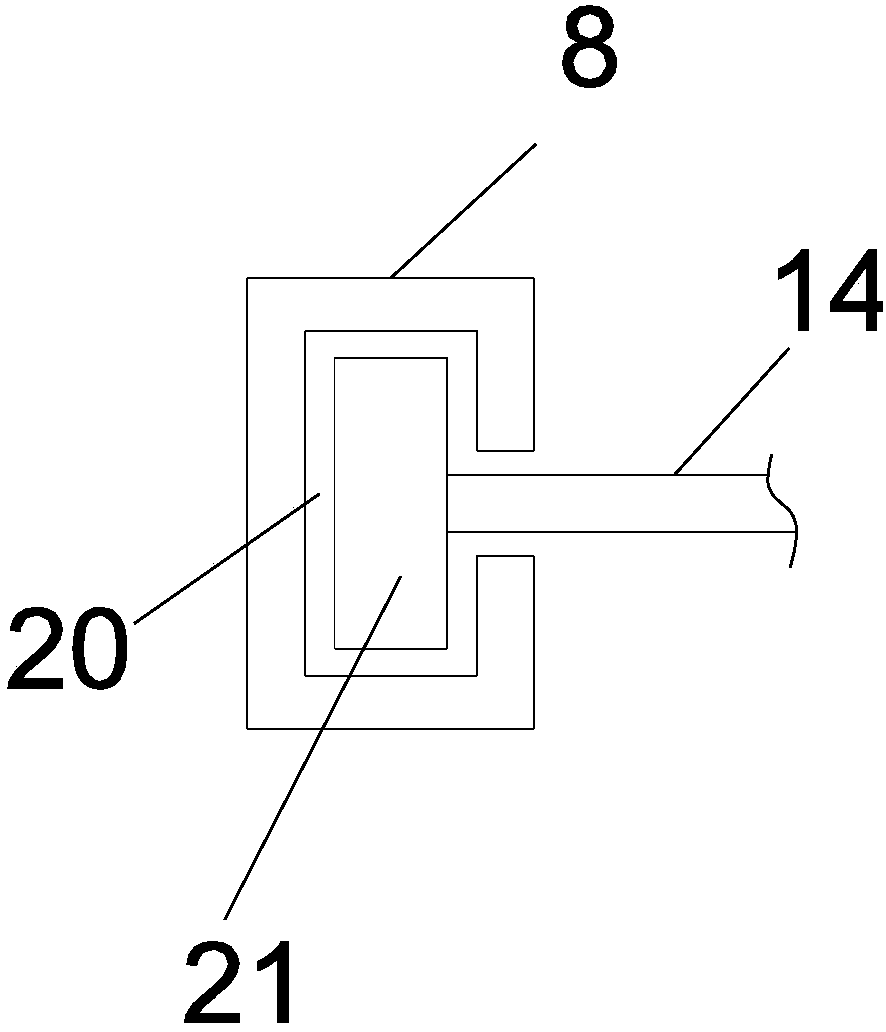

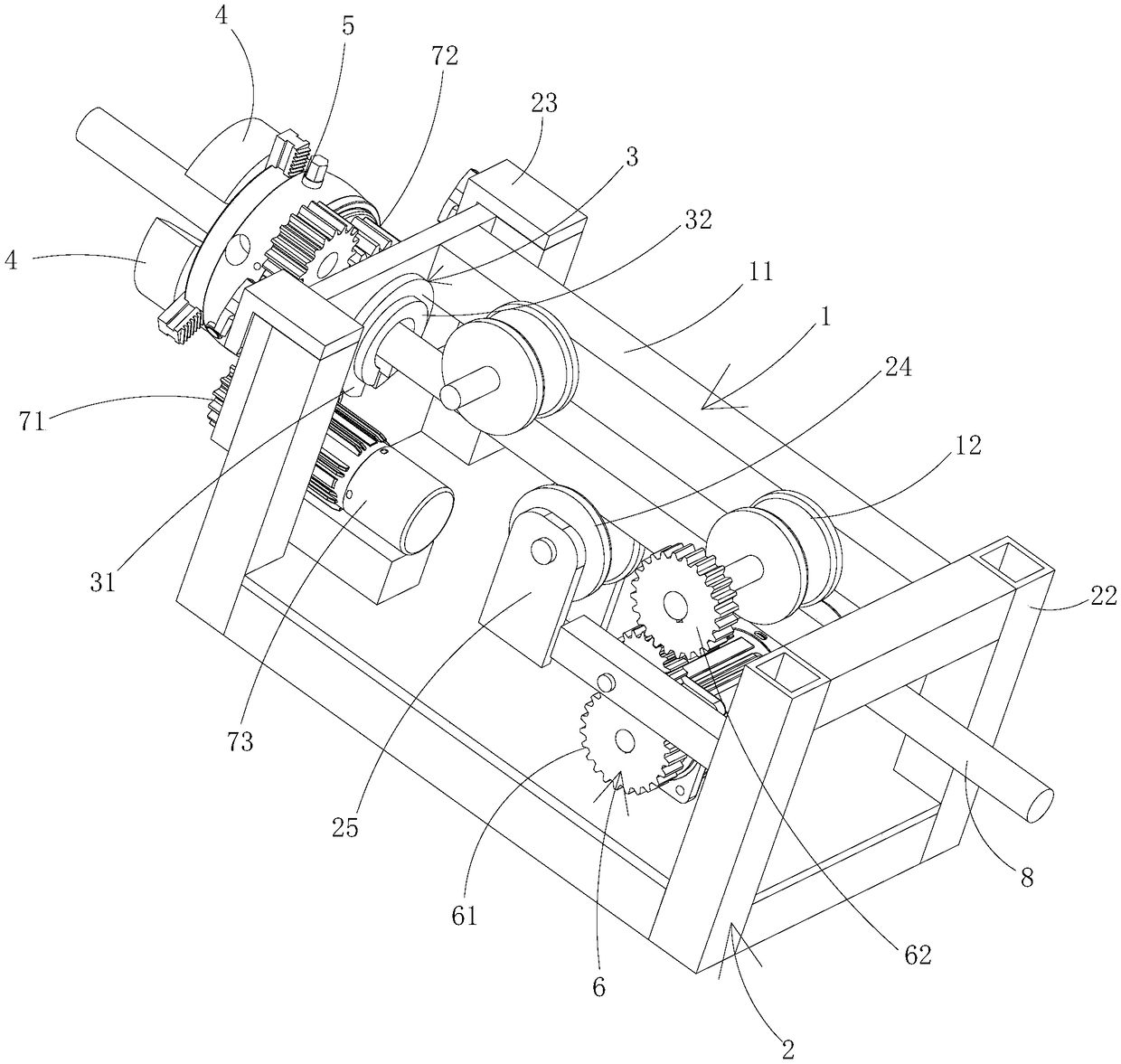

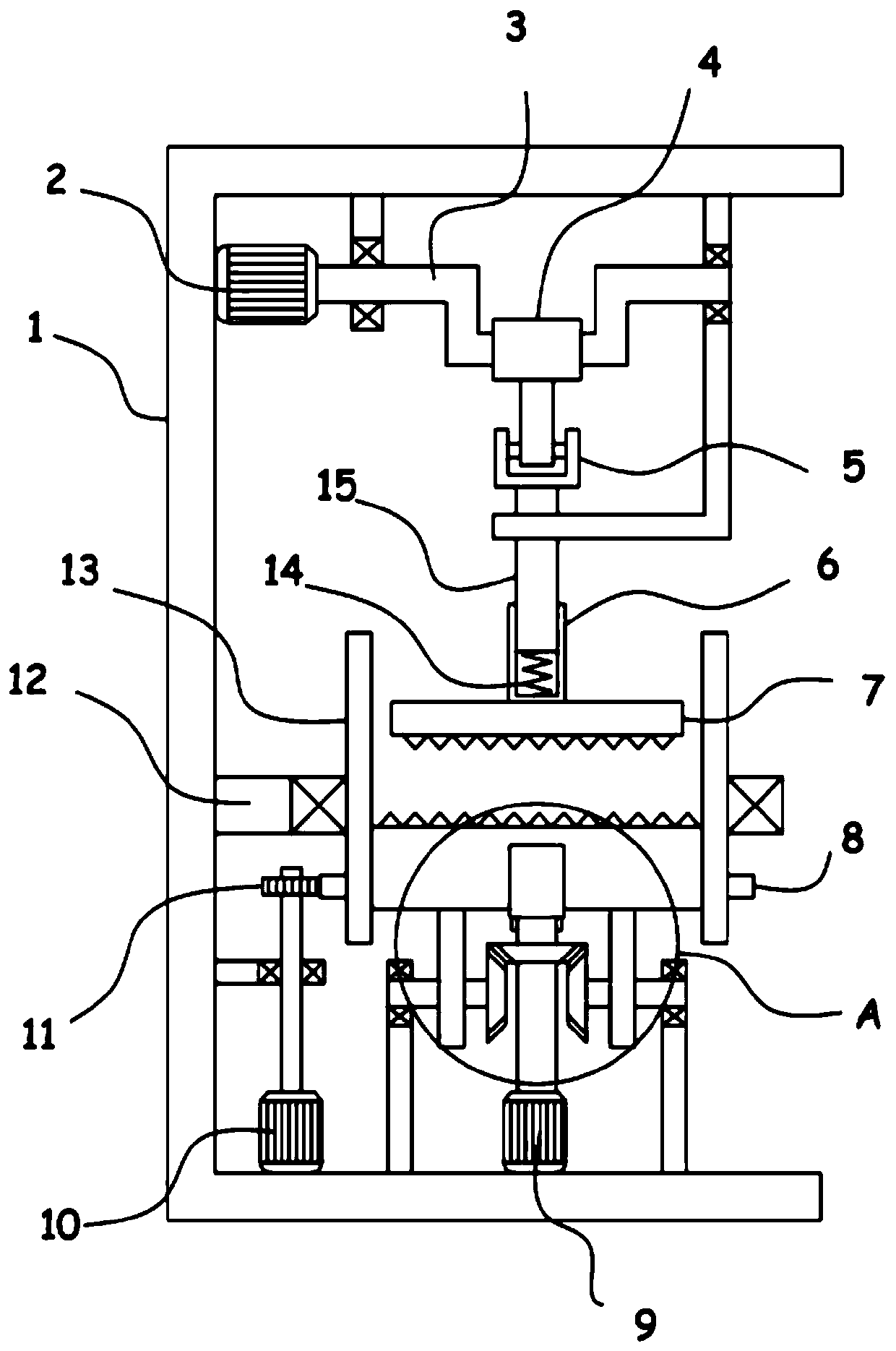

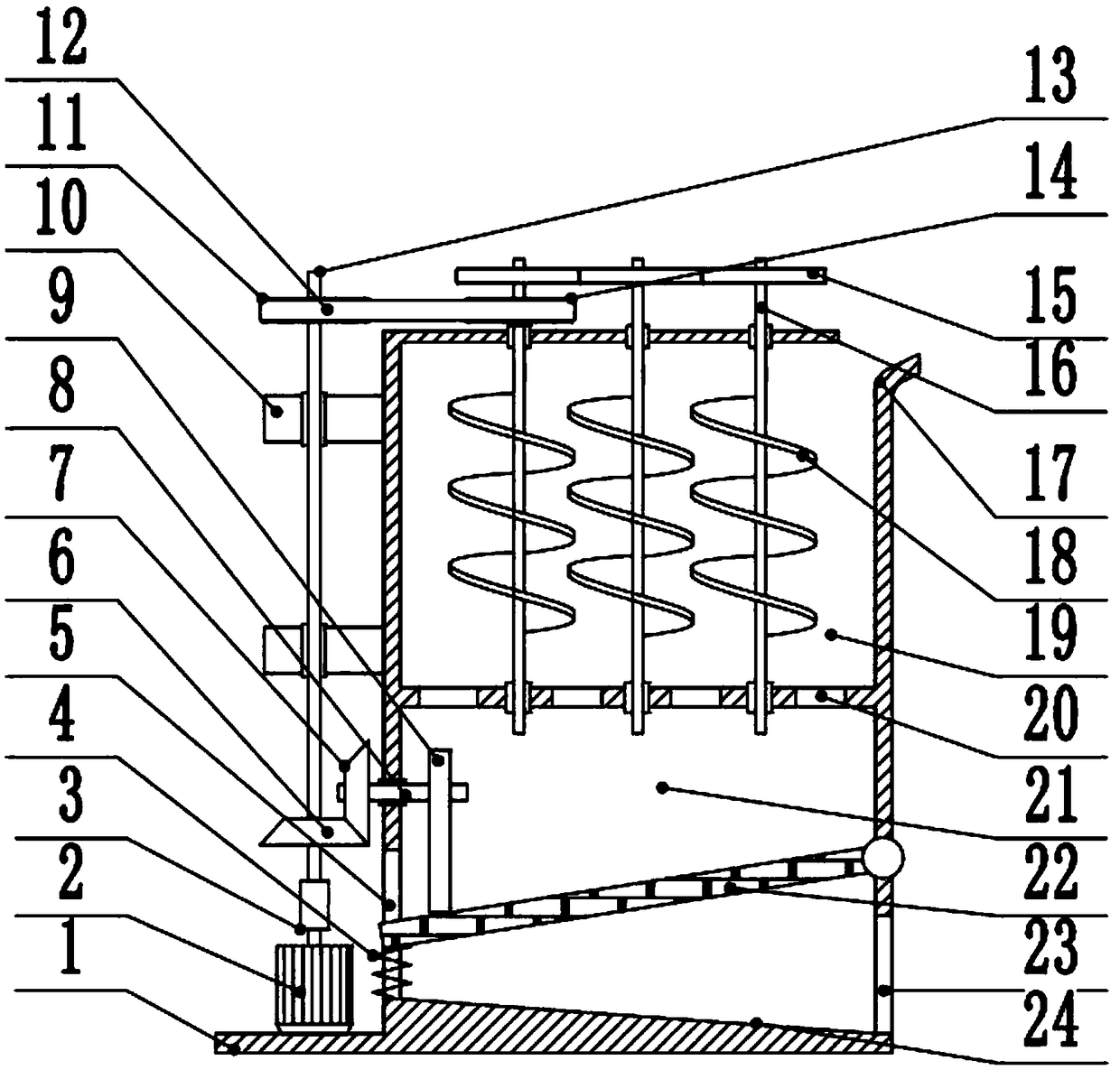

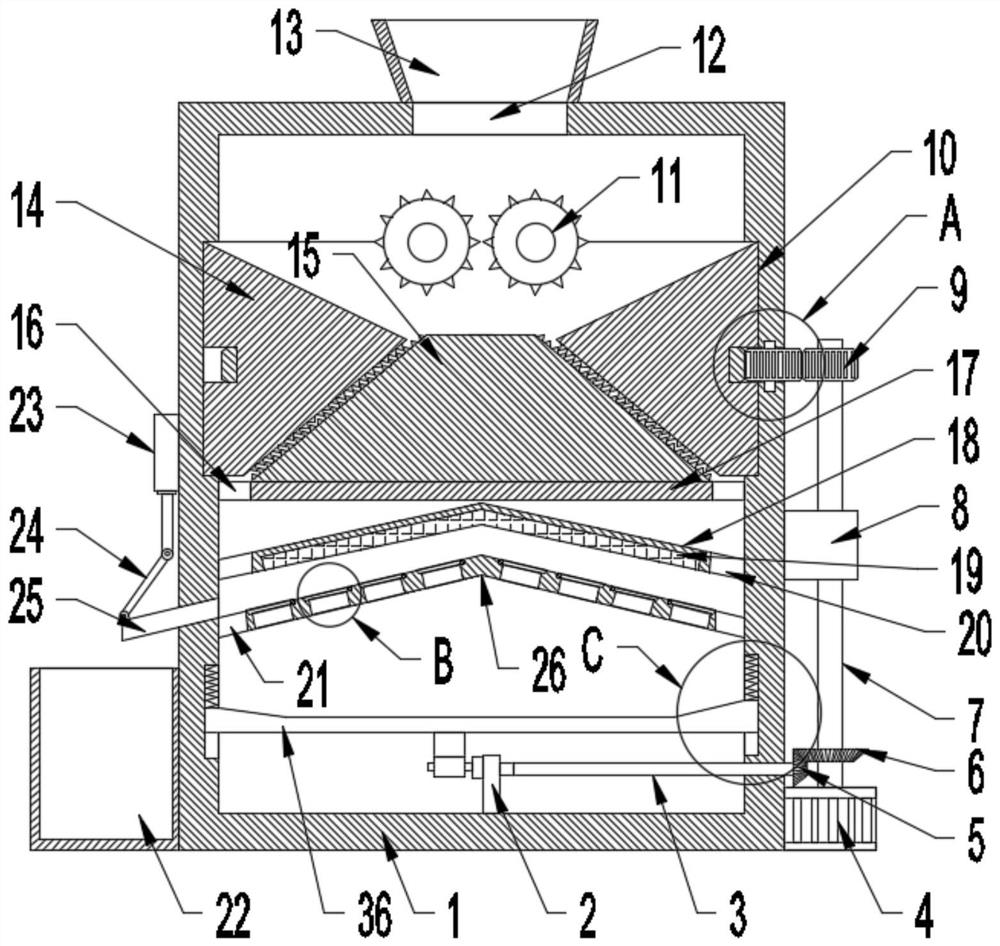

Environmentally-friendly efficient recovery crusher for waste injection molded parts

InactiveCN109333878AHas multiple functionsRealize intermittent feedingPlastic recyclingGrain treatmentsReciprocating motionEngineering

The invention relates to the technical field of waste injection molded part recovery, in particular to an environmentally-friendly efficient recovery crusher for waste injection molded parts. A firstshaft is driven by a drive motor to rotate to exert multiple effects that firstly, a second shaft is driven by transmission of bevel gears to rotate, so that a disc-shaped cam acts on a crushing basket, and cooperates with a piston barrel at the right side to make the crushing basket do reciprocating motion along a sliding rail, and therefore, the action region of a crushing tip is changed; secondly, a triangular cam is driven by a worm gear and a worm to rotate, and through functions of a roller and a first spring, the crushing tip is driven to vertically move to crush the injection molded parts in the crushing basket; thirdly, a spiral auger is also arranged on the inner section, located in a feed hopper, of the first shaft, and the waste injection molded parts firstly undergo the crushing action of the spiral auger when being put into the feed hopper, and then, fall into the crushing basket and are crushed; and fourthly, the outlet of a guide hopper is blocked by a baffle when the baffle is in an initial state, and during reciprocating motion of the crushing basket, the baffle moves along with the crushing basket to realize intermittent discharging.

Owner:李明军

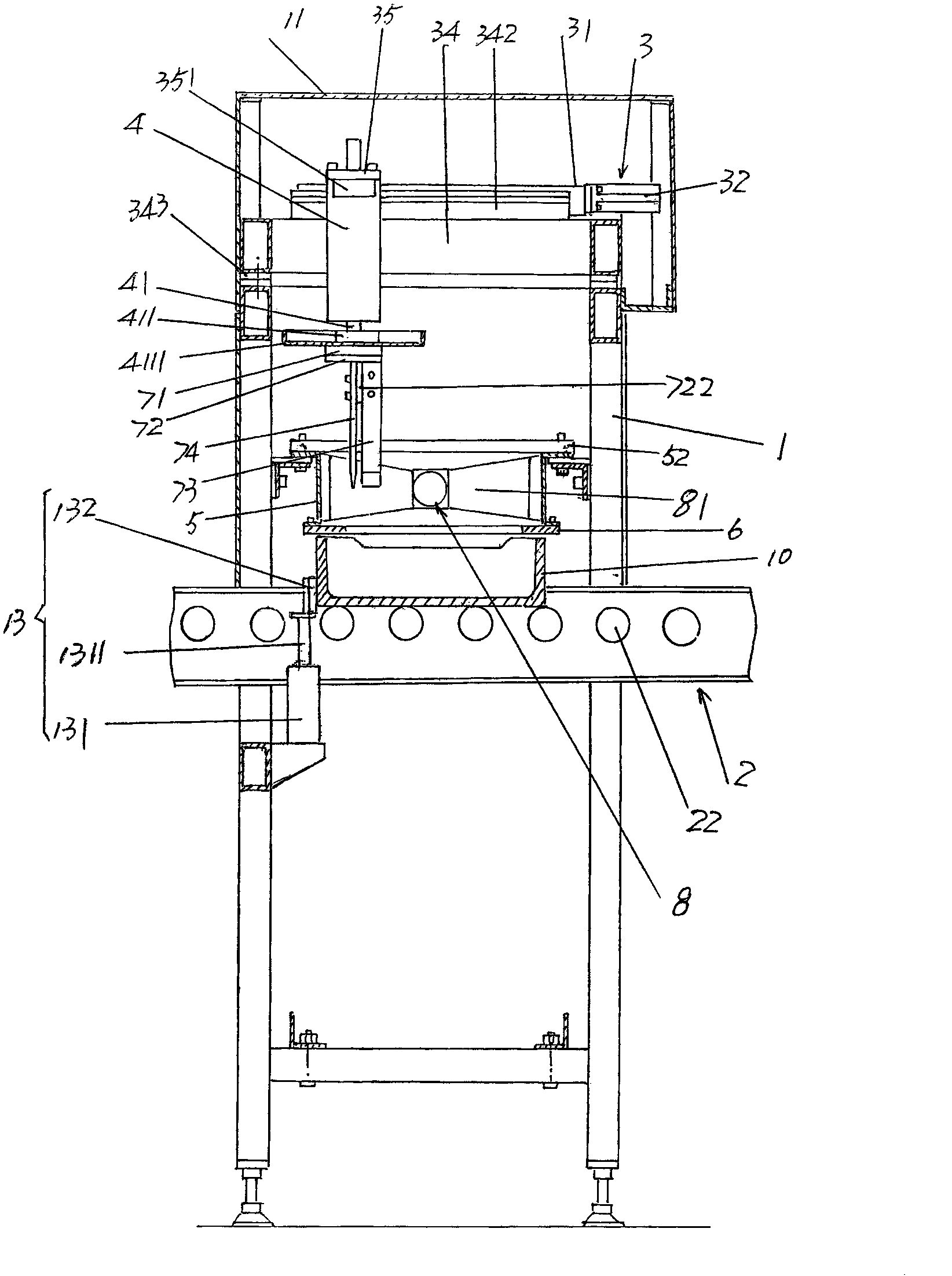

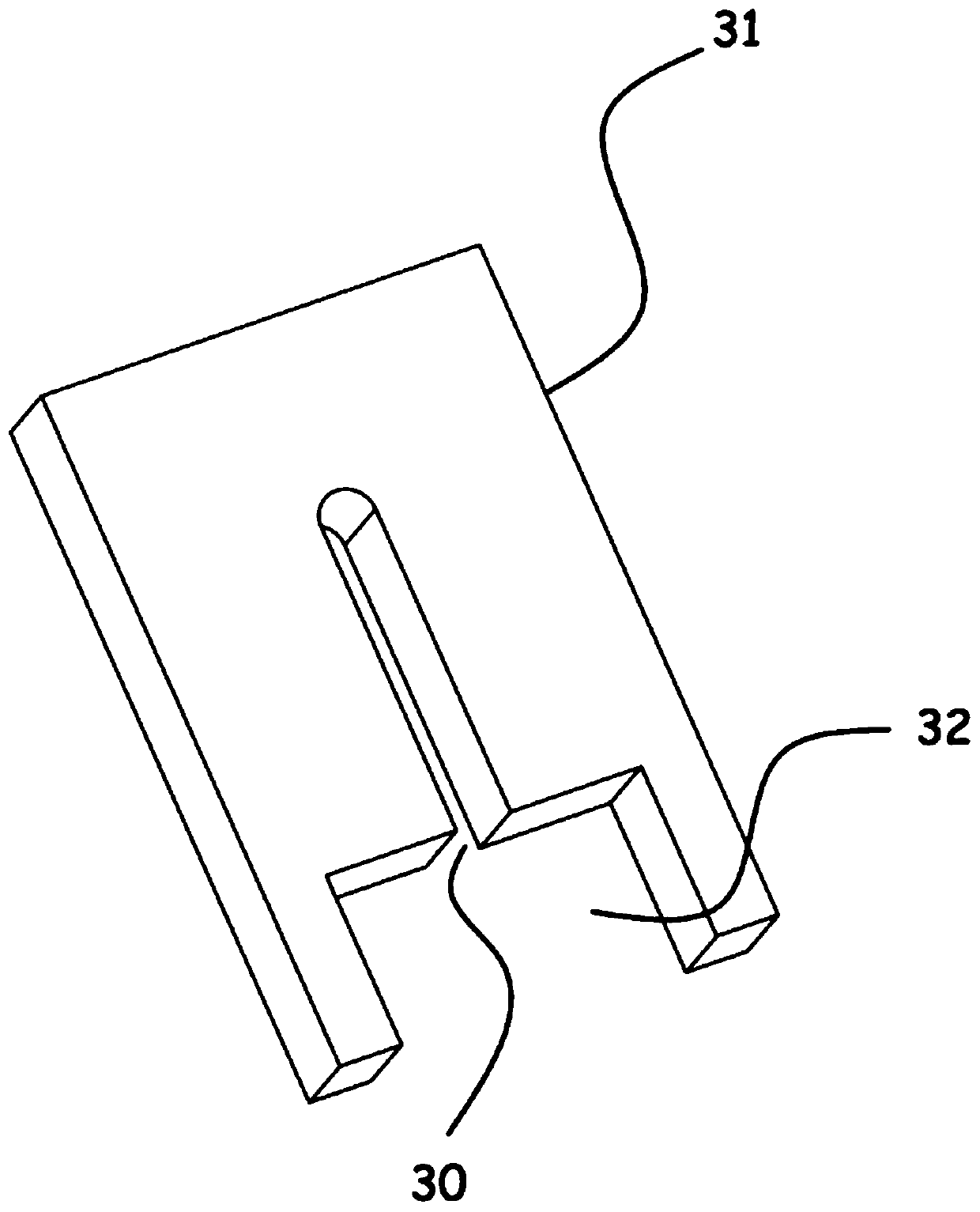

Crushing machine for electronic powder material

ActiveCN103521314BReduce work intensityMeet the use requirementsDirt cleaningGrain treatmentsEngineeringUltimate tensile strength

The invention relates to a crushing machine for an electronic powder material, belonging to the technical field of supporting facilities of an electronic kiln. The crushing machine for the electronic powder material comprises a machine frame, wherein the machine frame follows a saggar conveying mechanism of an automatic production flow line of an electronic kiln; a crushing action cylinder horizontal displacement mechanism is arranged on the top of the machine frame; a crushing action cylinder is connected with the crushing action cylinder horizontal displacement mechanism; a saggar mouth edge part enclosing pallet is fixed on the machine frame; a crushing blade scraping plate is fixed at the bottom of the saggar mouth edge part enclosing pallet; a crushing mechanism is connected with a crushing action cylinder column and corresponds to the crushing blade scraping plate; a dust leading-out mechanism is connected with the saggar mouth edge part enclosing pallet; a pair of saggar clamping action cylinders are arranged on the saggar conveying mechanism in a face-to-face state and correspond to the positions below the two corresponding sides of the crushing blade scraping plate. According to the crushing machine for the electronic powder material, the operation intensity is alleviated, scalding phenomenon is avoided, the efficiency is high, labor resources are saved, a clean environment is guaranteed, and the using requirement of the automatic production flow line of the electronic kiln can be met.

Owner:SUZHOU HUIKE EQUIP CO LTD

Sizing roller screen ore processing apparatus

Discloses a mined ore processing apparatus to process mined ores, such as oil sands ore, into granular material. An ore processor bed receives the ore to be processed. The ore processor bed has a frame supporting several rotating elements each separately driven to provide independent rotation rate and direction from the other. The ore processing bed is operable as a sizing device to decimate mined ore supply into granular material and separating it from rocks and other large lump mineral materials found in situ. The ore processing bed may be oriented to provide an upward inclination, which, when combined with alternating rotating element rotation directions, provides a crushing action to the ore material to crush larger rock. Alternately, a rock crusher is also provided to disintegrate oversized materials.

Owner:SUNCOR ENERGY INC

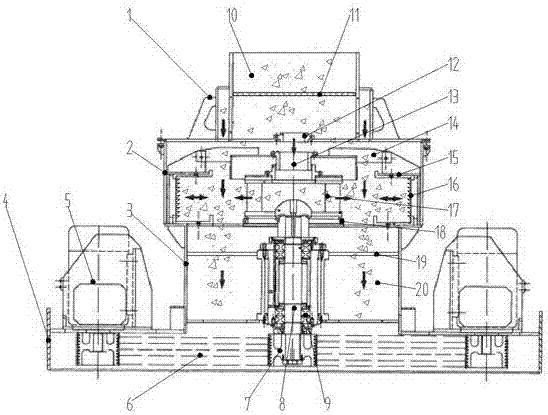

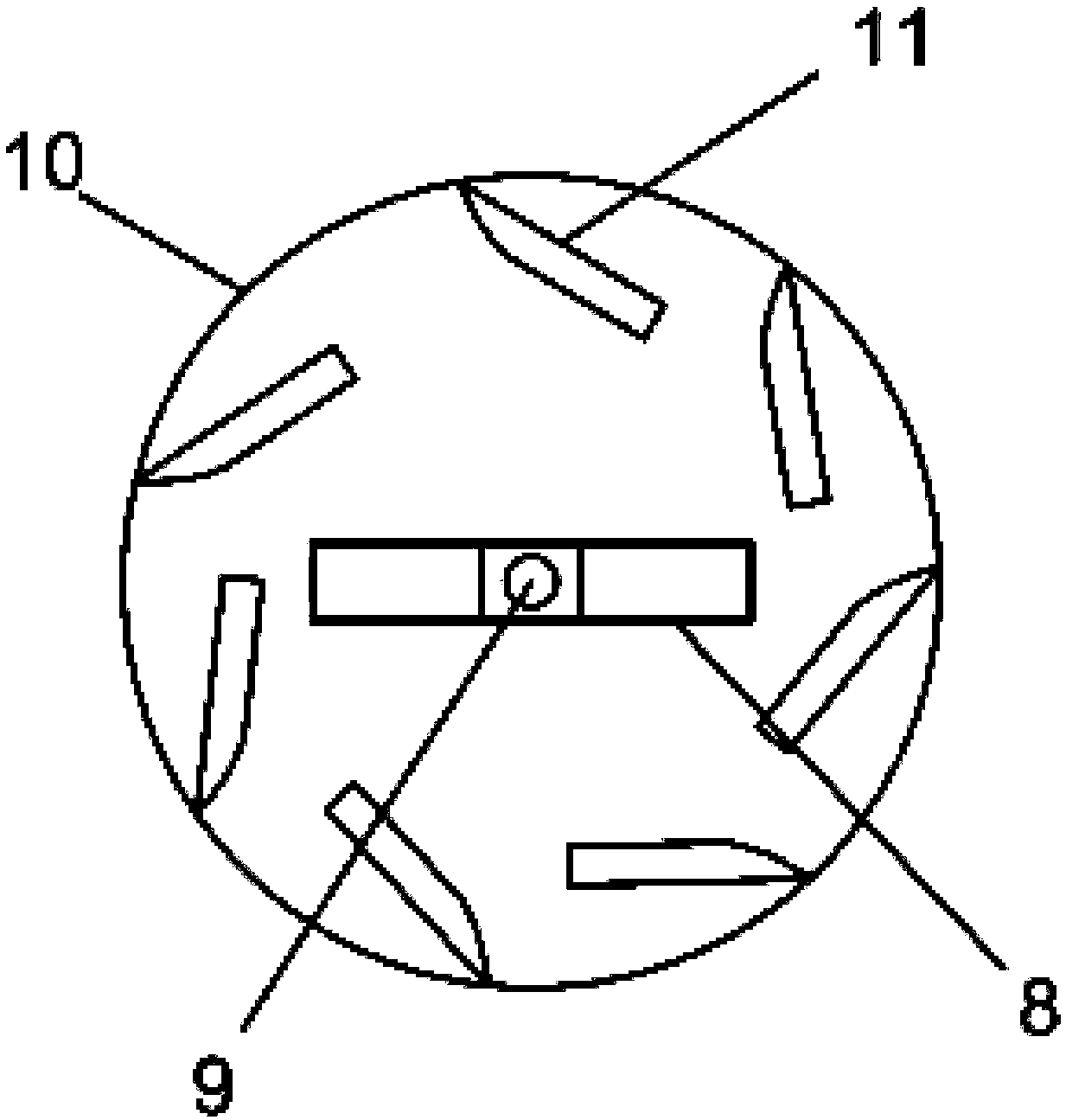

Combined type vibrating sand making machine

The invention discloses a composite vibrating sand making machine, which comprises an upper machine case, a lower machine case, a discharge box and a frame, which respectively correspond to a material inlet, a crushing cavity and a material discharge port, and the three are in the order of axes from top to bottom connection, the connection is connected with the lower frame as a whole; the drive motor is connected to the frame, and the drive motor is connected to the rotating main shaft inside the sand making machine through the transmission mechanism, and the upper end is connected to the impeller; the main shaft of the rotating shaft is also connected with The vibrating mechanism cooperates with the impeller; the vibrating screening is combined with the crushing structure of the sand making machine, which can screen the materials with uneven particle size to a certain extent and perform corresponding crushing. There is also a material distribution component. It can realize the switching of various crushing forms and has a wide range of applications. Through the above structure, the problems of unsmooth discharge, low crushing efficiency of sand making machine and insufficient crushing of materials in the prior art can be effectively solved, and the crushing efficiency of materials is greatly improved. The quality and beneficiation efficiency of the beneficiation process.

Owner:尹国祥

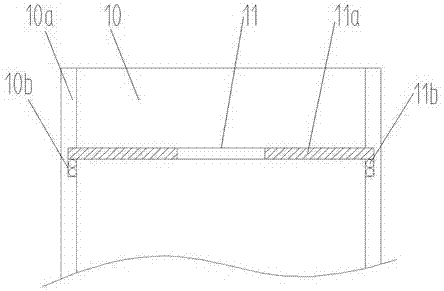

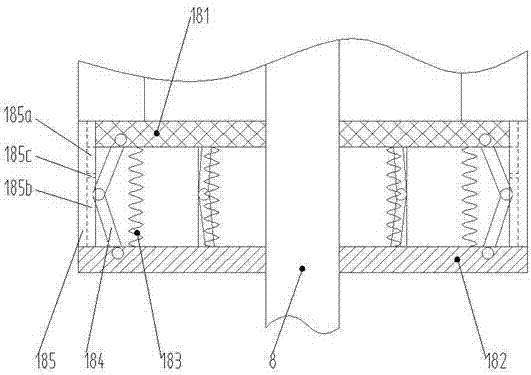

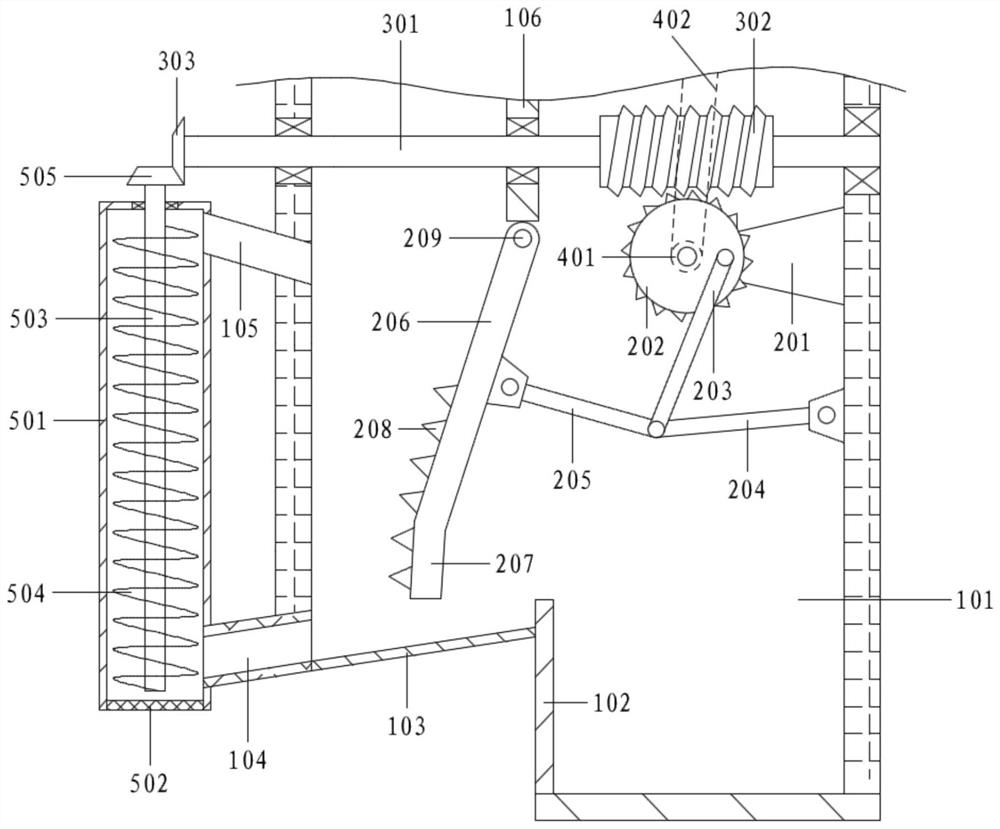

Damping type ore coarse crushing device for mining machining

InactiveCN108176434AFully brokenImprove smoothnessNon-rotating vibration suppressionGrain treatmentsDamping functionReciprocating motion

The invention discloses a damping type ore coarse crushing device for mining machining. The damping type ore coarse crushing device for mining machining comprises an operation frame. A crushing grooveis arranged in the operation frame. A sliding frame is arranged on a limiting and guiding slide groove in a sliding manner. A transmission belt is arranged between a driven belt pulley and a drive belt pulley in a sleeving manner. A hoisting frame connected with an L-shaped bent rod in a sliding manner is vertically and fixedly installed on the operation frame. A rack is fixedly installed on thelower bottom face of the L-shaped bent rod. According to the damping type ore coarse crushing device for mining machining, through vertical reciprocating movement of a sliding rod, an impacting pressblock is driven to conduct repeated impaction crushing action on ores in a crushing groove, in the impaction crushing process, supporting legs can slide in limiting sleeves, deformation elongation andcompression of damping springs achieve the damping function, and therefore the stability of ore crushing is improved; and left-right reciprocating movement of the crushing groove drives the ores in the crushing groove to shake left and right, the ores are promoted to be evenly laid and scattered in the crushing groove, the ores can receive the sufficient crushing action of the impacting press block, and therefore the crushing efficiency is higher.

Owner:ZHENGZHOU HAOEN ELECTRONICS INFORMATION TECH CO LTD

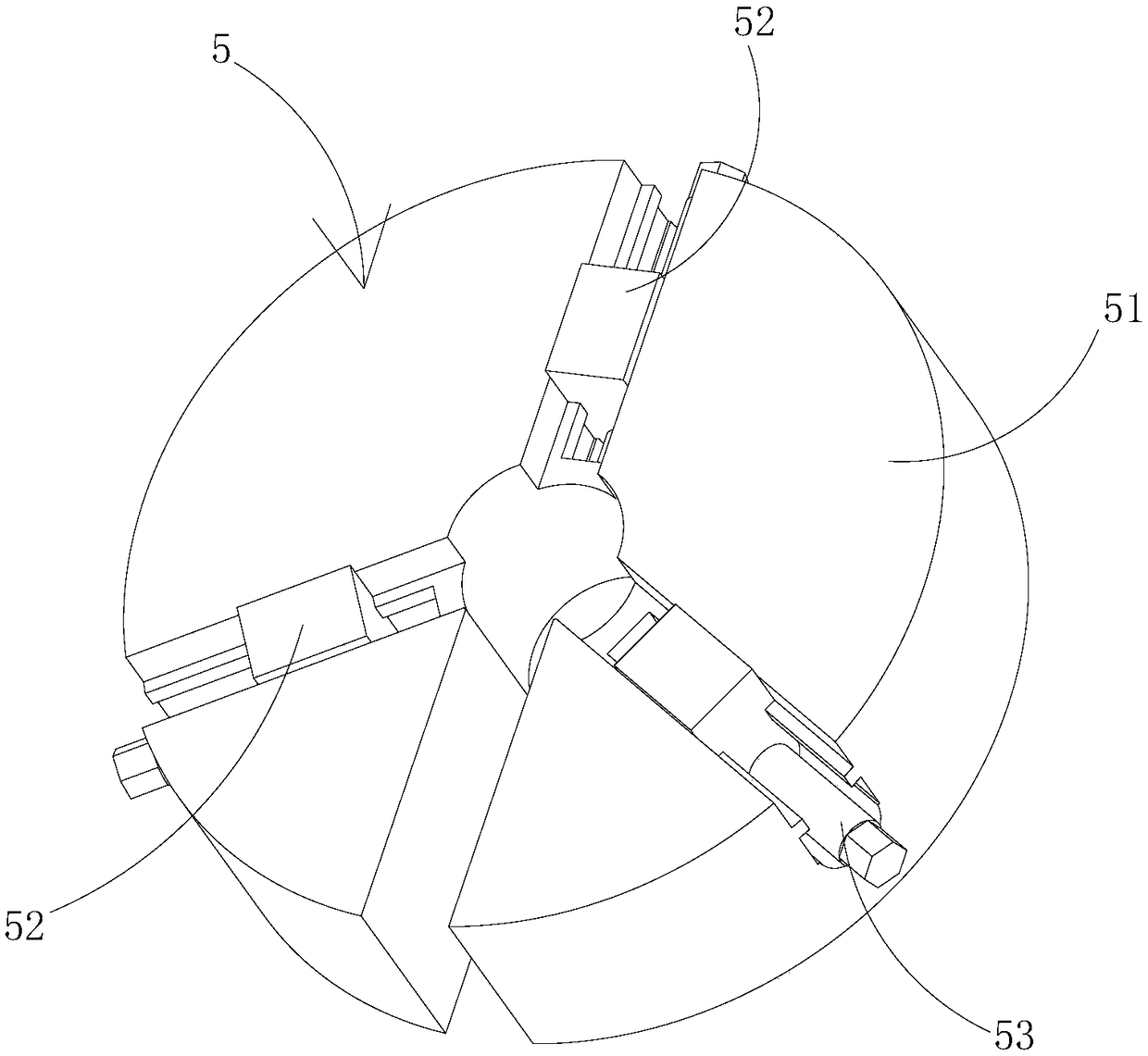

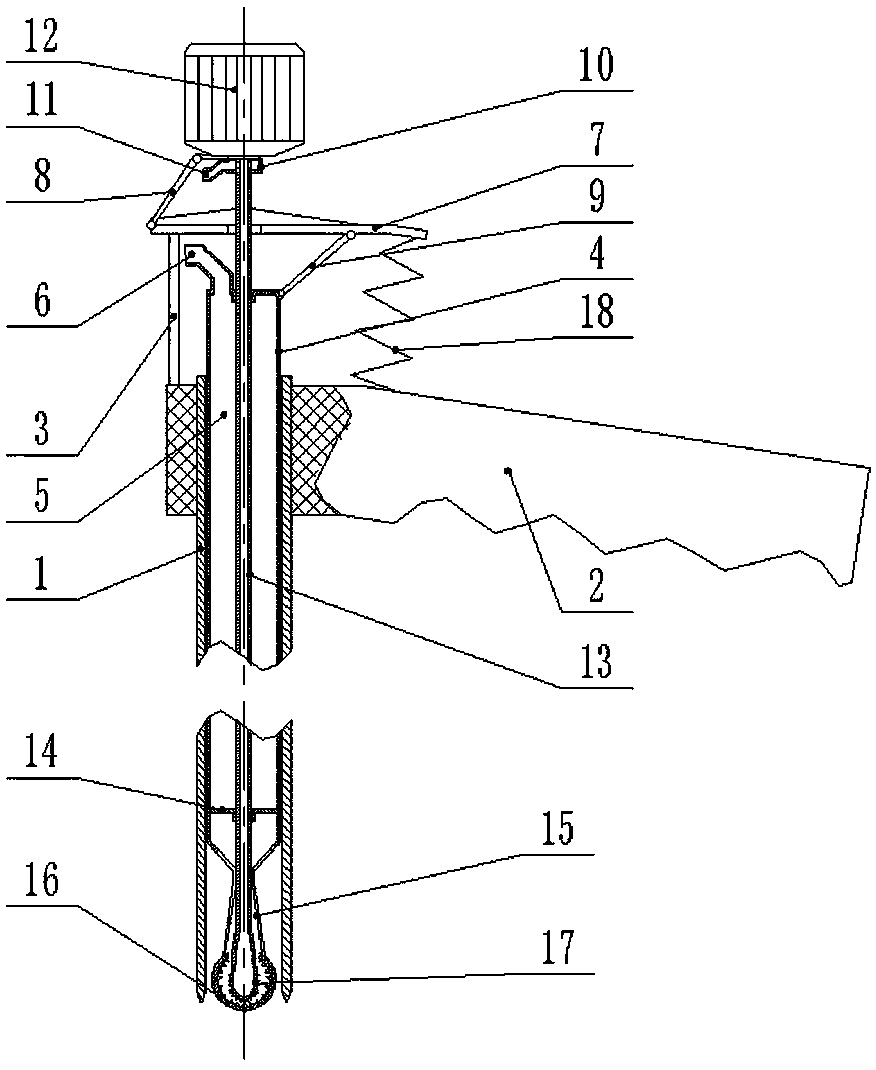

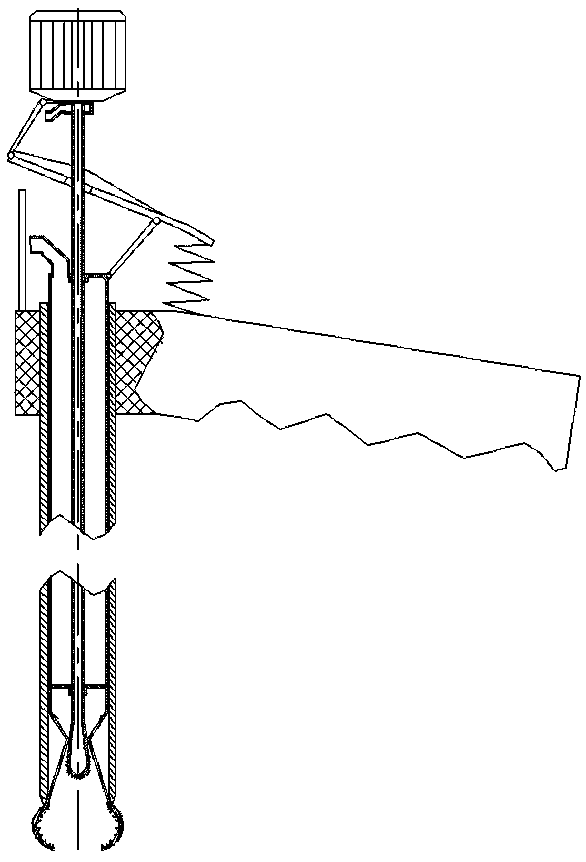

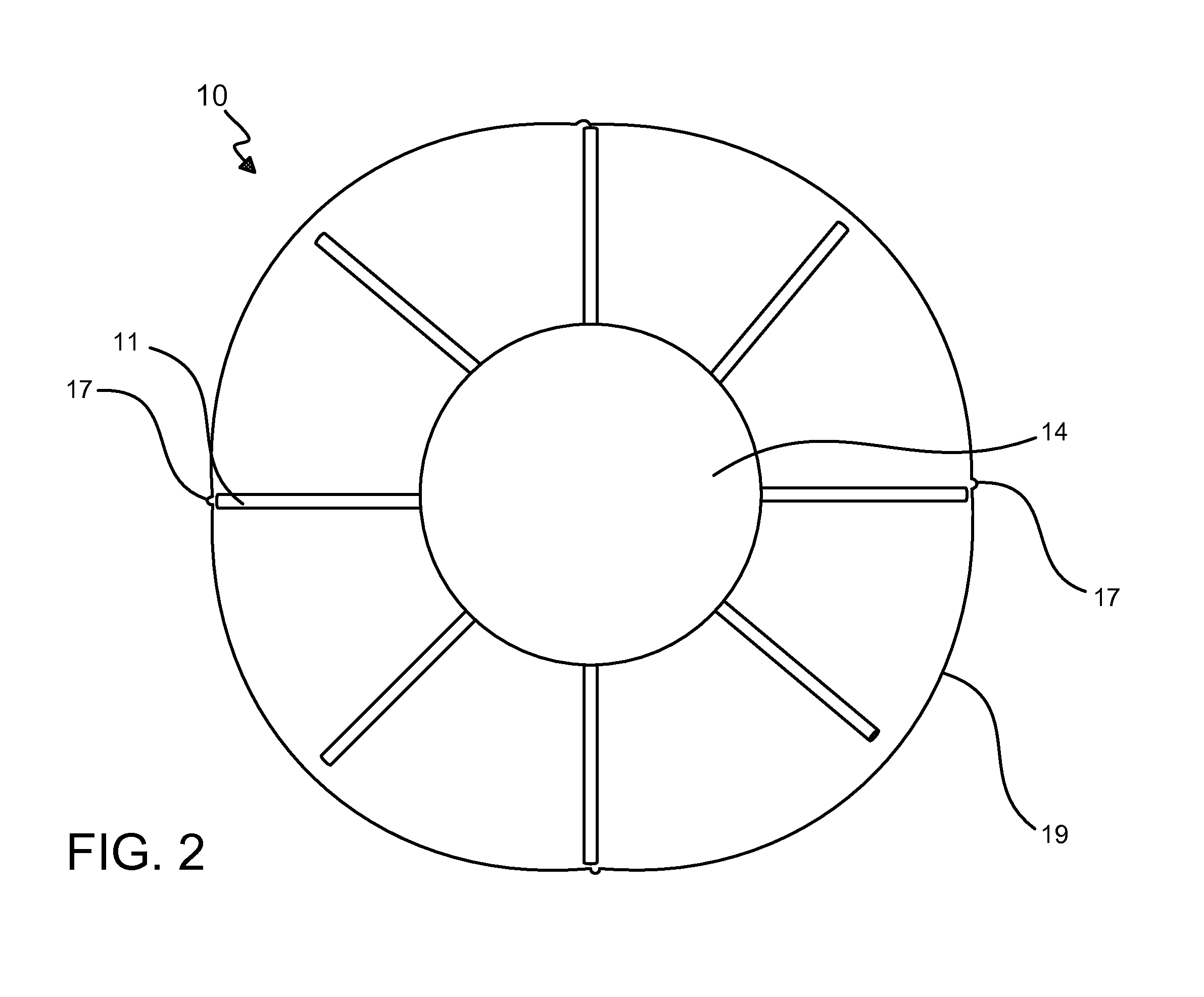

Power transmission line deicing device

The invention provides a power transmission line deicing device and belongs to the technical field of power transmission line maintenance equipment. The power transmission line deicing device comprises a walking mechanism, a bottom bracket, a first driving mechanism, a rotating disc, an ice cutter, an adjusting mechanism and a second driving mechanism. The power transmission line deicing device provided by the invention can adjust the position of the ice cutter on the rotating disc according to the diameter of the power transmission line and is more convenient to use, and a plurality of ice cutters are driven to rotate around the power transmission line through the rotating disc and walk along the power transmission line under the drive of the walking mechanism; the ice on the power transmission line is crushed by a crushing action of the ice cutter, and the crushed ice is scraped from the outer circumference of the power transmission line through the ice cutter so that cleaning of power transmission line icing is more thorough.

Owner:STATE GRID CORP OF CHINA +2

Recycling and crushing treatment machine for plastic products and method of use

The invention relates to the technical field of crushing treatment for hard plastic waste products, in particular to a recycling and crushing treatment machine for plastic products and a method of use. A No.1 transmission wheel is driven to rotate by a servo motor, and a No.2 transmission wheel is rotated by a transmission belt; the coaxial cam of the No.2 transmission wheel rotates along there-with and acts on a right pressure plate, a No.4 rod drives a blocking plate to move left and right with a spring to intermittently block a feeding opening to realize intermittent blanking, which is convenient for subsequent swing crushing action; the servo motor also drives a worm wheel to rotate, and the worm wheel rotates a No.1 rod to make No.2 and No.3 rods swing, thereby driving a rocking plateto swing left and right; the falling plastic products are crushed in cooperation with a left plate, the broken plastic products fall into a loading barrel through the guide of a guide plate and a guide tube, and are filtered through a screen, and plastic products that meet the requirements of particle size can be obtained by collection at the bottom of the screen.

Owner:安徽苿莱信息技术有限公司

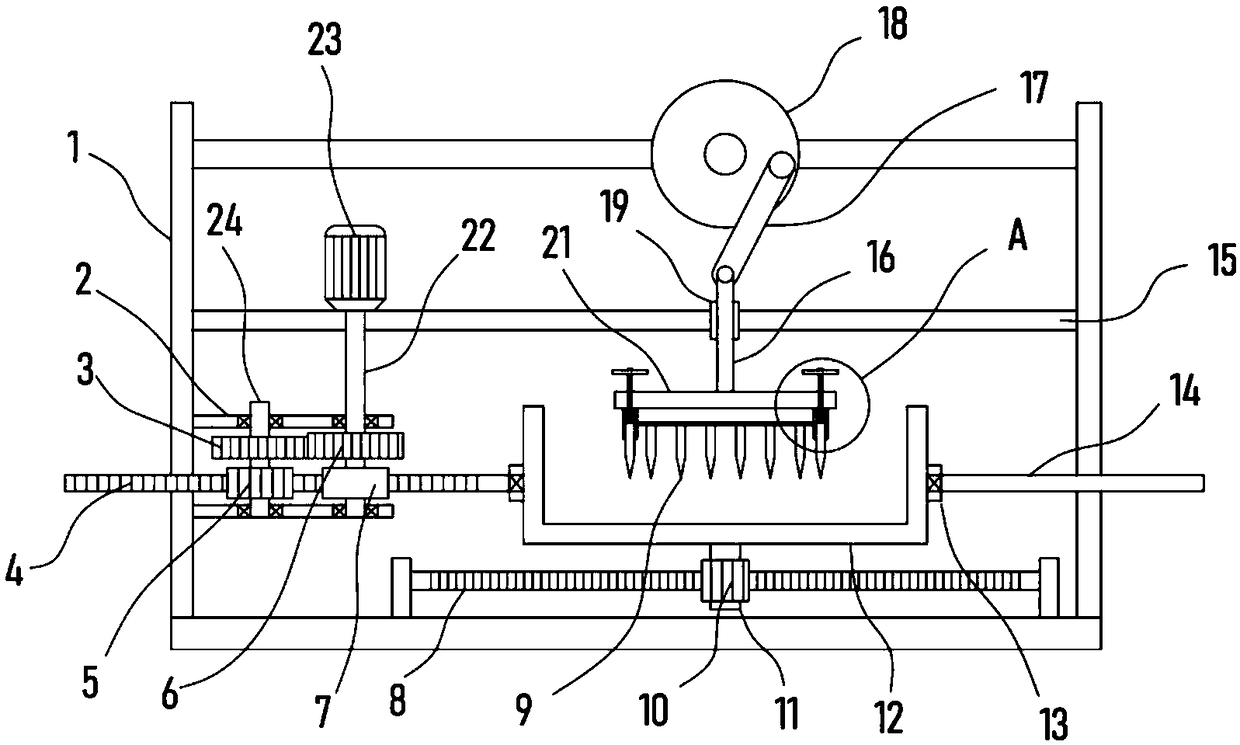

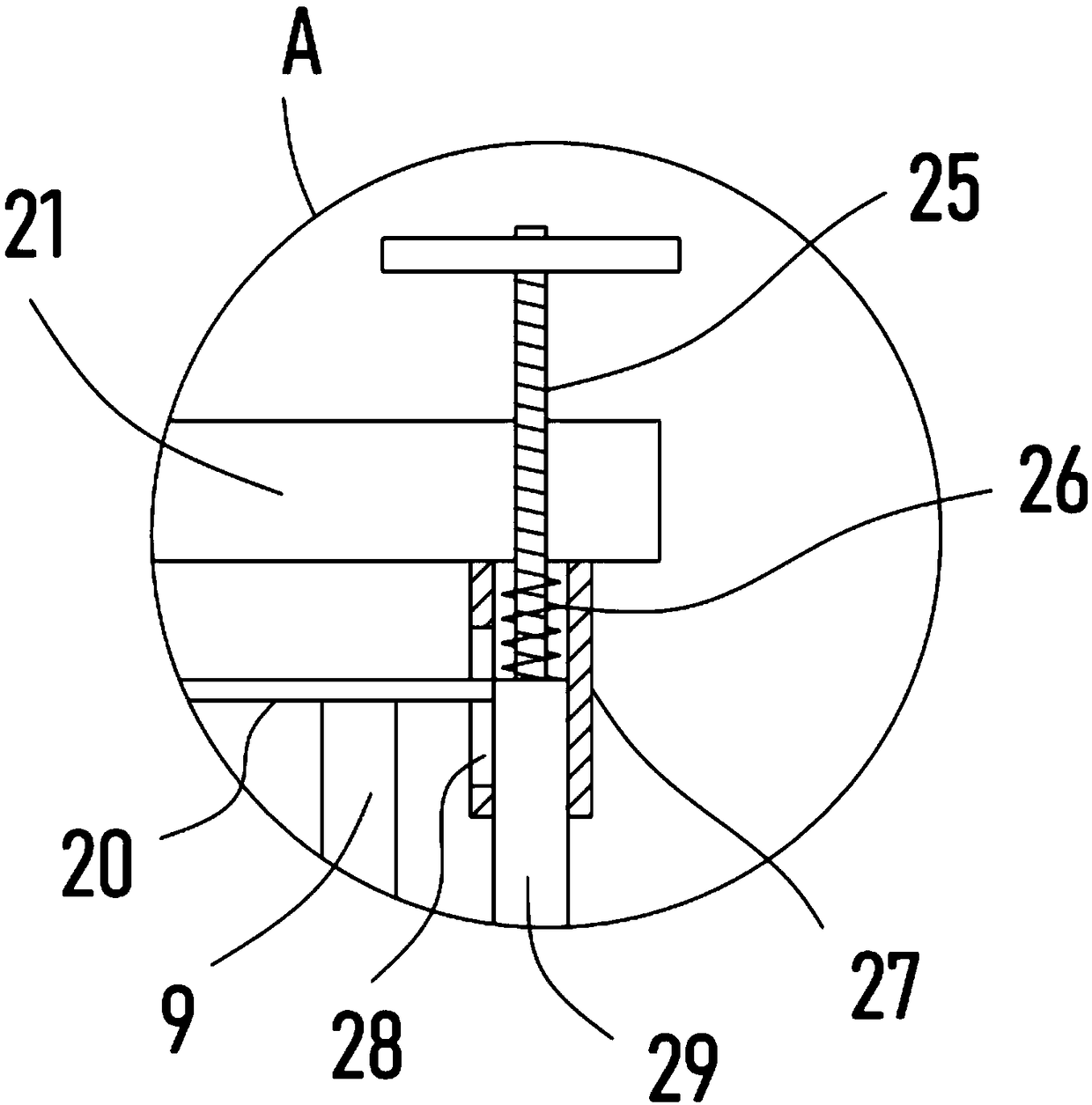

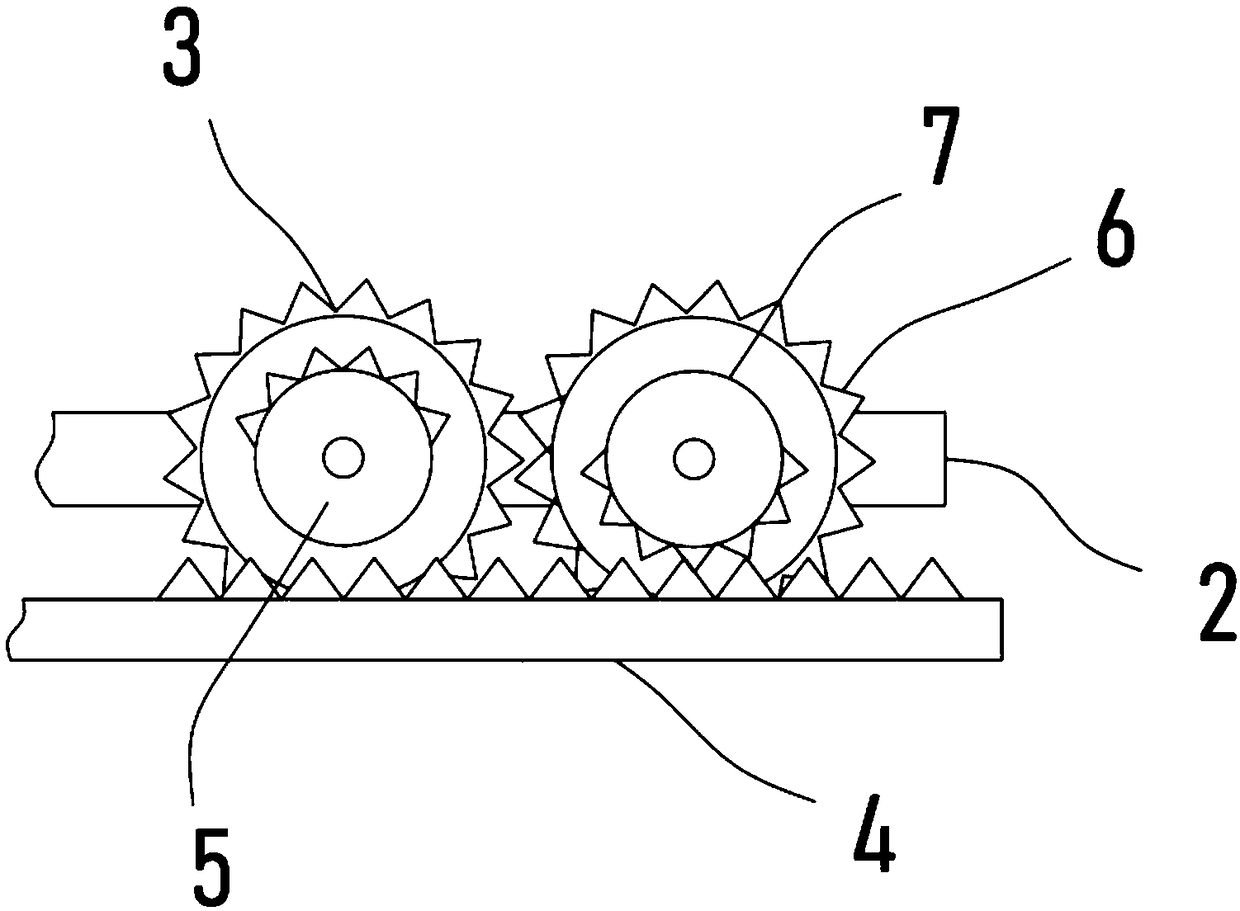

Coarse crushing device for Chinese herbal medicine processing

ActiveCN109331943ARealize repeated shreddingFull cutting and crushing effectGrain treatmentsReciprocating motionEngineering

The invention discloses a coarse crushing device for Chinese herbal medicine processing and relates to the technical field of Chinese medicinal herb processing. The coarse crushing device comprises asupport frame, wherein a crushing groove capable of moving in a sliding manner is formed in the support frame; a support plate is horizontally fixed in the support frame; a sleeve is vertically fixedon the support plate in a penetrating manner; a slide bar is vertically mounted in the sleeve in a sliding manner; a plurality of blades are vertically fixed at the bottom of a fixed plate at equal intervals; and a reciprocator comprises a spur rack I horizontally mounted in a sliding manner. According to the coarse crushing device, through up-down reciprocating motion of the fixed plate, repeatedchopping action of the blades to traditional Chinese medicine in the crushing groove is realized; in addition, the reciprocator drives the spur rack I through a drive motor to pull the crushing groove to do transverse reciprocating motion, so that the blades cut Chinese herbal medicine in transverse different positions of the crushing groove; and moreover, the crushing groove realizes self-rotation through meshing transmission of a cylindrical spur gear and a spur rack II, so that the cutting positions of the blades continuously change, and comprehensive and full cutting and crushing action to Chinese herbal medicine is realized.

Owner:ANHUI JINMA PHARMA

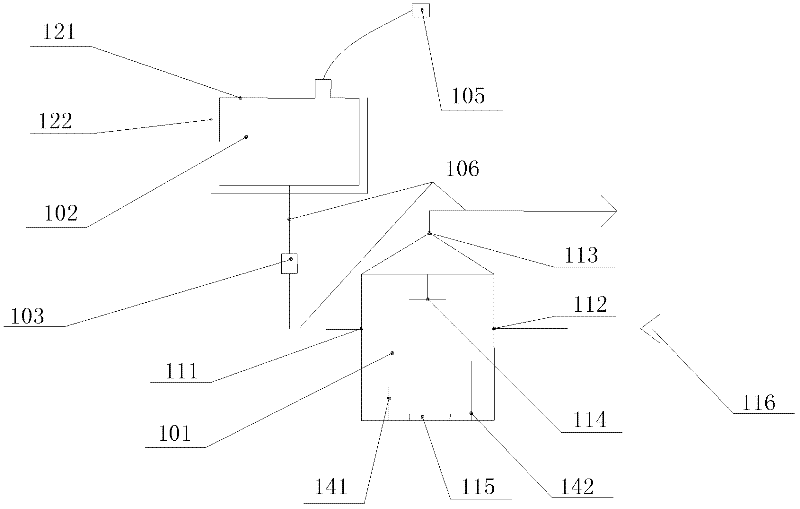

Disinfectant steam disinfection equipment

InactiveCN102552957AImprove disinfection effectImprove efficiencyDeodrantsAtomized substancesParticulatesControl system

The invention discloses disinfectant steam disinfection equipment, which comprises a disinfectant steam three-stage refining system, a filtering-catalyzing integrated system and a control system, wherein the disinfectant steam three-stage refining system is used for initially atomizing a disinfectant liquid with an ultrasonic atomizing device; a hybrid refining device is used for effectively crushing disinfectant atomized gas molecular groups under the colliding, cutting and crushing actions of air current in an atomized gas hybrid refining device to perform secondary refining on disinfectant atomized gas; an evaporator is used for fully contacting a mixed gas of a disinfectant and the air with the inner wall of the evaporator, heating and evaporating to perform third refining on the atomized gas, so that the aim of outputting ultrafine particulate disinfect steam is fulfilled; the filtering-catalyzing integrated system is used for catalytically decomposing disinfectant gas particles formed by the three-stage refining system to complete filtering and catalyzing work; and the control system is used for controlling the entire process of the three-stage refining system and the filtering-catalyzing system. Due to the adoption of the disinfectant steam disinfection equipment, disinfectant gas is further refined, micro-sized disinfectant gas particles are formed finally, and the decontamination effect and efficiency of disinfectant steam are improved greatly.

Owner:中国人民解放军防化学院 +1

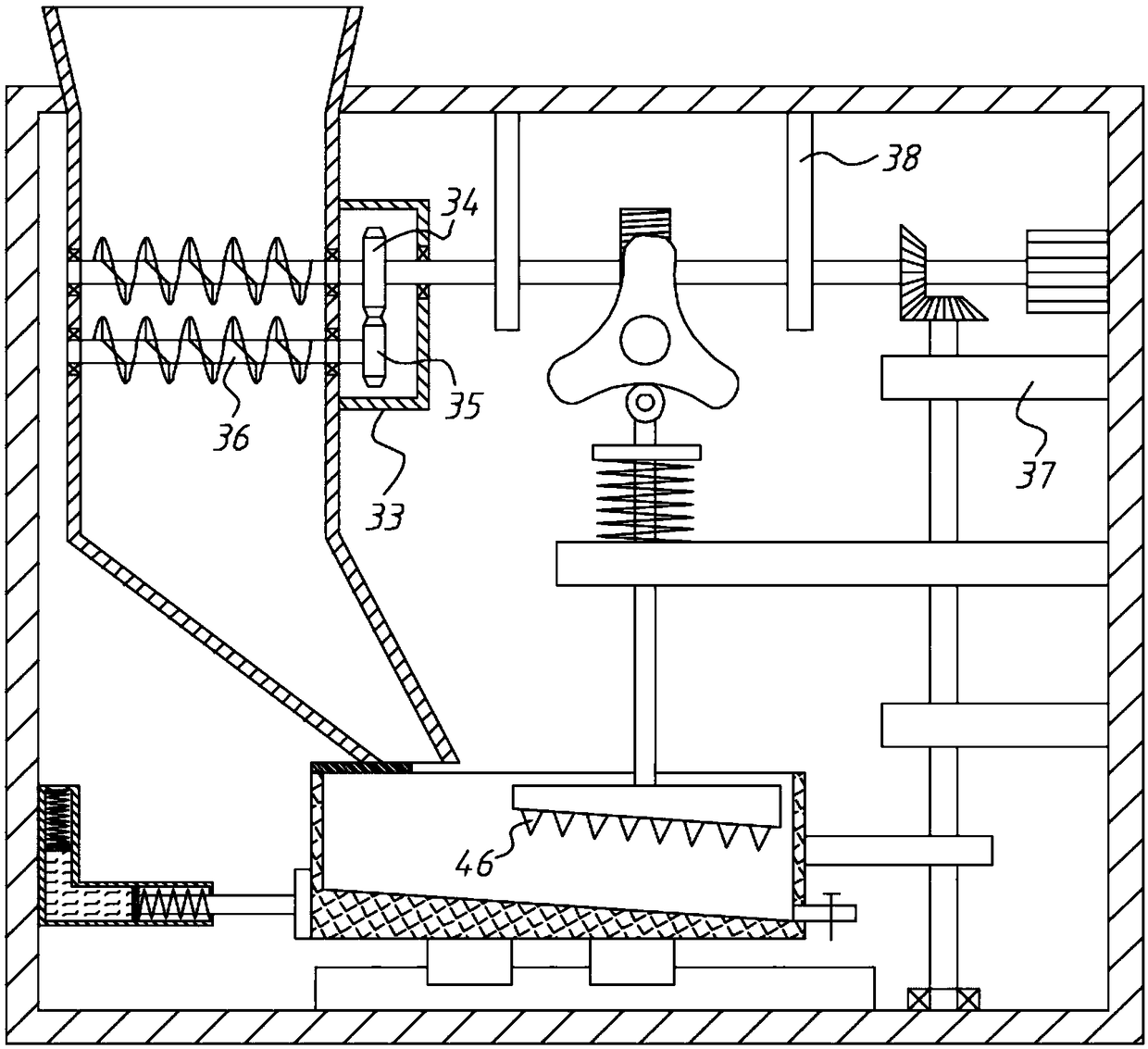

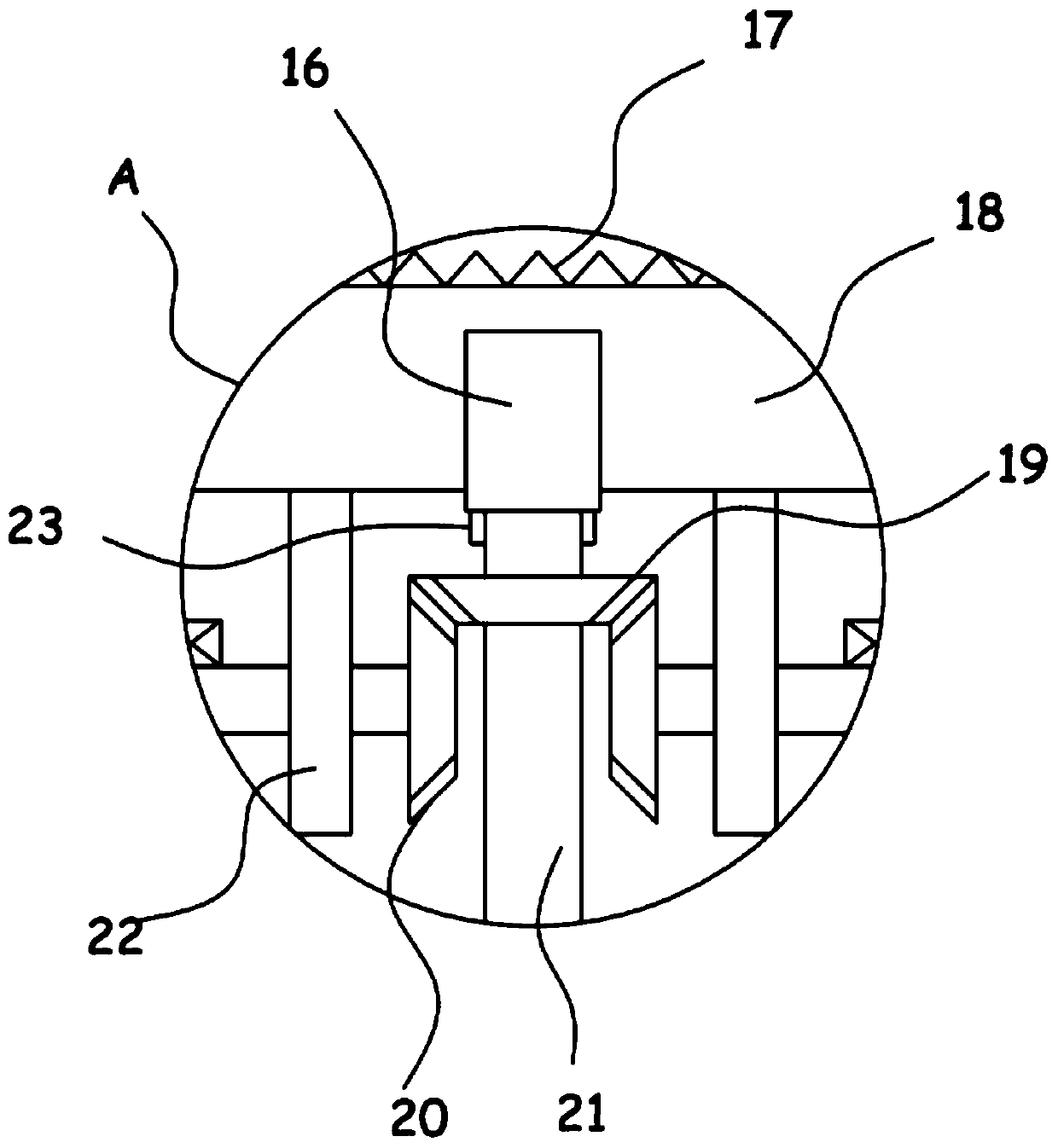

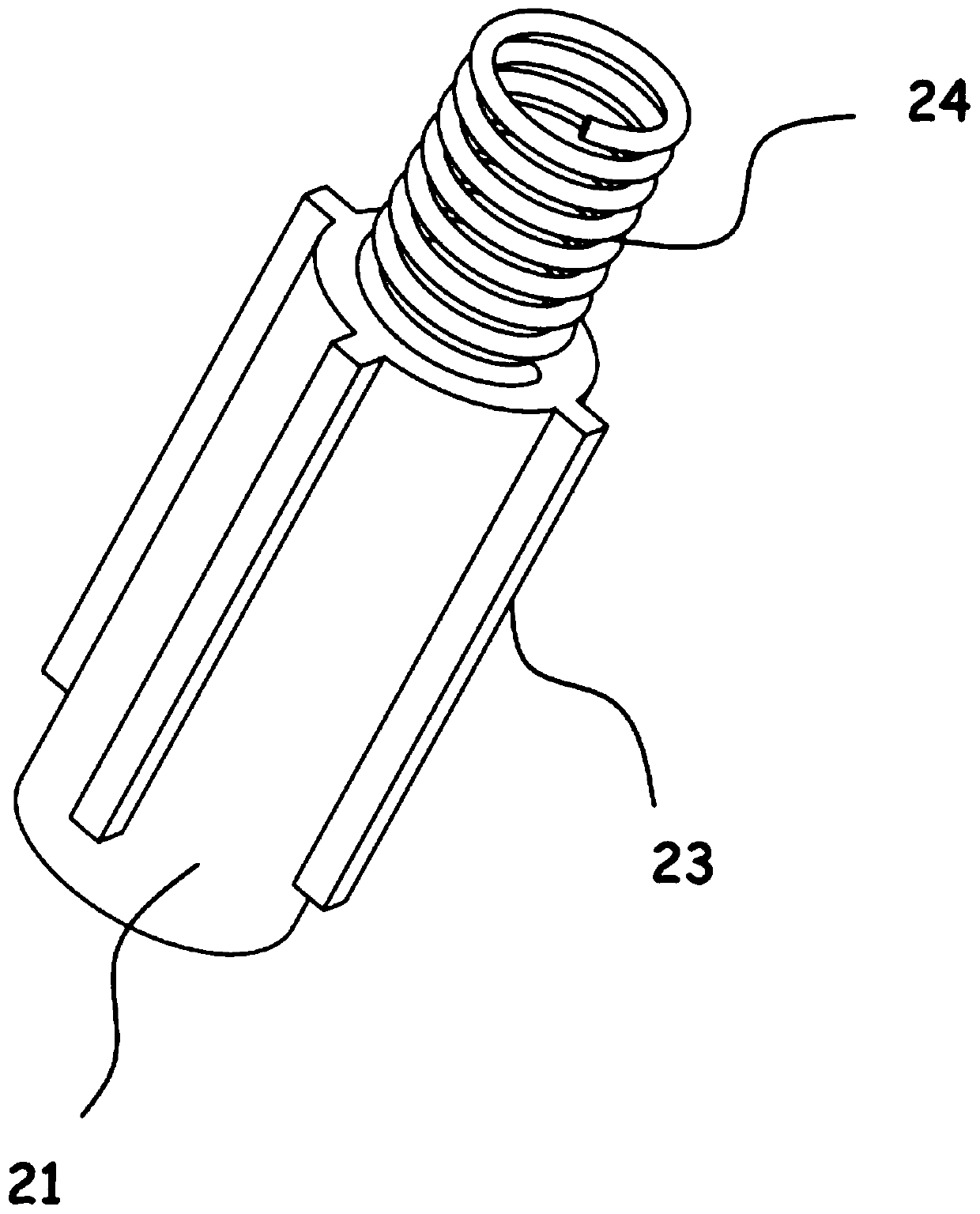

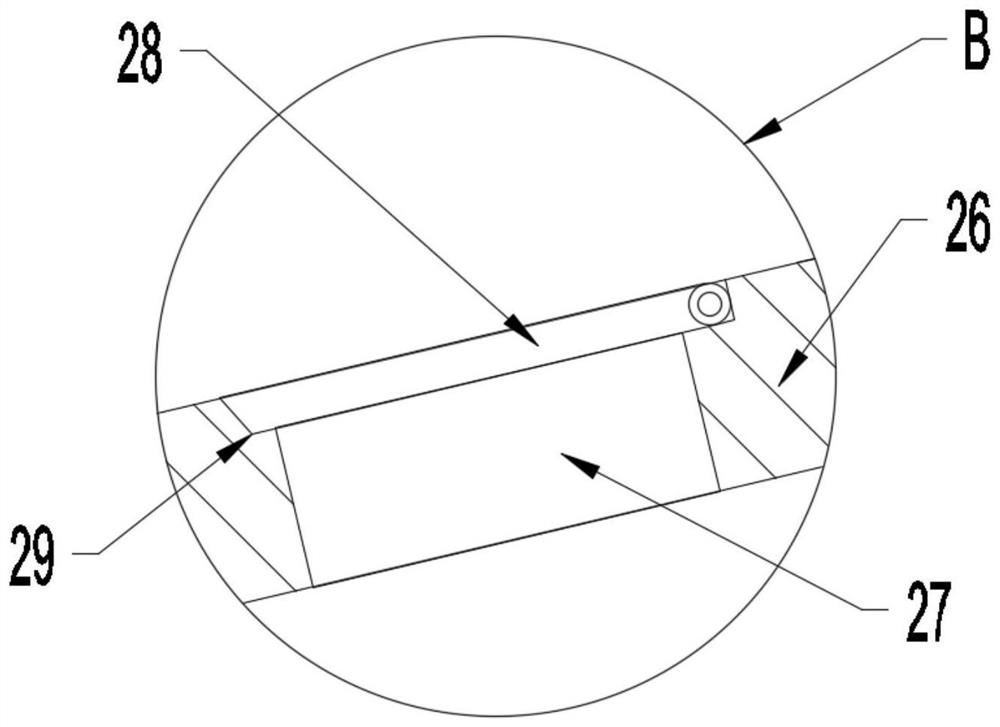

Crushing treatment device for recycling industrial solid waste

InactiveCN110801899ARealize repeated impact crushingThe crushing process is full and comprehensiveCocoaGrain treatmentsReciprocating motionProcess engineering

The invention discloses a crushing treatment device for recycling industrial solid waste, and relates to the technical field of industrial waste treatment. The device is characterized in that a supporting plate is horizontally fixed on a fixing frame, a crushing pressing plate vertically corresponding to a sliding bottom plate is arranged in a crushing barrel in a sliding mode, saw teeth are fixedon the sliding bottom plate, a lifting mechanism used for abutting against and pushing the sliding bottom plate to vertically slide is arranged on the fixing frame, and a reciprocating mechanism usedfor driving the crushing pressing plate to vertically reciprocate is arranged on the fixing frame. According to the device, an arranged rotating mechanism drives the sliding bottom plate to rotate, and at the moment, the solid waste on the sliding bottom plate can rotate between the sliding bottom plate and the crushing pressing plate, so that a kneading type crushing refining effect is realized;and the motion close to each other of the sliding bottom plate and the crushing pressing plate can be realized through the arranged lifting mechanism and the arranged reciprocating mechanism, repeated impact crushing action on the solid waste is realized, the crushing process of the solid waste in the crushing barrel is sufficient and comprehensive, and the working efficiency is effectively improved.

Owner:徐州正兴除尘设备制造有限公司

Method for obtaining extractive by solvent extraction method under conditions of pressurization and ultrasonic irradiation

InactiveCN101920128AStrong erosionStrong fragmentationSteroidsEnergy based chemical/physical/physico-chemical processesUltrasound irradiationSolvent

The invention relates to a method for obtaining an extractive by a solvent extraction method under conditions of pressurization and ultrasonic irradiation. The method comprises the following steps: removing impurities from a substance to be extracted, drying, crushing, putting the crushed substance into an extraction tank, adding a solvent, sealing the extraction tank, and utilizing the pressure device of the extraction tank to carry out pressurization, wherein the pressurized pressure is controlled at 1.1*105-1*106 Pa; and then opening an ultrasonic irradiation device, and extracting for 5-300 min at the extract temperature of 20-100 DEG C to obtain the extractive, wherein the ultrasonic frequency is controlled at 16-500kHz, the ultrasonic power is controlled at 10-5000W, and the ultrasonic strength is controlled at 1-10000W / cm<2>. Since pressurization enables the process of producing cavitation bubble collapse by utilizing the solvent subject to ultrasonic irradiation to be faster and more severe, produces strong washout and crushing actions on the surface of the substance to be extracted and quickens inner and outer diffusion mass transfer in the extraction process, thus the invention has the advantages of fast extraction speed, short extraction time, high extraction yield and the like.

Owner:HENAN UNIV OF SCI & TECH

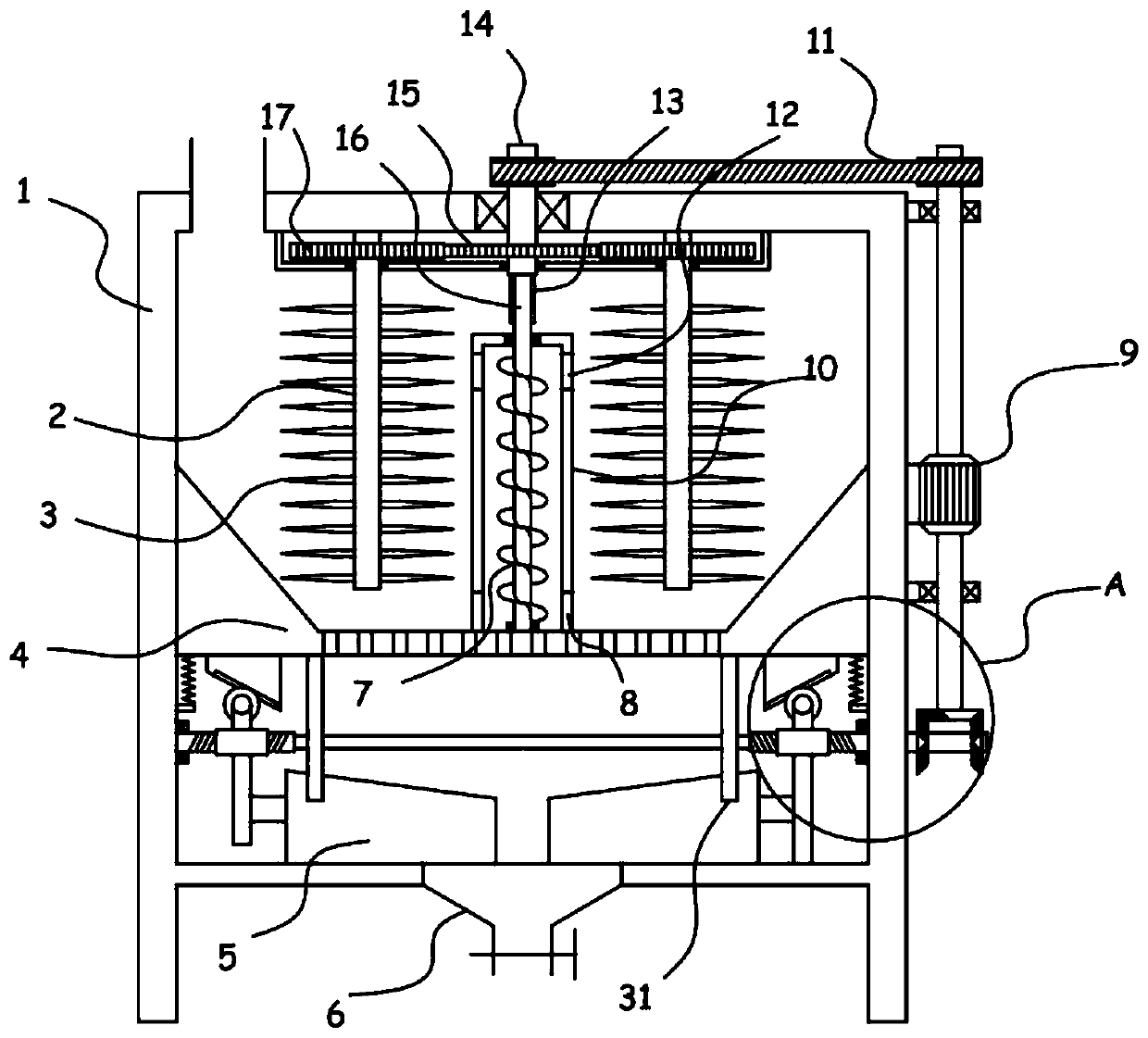

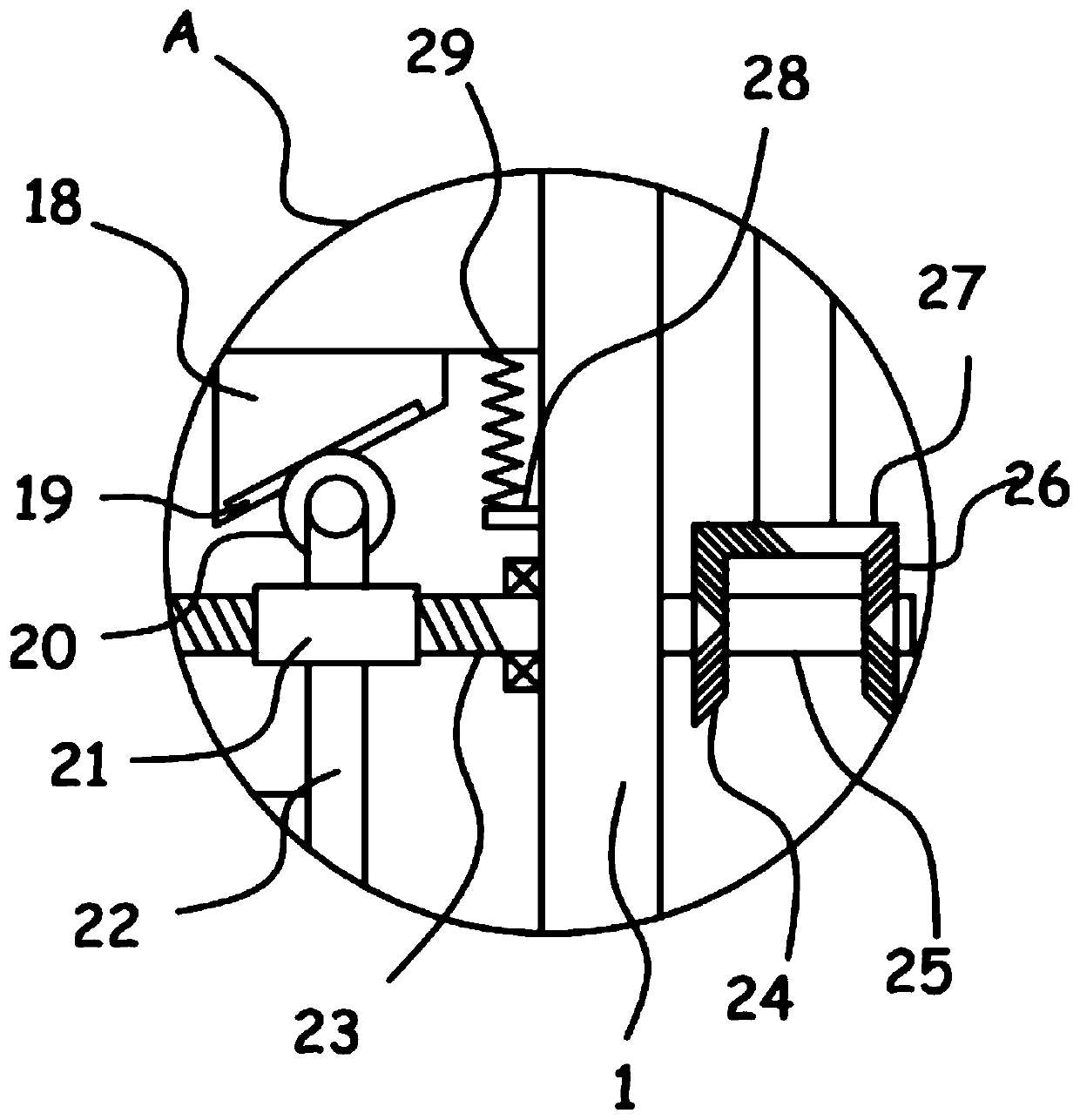

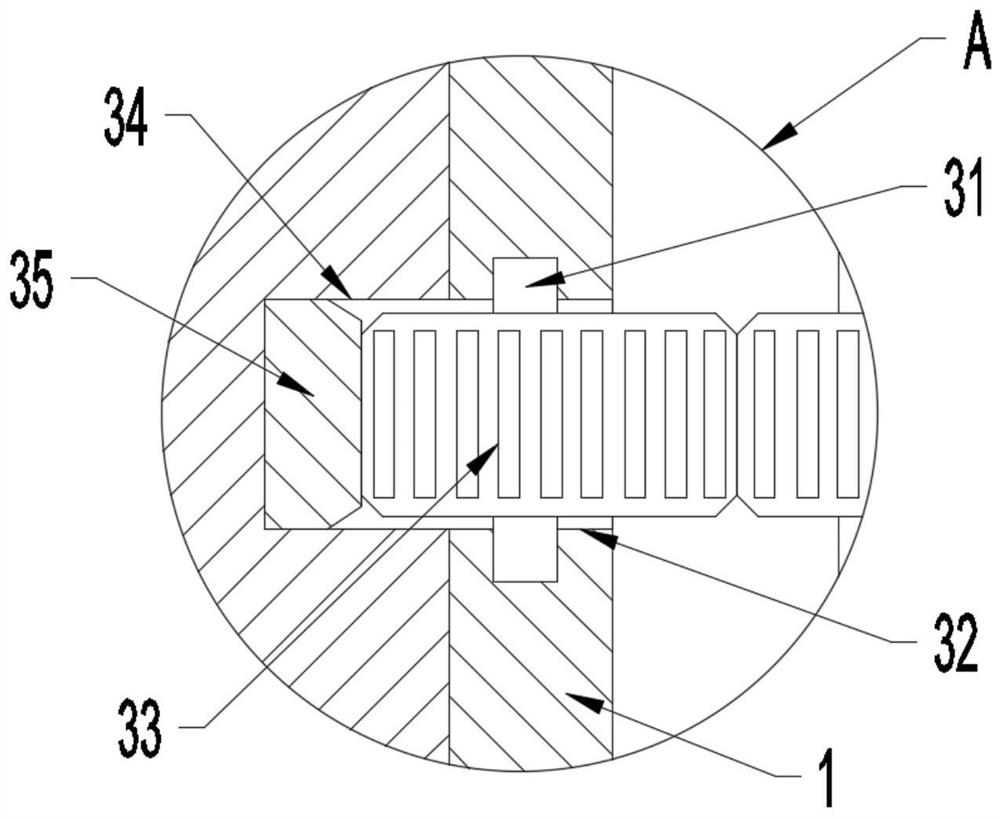

Chemical raw material crushing and refining device

InactiveCN110961208AImprove Flip EffectThe crushing effect is sufficientSievingScreeningDrive shaftCrushing action

The invention discloses a chemical raw material crushing and refining device, and relates to the technical field of chemical engineering. The device comprises a crushing box, a plurality of pairs of crushing blades are fixed to the side wall of a driven shaft at equal intervals, a lifting mechanism used for driving a bearing net plate to vertically ascend and descend is arranged on the crushing box, a crushing mechanism used for impacting and crushing chemical raw materials is arranged on the lifting mechanism, and a discharging hopper is vertically installed at the bottom of the crushing box.Rotation of the driven shaft and a driving shaft is achieved through an arranged transmission mechanism. The driven shaft drives the crushing blades to rotationally crush the chemical raw materials;through the arrangement of the lifting mechanism, materials can be vertically and repeatedly circulated; under the repeated cutting and crushing action of the crushing blades in the circulating process, the arranged lifting mechanism can drive the bearing net plate to vibrate up and down, the turning action of the raw materials is promoted, the raw material crushing effect is more sufficient, arranged extrusion blocks can repeatedly impact and crush the chemical raw materials, and the refining efficiency of the raw materials is greatly improved.

Owner:王淑英

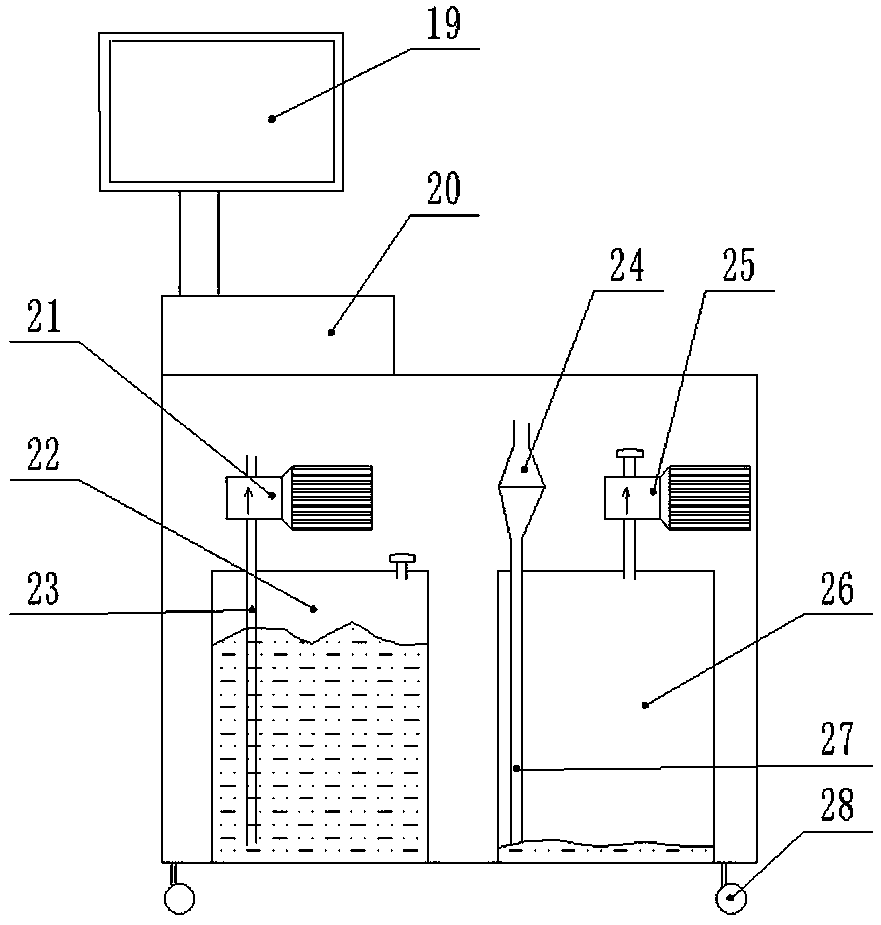

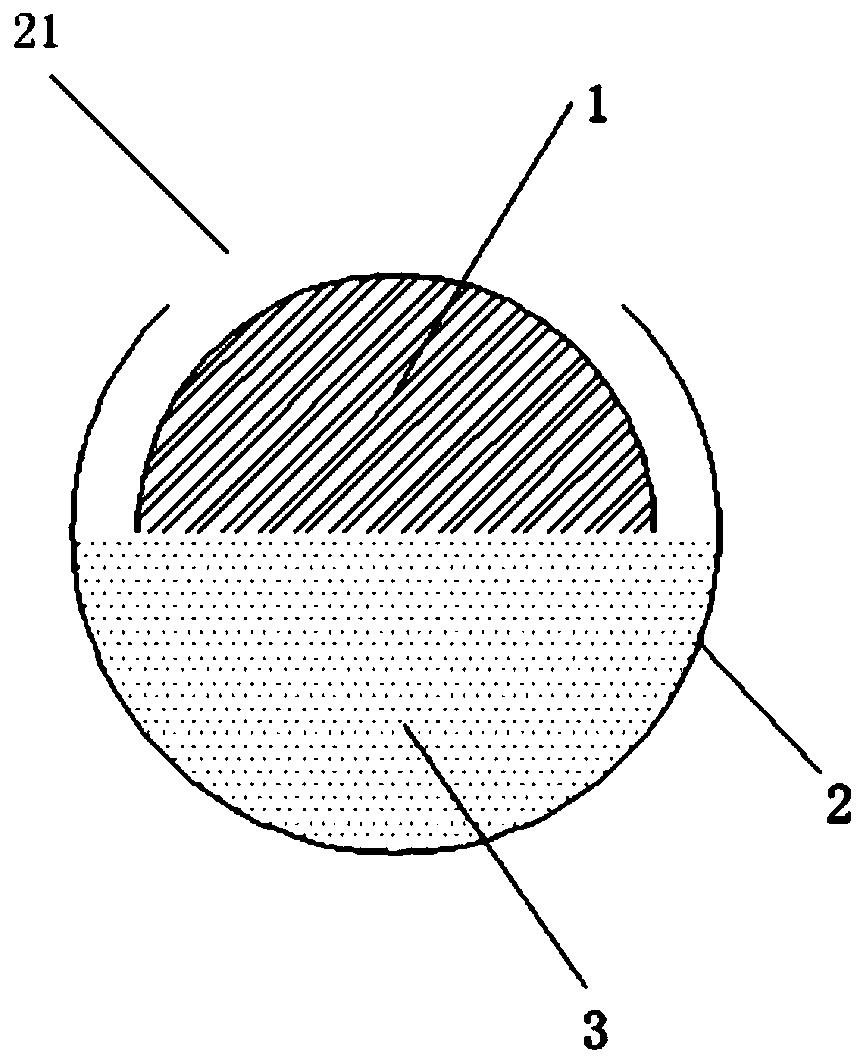

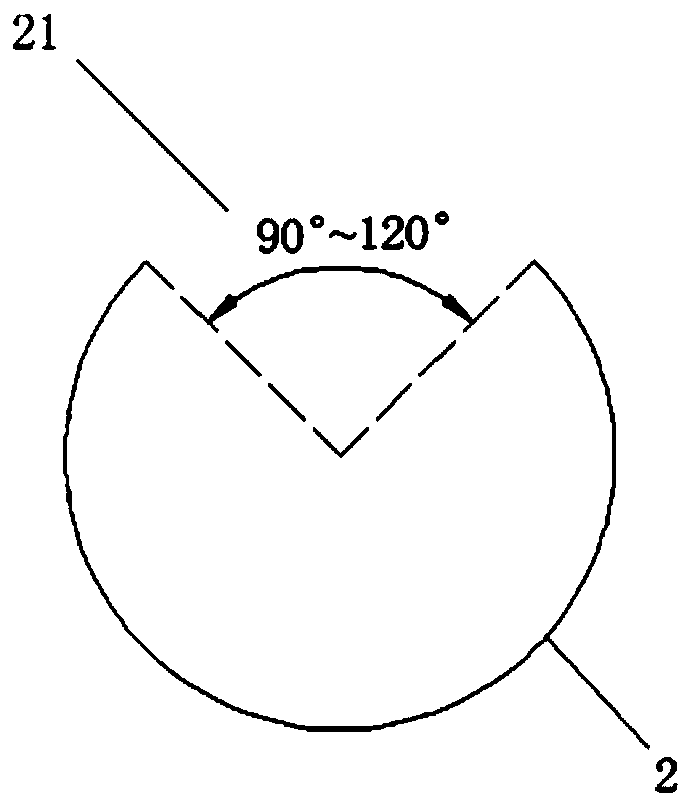

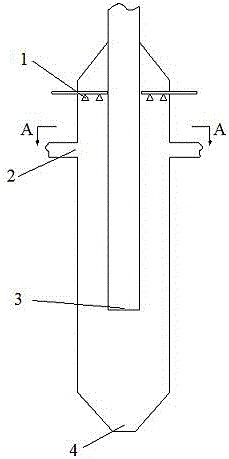

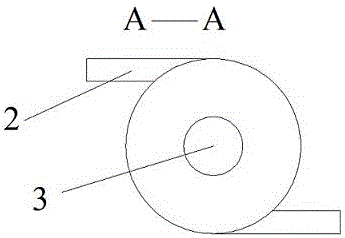

Calculus breaking device for urinary surgery

InactiveCN110141301AAvoid the risk of residues in the patientRealize the function of double gravelCannulasEnemata/irrigatorsUrologic surgeryEngineering

The invention discloses a calculus breaking device for urinary surgery. The device comprises a calculus breaking module and a cleaning module, wherein the calculus breaking module comprises a liquid return cavity, an inner rod is arranged in the middle of the liquid return cavity, the inner rod slides up and down and is rotatably arranged in the middle of the liquid return cavity, the inner rod isarranged in a hollow manner, an inner rod head is arranged at the lower end of the inner rod, the upper end of the inner rod is connected to a stock solution box in the cleaning module, the upper endof the liquid return cavity is communicated with a waste solution box in the cleaning module, two crushing heads are arranged at the lower end of the liquid return cavity, the upper parts of the crushing heads are connected to the liquid return cavity through crushing springs, and the lower parts of the two crushing head are of an openable structure. When the inner rod moves upwards in the liquidreturn cavity in a working state, the lower part of the inner rod opens the crushing springs, and the two crushing heads open. The device realizes the function of double calculus breaking through theextrusion action of the two crushing heads and the rotary crushing action of the inner rod head, and has better effect; and by arranging the cleaning module, the device realizes the cleaning functionafter calculus breaking, and avoids the risk that broken calculus residues remain in the body of a patient.

Owner:THE FIRST AFFILIATED HOSPITAL OF MEDICAL COLLEGE OF XIAN JIAOTONG UNIV

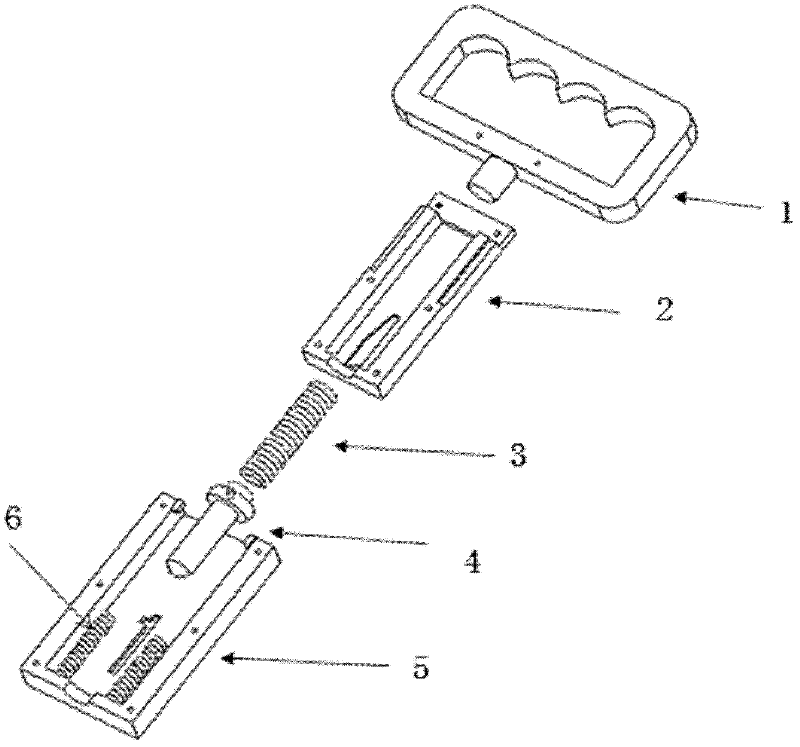

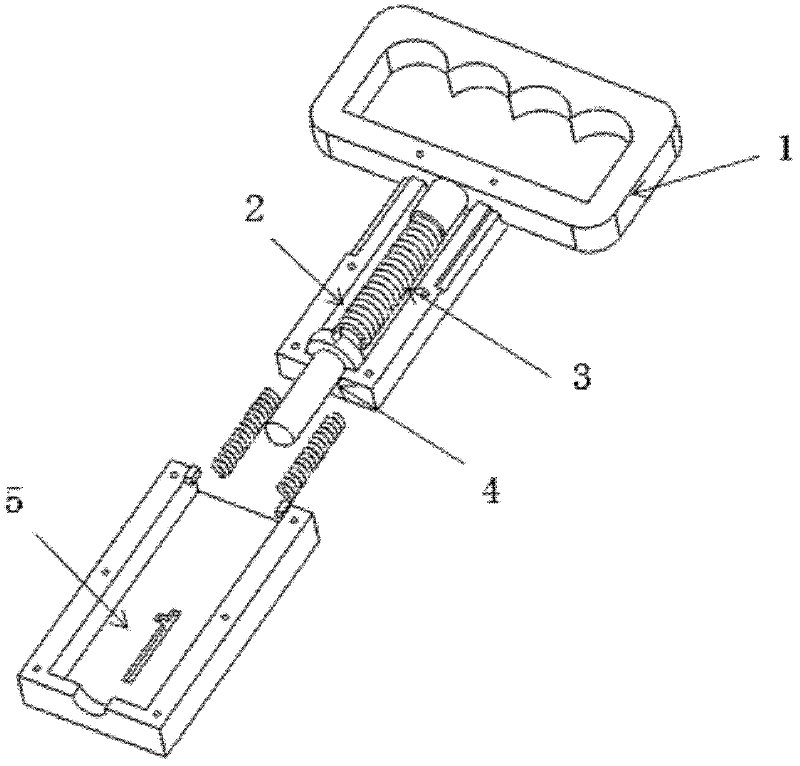

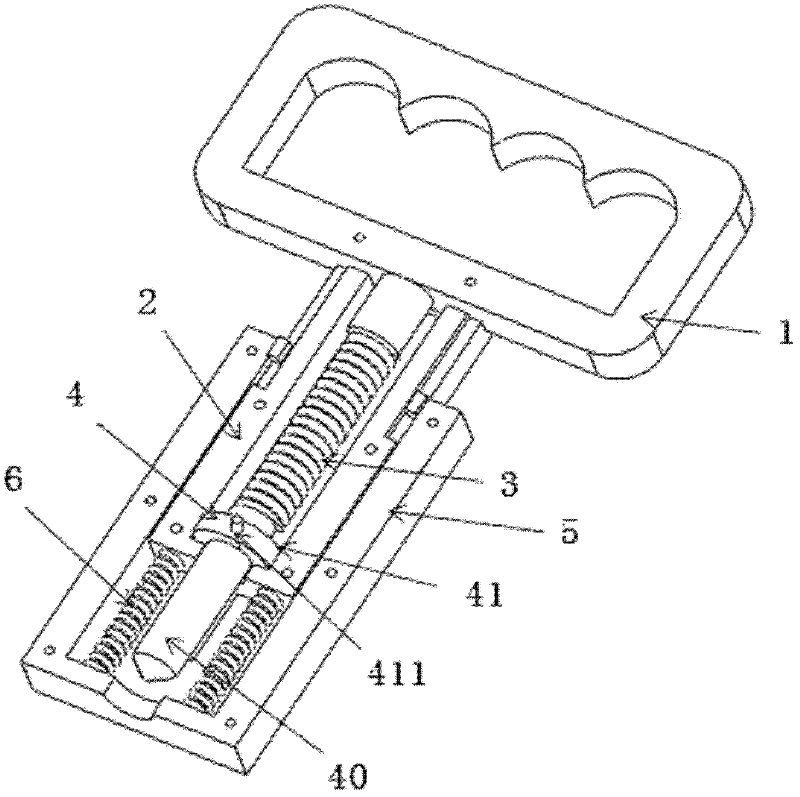

Powerful vehicle-mounted safety hammer

InactiveCN102555968AMake up for deficienciesEasy to usePedestrian/occupant safety arrangementEngineeringCrushing action

The invention provides a powerful vehicle-mounted safety hammer which comprises a handle, an inner shell, an impact spring, a firing pin and an outer shell, wherein the handle is fixed at the back side of the inner shell; one end of the impact spring is connected with the handle, and the other end of the impact spring is connected with the firing pin; the inner shell is slidably installed in the outer shell; the back side of the outer shell is provided with a limit device used for preventing the inner shell from sliding out of the outer shell; the firing pin comprises a head part and a limit part connected with the head part; the limit part is provided with a pin; the limit part of the firing pin and the impact spring are contained in the inner shell; the front end of the firing pin is provided with a groove by which the head part can pass through the inner shell; the outer shell is provided with a guide groove and a positioning groove communicated with the guide groove; the pin is located in the guide groove or the positioning groove; and the front end of the outer shell is provided with a through hole through which the head part can penetrate. In the use process of the safety hammer, the spring is just compressed through the handle, and energy is stored by the spring; when the energy is accumulated to a certain degree, the energy can be automatically released so as to smoothly complete a crushing action; and the powerful vehicle-mounted safety does not need large waving space any more, is easy to operate and is not limited by knocking position.

Owner:SHAANXI UNIV OF SCI & TECH

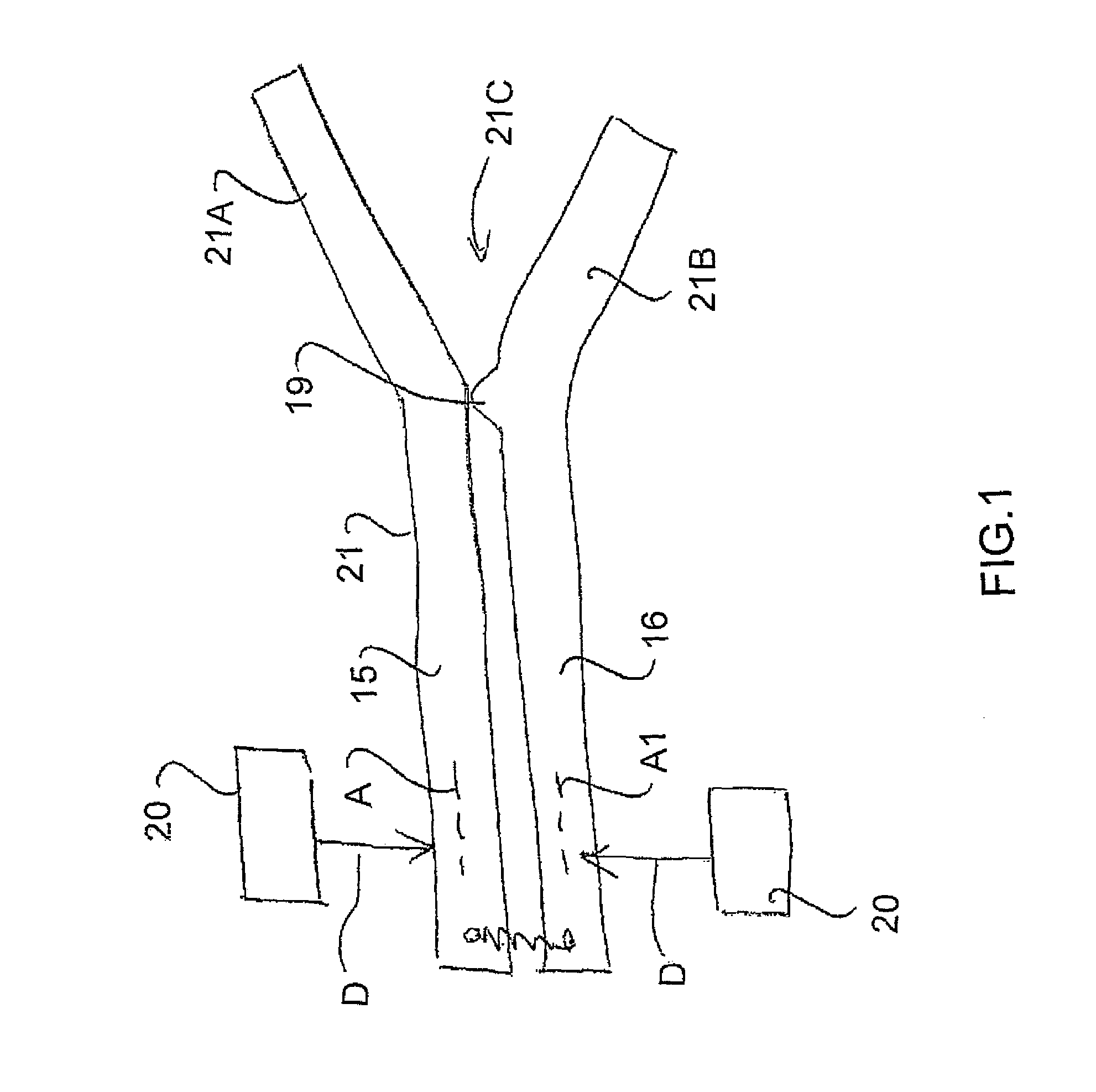

Euthanasia of poultry

InactiveUS8216031B2Prevent escape of blood from the neckPrevent skin cutsSlaughtering/stunningSlaughterhouse arrangementsEngineeringCrushing action

Owner:CRYSTAL SPRING COLONY FARMS

Electronic product continuous recovery device

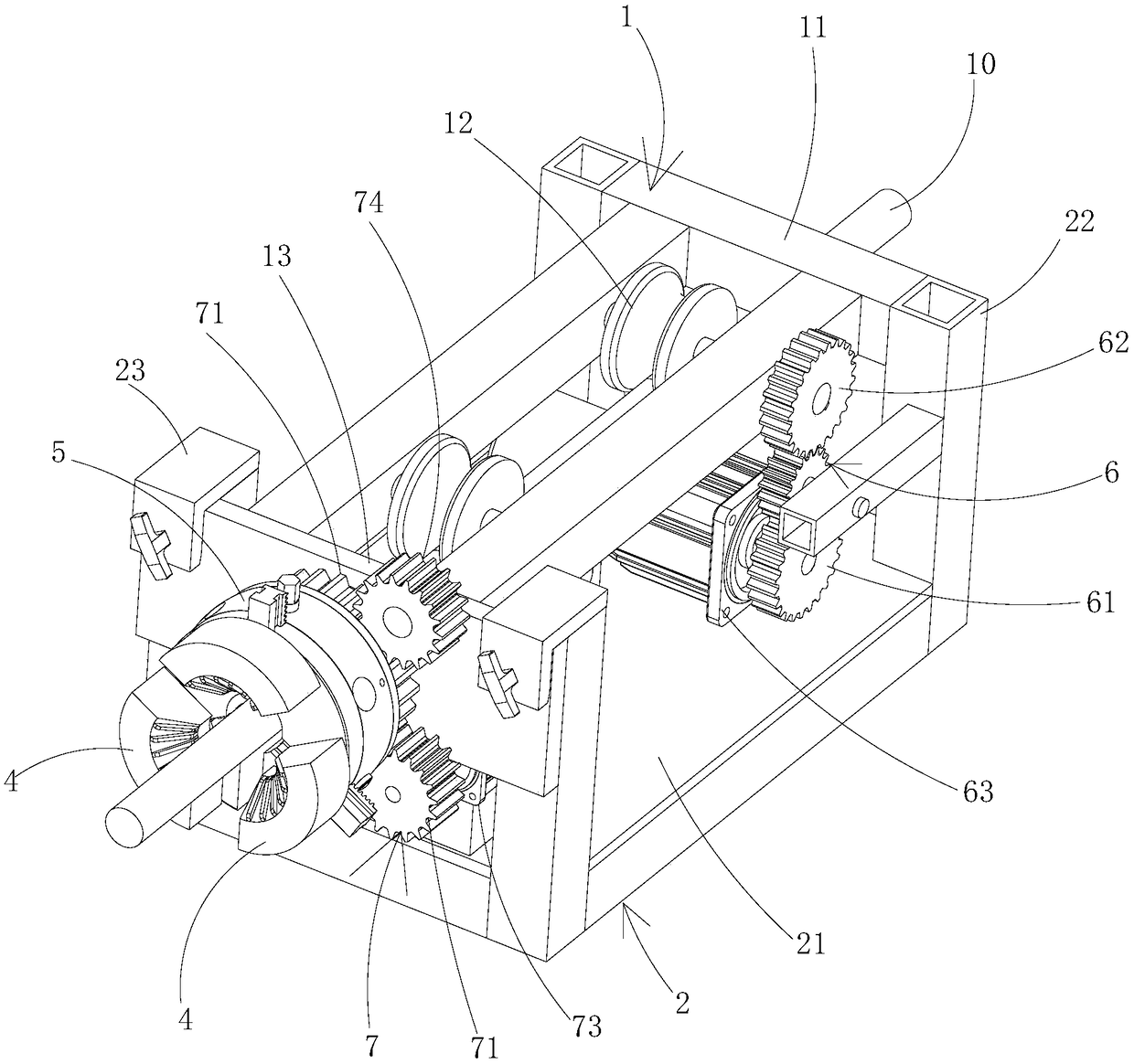

InactiveCN109331947AComply with particle size requirementsContinuously workingGrain treatmentsProduction lineDrive shaft

The invention relates to the field of electronic products, and discloses an electronic product continuous recovery device. The electronic product continuous recovery device comprises a framework, wherein a driving motor is fixedly arranged on the left side of the framework; a crushing bin is arranged at the upper part of the framework, and a screening bin is arranged at the lower part of the framework; a feeding hole is formed in the right upper corner of the crushing bin, and a discharging opening is formed in the right lower corner of the screening bin; the driving motor is fixedly connectedwith a driving shaft through a connecting shaft; the driving shaft is connected with a first bevel gear in a clamped mode, and the first bevel gear is meshed with a second bevel gear; the second bevel gear is connected with a rotating shaft in a clamping mode; a cam is clamped on the right side of the rotating shaft; the upper part of the driving shaft is clamped and connected with a first belt wheel; and the first belt wheel is connected with a second belt wheel through a belt. By virtue of the continuous crushing action, the electronic product continuous recovery device can carry out continuous working, so that the working yield is greatly improved; by mounting a screening plate, it is ensured that the output materials can meet the particle size requirements, and the manual screening process is omitted; and by matching a material conveying device on a production line, the production line task of the whole crushing and sieving process can be completed, and the practical production isgreatly facilitated.

Owner:李少伟

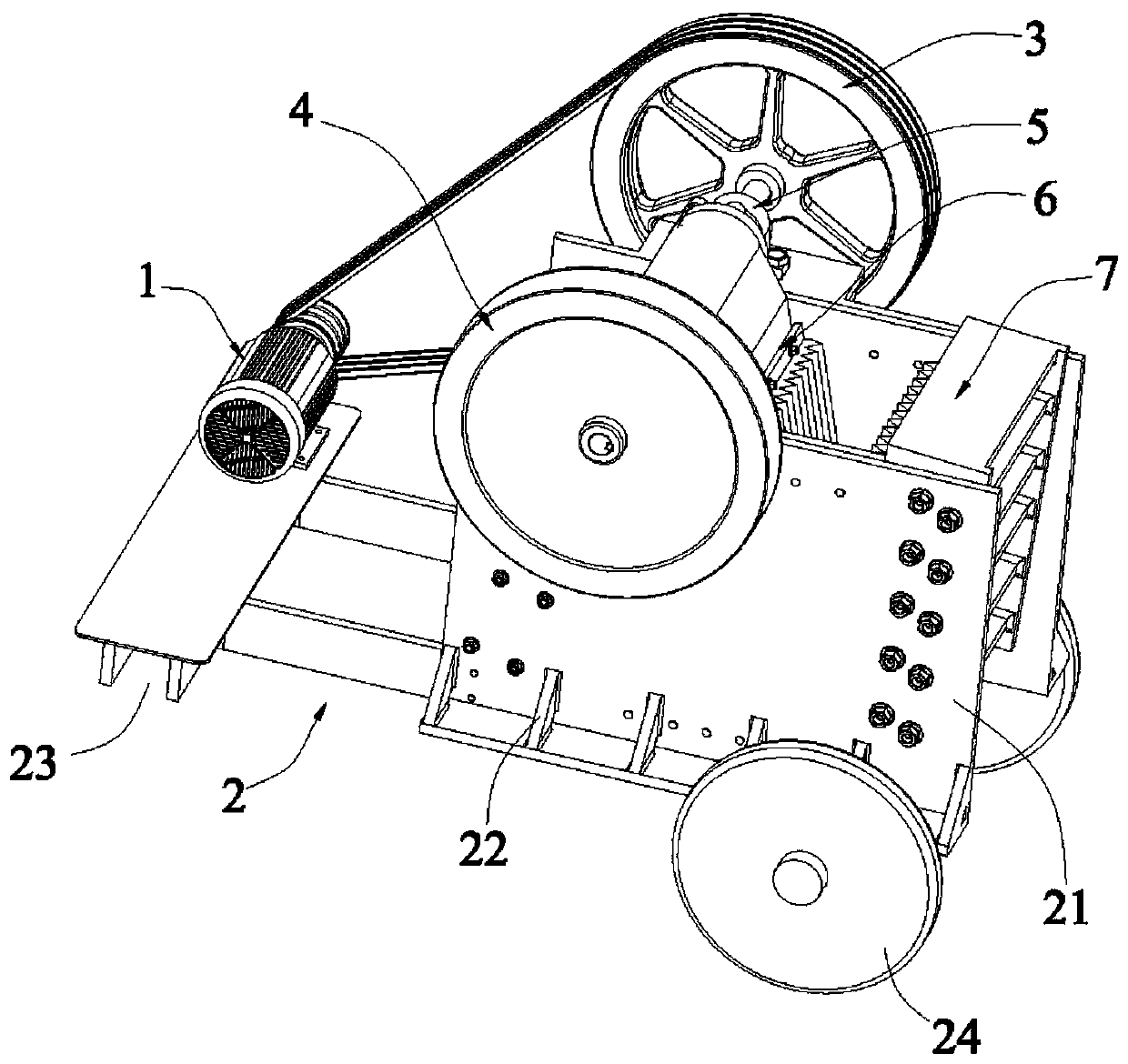

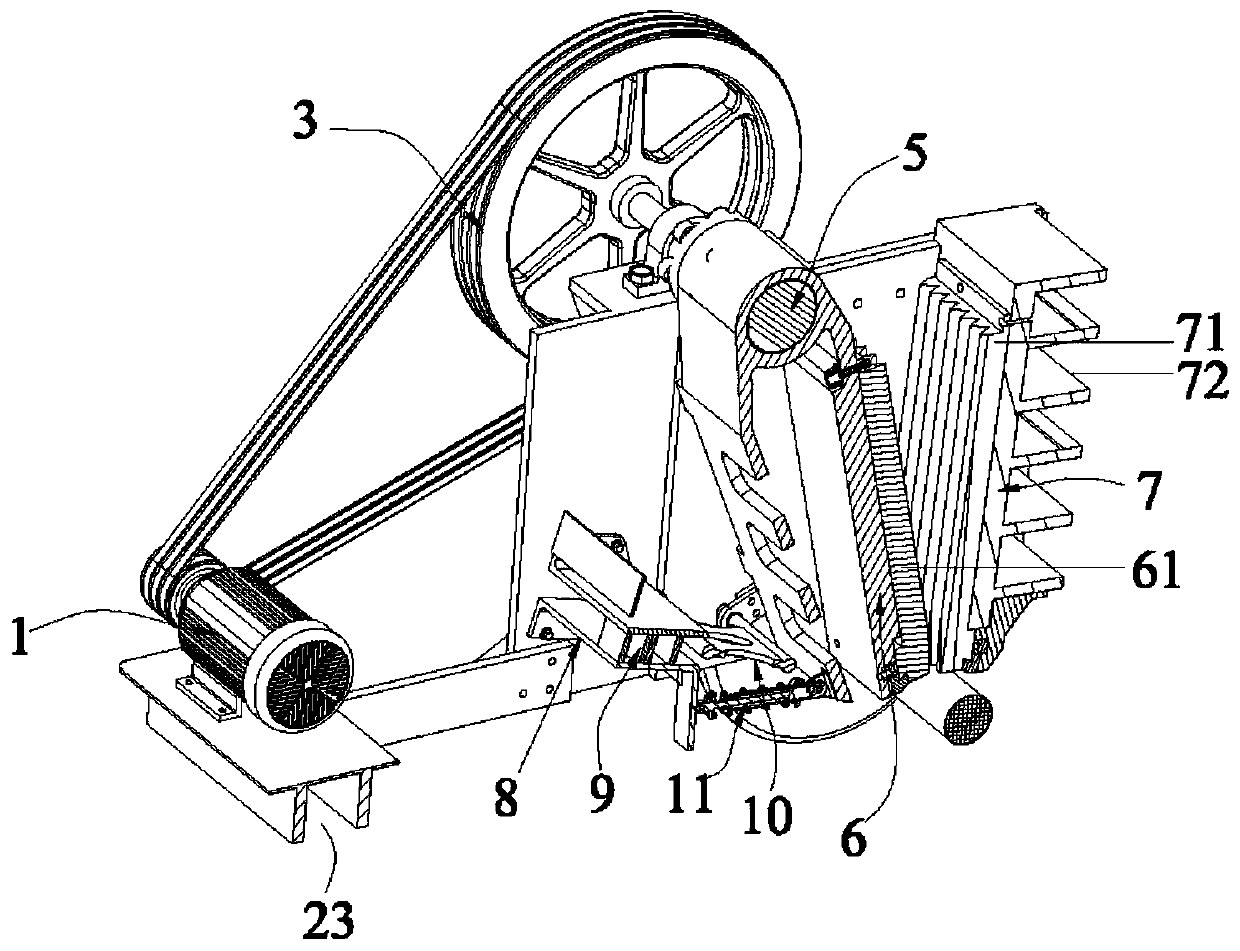

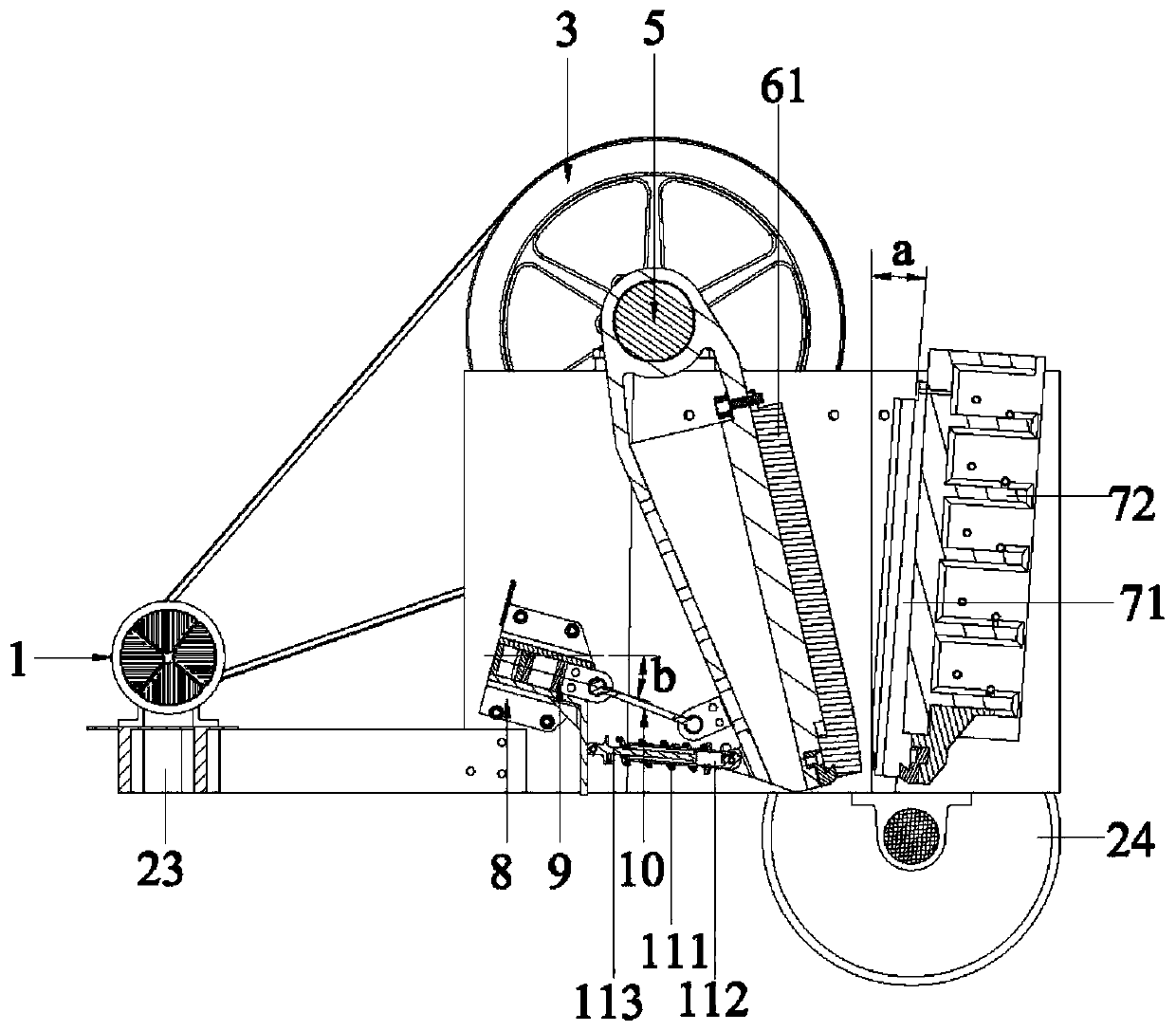

Movable jaw crusher

PendingCN110639642AEasy to moveIngenious structural designGrain treatmentsSocial benefitsEconomic benefits

The invention discloses a movable jaw crusher which comprises a driving motor, a movable frame, a belt pulley, an inertia wheel, an eccentric shaft, a movable jaw plate, a fixed jaw plate, a guide seat, a guide block, a limiting plate and an elastic reset device. The two sides of the movable frame are symmetrically provided with machine plates, and an installation cavity is formed between the twomachine plates. The movable jaw crusher is ingenious in structural design, the structure of the movable frame is reasonably designed to form the installation cavity, convenience is brought to installation of other components, the size is effectively reduced, the bottom surface of the tail of the movable frame is provided with movable wheels, the whole can be conveniently dragged through a hook groove, movability is good, transportation and use are convenient, meanwhile, the movable jaw plate is of an obliquely-arranged structure, the crushing action of the movable jaw plate can be matched better, the working efficiency is effectively improved, the crushing effect is good, working stability is good, the economic benefits and the social benefits are good, and wide application and popularization are facilitated.

Owner:张山

Mobile apparatus for crushing containers

InactiveUS20060086264A1Easily and quickly attached to forkliftFacilitated releasePress ramMobile deviceCrushing action

The present invention provides a mobile crusher for crushing containers such as 55-gallon drums. The apparatus includes a crusher head and crusher base, each of which are quickly and easily attached to a forklift. When actuated, the forks of the forklift drive the crusher base and container resting on it into the crusher head, thereby crushing the container. The apparatus may be configured to accommodate different sizes of forklifts and may include an optional device to puncture the container at the onset of the crushing action.

Owner:BREES THEODORE H

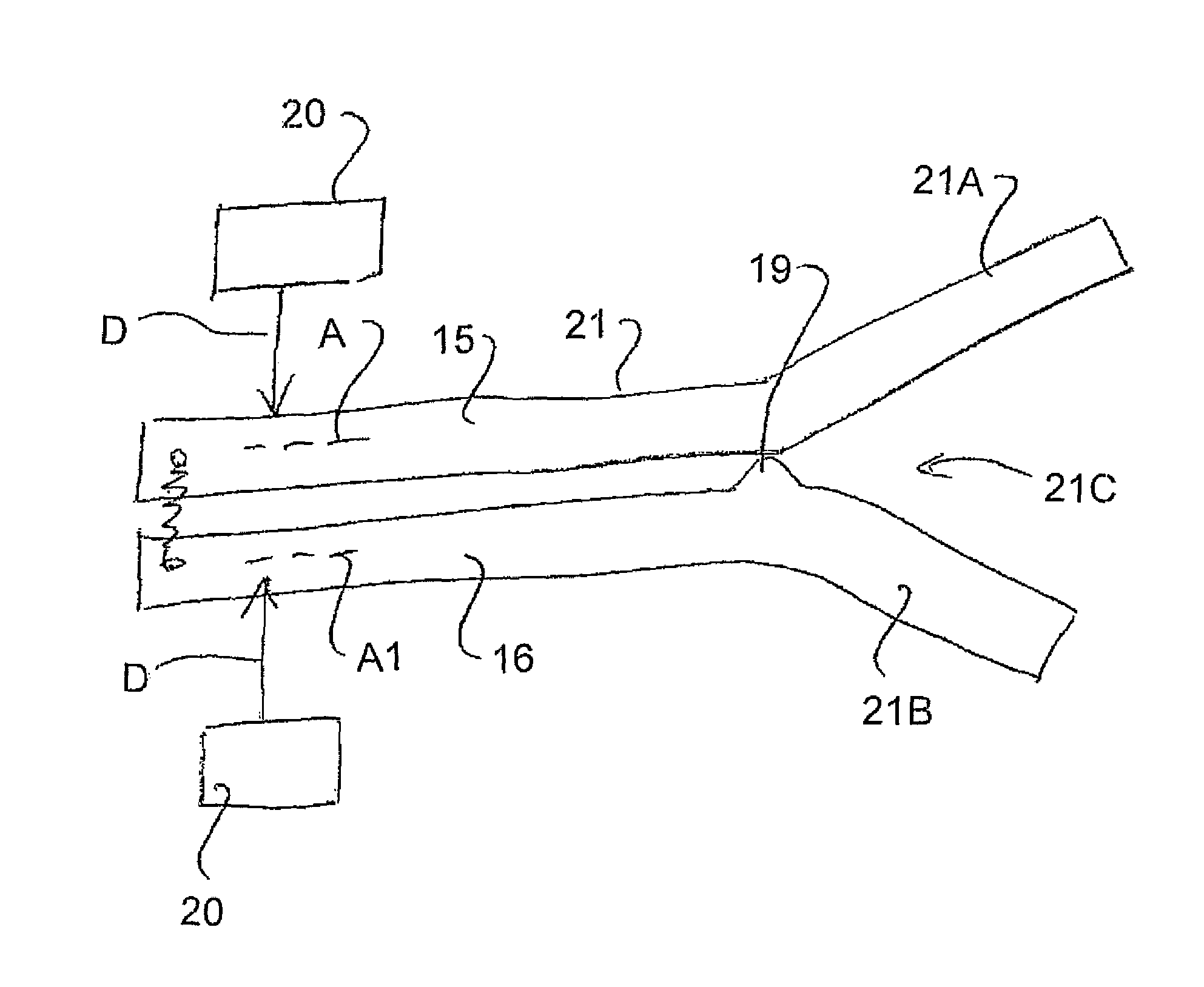

System and method for charging peripheral hole in smooth blasting of tunnel

The invention provides a system and a method for charging a peripheral hole in smooth blasting of a tunnel. The system comprises an elastic C-shaped pipe, curing foam, an explosive cartridge and a detonating apparatus, wherein the length of the C-shaped pipe is matched with the length of the to-be-charged peripheral hole; the curing foam is coated to the inner wall of the C-shaped pipe, the explosive cartridge fills the C-shaped pipe and is positioned by an elastic constraining force of the C-shaped pipe, and the detonating apparatus is inserted into the explosive cartridge. When the peripheral hole is charged, the C-shaped pipe filled with the explosive cartridge and the detonating apparatus is plugged into the peripheral hole and the outer wall of a part, coated by the curing foam, of the C-shaped pipe is attached to a hole wall, located on one side of a surrounding rock, of the peripheral hole. The system provided by the scheme plays roles of buffering the pressure to protect the wall and guiding energy release, so that the detonating damage to the surrounding rock is reduced effectively, the crushing action to an excavated rock body is enhanced, and differentiated action of peripheral hole blasting is achieved. The system and the method are particularly suitable for excavating the tunnel with a joint crushed zone.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Apparatus and process for treatment of fibers

InactiveUS20120180962A1Reduction in accessibilityShorten the lengthPretreatment with water/steamWashing/displacing pulp-treating liquorsFiberTreatment results

A process for treatment of fibers is disclosed. The treatment comprises simultaneously and continuously macerating the fibers and exposing the fibers to superheated steam, ammonia gas and ethylenediamine gas. The treatment is carried out in a chamber where the fibers are subjected to the mechanical rubbing and crushing action of a plurality of rotating pins against channels disposed on the chamber interior wall. The treatment results in improved fiber water holding capacity and improved conversion efficiency in the production of biofuels from the treated fibers.

Owner:ROA ESPINOSA AICARDO

Ethanol extraction method

ActiveCN110237888AImprove efficiencyFully leachedTransportation and packagingRotary stirring mixersEngineeringCrushing action

The invention discloses an ethanol extraction method. An ethanol extraction device comprises a main body, an action cavity is formed in the main body, a feeding pipe is arranged on the upper end wall of the action cavity, a feeding valve is arranged in the end wall of the feeding pipe, a feeding hole communicated with the outside is formed in the feeding pipe, an annular leakage cavity is formed in the lower end wall of the action cavity in a communicated mode, a left and right symmetric connecting cavity is formed in the lower end wall of the leakage cavity, and a connecting cavity valve is arranged in the end wall of the connecting cavity. The device is simple in structure and convenient to operate, the grinding rod has a rotary chopping action and a knocking crushing action in the grinding plant raw material process, so that the grinding of the plant raw materials is sufficient and the efficiency is extremely high, a centrifugal stirring mode is adopted in the process of extracting the plant liquid by the extraction agent, so that the extraction of the plant liquid is more rapid and more convenient, the ethanol content of the extraction is also improved., the residue of the plant liquid does not need to be cleaned, only the nylon cloth needs to be replaced, so that the physical labor of people is reduced.

Owner:嘉兴卓十生物科技有限公司

Sludge slurry gasification method and device

ActiveCN106316049AEasy to passImprove gasification efficiencySludge treatment by de-watering/drying/thickeningGasification processes detailsReduction treatmentEvaporation

The invention provides a sludge slurry gasification method and device. The device comprises an atomization range and a gasification region. The method comprises the following steps: carrying out crushing treatment on dewatered sludge by using ultrasonic, mixing with biomass and additives to prepare sludge slurry, atomizing the sludge slurry into small-particle liquid drops by using the device, and gasifying to obtain combustible gas. The atomized small-particle liquid drops move helically in the device along with the gas flow and are quickly gasified; and moisture in the liquid drops can generate a crushing action on solid particles in the sludge slurry in the heating-induced evaporation precipitation process, thereby further reducing the particle size, and enhancing the thermal mass transfer rate and gasification efficiency. The method solves the problems of hardening, wall adhesion and the like caused by wet sludge direct gasification, widens the applicability of the sludge gasification technique, and implements cyclic harmless and reduction treatment on the sludge.

Owner:莘县鲁开综合服务有限公司

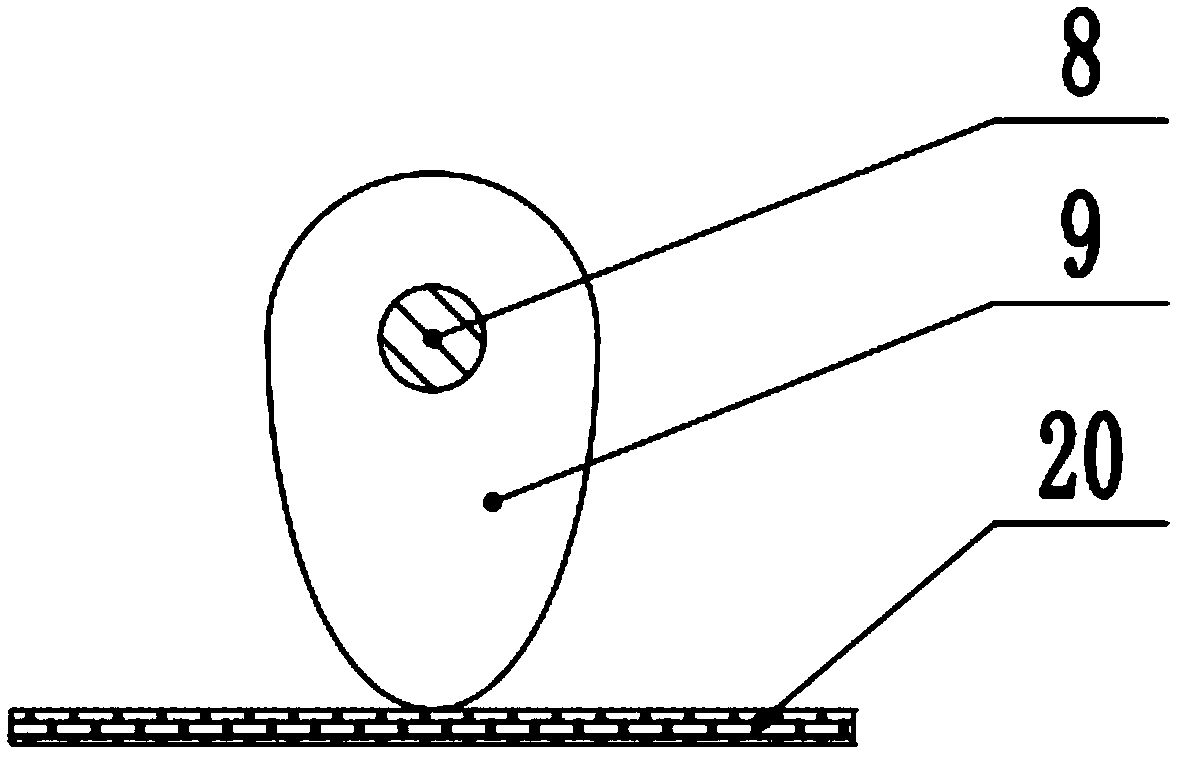

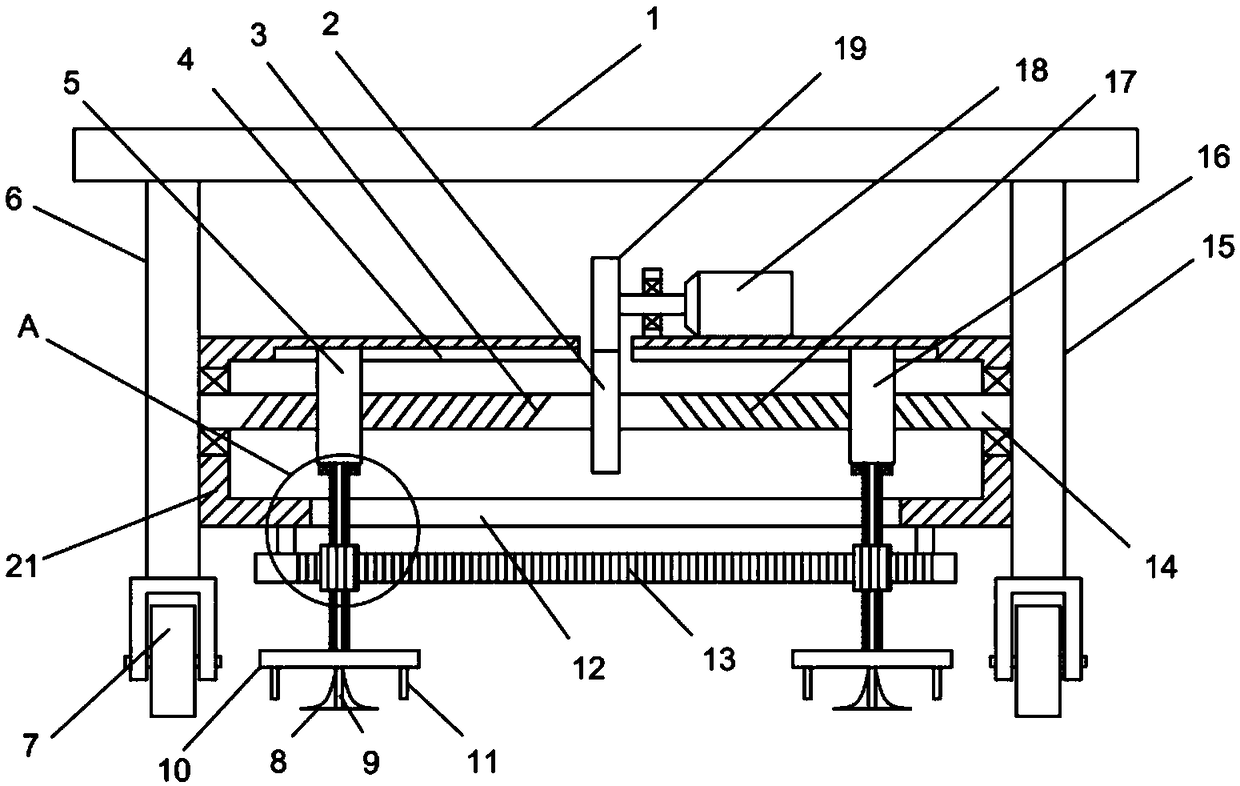

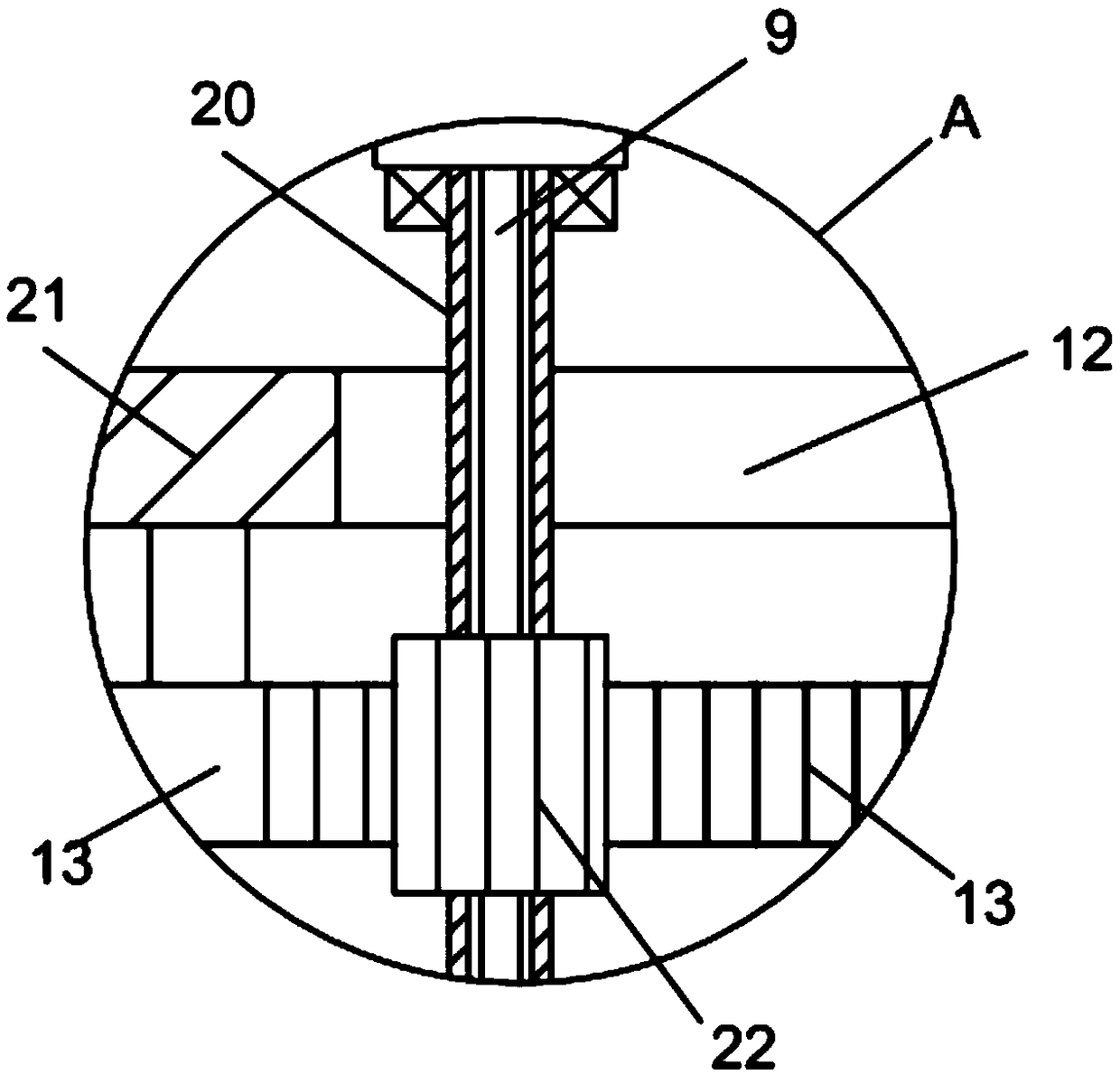

Soil loosening vehicle for forestry planting

InactiveCN108811551ARealize the rotary crushing effectAchieve efficient soil looseningSpadesPloughsGear wheelReciprocating motion

The invention discloses a soil loosening vehicle for forestry planting, which is characterized in that a left vertical plate and a right vertical plate are vertically fixed at the bottom of a horizontal plate, a transmission box is horizontally fixed between the left vertical plate and the right vertical plate, a positive and negative rotation motor is fixedly arranged at the top of the transmission box, a rotating sleeve which passes through a strip-shaped hole is rotatably arranged at the lower end of the first sleeve block and second sleeve block through a bearing; a straight rack meshed with a cylindrical straight gear is fixedly arranged at the bottom of the transmission box; a rotating disc is horizontally fixed at the lower end of the rotating sleeve, a vertical rod which runs through the rotating disc is vertically arranged in the rotating sleeve, and the left side wall and right side wall of the vertical rod are both fixedly provided with a soil-turning plough; according to the invention, the soil-turning motion to the soil is achieved through the left-right reciprocating motion of the soil-turning plough, the rotation of a turntable drives soil-crushing blades to rotate to achieve the rotating crushing action on the soil block which is turned over by the soil-turning plough, the crushing degree of the soil is greatly improved, the crushing effect is good, the crushingefficiency is high, thereby achieving the efficient soil loosening action of the soil during the forestry planting process.

Owner:湖南图强科技开发有限公司

Building solid waste treatment device

InactiveCN113522433AEasy to recycleAvoid pollutionMagnetic separationGrain treatmentsSlagArchitectural engineering

The invention is applicable to the field of building solid waste treatment, and provides a building solid waste treatment device. The building solid waste treatment device comprises a treatment box and further comprises a crushing mechanism and an iron slag collecting mechanism, wherein the crushing mechanism is mounted in the treatment box, and the crushing mechanism carries out refining crushing on building solid waste through the secondary crushing action; the iron slag collecting mechanism is mounted in the treatment box; the iron slag collecting mechanism comprises a collecting assembly, an upward throwing assembly, an auxiliary collecting assembly and a driving assembly; and the driving assembly is used for driving the upward throwing assembly to throw the refined and smashed waste upwards. The crushing mechanism carries out secondary crushing on the building solid waste to refine the building solid waste into particles so as to facilitate recovering iron slags of the building solid waste; the driving assembly drives the upward throwing assembly to throw the refined building solid waste upwards; the collecting assembly adsorbs and collects the iron slags in the particles through magnetism; and the rest of particles fall into the treatment box under the action of gravity.

Owner:林志翰

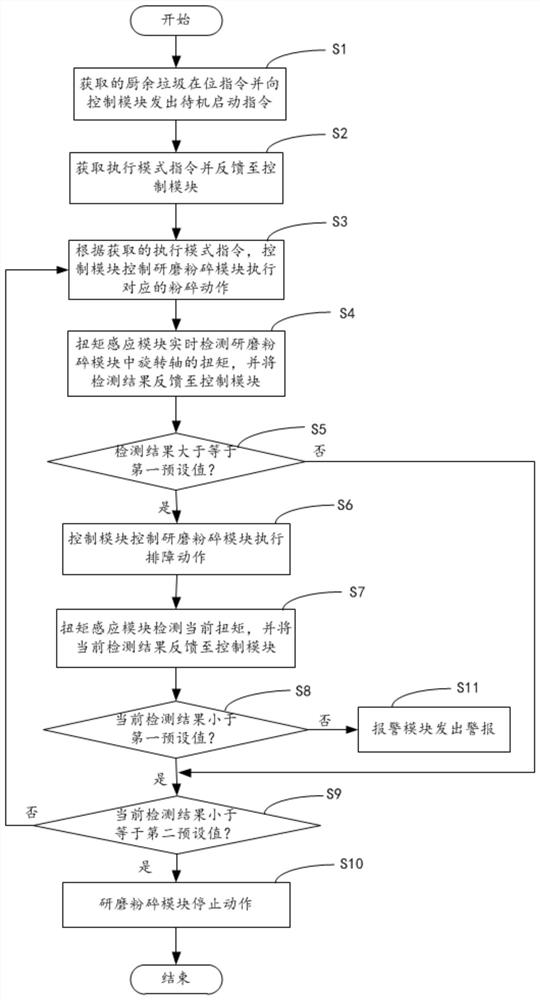

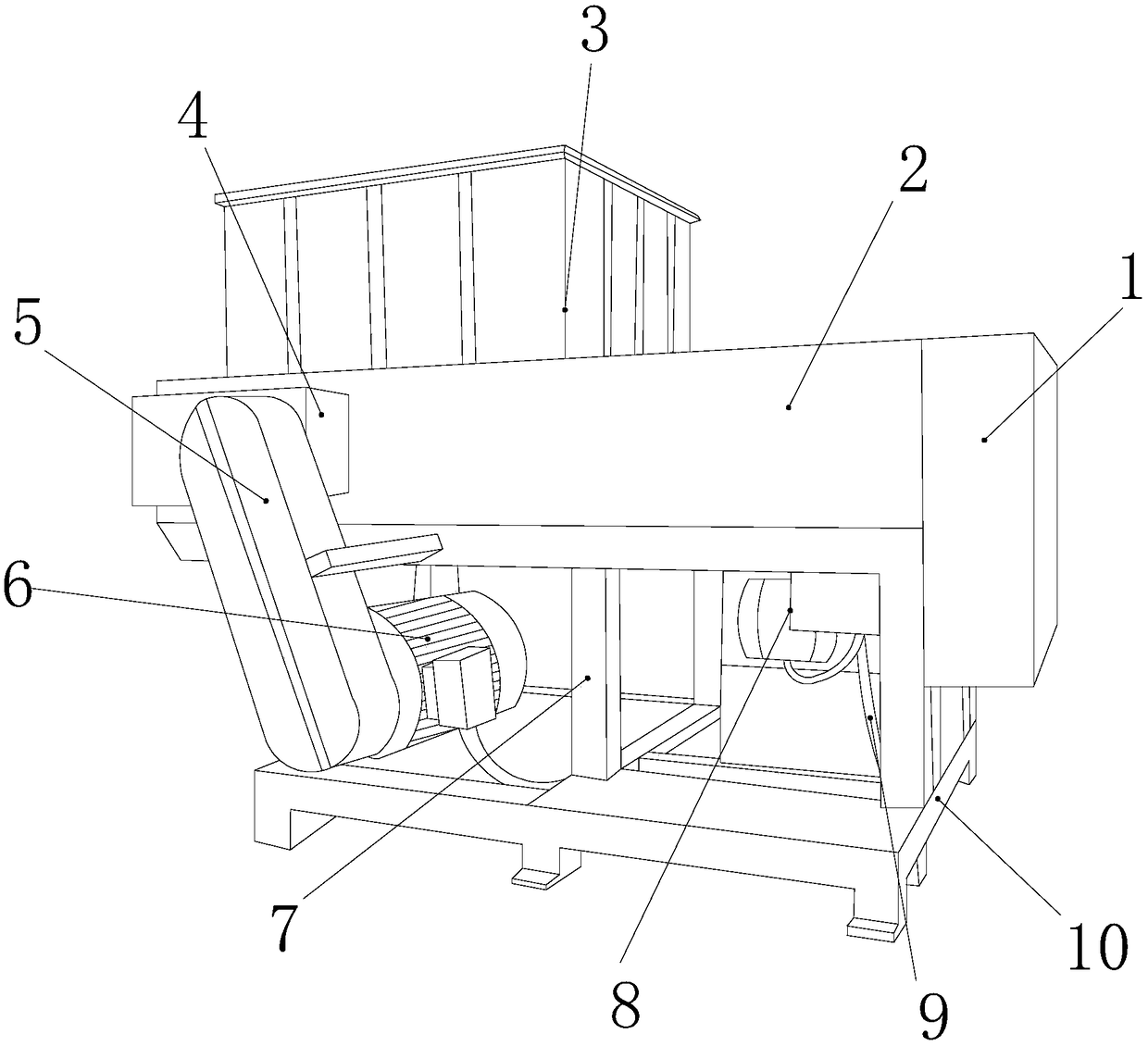

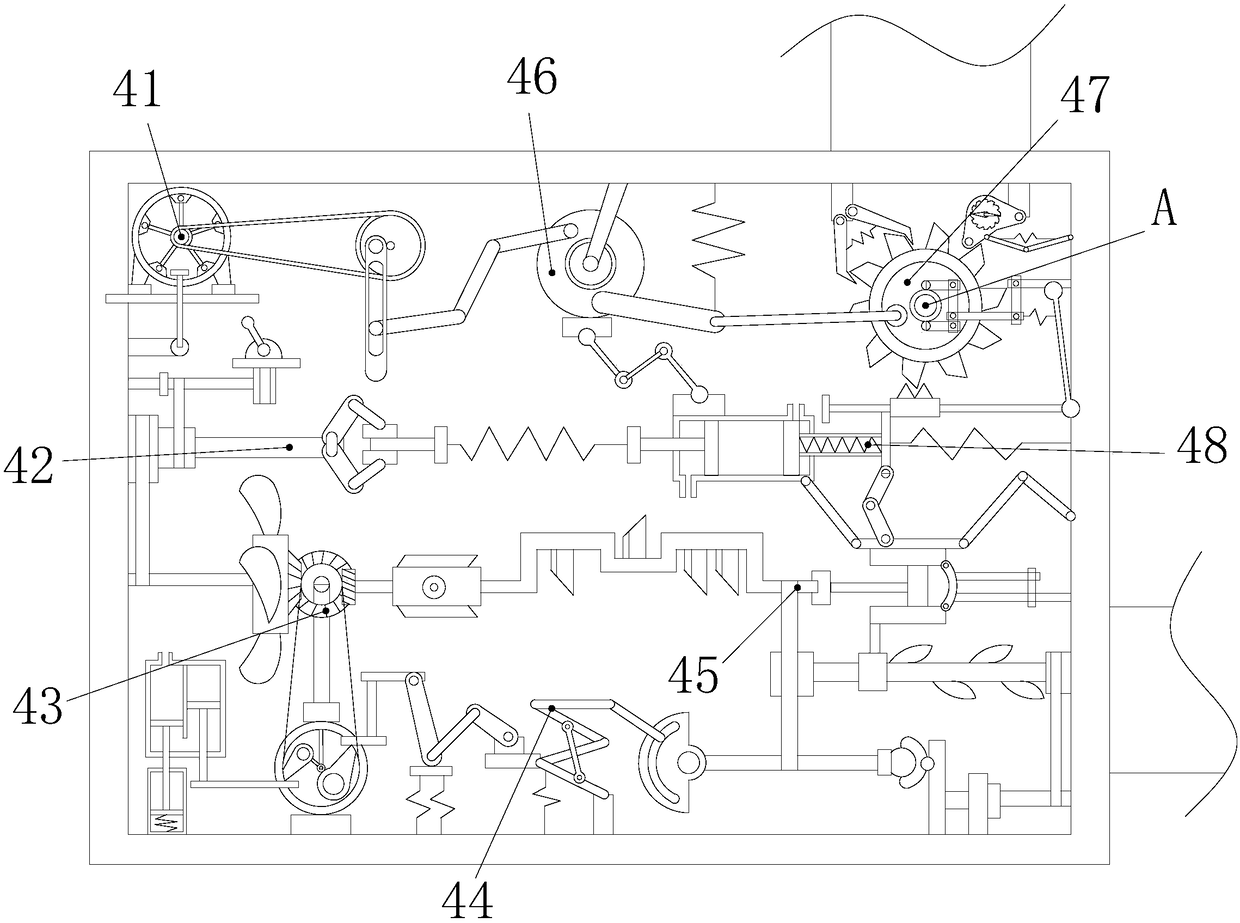

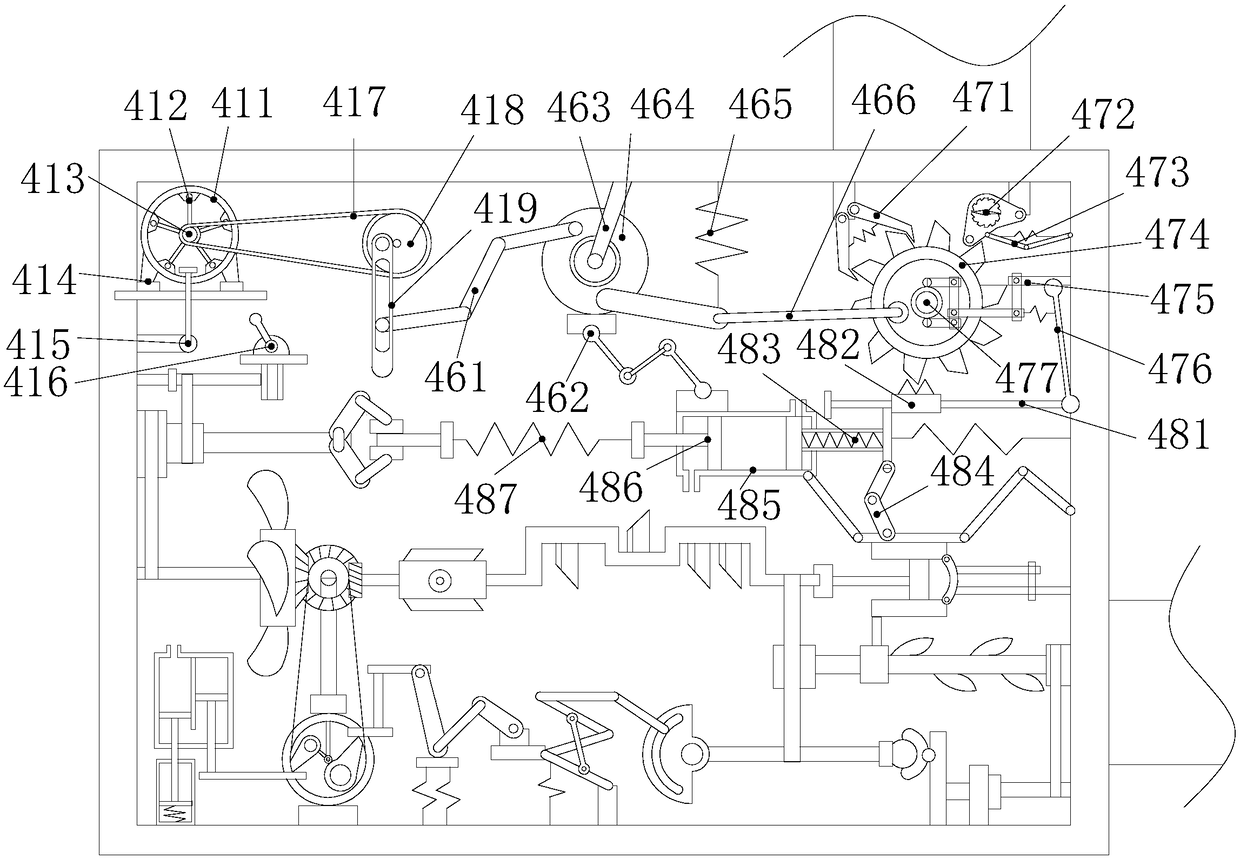

Kitchen waste processor with detection and fault removal functions and control method

PendingCN113102441AHigh degree of intelligenceAccurate judgmentSolid waste disposalRotational axisControl engineering

The invention provides a kitchen waste processor with detection and fault removal functions and a control method. The kitchen waste processor comprises a shell, a control module, a grinding and crushing module and a torque sensing module, wherein the grinding and crushing module and the torque sensing module are respectively connected with the control module; the grinding and crushing module is used for executing a crushing action and a fault removal action, the grinding and crushing module comprises a rotating shaft, and the grinding and crushing module executes the crushing action and the fault removal action through rotation of the rotating shaft; the torque sensing module is used for detecting the torque of the rotating shaft of the grinding and crushing module in real time and feeding back a detection result to the control module; the control module is used for judging whether the obtained detection result is larger than or equal to a first preset value or not, and if yes, the control module controls the grinding and crushing module to execute the fault removal action. Whether the kitchen waste processor is abnormal or failed or not is judged by detecting the torque of the rotating shaft in the grinding and crushing module in real time, and when the kitchen waste processor is abnormal or failed, the fault removal action can be automatically performed in the first time, so that the kitchen waste processor is prevented from being damaged.

Owner:珠海市恒秀环保科技有限公司

Energy-saving and high-efficiency self-cleaning polymerization process

InactiveCN103408680ASolve the sticky kettle problemAvoid the disadvantages of traditional production methodsChemical reactionReaction rate

The invention relates to an energy-saving and high-efficiency self-cleaning polymerization process which is characterized in that a shell and tube reactor is adopted as a polymerization device, and a rotor type strengthened heat transfer and self-cleaning device is arranged in a tube pass of the shell and tube reactor; when a material participating the polymerization enters the tube pass, a rotor rotates in a tube pass reaction liquid by depending on a suspension mechanism, the probability that the tube pass fluid attaches to the tube wall is reduced by depending on high flowing speed in a gap between the tube wall and the rotor and a spiral pushing action of a rotor blade to the tube pass fluid, the phenomenon that attachment on the tube wall is avoided; reaction fluids of different viscosities can be in large-area mutual contact by depending on a shearing and crushing action of the rotor blade to the reaction fluid, mass transfer between the reaction fluids of different viscosities is frequent and easy by depending on the turbulent flow of the blade, the polymerization is thorough, the function of a stirring rod in chemical reaction is realized, and the reaction rate is greatly increased.

Owner:BEIJING UNIV OF CHEM TECH

Waste tire crusher for rubber plastics

ActiveCN109435108ARealize the effect of water injection pressurizationIncrease squeezePlastic recyclingCleaning using liquidsWater flowDrive motor

The invention disclose a waste tire crusher for rubber plastics, the structure comprises a discharging chute, a transmission groove, a feeding square tube, a hydraulic crushing box, a transmission chain belt, a shaft driven motor, an iron column chassis, a power distribution box, a cable and a substrate plate; the left face of the discharging chute is adhered to the right side of the transmissiongroove and interpenetrates; the feeding square tube is inserted into the upper left corner of the transmission groove; the hydraulic crushing box provided by the invention is provided with an opticalaxes motor, a fan wheel device, a pushing mechanism, a connecting rod device, a shaft rod mechanism, a traction device, a crusher mechanism and a piston device, so that the effect of water injection and pressurization of the crushing action of the tire crusher is realized; the extrusion force and the impact force are increased by fitting with crushing; moreover, the dope of a crushing cutter and aroller is cleaned for a long time so as to keep sharp degree; the parts of the equipment are maintained effectively so as to improve the crushing performance and prolong the service life of the equipment; the crushed material is scoured, cleaned and crushed; and the work of the equipment is assisted by combing with steam pressurization in multi-direction.

Owner:KARAMAY BODA ECOLOGICAL ENVIRONMENTAL PROTECTION SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com