System and method for charging peripheral hole in smooth blasting of tunnel

A smooth surface blasting and surrounding technology, which is applied in blasting and other directions, can solve problems such as the difficulty in accurately controlling the position and spacing of the drug rolls, the cumbersome procedures of bamboo chip processing and drug roll binding, affecting the effect of light blasting and the stability of surrounding rocks, etc., to achieve improved The effect of improving charge efficiency, improving the quality of smooth blasting, and reducing blasting damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

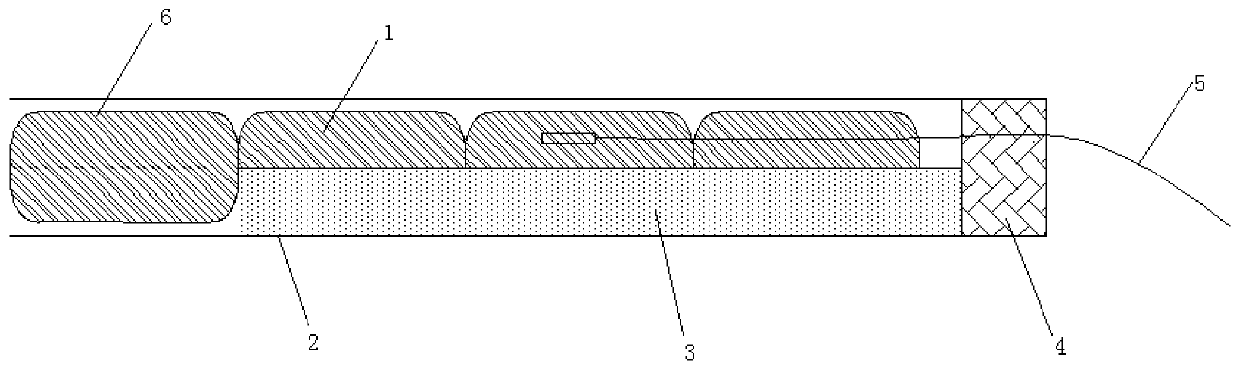

[0072] In this embodiment, the blasting footage of grade III surrounding rock is 3m as an example.

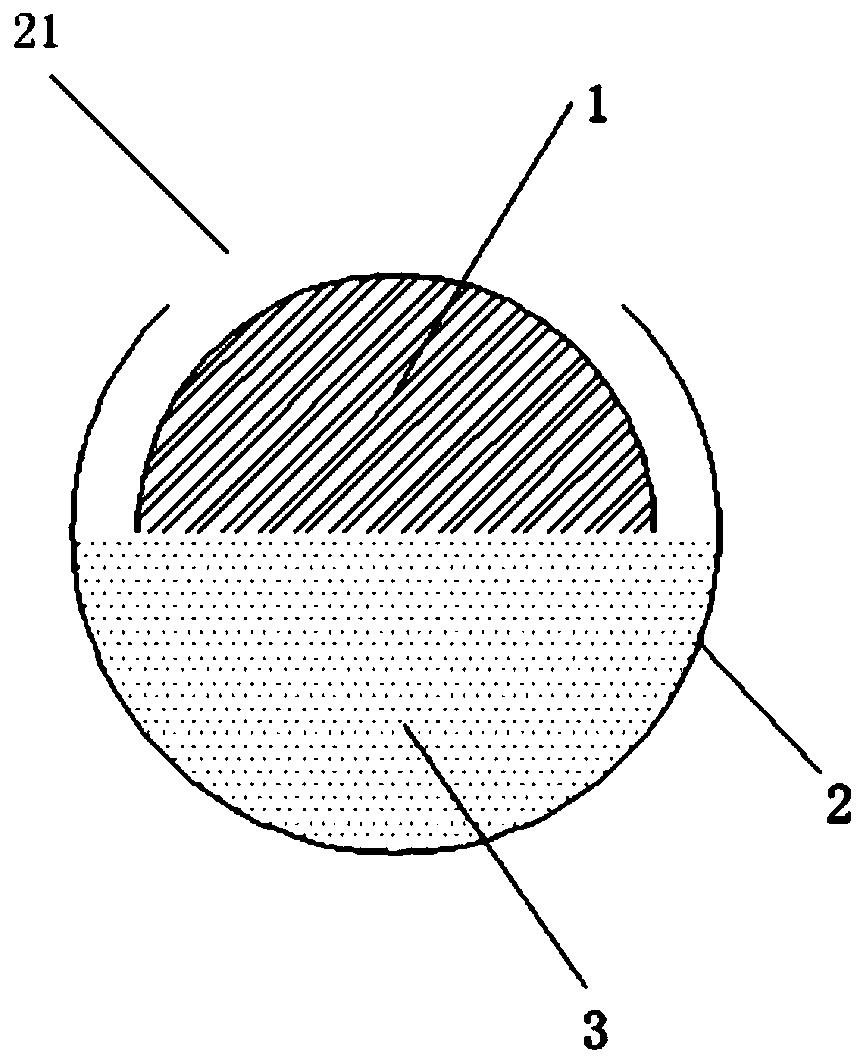

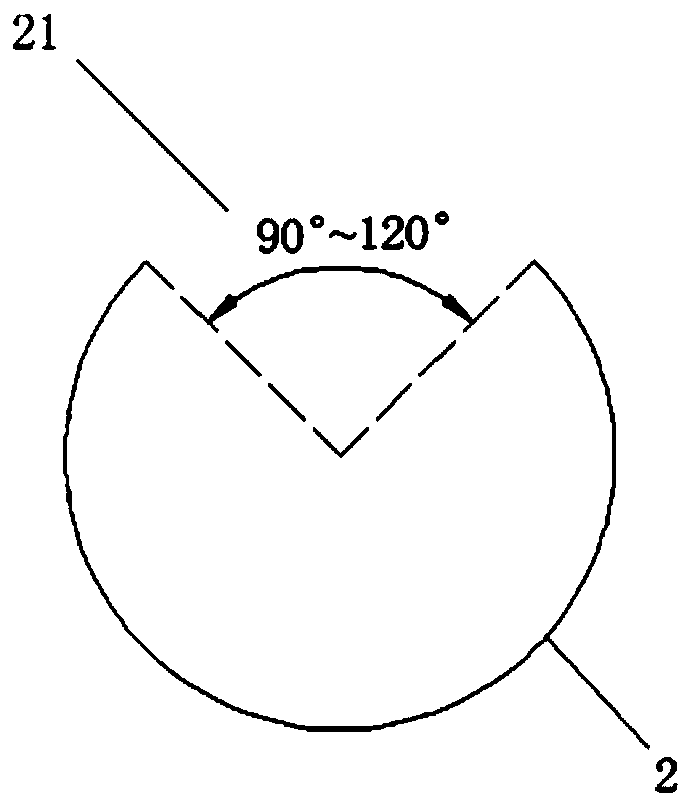

[0073] In the first step, before blasting, the thin-walled PVC pipe is processed into a C-shaped pipe segment. The length of the C-shaped pipe is 3.1m, and the opening angle of the C-shaped pipe is 90°.

[0074] In the second step, use a spray gun to evenly apply the filled one-component polyurethane foam material to the side of the inner wall of the C-shaped tube opposite to the opening, wherein one end of the C-shaped tube is left with a length of medicine roll without applying the foam material as a reinforcement. Charge section, leave 20cm pipe section at the other end to fill up the foam material as a filling section. After the foam material is foamed and hardened, the prefabrication of the charge device with peripheral holes is completed.

[0075] The third step is to transport the finished explosive roll and electronic detonator to the blasting site after cleaning the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com