Electronic product continuous recovery device

A technology for recycling devices and electronic products, which is applied in grain processing, etc., can solve problems such as insufficient recycling efficiency and insufficient continuity, and achieve the effect of eliminating manual screening and improving work output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

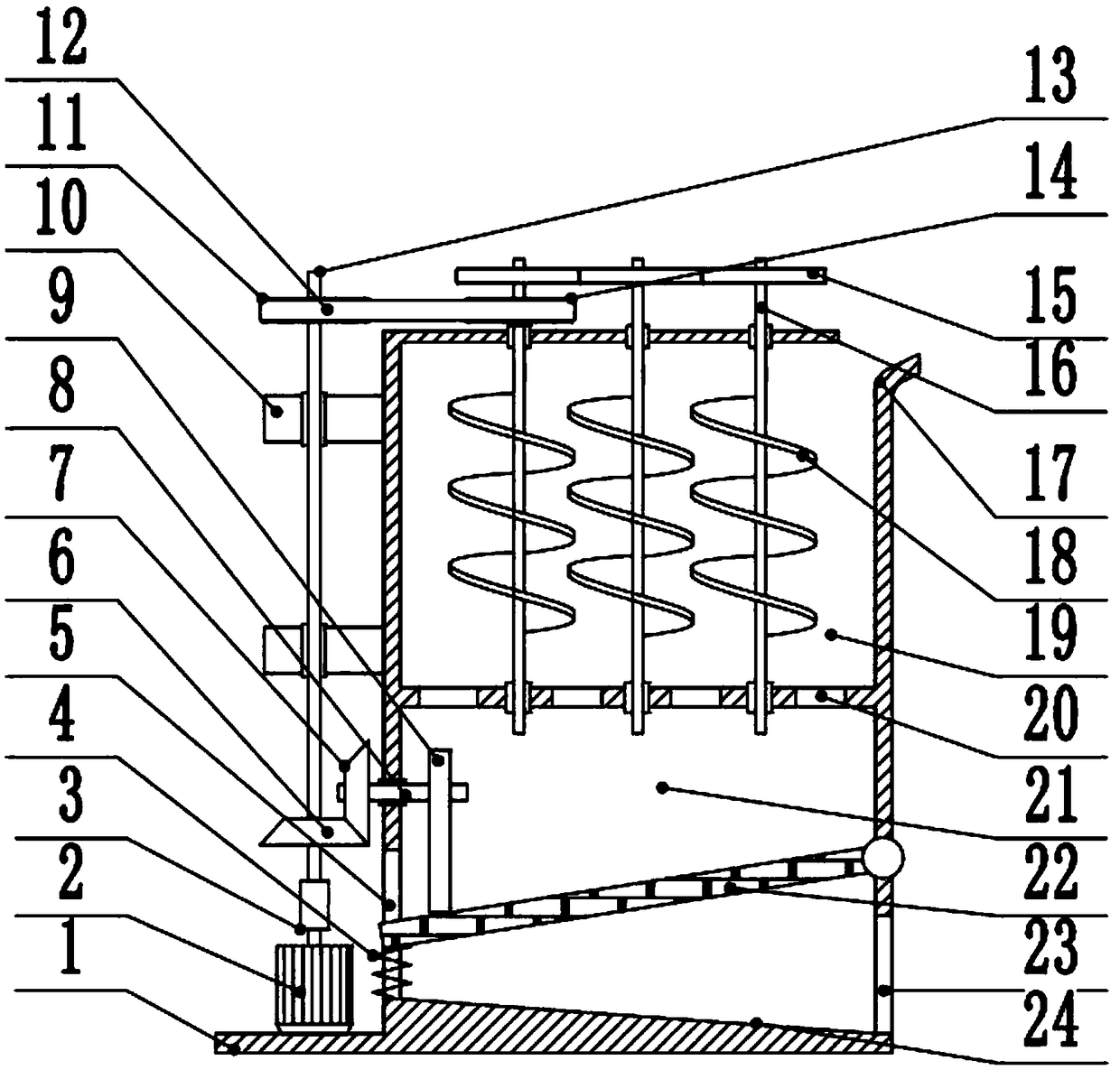

[0019] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

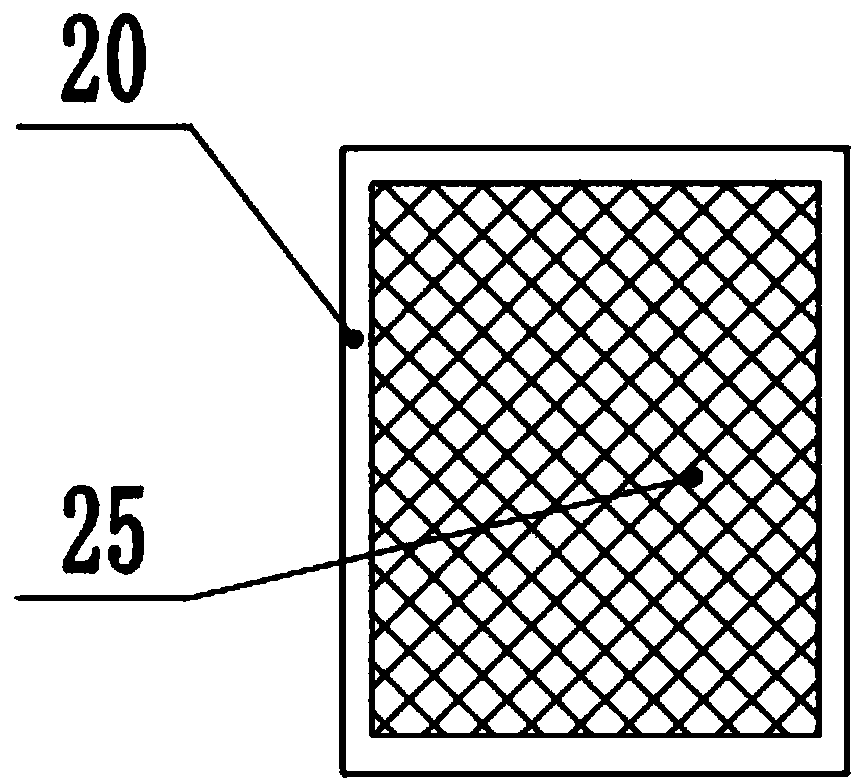

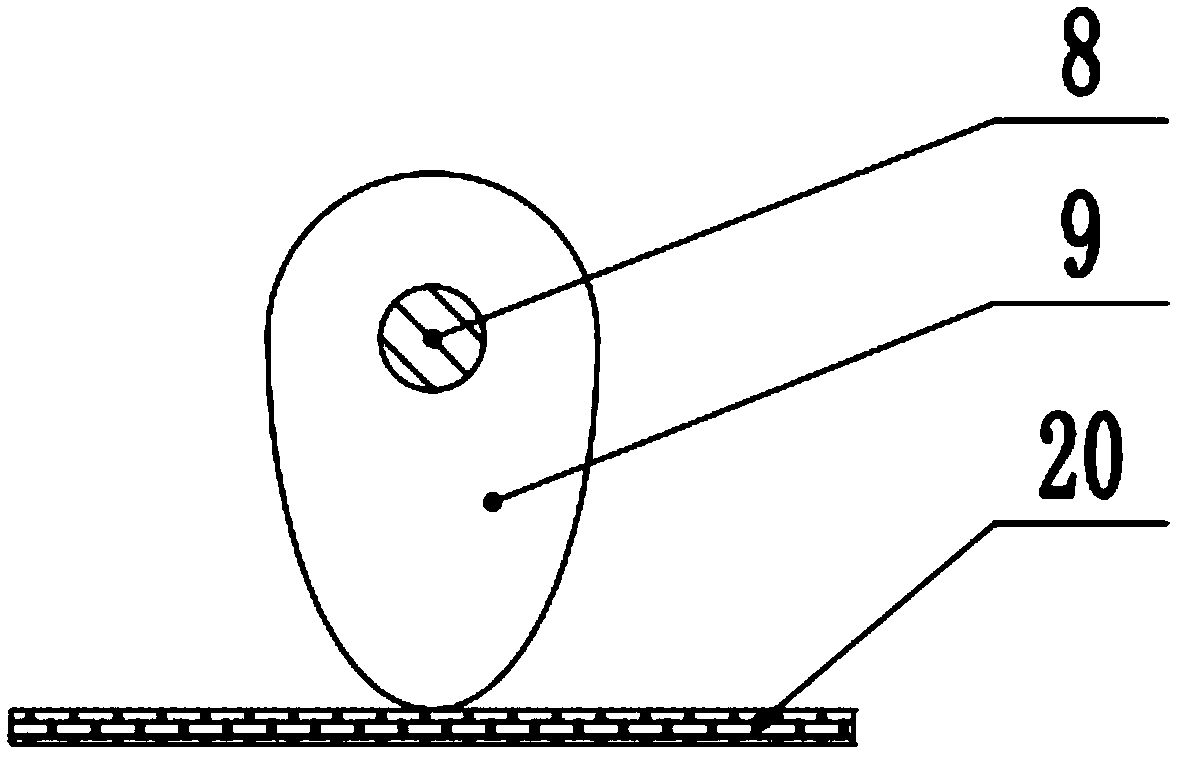

[0020] See Figure 1-3 , A continuous recycling device for electronic products, comprising a frame 1, a drive motor 2 is fixedly installed on the left side of the frame 1, a crushing bin 19 is provided in the upper part of the frame 1, a screening bin 21 is provided in the lower part of the frame 1, and a crushing bin 19 is provided in the upper right corner There is a feed port 17, the material to be crushed can enter the recycling device from the feed port 17, which can be manually put in or set up a conveying device; the lower right corner of the screening bin 21 is provided with a discharge port 23, and the lower part of the screening bin 21 Discharging chute 24 is provided, and discharging chute 24 is provided, so that the crushed material can roll down from the discharging chute 24, and due to its own weight, it is output from the discharge port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com