Waste tire crusher for rubber plastics

A technology of waste tires and shredders, applied in plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of low maintenance efficiency of crushing cylinders and crushing blades, passivation of blades, hidden safety hazards of shredders, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

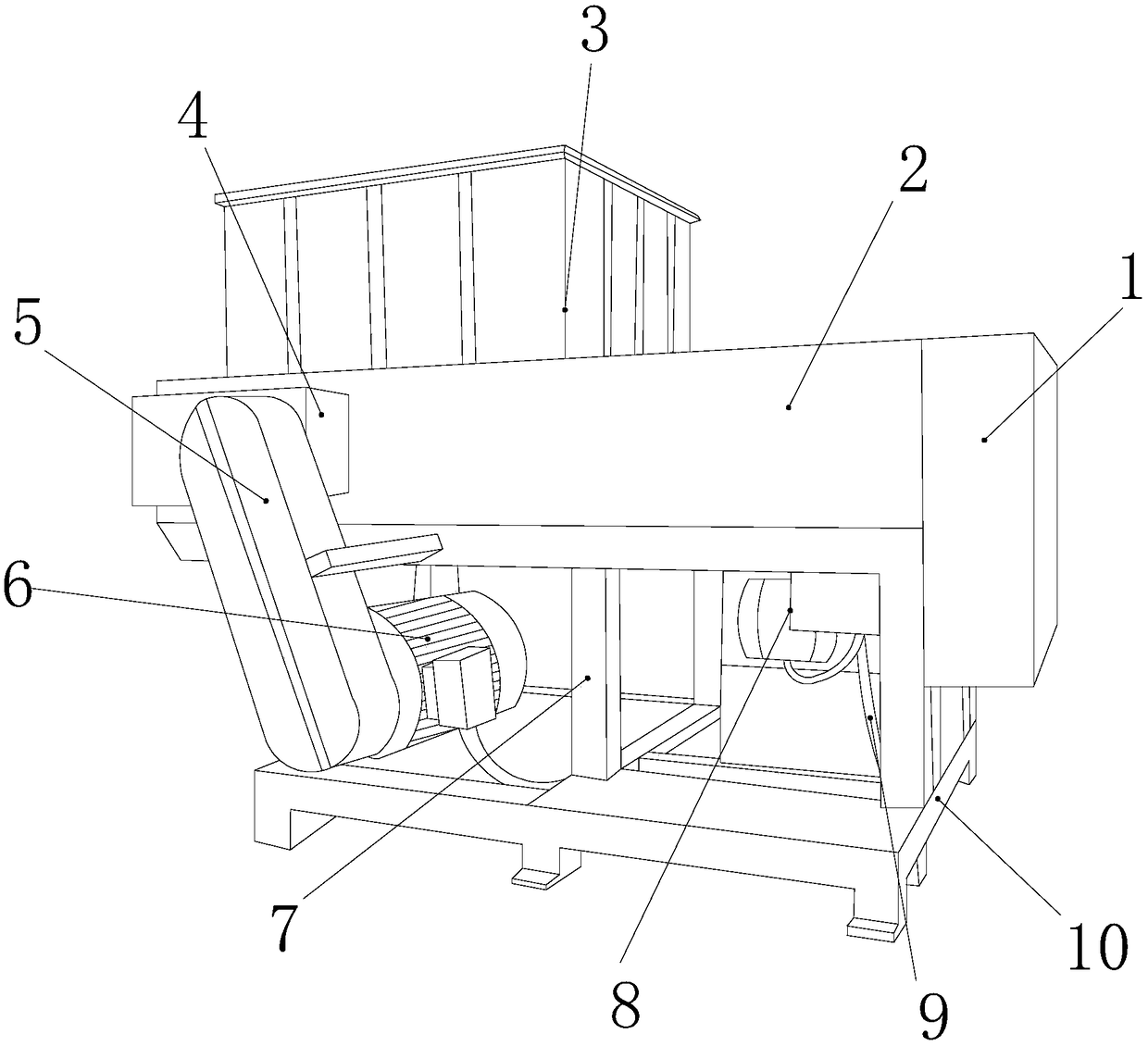

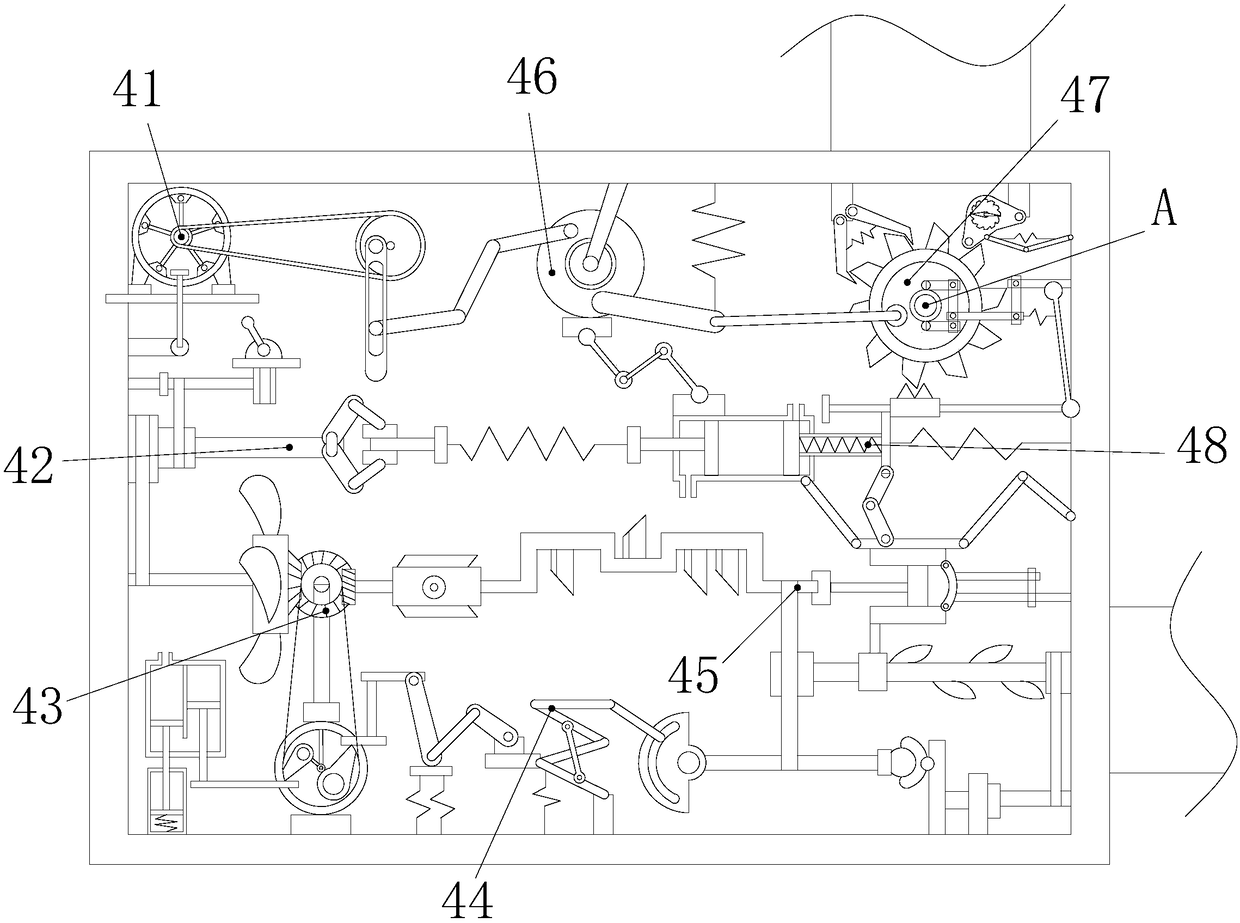

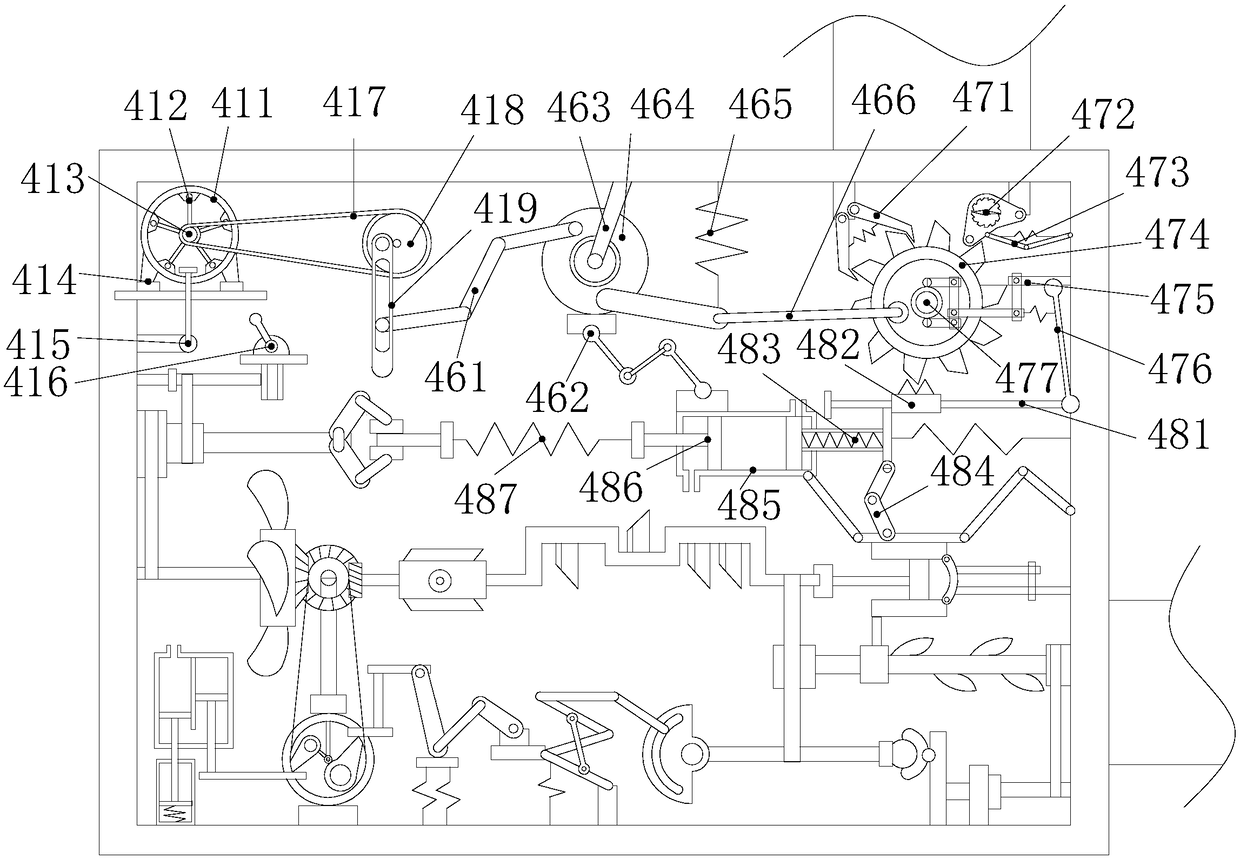

[0026] see Figure 1-Figure 6 , the present invention provides a waste tire shredder for rubber and plastics, the structure of which includes: a discharge chute 1, a transmission groove 2, a square feeding cylinder 3, a hydraulic crushing box 4, a transmission chain belt 5, and a shaft motor 6 , iron column underframe 7, distribution box 8, cable 9, base plate 10, the left side of described discharging chute 1 is close to the right side of transmission groove 2 and interpenetrates each other, and described feeding square tube 3 Inserted in the upper left corner of the transmission groove 2, the hydraulic crushing box 4 is longitudinally attached to the left end of the front transmission groove 2, and the hydraulic crushing box 4 is mechanically co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com