Crushing treatment device for recycling industrial solid waste

A solid waste and processing device technology, applied in the direction of grain processing, application, cocoa, etc., can solve the problems of unsatisfactory, low degree of waste crushing, solid waste cannot be fully impacted, etc., to achieve full crushing process and improve work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

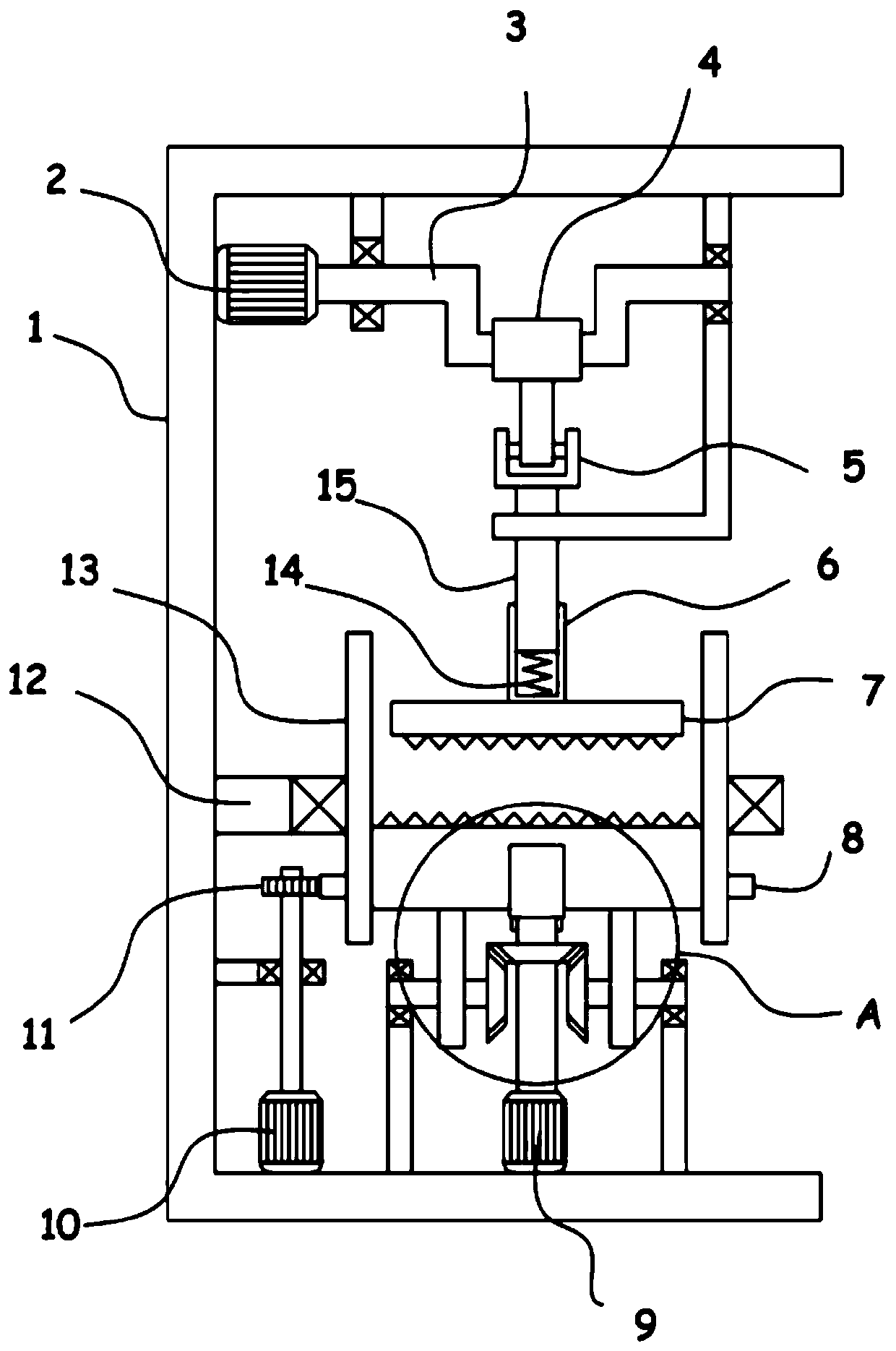

[0021] See Figure 1-3 , A crushing treatment device for industrial solid waste recycling, including a support plate 12 fixed horizontally on a fixed frame 1, a crushing bucket 13 fixed on the support plate 12, and a sliding bottom plate 18 installed in the crushing bucket 13 through a rotating mechanism. The crushing bucket 13 is slidably installed with a crushing plate 7 vertically corresponding to the sliding bottom plate 18, the sliding bottom plate 18 is fixed with serrations 17, and the fixing frame 1 is provided with a lifting mechanism for pushing the sliding bottom plate 18 to vertically slide, so A reciprocating mechanism for driving the crushing press plate 7 to reciprocate vertically is installed on the fixing frame 1.

[0022] The crushing barrel 13 provided in the device is used to store the industrial solid waste to be crushed and refined. The crushing press plate 7 is set to reciprocate up and down under the driving action of the reciprocating mechanism to realize...

Embodiment 2

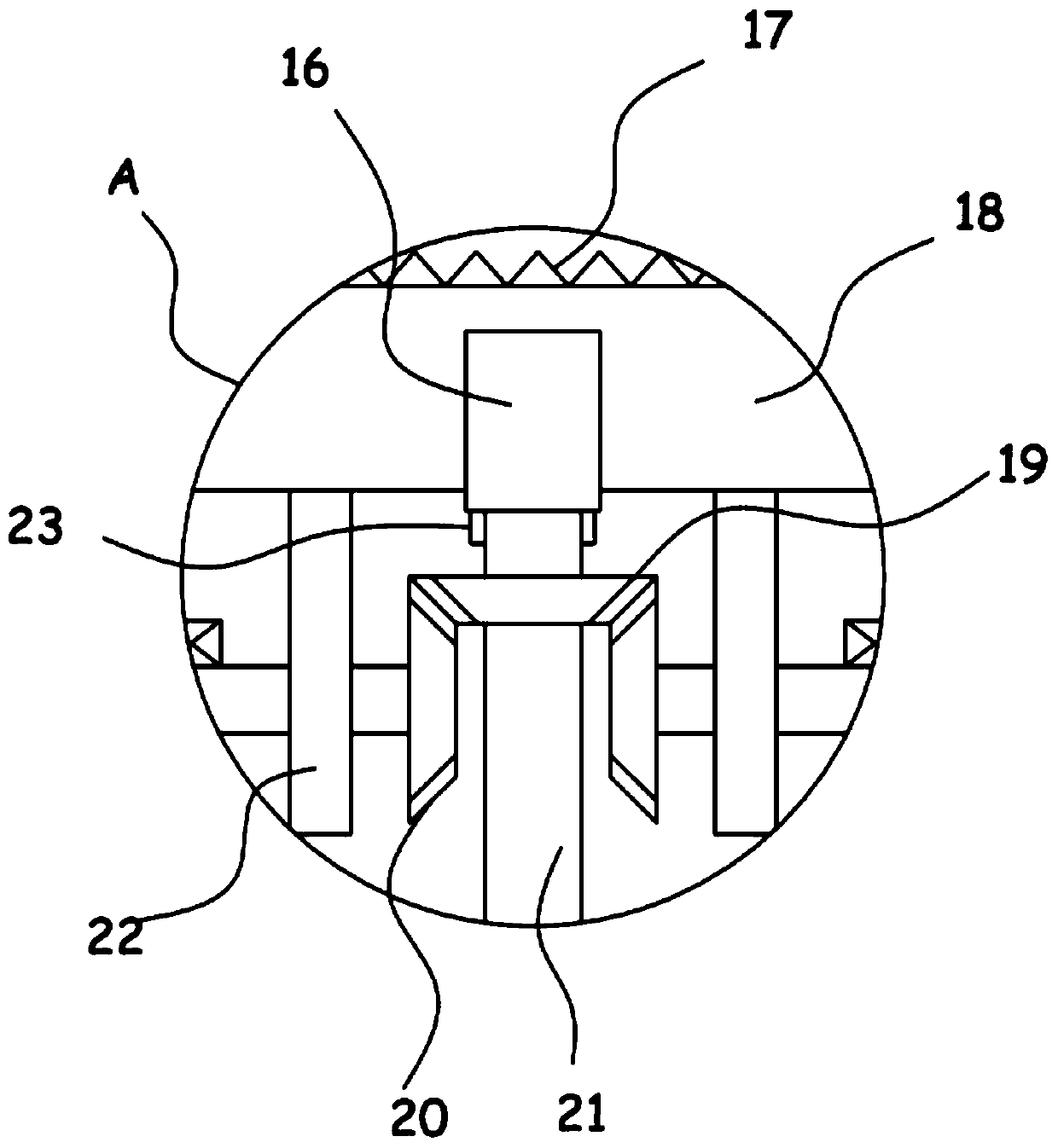

[0028] In order to further improve the efficiency of solid waste crushing and refinement, on the basis of embodiment 1, in addition, the device is equipped with a rotating mechanism, which includes a drive shaft 21 driven by a drive motor II9, and the drive shaft 21 is connected with a sliding bottom plate for transmission. 18 Coaxially fixed limit block 16.

[0029] The drive motor II9 is used to drive the drive shaft 21 to rotate, and the drive shaft 21 drives the limit sleeve 16 to rotate, thereby realizing the rotation of the sliding bottom plate 18, so that the sliding bottom plate 18 and the crushing plate 7 can achieve a rotating and rubbing crushing effect, and solid waste The degree of fragmentation is higher.

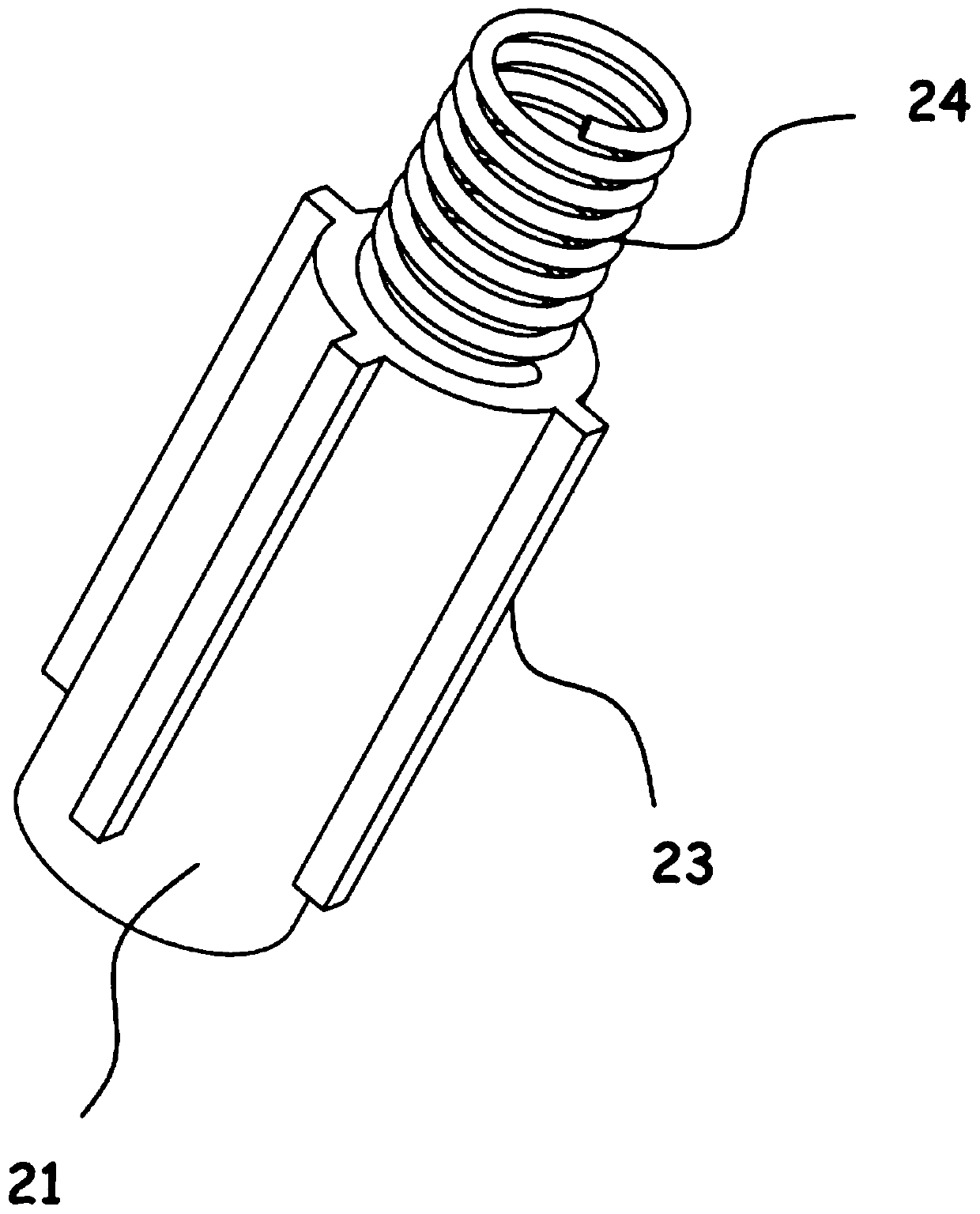

[0030] Further, a transmission bar block 23 slidably embedded in the limit sleeve block 16 is fixed on the side wall of the drive shaft 21, a spring ring II24 is fixedly connected between the transmission bar block 23 and the drive shaft 21, and the drive shaft 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com