A rice grain-like porous micro-nano structure znmn 2 o 4 Lithium-ion battery anode material

A lithium-ion battery, micro-nano structure technology, applied in the direction of battery electrodes, negative electrodes, structural parts, etc., can solve the problems of low reversible capacity for high-current charge and discharge, complex preparation process, short cycle life, etc., and achieve product shape and size Controllable, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 0.5mmol of zinc acetate dihydrate, 1mmol of manganese acetate tetrahydrate and 30mmol of ammonium bicarbonate to 40ml of triethanolamine in sequence, and stir to form a clear solution. Then the solution was transferred to a reaction kettle with a polytetrafluoroethylene liner, and reacted at a constant temperature of 180° C. for 10 h. After the completely reacted solution was cooled and precipitated, it was filtered, washed three times with deionized water and absolute ethanol respectively, and dried at 80° C. in a blast drying oven to obtain a white solid precursor powder. The obtained precursor powder was put into a tube furnace, the temperature was raised at a rate of 3°C / min, and heat-treated at 600°C in air for 5h to obtain a brown-yellow product.

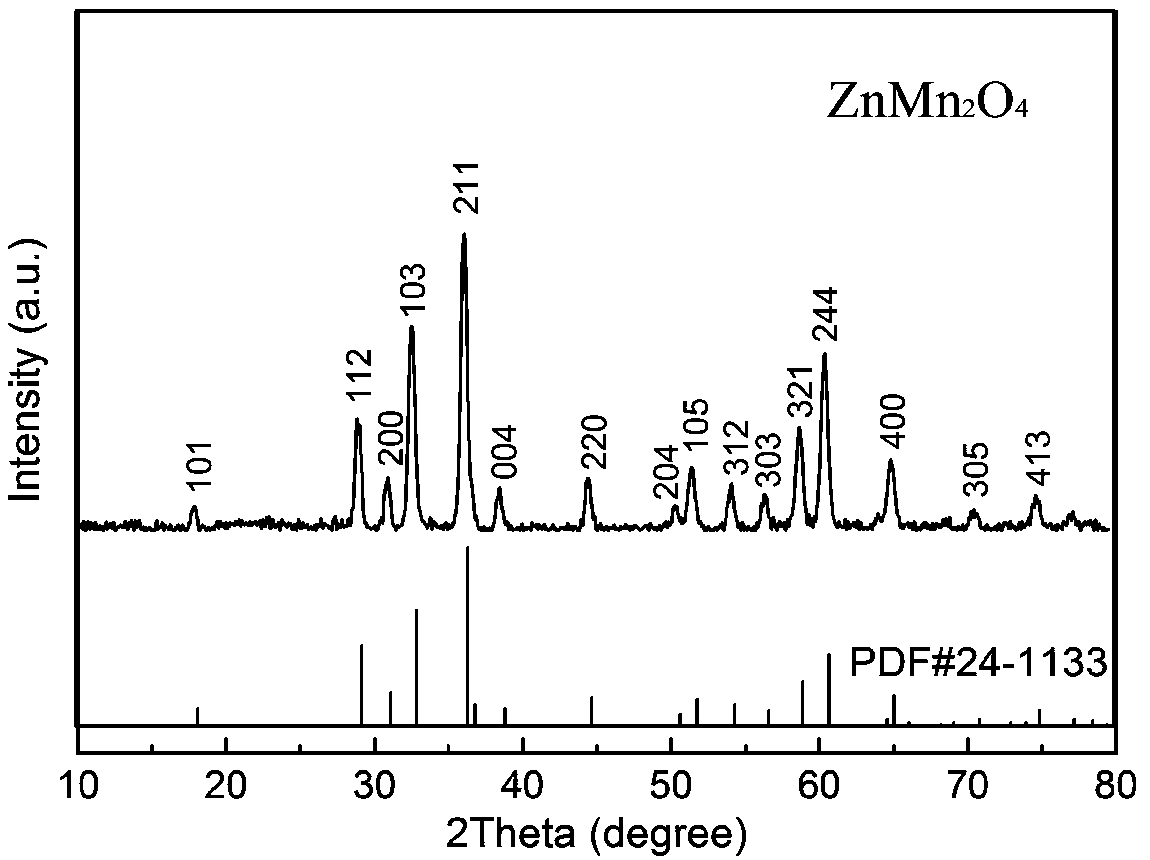

[0031] figure 1 For the ZnMn that embodiment 1 obtains 2 o 4 The XRD pattern of the product. It can be seen from the figure that the prepared product has ZnMn 2 o 4 Spinel phase structure.

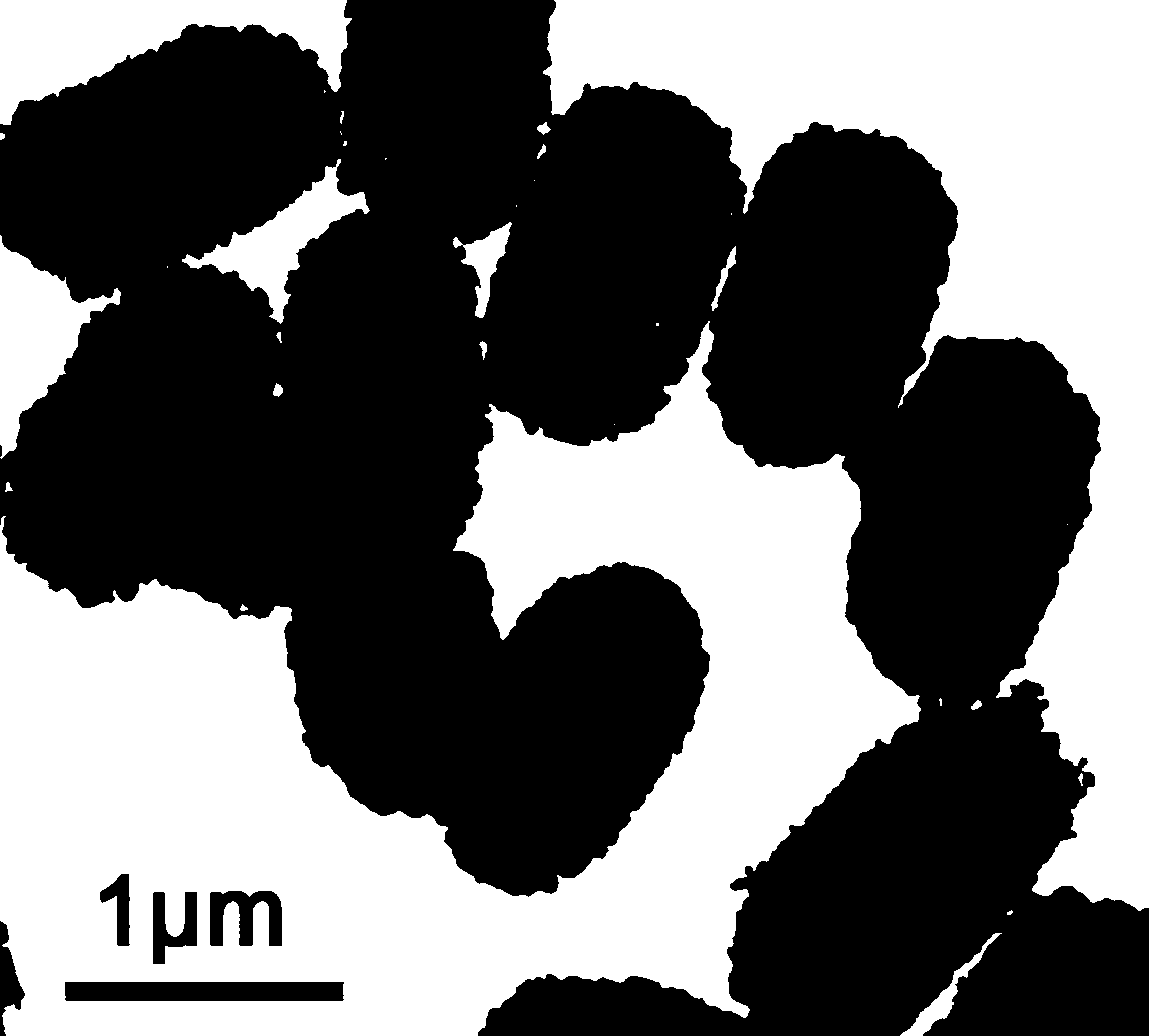

[0032] figure 2...

Embodiment 2

[0037] Add 0.25mmol of zinc acetate dihydrate, 0.5mmol of manganese acetate tetrahydrate and 20mmol of ammonium bicarbonate to 40ml of triethanolamine in sequence, and stir to form a clear solution. Then the solution was transferred to a reaction kettle with a polytetrafluoroethylene liner, and reacted at a constant temperature of 180°C for 0.5h. After the completely reacted solution was cooled and precipitated, it was filtered, washed three times with deionized water and absolute ethanol respectively, and dried at 80° C. in a blast drying oven to obtain a white solid precursor powder. Put the obtained precursor powder into a tube furnace, heat up at a rate of 3°C / min, and heat-treat at 700°C in air for 3h to obtain a brown-yellow product.

[0038] Figure 6 For the ZnMn that embodiment 2 obtains 2 o 4 Scanning electron microscope image of the product precursor. It can be seen from the figure that the solvothermal reaction time is as short as 0.5h, and the precursor micro-...

Embodiment 3

[0040] Add 1mmol of zinc acetate dihydrate, 2mmol of manganese acetate tetrahydrate and 30mmol of ammonium bicarbonate to 40ml of triethanolamine in sequence, and stir to form a clear solution. Then the solution was transferred to a reaction kettle with a polytetrafluoroethylene liner, and reacted at a constant temperature of 160° C. for 1 h. After the completely reacted solution was cooled and precipitated, it was filtered, washed three times with deionized water and absolute ethanol respectively, and dried at 80° C. in a blast drying oven to obtain a white solid precursor powder. The obtained precursor powder was put into a tube furnace, the temperature was raised at a rate of 2°C / min, and heat-treated at 500°C in air for 3 hours to obtain a brown-yellow product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com