Rope-shaped hemp pulling, cutting and thinning processing equipment with dispersed comb strip

A needle row and dispersion technology, which is applied in drafting equipment, textiles, papermaking, spinning machines, etc., can solve the problems of reduced damage to the drafting top roller and slipping of the drafting top roller, shortening the processing process and prolonging the service life. The effect of life, perfect pulling, cutting and refining quality

Inactive Publication Date: 2010-12-01

DONGHUA UNIV +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a rope-shaped hemp stretch-cutting and thinning processing equipment with dispersed needle rows to solve the problem of the semi-wet state of the rope-shaped hemp strips being very high in strength in the existing stretch-cutting and thinning processing. , the drafting process is prone to slippage of the drafting top roller, thus ensuring the smooth implementation of rope-like hemp drawing and cutting refinement, and also significantly reducing the damage of the drafting top roller and prolonging the service life

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Login to View More

Abstract

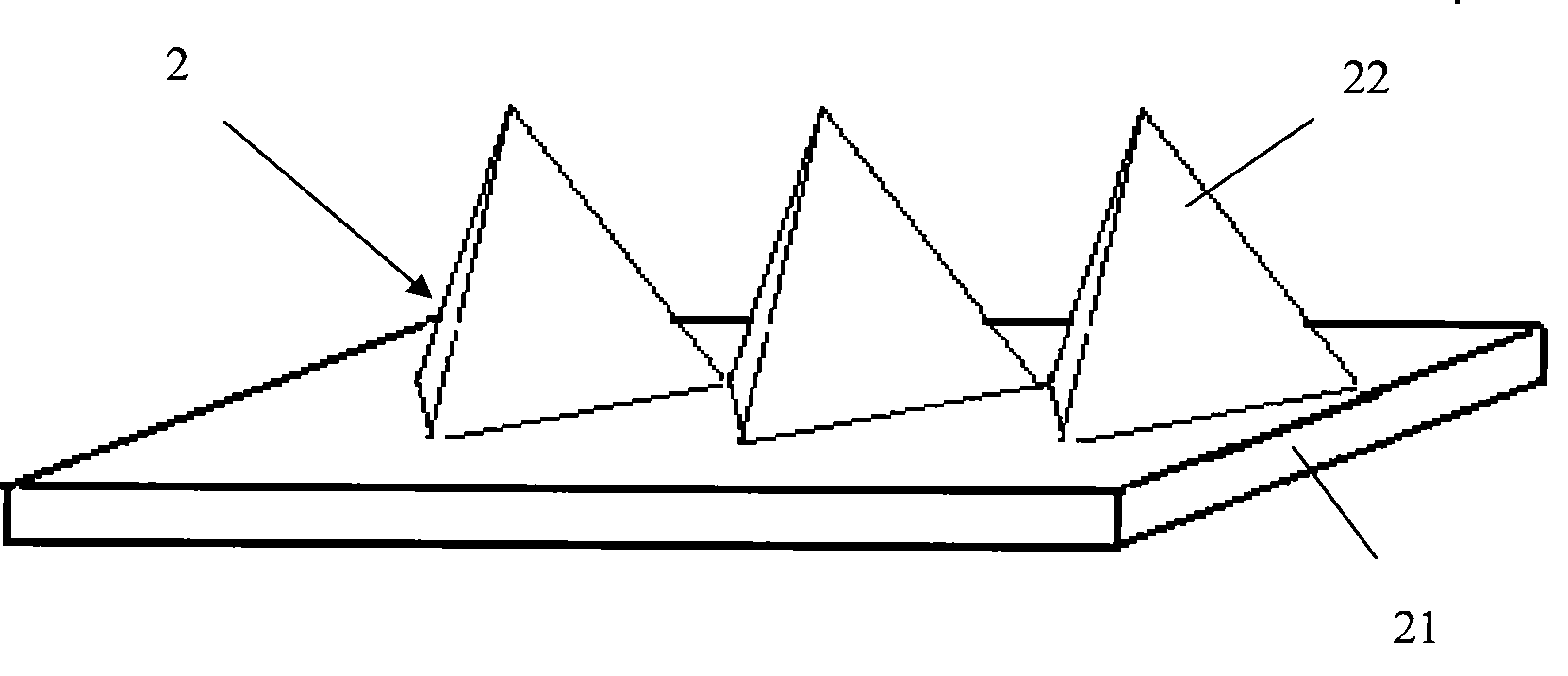

The invention belongs to the textile field, and discloses rope-shaped ramie stripe stretch-breaking refining processing equipment provided with a dispersed hackle, the equipment is newly provided with a dispersed hackle which consists of a hackle bottom plate and pin teeth on the existing rope-shaped ramie stripe stretch-breaking processing equipment. The equipment solves the defects in the existing stretch-breaking refining process that: as rope-shaped ramie stripes after degumming have high strength, a drafting upper leather roller is easy to slip in the drafting process and the rope-shapedramie stripes are difficult to be treated with complete stretch-breaking and refining, thus not only ensuring the continuous and effective running of the stretch-breaking and refining of the rope-shaped ramie stripes, but also prolonging the abrasion period of the upper leather roller.

Description

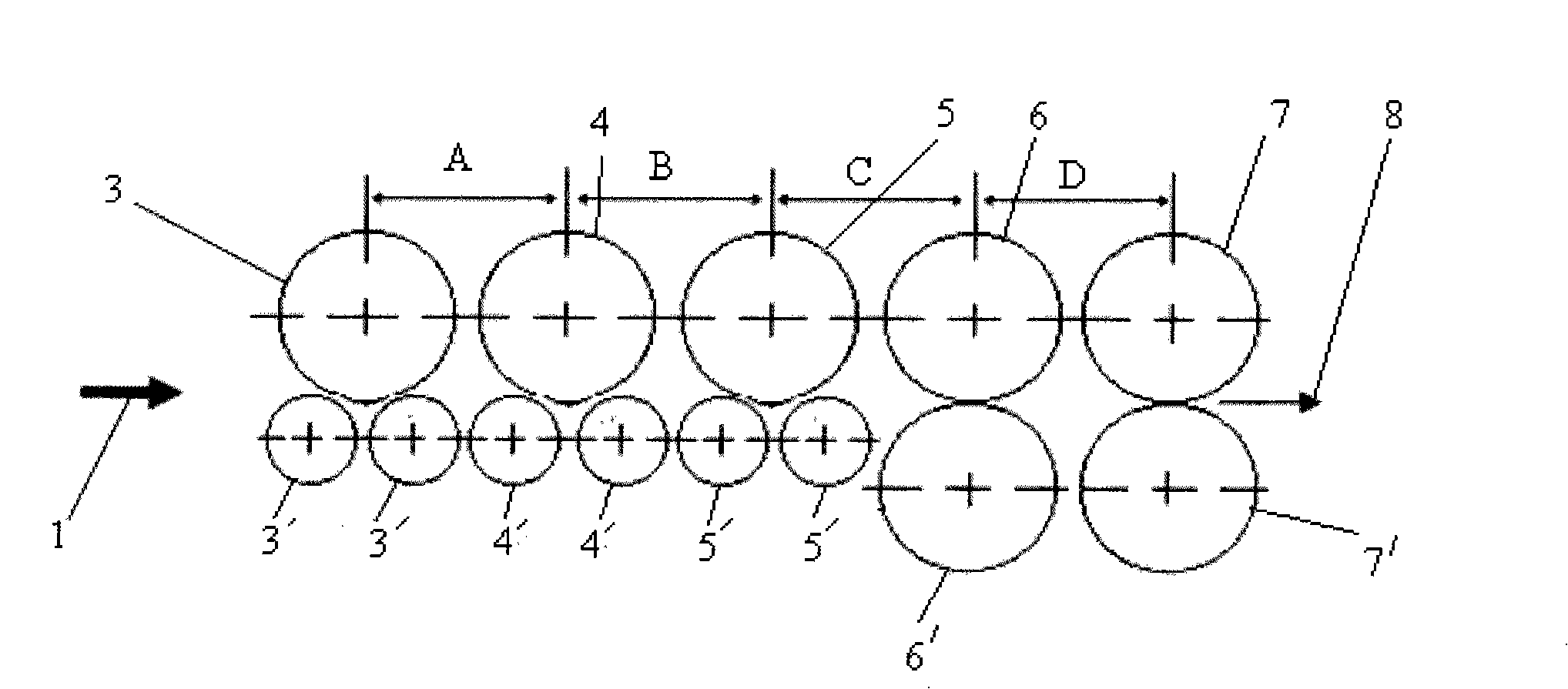

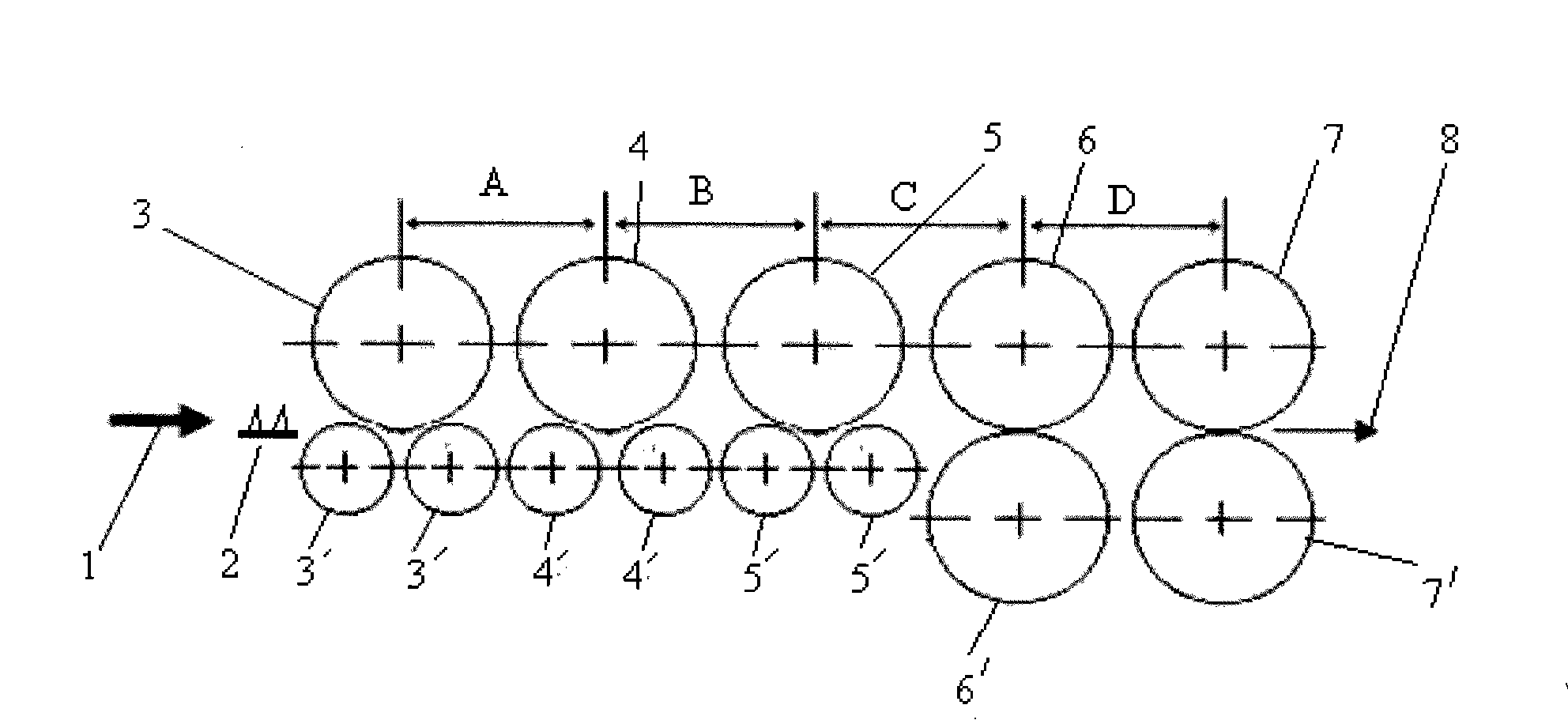

Rope-shaped hemp stretching and thinning processing equipment with dispersed needle row technical field The invention belongs to the field of textiles, and relates to a rope-shaped hemp stretching and thinning processing equipment with dispersed needle rows, which is the key equipment for rope-shaped hemp stretching and thinning. Background technique Existing rope-shaped hemp stretch-cutting processing equipment as shown in Figure 1, it comprises by the first pre-draft upper top roller 3 and the first pre-draft bottom roller 3 ' and the second pre-draft upper top roller 4 and the second pre-drawing The A pre-drafting area composed of the stretching bottom roller 4', the second pre-drafting top roller 4 and the second pre-drafting bottom roller 4', the third pre-drafting top roller 5 and the third pre-drafting bottom roller 5 ’ consisting of the B pre-drafting area, the C consisting of the third pre-drafting top roller 5 and the third pre-drafting bottom roller 5’, the four...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D01H5/02D01H5/00

Inventor 程隆棣俞建勇荣金莲薛文良刘丽芳夏兆鹏袁力军

Owner DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com