Vehicle-mounted eddy strong pulse resonant jet cleaning device

A technology of powerful pulse and cleaning device, applied in the direction of spray device, spray device, cleaning method and utensils, etc., can solve the problems of unsuitable field and mobile operation, unfavorable promotion and use, inconvenient operation, etc., to improve mobility and field operation. Ability to work, reduce manufacturing costs and O&M costs, enhance the effect of erosion and crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

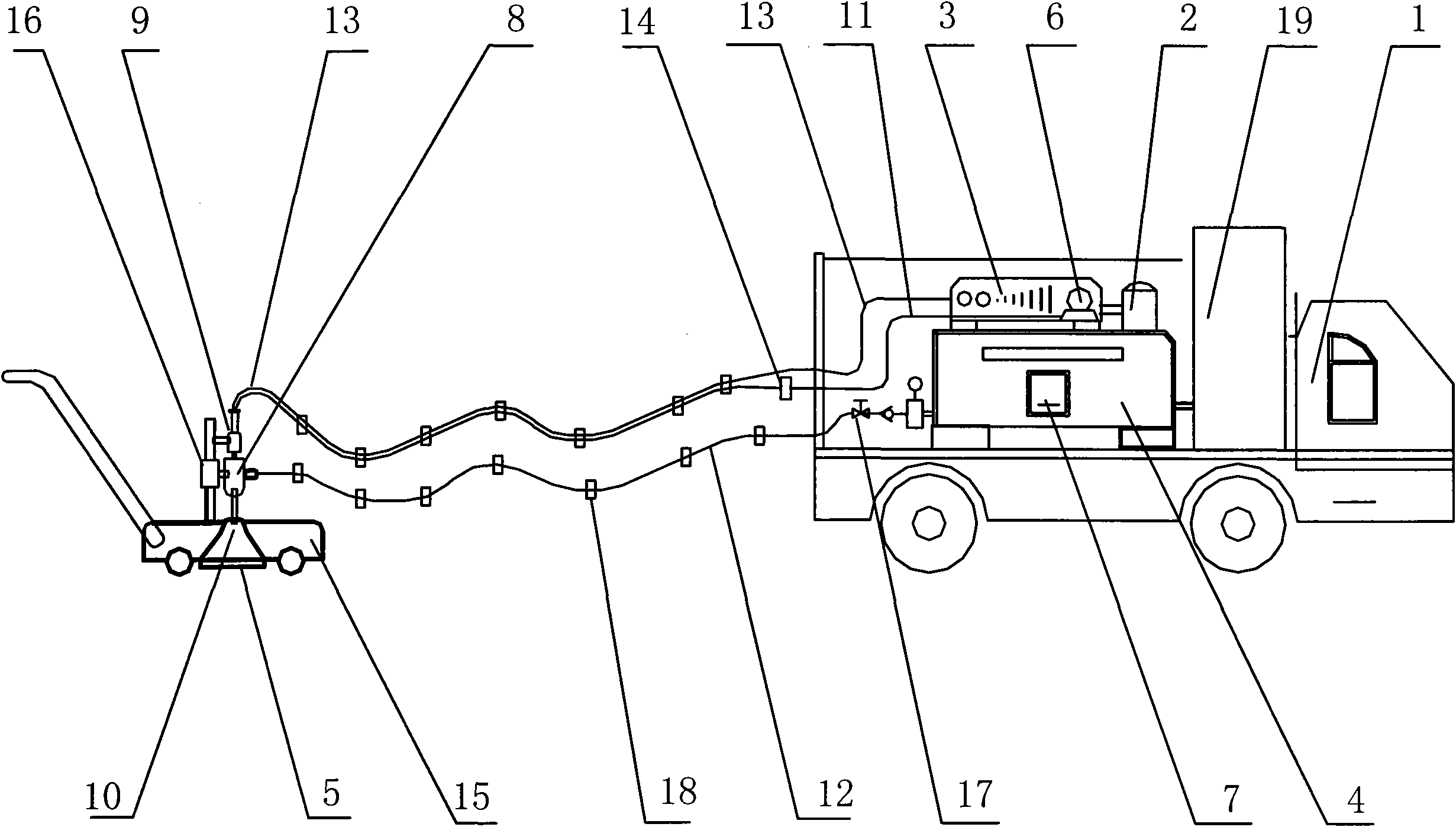

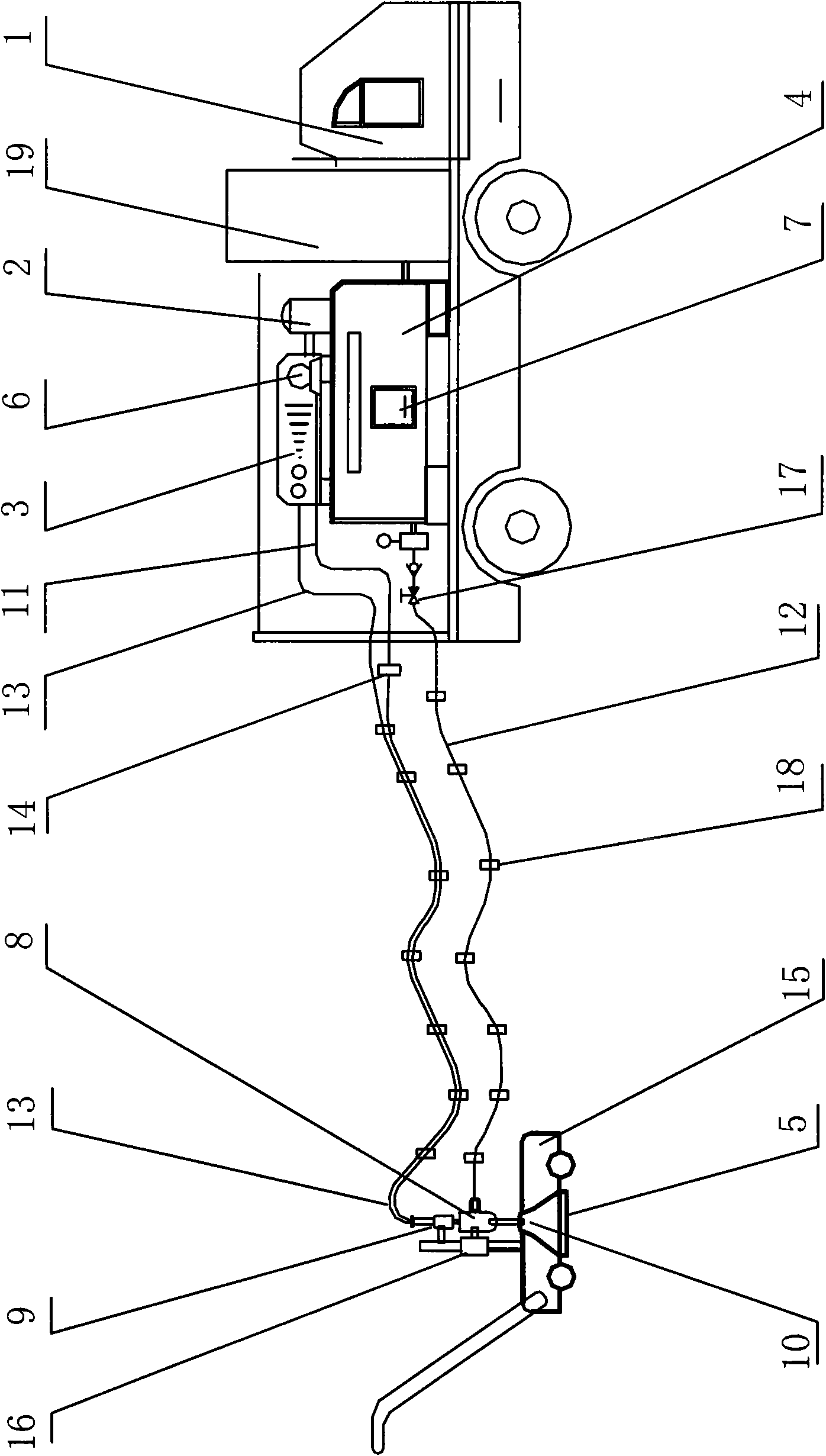

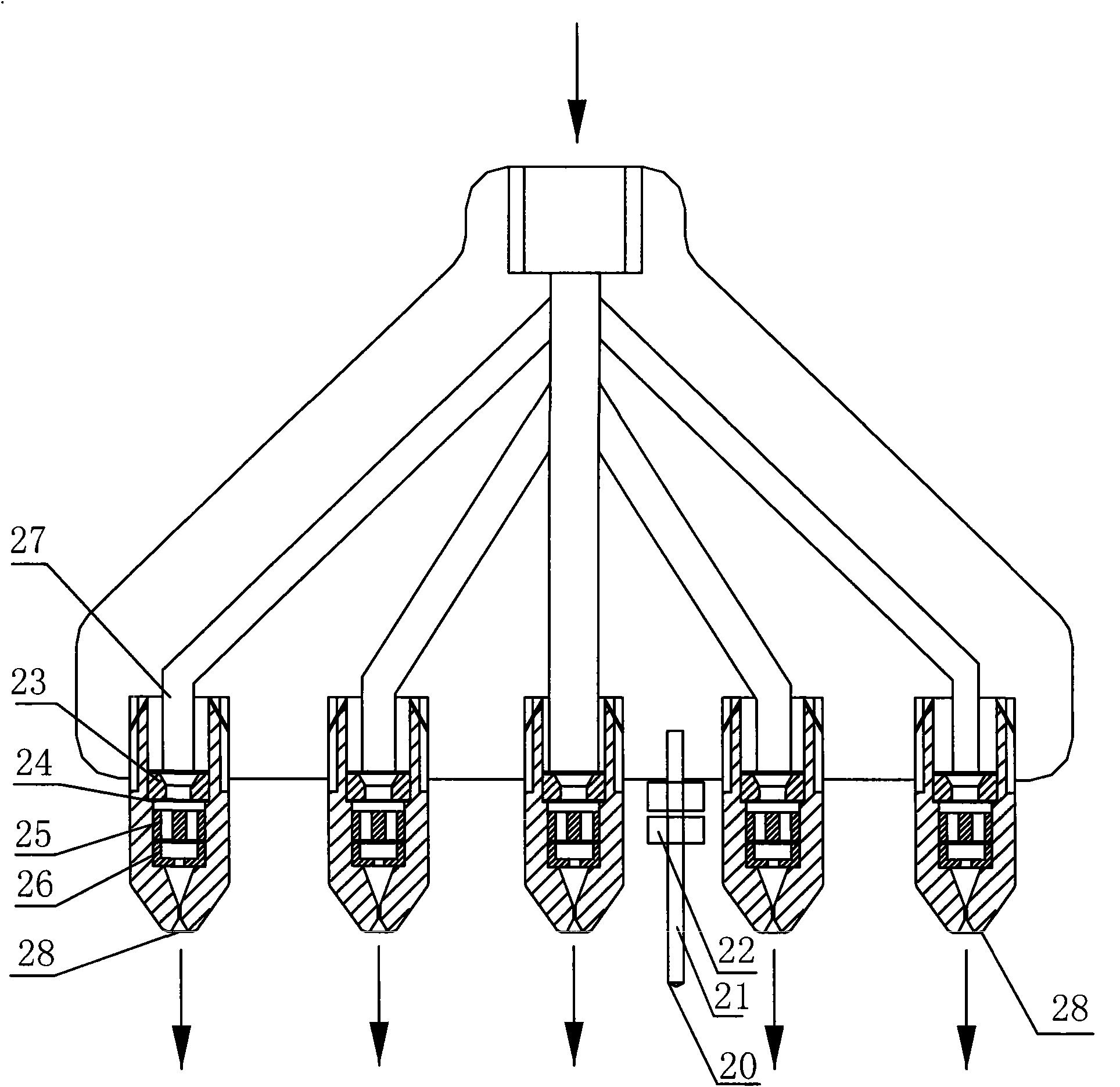

[0021] As shown in Figure 1 and Figure 2, the vehicle-mounted eddy current strong pulse resonance jet cleaning device described in the embodiment of the present invention includes a carrier vehicle 1, a power supply 2, an electrical control device 7, an ultrasonic generating device 3, an air cooling device 6, a high-pressure The water jet generating device 4 and the nozzle device, the nozzle device includes an ultrasonic transducer vibrator 9, a horn 10, a powerful pulse oscillation chamber 8 and a vortex resonance jet nozzle 5; the ultrasonic transducer vibrator 9 passes through the ultrasonic generator 3 The ultrasonic transmission cable 13 is connected to the air cooling device 6 through a cooling compressed air pipe 11 ; the powerful pulse oscillation chamber 8 is connected to the high-pressure water jet generator 4 through a high-pressure water inlet pipeline 12 .

[0022] Water tank 19, electrical control device 7, ultrasonic generator 3, high-pressure water jet generator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com