Sludge slurry gasification method and device

A gasification device and mud technology, which is applied in the field of solid waste recycling, can solve the problems that sludge is prone to hardening and sticking to the wall, it is difficult to realize industrial production, and the equipment is difficult to operate continuously, so as to avoid sticking to the wall and shorten the residence time , The effect of improving processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

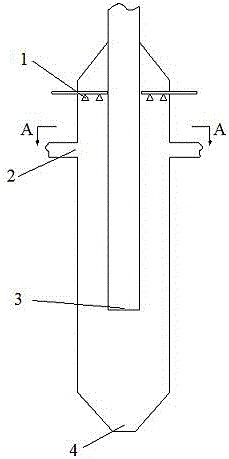

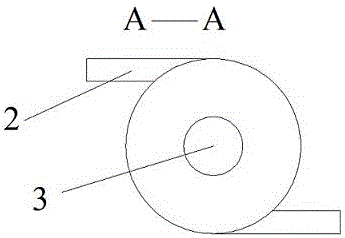

[0021] Such as figure 1 As shown, a sludge slurry gasification device described in this embodiment includes an atomization area and a gasification area from top to bottom; the upper part of the atomization area is provided with a sludge slurry spraying device 1, and the lower part is along There is an inlet 2 for backflow flue gas in the tangential direction; a gas outlet 3 is opened at the lower part of the gasification zone, and an outlet 4 for gasification residue is arranged at the bottom.

[0022] The method of utilizing the above-mentioned device for sludge slurry gasification described in this embodiment is characterized in that it comprises the following steps:

[0023] Step 1. Preparation of sludge slurry: Dewater the sludge, control the moisture content of the sludge at 80% after dehydration, and then use ultrasonic waves to crush the sludge, and the particle size of the crushed sludge is between 40 μm and 50 μm The biomass and lignin-based dispersant are stirred an...

Embodiment 2

[0029] The method of utilizing the above-mentioned device for sludge slurry gasification described in this embodiment is characterized in that it comprises the following steps:

[0030] Step 1. Preparation of sludge slurry: Dewater the sludge, control the moisture content of the sludge at 80% after dehydration, and then use ultrasonic waves to crush the sludge, and the particle size of the crushed sludge is between 20 μm and 30 μm The intermediate biomass and humic acid dispersant are stirred and mixed according to the mass ratio of 1.0:0.6:0.2 to make sludge slurry;

[0031] Step 2. Atomization of the sludge slurry: the sludge slurry is sprayed and atomized to form a droplet group with a droplet size below 1mm, and the outlet velocity of the atomizing nozzle is 200m / s;

[0032] Step 3, gasification of the sludge slurry: the sludge droplets are disturbed by the spiral air flow, close to the inner wall of the gasification furnace, and undergo a gasification reaction at 1000°C t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com