Rope-shaped hemp pulling, cutting and thinning processing equipment with dispersed comb strip

A technology of processing equipment and needle rows, applied in drafting equipment, textiles, papermaking, spinning machines, etc., can solve problems such as drafting top roller slipping and drafting top roller damage reduction, to ensure yarn quality, The effect of shortening the processing flow and improving the efficiency of drawing and cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

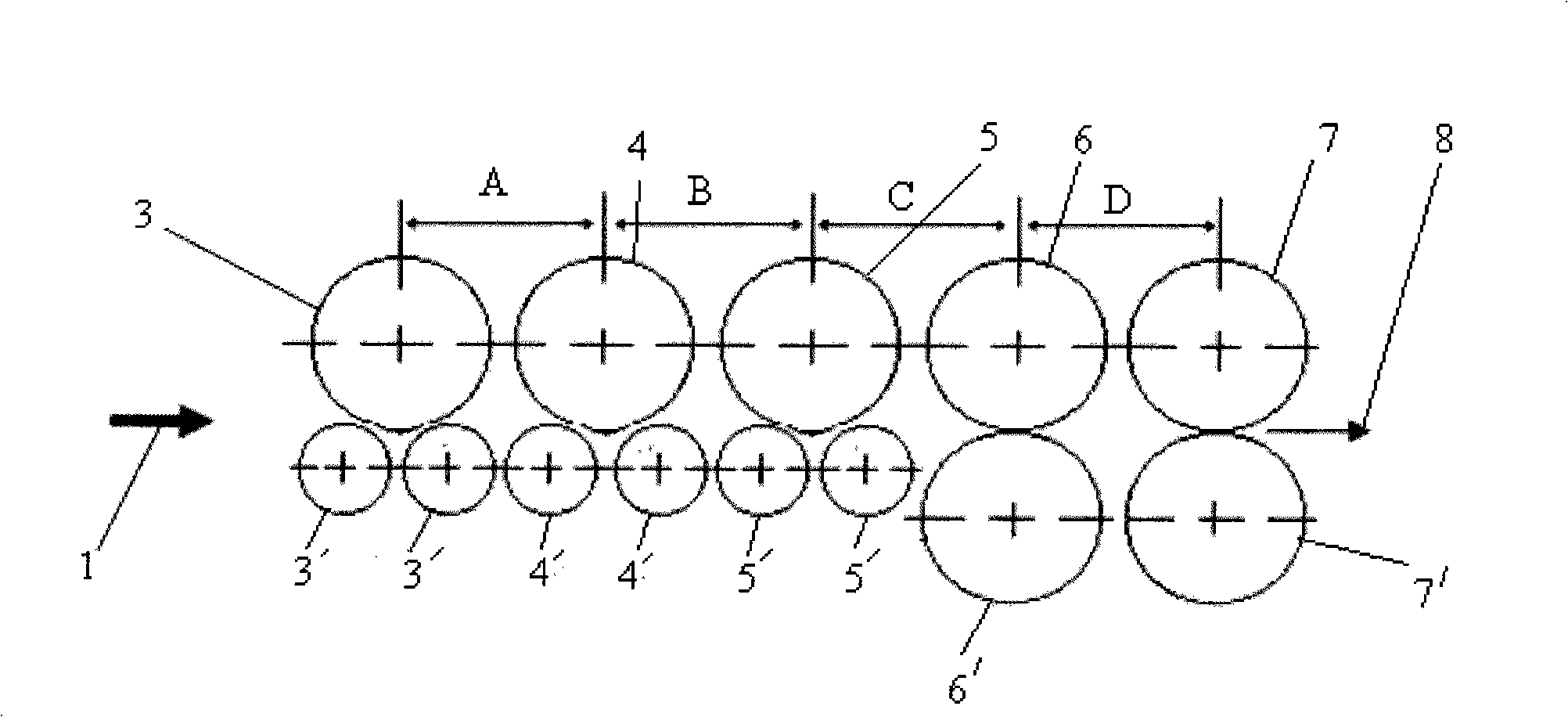

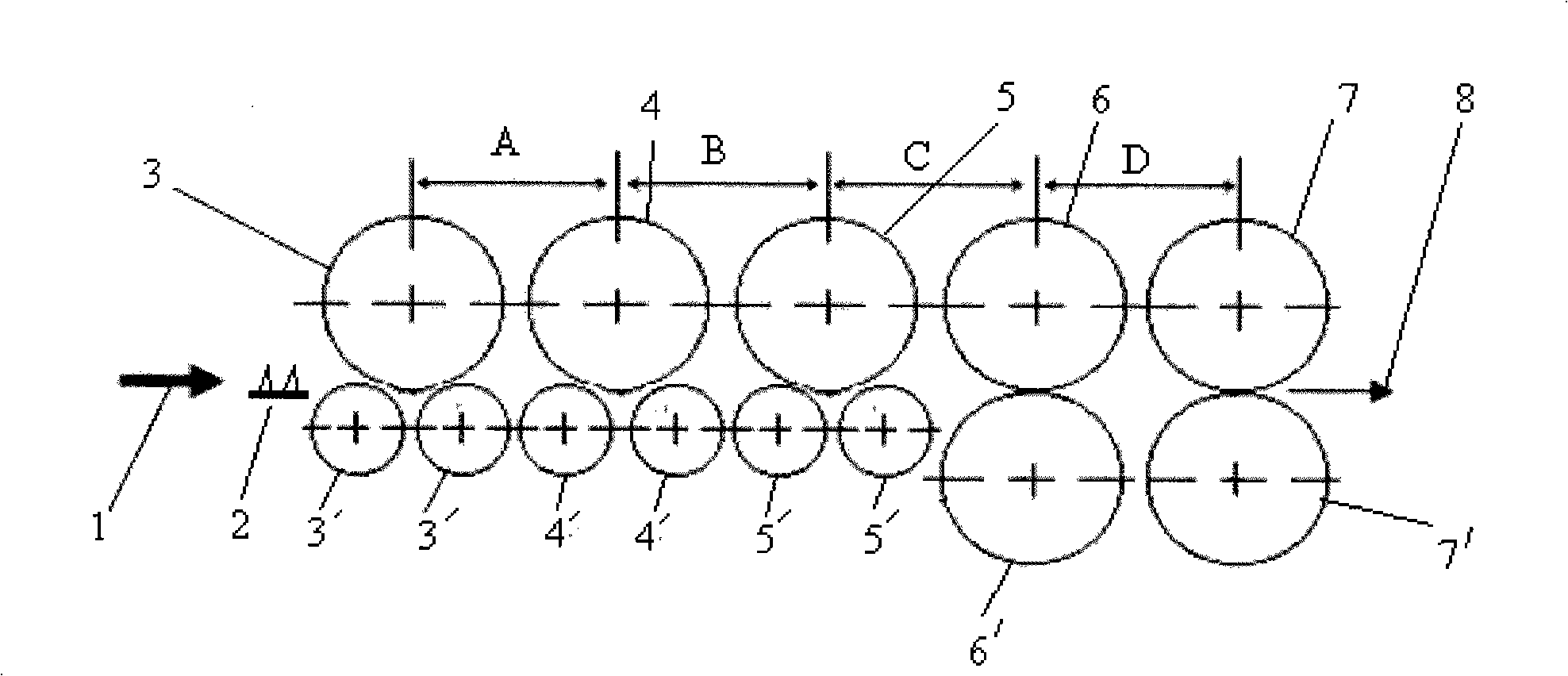

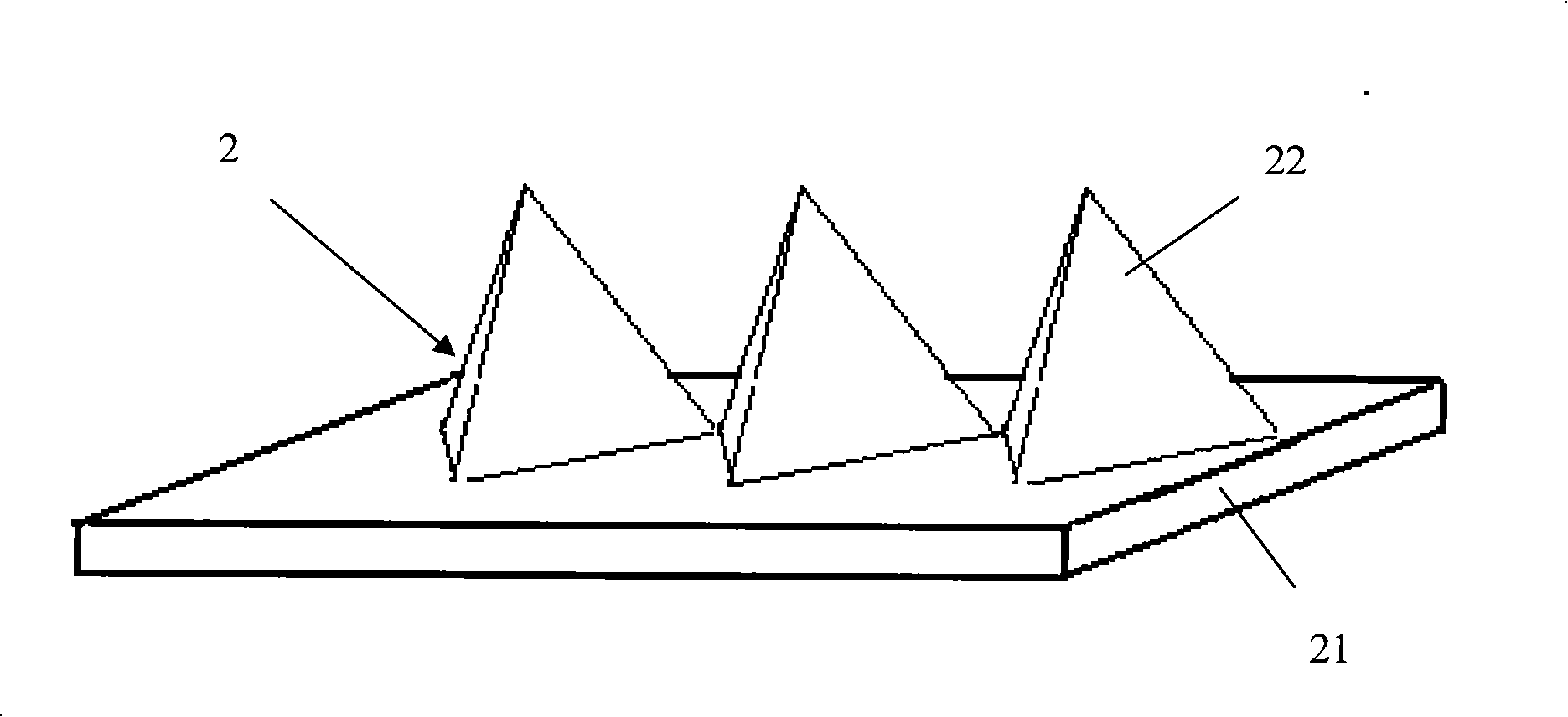

[0025] The rope-shaped hemp drawing-cutting thinning processing equipment with dispersed needle row of the present invention is as figure 2 As shown, the key is in the figure 1 Shown includes the first pre-drafting top roller 3 and the first pre-drafting bottom roller 3', the second pre-drafting top roller 4 and the second pre-drafting bottom roller 4', the third pre-drafting top roller 5 and the third pre-drafting bottom roller 5', the fourth drafting top roller 6 and the fourth drafting bottom roller 6', the fifth main drafting top roller 7 and the fifth main drafting bottom roller 7' A newly conceived dispersing needle row 2 composed of a needle row bottom plate 21 fixed on the frame and pin teeth 22 fixed on the needle row bottom plate 21 is provided in the rope-like hemp strip traction-cutting processing equipment.

[0026] Described dispersing needle row 2 is as image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the length L of the needle row bottom plate 21 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com