Preparation method for difficult-to-deformation metal block material room temperature equal-diameter bending passage deformation

A technology of equal-diameter bending and difficult deformation, applied in the field of high-strength and difficult-to-deform metal blocks, it can solve the problems of affecting the grain refinement effect, complicated operation, complicated equipment, etc., achieving obvious grain refining effect and simplifying the process flow. , the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] According to the technical scheme of the present invention, the method for preparing the deformation of the hard-to-deform metal block at room temperature isometric curved channel, comprises the following steps:

[0030] ① Use materials that are difficult to deform at room temperature - industrial pure titanium TA1 and TA2 hot-rolled plates as raw materials, and the hot-rolled plates must be annealed;

[0031] ② Cut the annealed industrial pure titanium TA1 and TA2 hot-rolled plates into billets, cut the head into a certain wedge angle, and polish the surface;

[0032] ③Apply lubricant on the surface of the billet;

[0033] ④Apply lubricant in the cavity of the equal-diameter curved channel deformation mold;

[0034] ⑤ Put the billet coated with lubricant into the channel of the equal-diameter curved channel deformation mold coated with lubricant, and then carry out room temperature equal-diameter curved channel deformation and extrusion deformation on the billet on th...

Embodiment 1

[0047] In this embodiment, industrial pure titanium (TA2) hot-rolled plates are used as raw materials, and the hot-rolled plates are annealed at 700° C., kept for 1 hour, and the annealed industrial pure titanium TA2 hot-rolled plates are cut into cross-sections by using a wire electric discharge machine. The size is 15mm×15mm, the length is 70mm blank, the head wedge is processed with a radius of 23.3mm, and the surface is polished, and the processing roughness is required to be Ra≤3.2μm. Then, the inner surface of the mold cavity (deformation channel) of the ECAP deformation mold with an outer fillet angle Ψ=20° at the blank surface and the channel included angle Ф=110° is uniformly coated with molybdenum disulfide and graphite composite lubricant (10% disulfide disulfide) Molybdenum and 90% graphite), after molybdenum disulfide and graphite powder are mixed evenly, add oily solvent, adjust into paste and apply to the surface of the blank and the mold cavity of the ECAP defor...

Embodiment 2

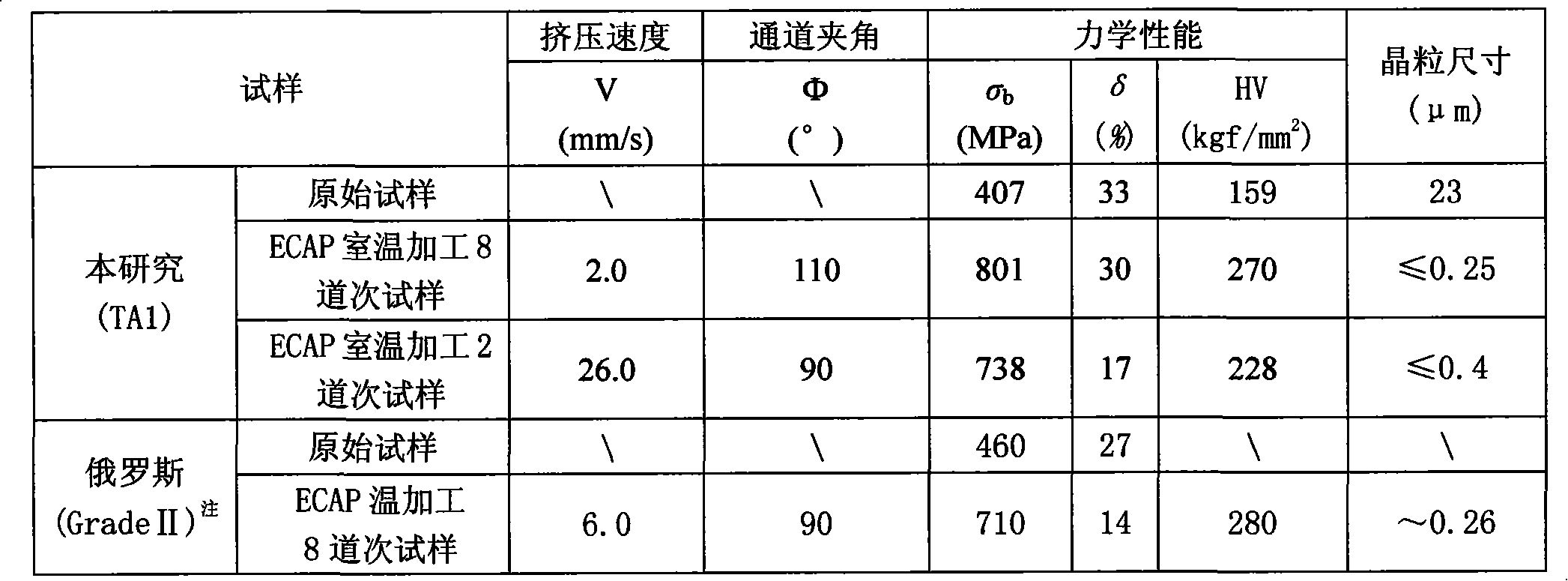

[0049] In this example, industrial pure titanium (TA1) hot-rolled plates are used as raw materials, and the hot-rolled plates are annealed at 700° C., kept for 1 hour, and the annealed industrial pure titanium TA1 hot-rolled plates are cut into cross-sections by wire electric discharge machine. The size is 15mm×15mm, the length is 70mm blank, the head wedge is processed with a radius of 25.5mm, and the surface is polished, and the processing roughness is required to be Ra≤3.2μm. Then, the inner surface of the mold cavity (deformation channel) of the ECAP deformation mold with an outer fillet angle Ψ=20° at the blank surface and the channel included angle Ф=110° is uniformly coated with molybdenum disulfide and graphite composite lubricant (10% disulfide disulfide) Molybdenum and 90% graphite), after molybdenum disulfide and graphite powder are mixed evenly, add oily solvent, adjust into paste and apply to the surface of the blank and the mold cavity of the ECAP deformation mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com