Environmentally-friendly efficient recovery crusher for waste injection molded parts

A technology for injection molding parts and crushers, which is applied in the field of high-efficiency recycling crushers for waste injection molding parts for environmental protection, can solve the problems that the finished products cannot meet the factory requirements, cracking/cracking, and size out of tolerance, etc., and achieve the effect of improving the crushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

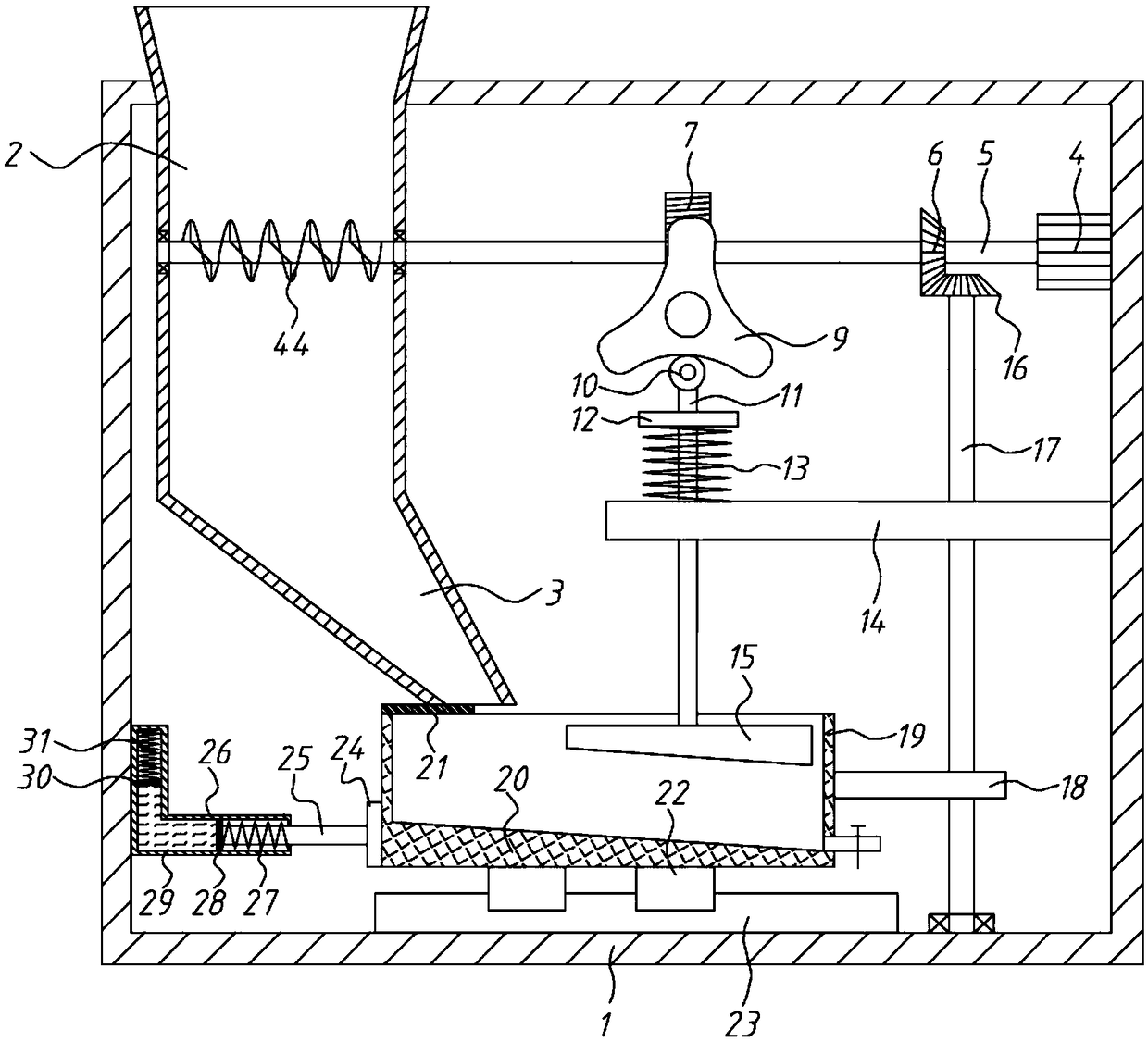

[0044] A crusher for recycling waste injection molded parts for environmental protection, including a casing 1, a feeding hopper 2, a crushing basket 19 and crushing components;

[0045] The feed hopper 2 is installed on the upper left part of the shell 1, the top of the feed hopper 2 protrudes from the top of the shell 1, and the bottom extends into the inner cavity of the shell 1 and is connected with a guide hopper 3, which is inclined downward to the right;

[0046] The middle part of the bottom plate of the housing 1 is equipped with a slide rail 23, the top of the crushing basket 19 is provided with an opening, and the bottom is fixedly connected with a slider 22, and the slider 22 is slidingly connected with the slide rail 23; the top of the left side plate of the crushing basket 19 is connected with a stop Plate 21, baffle plate 21 corresponds to the outlet at the bottom of the guide hopper 3;

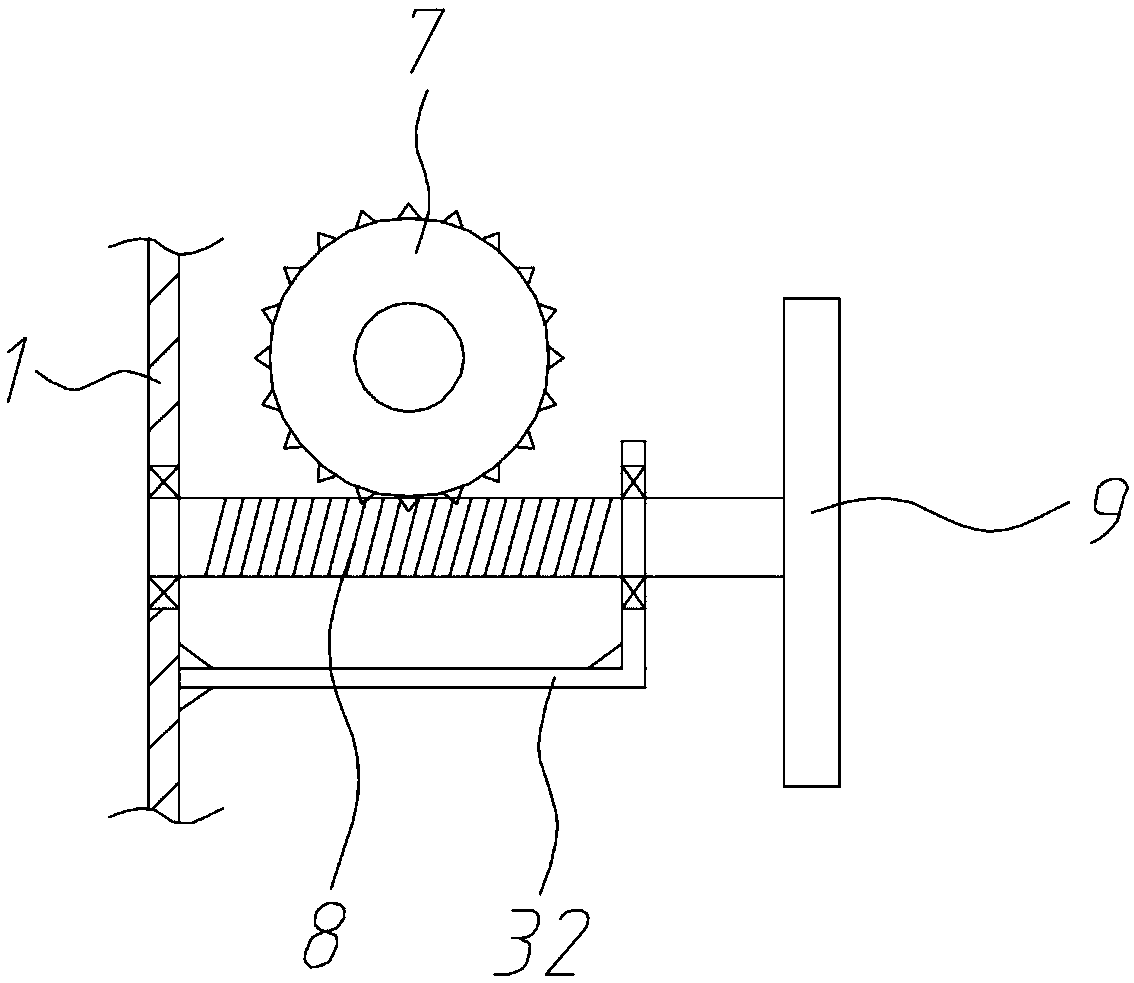

[0047] The crushing assembly includes a driving motor 4, a No. 1 shaft 5, ...

Embodiment 2

[0052] A crusher for recycling waste injection molded parts for environmental protection, including a casing 1, a feeding hopper 2, a crushing basket 19 and crushing components;

[0053] The feed hopper 2 is installed on the upper left part of the shell 1, the top of the feed hopper 2 protrudes from the top of the shell 1, and the bottom extends into the inner cavity of the shell 1 and is connected with a guide hopper 3, which is inclined downward to the right;

[0054] The middle part of the bottom plate of the housing 1 is equipped with a slide rail 23, the top of the crushing basket 19 is provided with an opening, and the bottom is fixedly connected with a slider 22, and the slider 22 is slidingly connected with the slide rail 23; the top of the left side plate of the crushing basket 19 is connected with a stop Plate 21, baffle plate 21 corresponds to the outlet at the bottom of the guide hopper 3;

[0055] The crushing assembly includes a driving motor 4, a No. 1 shaft 5, ...

Embodiment 3

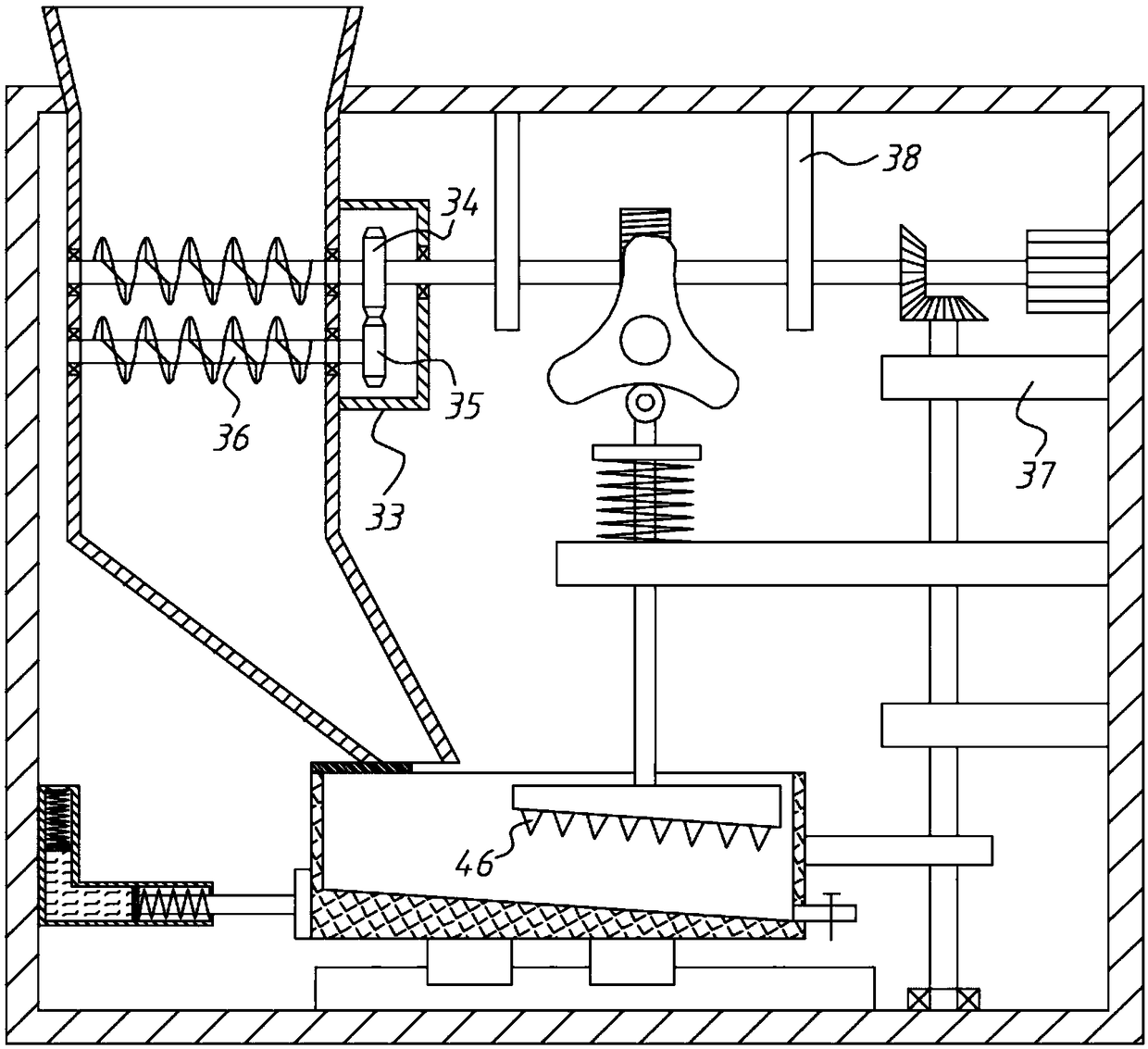

[0060] A crusher for recycling waste injection molded parts for environmental protection, including a casing 1, a feeding hopper 2, a crushing basket 19 and crushing components;

[0061] The feed hopper 2 is installed on the upper left part of the shell 1, the top of the feed hopper 2 protrudes from the top of the shell 1, and the bottom extends into the inner cavity of the shell 1 and is connected with a guide hopper 3, which is inclined downward to the right;

[0062] The middle part of the bottom plate of the housing 1 is equipped with a slide rail 23, the top of the crushing basket 19 is provided with an opening, and the bottom is fixedly connected with a slider 22, and the slider 22 is slidingly connected with the slide rail 23; the top of the left side plate of the crushing basket 19 is connected with a stop Plate 21, baffle plate 21 corresponds to the outlet at the bottom of the guide hopper 3;

[0063] The crushing assembly includes a driving motor 4, a No. 1 shaft 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com