Recycling and crushing treatment machine for plastic products and method of use

A technology for plastic products and processors, applied in the fields of plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of poor pulverization effect of hard plastic products, no pulverization of waste plastic products during contact time, incomplete pulverization, etc. Simple and convenient operation, high processing efficiency, good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

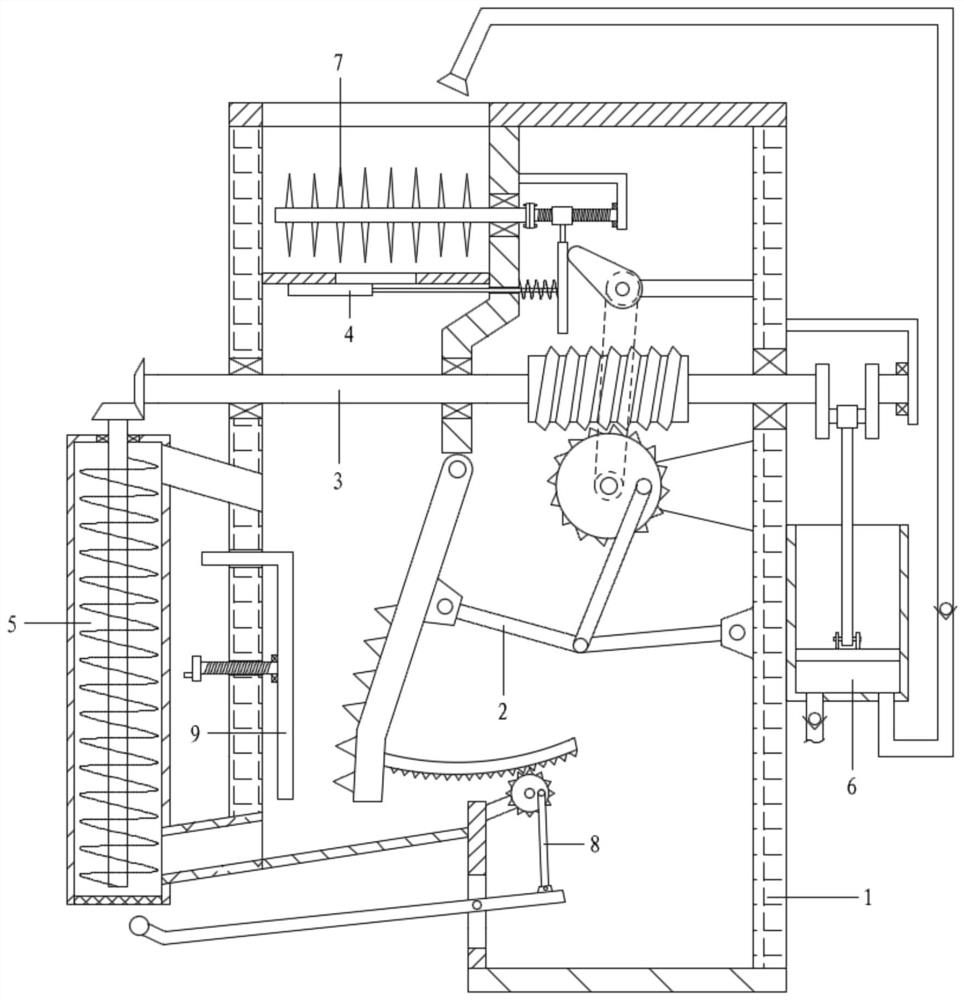

[0064] With reference to the accompanying drawings, a recycling and crushing processor for plastic products includes a shell assembly 1, a crushing assembly 2, a transmission assembly 3, a blanking assembly 4 and a circulation assembly 5;

[0065] The shell assembly 1 includes a shell 101, a No. 1 partition 102, a material guide plate 103, a material guide pipe 104, a return pipe 105 and a No. 2 partition 106; the left part of the top plate of the shell 101 is provided with a feeding port 107, and the bottom surface of the top plate corresponds to The right side of the feeding port 107 is fixedly connected with a No. 1 partition 102; the bottom plate of the casing 101 is fixedly connected with a No. 2 partition 106, and the left side of the No. 2 partition 106 is connected with the bottom end of the left side plate of the casing 101 through the material guide plate 103; The material guide plate 103 is set low on the left and high on the right;

[0066] The circulation assembly...

Embodiment 2

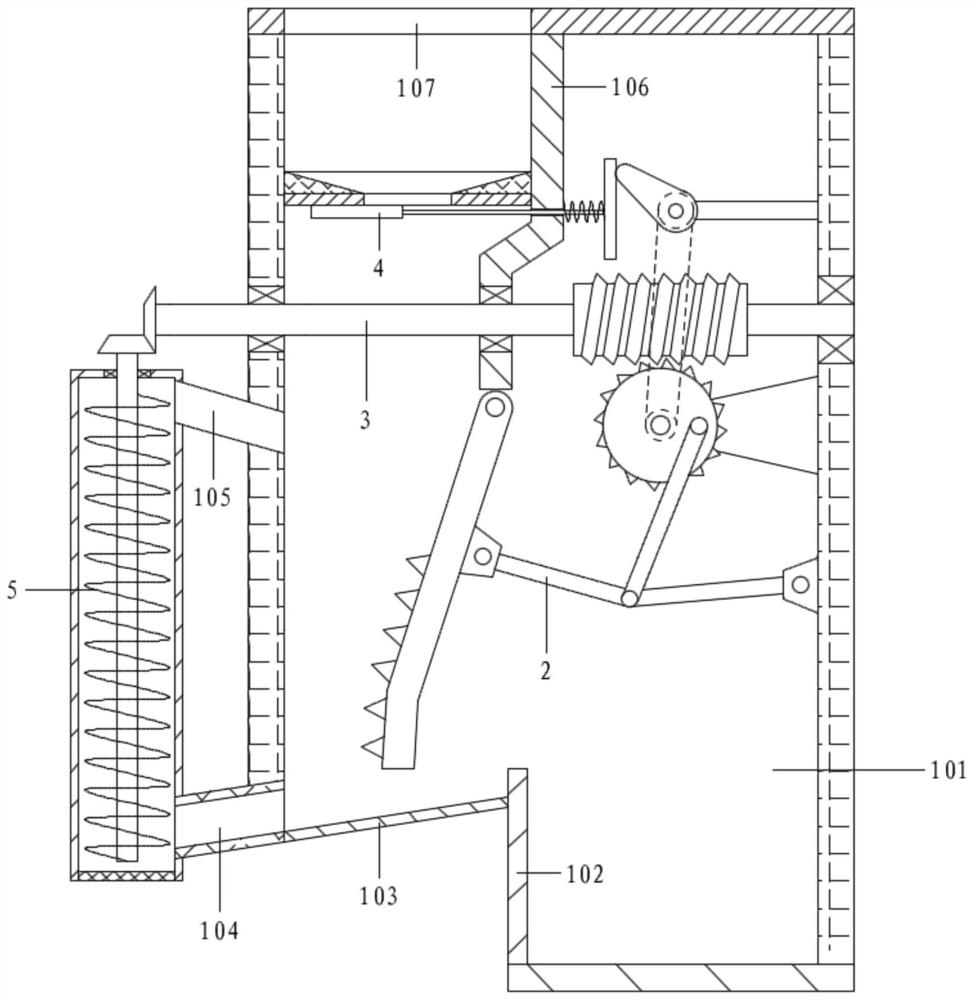

[0068] With reference to the accompanying drawings, a recycling and crushing processor for plastic products includes a shell assembly 1, a crushing assembly 2, a transmission assembly 3, a blanking assembly 4 and a circulation assembly 5;

[0069] The shell assembly 1 includes a shell 101, a No. 1 partition 102, a material guide plate 103, a material guide pipe 104, a return pipe 105 and a No. 2 partition 106; the left part of the top plate of the shell 101 is provided with a feeding port 107, and the bottom surface of the top plate corresponds to The right side of the feeding port 107 is fixedly connected with a No. 1 partition 102; the bottom plate of the casing 101 is fixedly connected with a No. 2 partition 106, and the left side of the No. 2 partition 106 is connected with the bottom end of the left side plate of the casing 101 through the material guide plate 103; The material guide plate 103 is set low on the left and high on the right;

[0070] The circulation assembly...

Embodiment 3

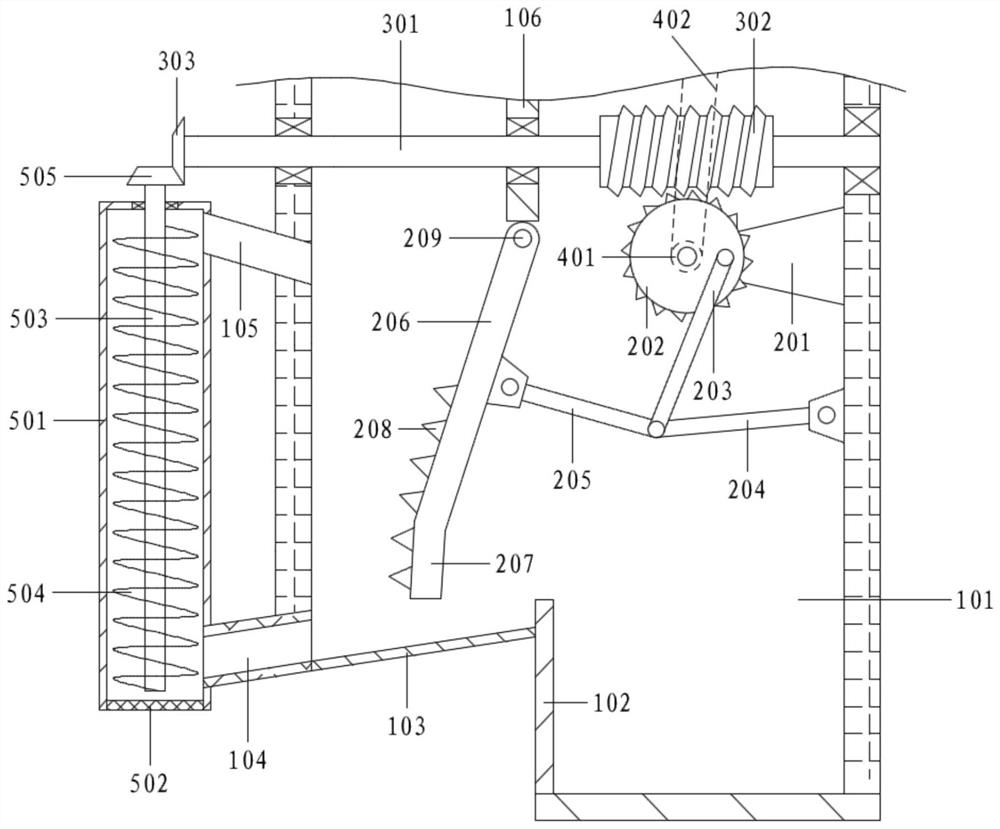

[0085] On the basis of embodiment 2,

[0086] It also includes a crushing assembly 7; the crushing assembly 7 is arranged above the blanking assembly 4, including No. 2 mounting frame 701, No. 1 screw 702, threaded sleeve 703, No. 5 rod 704, coupling 705, No. 3 rotating shaft 706 and crushing knife 707 ;

[0087] The No. 3 rotating shaft 706 is set above the No. 3 partition 410, and is evenly equipped with a crushing knife 707; the right end of the No. 3 rotating shaft 706 runs through and rotates to connect with the No. 1 partition 102; The screw 702 and the No. 2 installation frame 701 are fixedly connected to the right side of the No. 1 partition 102, and the right end of the No. 1 screw 702 is rotated to connect with the No. 2 installation frame 701; the No. 1 screw 702 is screwed with a threaded sleeve 703, which passes through the No. 5 The rod 704 is connected with the right pressure plate 406 .

[0088] Specifically, while the right pressing plate 406 moves left and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com