Patents

Literature

56results about How to "Obvious reunion phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

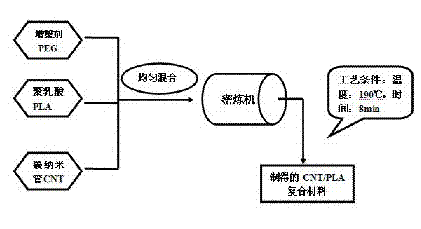

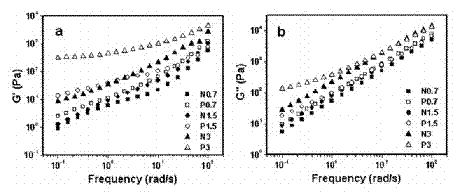

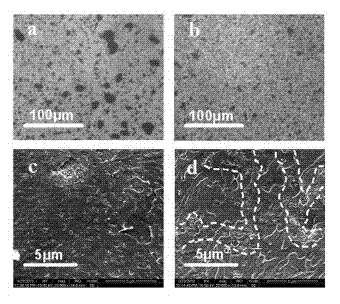

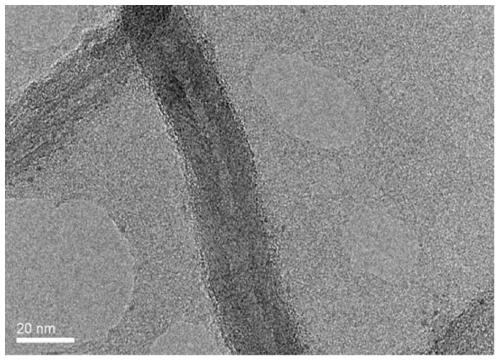

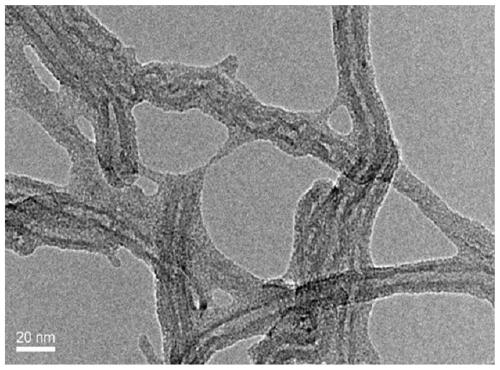

Carbon nano tube (CNT)/ polylactic acid (PLA) composite material and preparation method thereof

The invention belongs to the technical field of macromolecular polymer based composite materials, particularly relates to a carbon nano tube (CNT) / polylactic acid (PLA) composite material and a preparation method thereof. The method is characterized in that a plasticizer is added in the traditional melt blending process, therefore, the affinity of carbon nano tubes with a PLA matrix can be improved and a CNT percolation network can be formed in the PLA. The preparation process is very simple and the preparation cost is lower. The molecular motion of the PLA is limited to a certain extent by the formation of the percolation network, therefore, the composite material shows an approximately solid elastic behavior; and the carbon nano tubes can disperse in the PLA matrix very well, therefore, a solid foundation is laid for improving the properties of the PLA.

Owner:EAST CHINA UNIV OF TECH

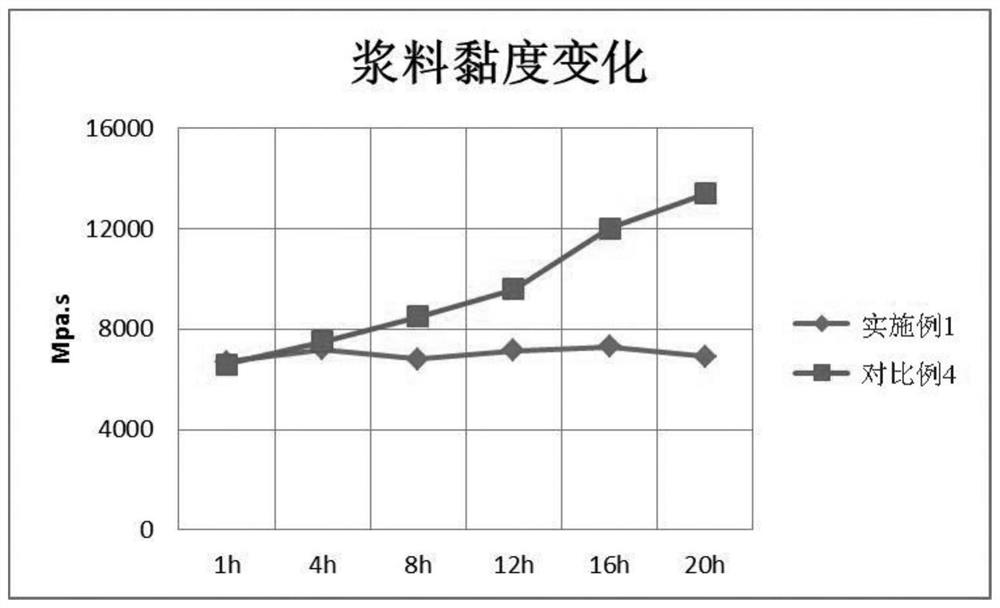

Preparation method of lithium ion battery cathode slurry

InactiveCN111883736AFully dispersedAvoid reunionElectrode manufacturing processesSecondary cellsElectrical batteryAdhesive

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a preparation method of lithium ion battery positive electrode slurry. The method comprises the following steps: S1, adding a conductive agent into a dispersing agent, and performing stirring and dispersing to obtain a conductive agent dispersion liquid with the solid content of 0.5-3%; S2, dissolving an adhesive in a solvent, and acquiring an adhesive solution with the solid content being 5-9%; S3, adding the adhesive solution into the conductive agent dispersion liquid, performing pre-stirring,and then fully stirring to obtain mixed slurry; S4, adding a positive electrode active material into the mixed slurry, performing pre-stirring, and then fully stirring to obtain positive electrode slurry with the solid content of 58-65%; wherein the step S1 and the step S2 are simultaneously carried out, the step S1 is firstly carried out and then the step S2 is carried out, or the step S2 is firstly carried out and then the step S1 is carried out. Compared with the prior art, the preparation method is high in preparation efficiency, the prepared positive electrode slurry is uniformly dispersed and good in stability, and the overall performance of the lithium ion battery can be improved.

Owner:HUIZHOU LIWINON NEW ENERGY TECH CO LTD

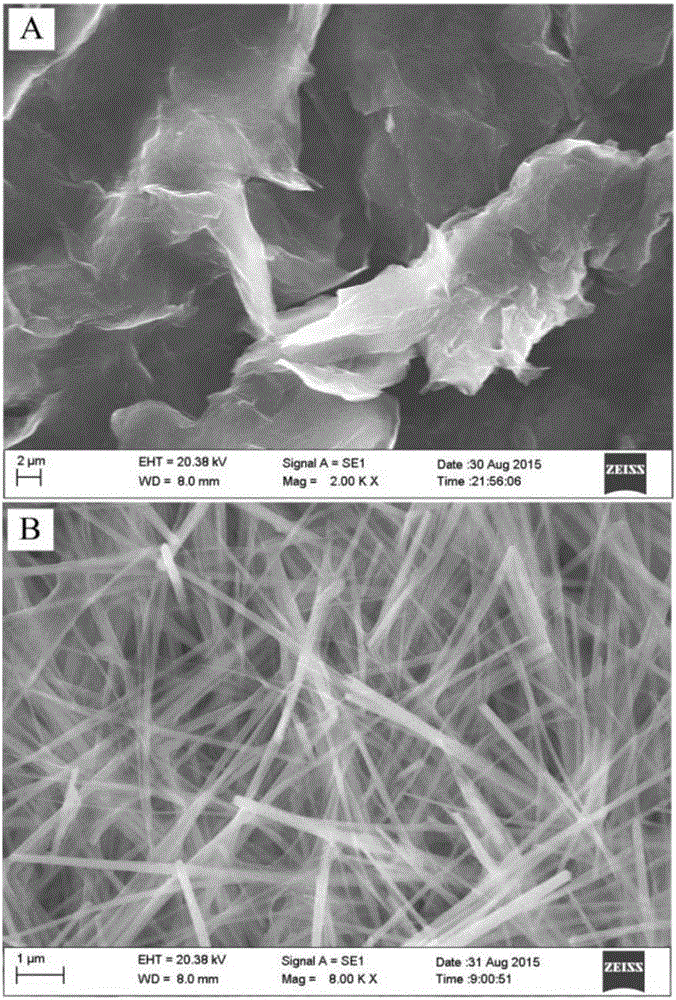

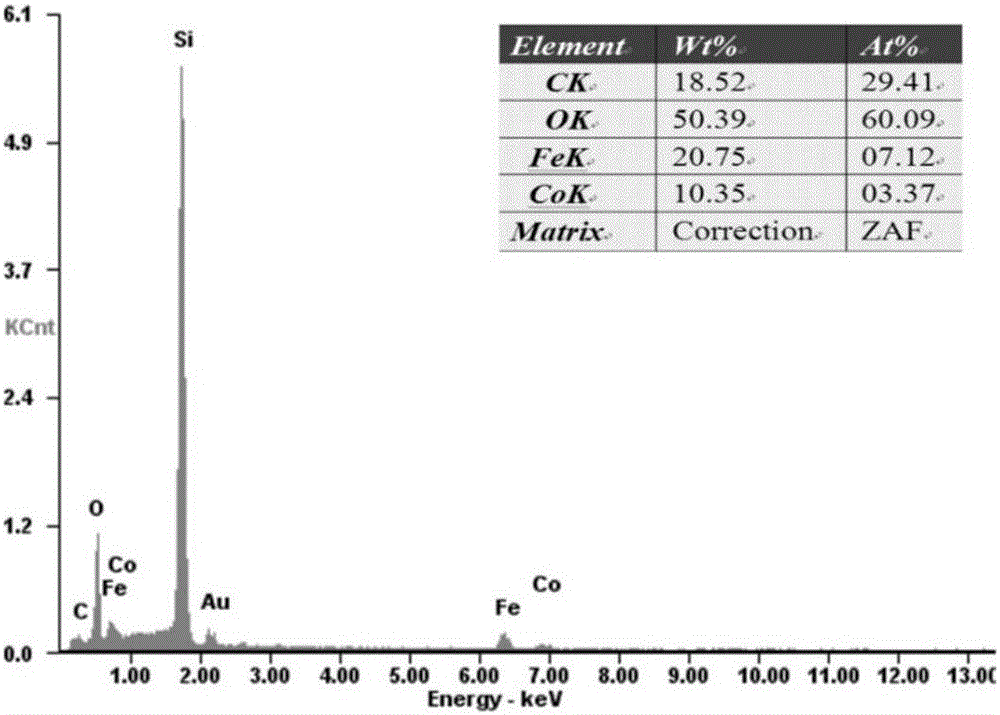

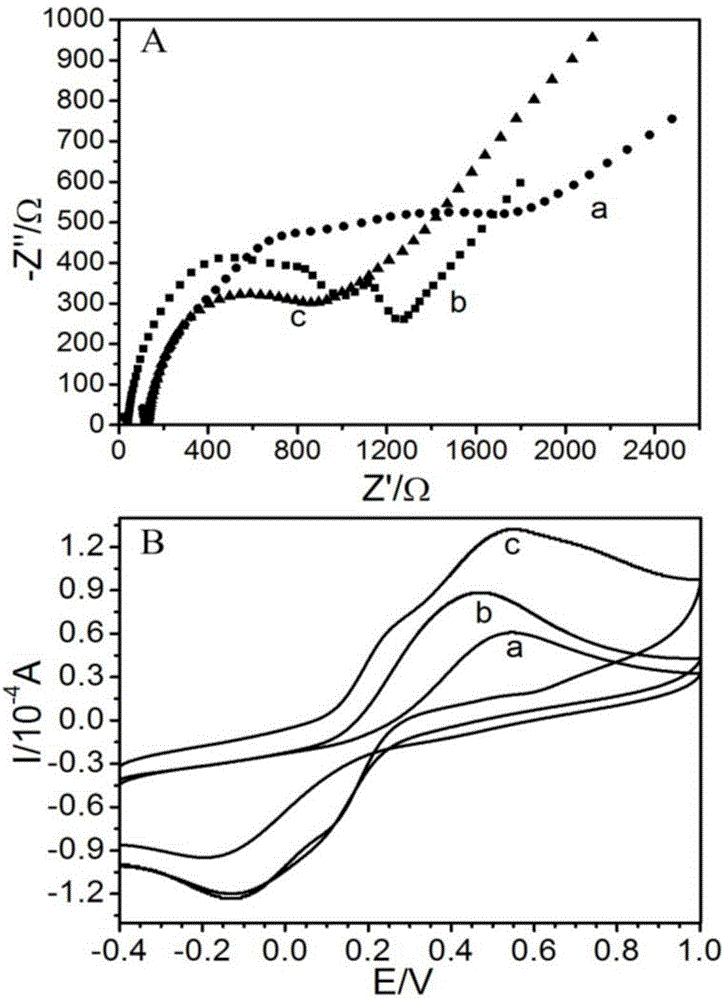

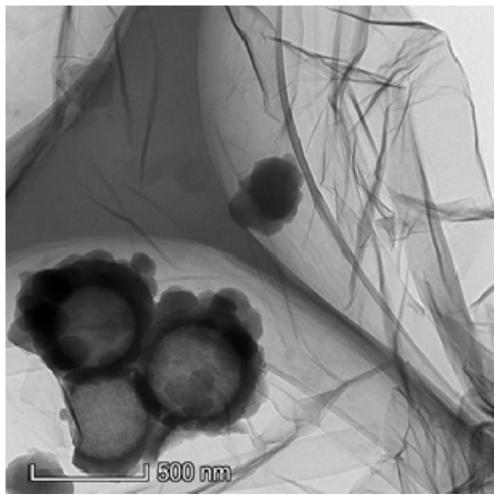

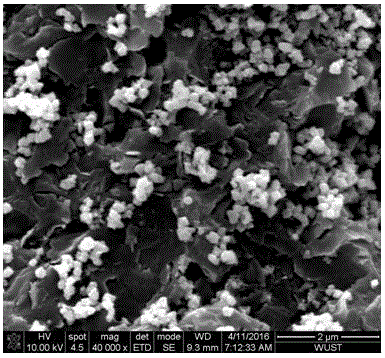

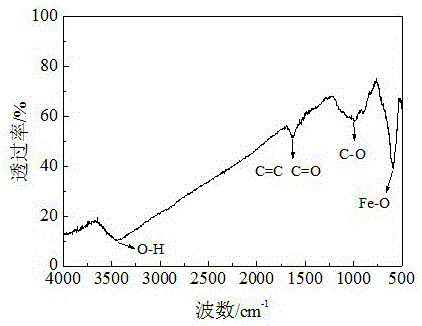

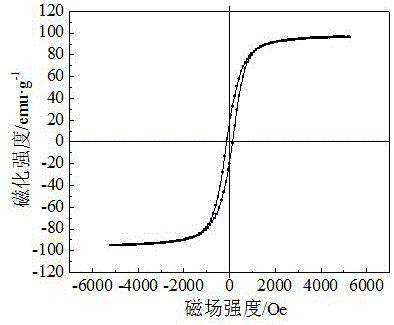

CoFe2O4NWs/RGO composite nano-material, and paracetamol electrochemical sensor obtained through composite nano-material

ActiveCN106248766AUniform thicknessNo obvious reunionMaterial electrochemical variablesHydrazine compoundHigh selectivity

The invention relates to the technical field of material preparation and electroanalytical chemistry, and concretely relates to a CoFe2O4NWs / RGO composite nano-material, and a paracetamol electrochemical sensor obtained through the composite nano-material. The composite nano-material is prepared through the following steps: S11, carrying out ultrasonic treatment on graphene oxide (GO) in water for 10-30 min, adding citric acid, and continuously carrying out ultrasonic treatment for 10-60 min to obtain a GO dispersion; S12, adding FeCl3.6H2O and CoCl2.6H2O to the GO dispersion, and carrying out ultrasonic treatment for 10-60 min; S13, adjusting the pH value of the above obtained dispersion to 9.5-10.5, adding hydrazine, stirring the dispersion and hydrazine for 30-120 min, and ageing the obtained mixture for 18-48 h; and S14, centrifuging the aged mixture, washing the centrifuged mixture, and drying the washed mixture to obtain the CoFe2O4NWs / RGO composite nano-material. An electrochemical electrode or the electrochemical sensor obtained through the composite nano-material has the advantages of good stability, low detection limit, high sensitivity and high selectivity in the paracetamol detection process.

Owner:HENGYANG NORMAL UNIV

High-capacity lithium ion battery positive electrode slurry and preparation method and application thereof

InactiveCN108878767AIncrease productivitySmall particle sizeElectrode manufacturing processesSecondary cellsCooking & bakingInternal resistance

The invention belongs to the technical field of lithium ion battery manufacturing, and particularly provides a preparation method of high-capacity lithium ion battery positive electrode slurry. The preparation method comprises the following steps that various raw materials are weighed and subjected to baking processing before use; polyvinylidene fluoride is dissolved into an N-methyl-2-pyrrolidonesolution with the weight 12-19 times of that of polyvinylidene fluoride, and after stirring and filtering are conducted, an adhesive solution A is obtained; a carbon nanotube solution is added into the adhesive solution A, and after the mixed solution is stirred to be uniform, a conducting adhesive solution B is obtained; the conducting adhesive solution B is added into a stirrer in twice, and stirring is conducted to obtain slurry C; ethyl alcohol is added into the slurry C, the slurry viscosity is adjusted with N-methyl-2-pyrrolidone, and after stirring is conducted, slurry D is obtained; and after the slurry D is subjected to processing of a high-speed dispersion machine, filtration processing and vacuum deformation processing, the final slurry is obtained. According to the preparationmethod, in the production process, preparation of the conducting adhesive solution B and preparation of the final slurry are conducted independently and synchronously, and the production efficiency of the positive electrode slurry is effectively improved; and a lithium ion battery prepared from the slurry is low in internal resistance, high in energy density and beneficial to exertion of the maximum gram capacity.

Owner:CALB CO LTD

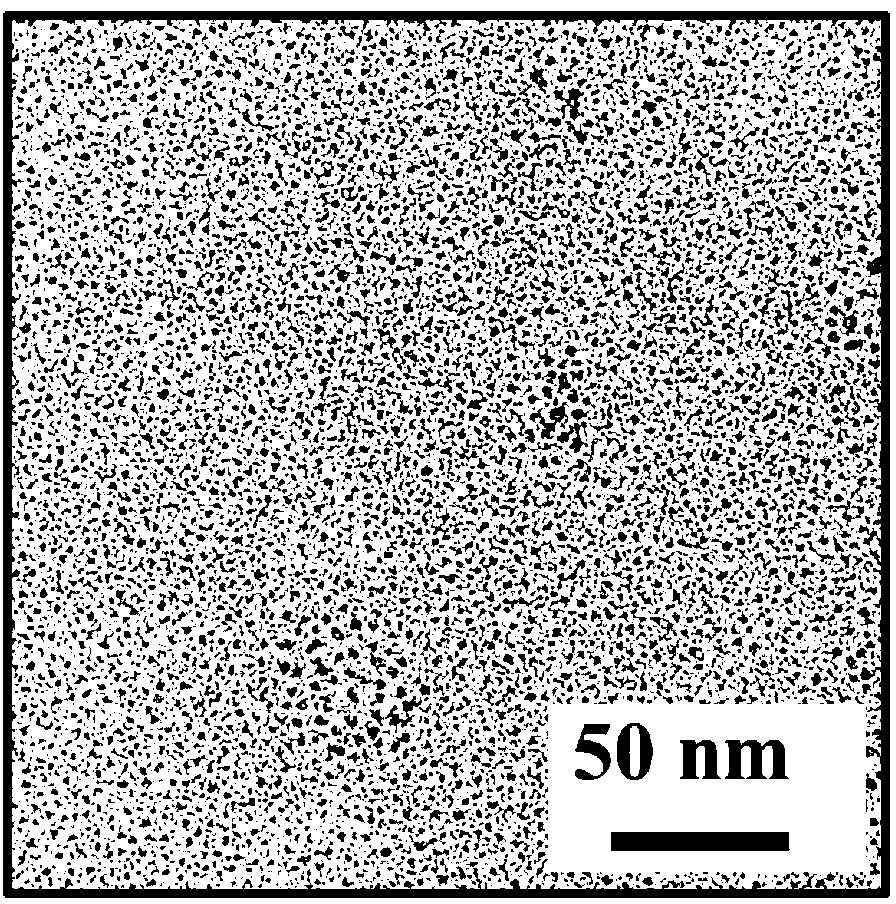

Method for preparing water-soluble ferroferric oxide nano particle

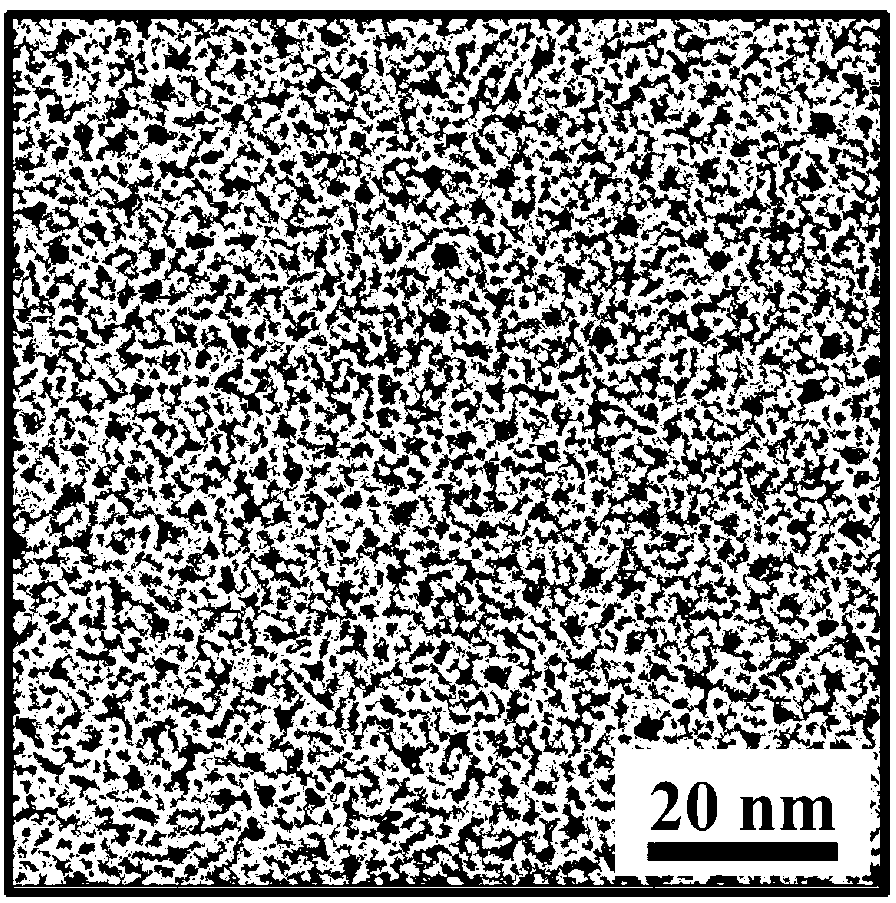

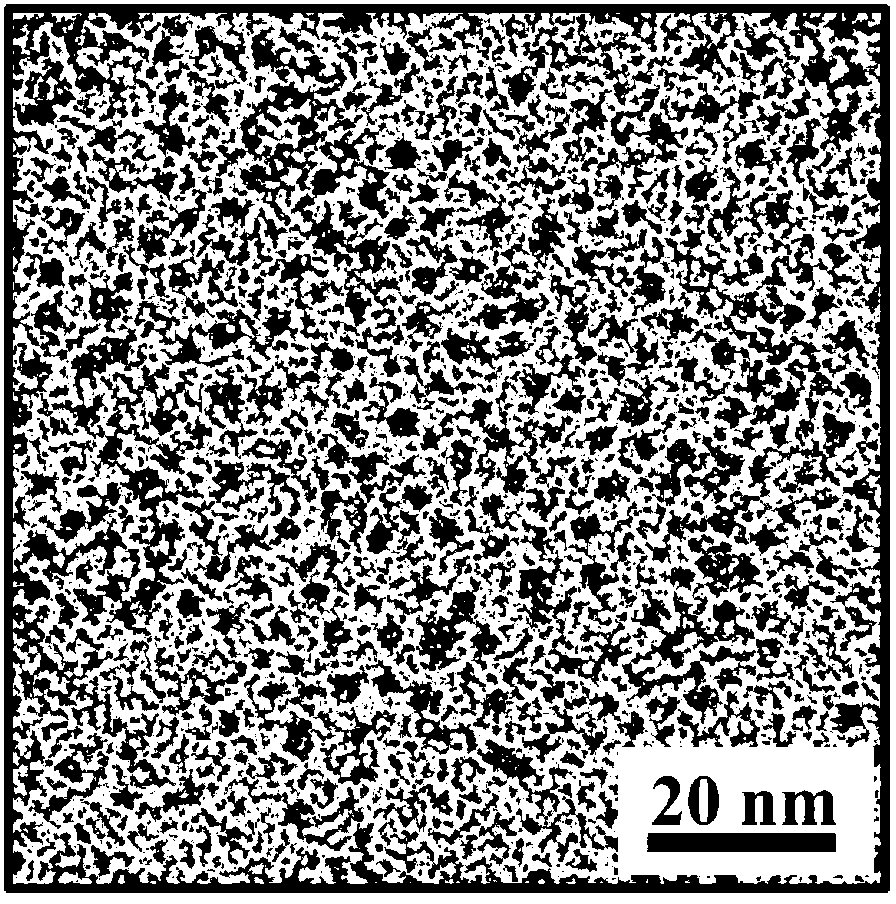

InactiveCN103274478ASimple methodGood water dispersibilityMaterial nanotechnologyFerroso-ferric oxidesDiethylene glycolRoom temperature

The invention discloses a method for preparing a water-soluble ferroferric oxide nano particle, relates to a nano particle, and provides the ferroferric oxide nano particle which has the grain diameter of less than 4 nm and narrow particle diameter distribution. The method for preparing the water-soluble ferroferric oxide nano particle of a typical monodisperse particle is provided. The method comprises the steps as follows: 1), anhydrous ferric chloride and trisodium citrate are immersed in diethylene glycol and heated until the anhydrous ferric chloride and the trisodium citrate are dissolved completely; 2), anhydrous sodium acetate is added into a mixed solution obtained in the step 1), and the mixed solution is waited to be dissolved completely; 3), the mixed solution obtained in the step 2) is placed into a reaction still, the reaction still is closed, and after the reaction, the mixed solution is naturally cooled to the room temperature; and 4), the ferroferric oxide nano particle is separated from the reaction solution prepared in the step 3) by a magnet, the particle is washed and dried, so that the monodisperse water-soluble ferroferric oxide nano particle is obtained.

Owner:XIAMEN UNIV

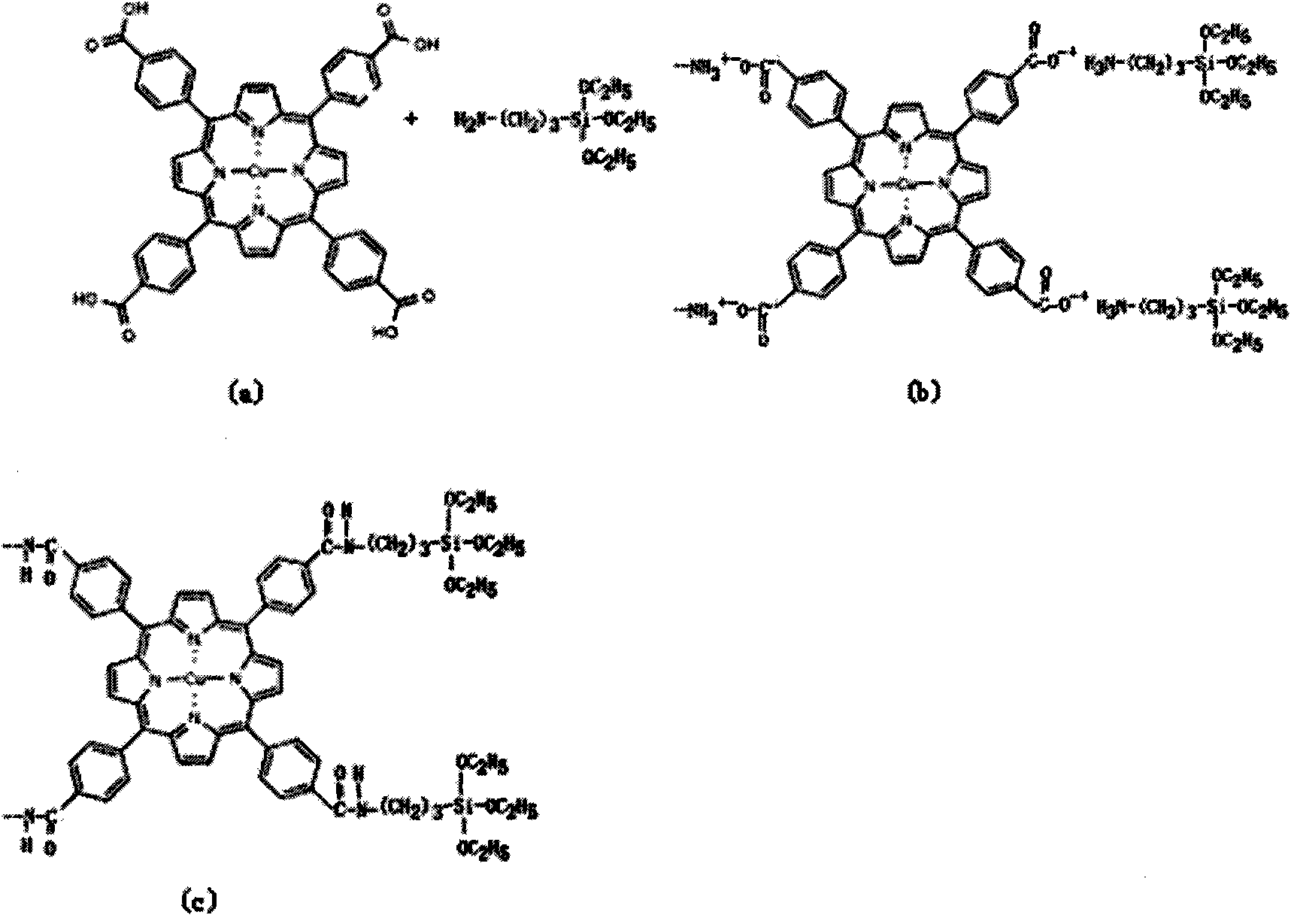

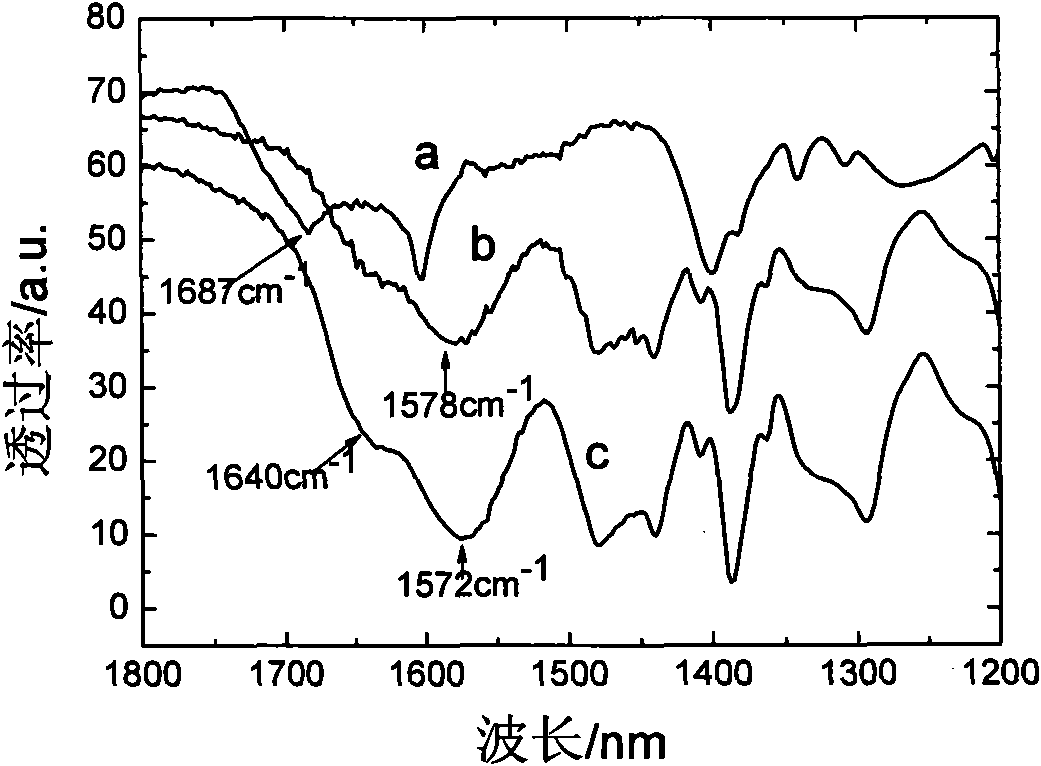

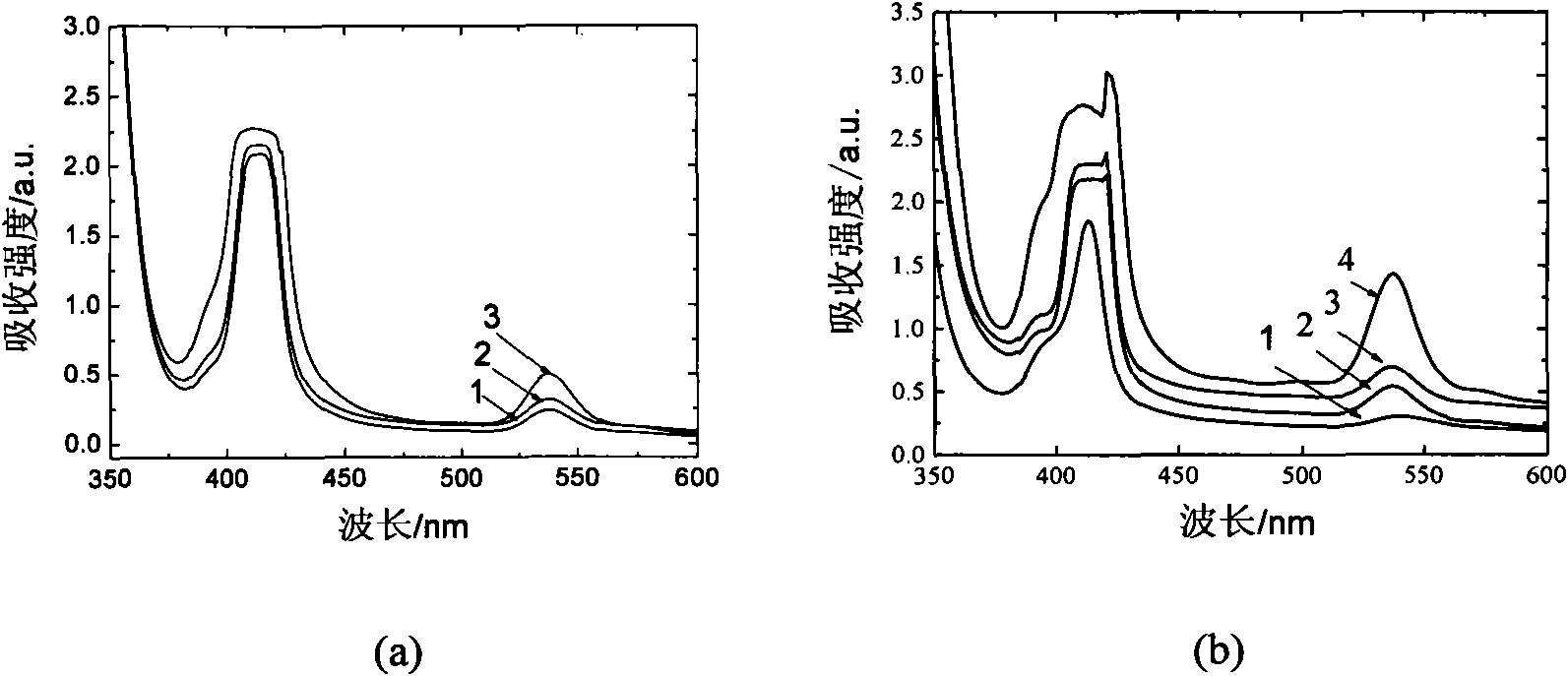

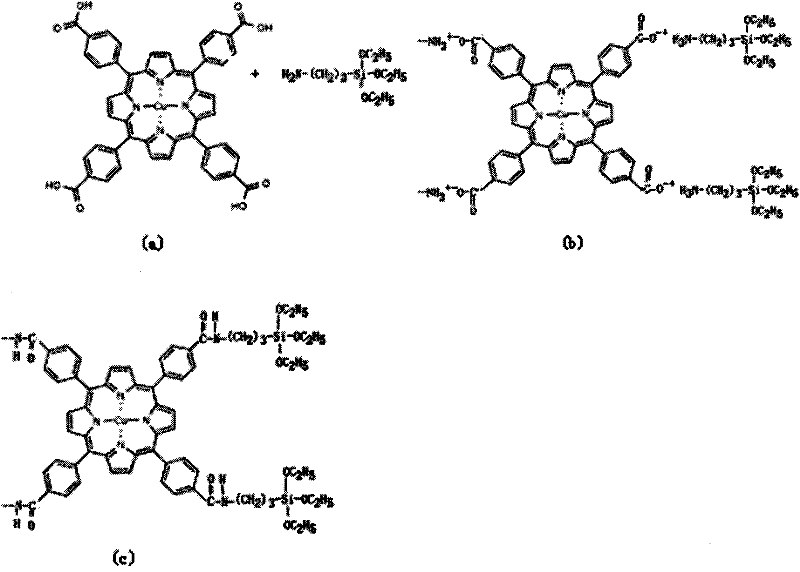

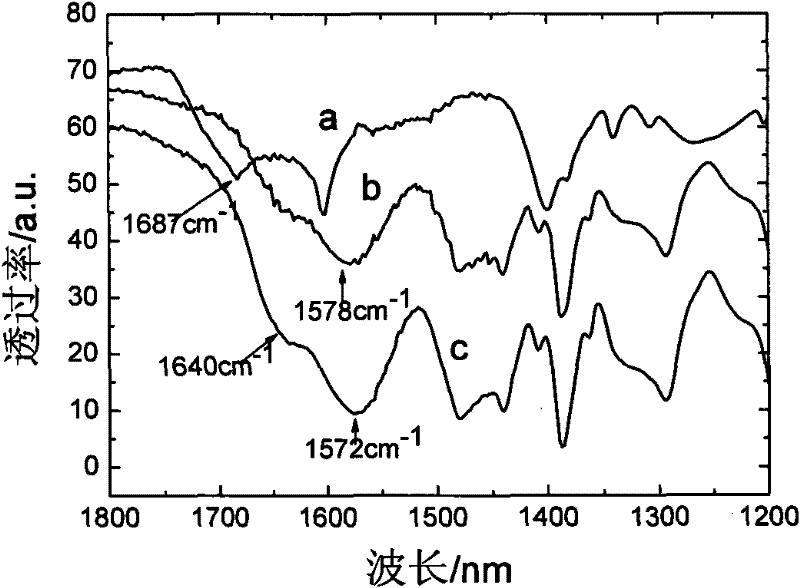

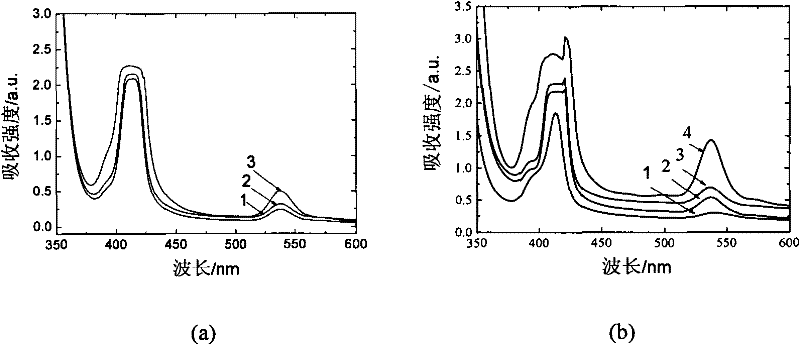

Preparation method of porphyrin coupled silicon dioxide organic-inorganic nonlinear optical material

InactiveCN101840124AIncrease the doping concentrationMaintain structural propertiesNon-linear opticsMetal alkoxideOrganic inorganic

The invention discloses a preparation method of a porphyrin coupled silicon dioxide organic-inorganic nonlinear optical material, which comprises the following steps: 1. heating and reflowing a mixed solution of Msco-tetra-(4-carbomethoxyphenyl) porphyrin copper and gamma-aminopropyltriethoxysilane at the temperature of 160 to 250 DEG C for 10 to 60 hours to obtain a transparent deep red liquid; 2. dissolving a reaction product of step 1 and metal alkoxide into anhydrous ethanol, and stirring at room temperature for 1 to 2 hours; 3. dropwise adding a (H2O) / (C2H5OH) mixed liquid into the reaction product of step 2 at the room temperature for hydrolysis and polymerization reaction for 1 to 5 hours; and 4. pouring the obtained transparent sol into a glass or plastic utensil, sealing with a thin film, ageing at the room temperature for 35 to 45 days, and pricking a hole on the thin film every day to finally prepare compound dried gel. The invention has the advantages that the monomer doping concentration of porphyrin molecules in a gel solid medium can be greatly improved, and the molecular energy level structure and the spectral characteristic of the porphyrin molecules in the gel medium are kept.

Owner:NINGBO UNIV

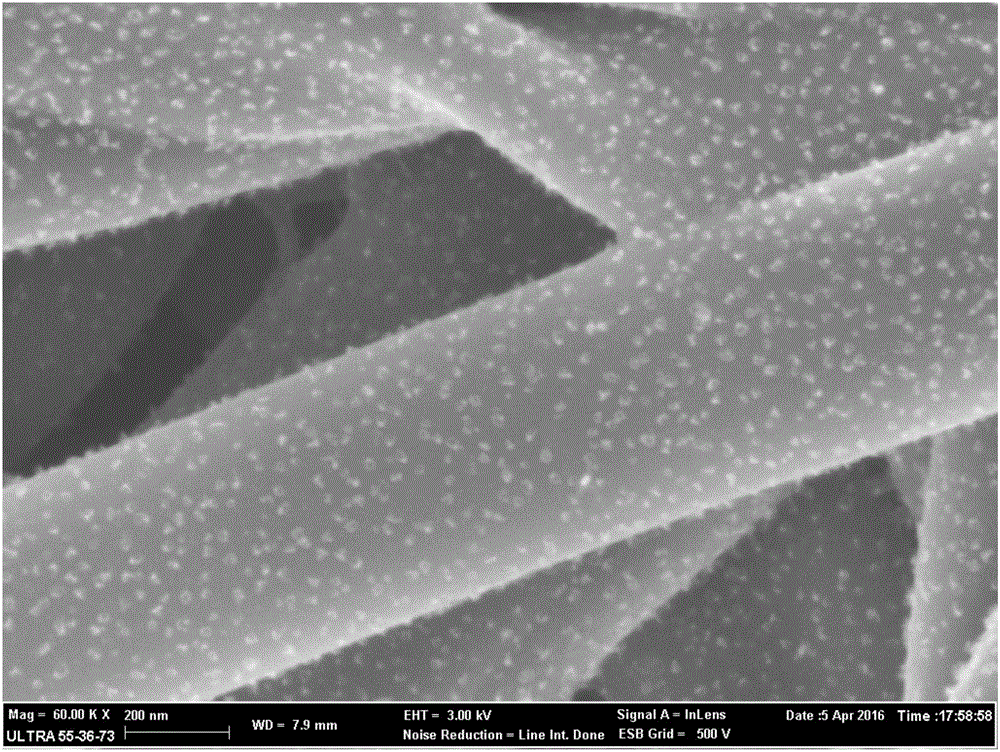

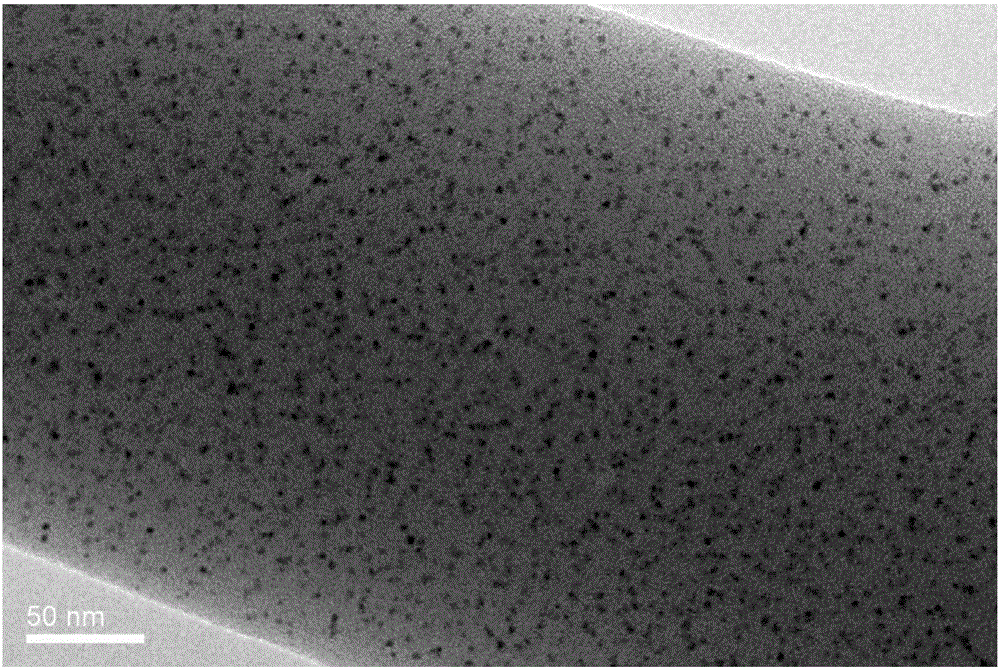

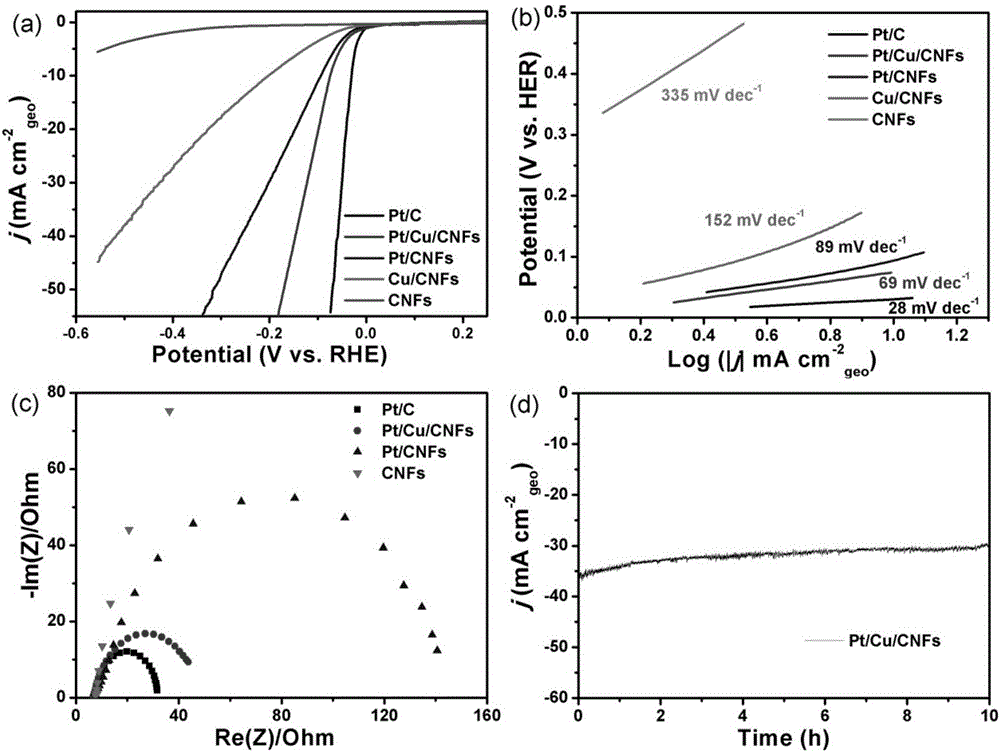

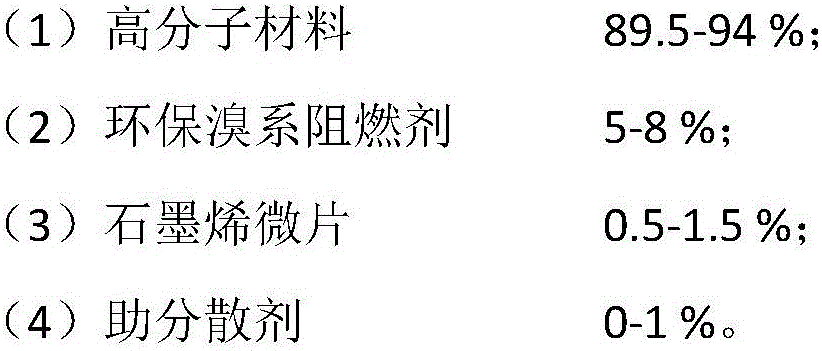

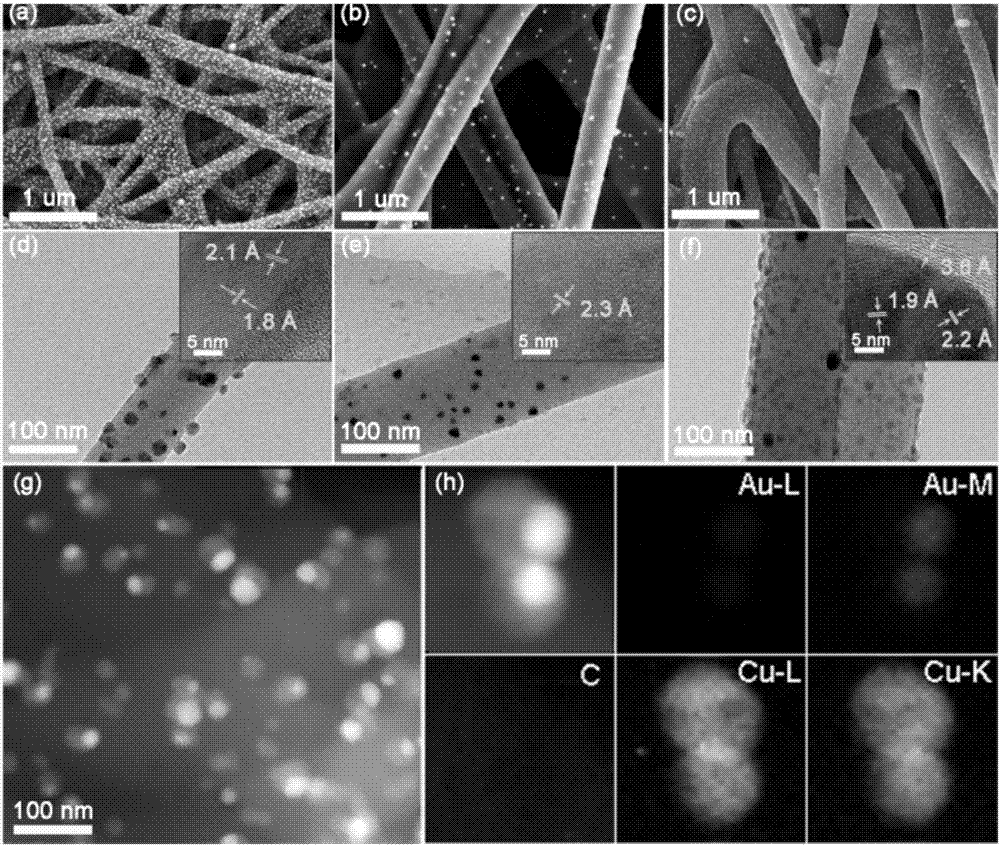

Nanometer platinum-copper alloy catalytic material for electrolysis of water

InactiveCN106362767AEvenly dispersedSmall particle sizeCatalyst activation/preparationMonocomponent synthetic polymer artificial filamentMetallurgyGas phase

The invention discloses a nanometer platinum-copper alloy catalytic material for electrolysis of water. The nanometer platinum-copper alloy catalytic material for electrolysis of water is prepared by using electrospinning technique and chemical vapor deposition; platinum-copper alloy nanoparticles are uniformly dispersed on carbon nanofibers, and the nanoparticles are free of obvious agglomeration, small in particle size and uniform in distribution and have a great number of active sites, thereby improving the catalytic activity of the material; and a preparation method for the nanometer platinum-copper alloy catalytic material is simple in process flow, free of production of toxic substances, friendly to environment, free of pollution and good in repeatability, and has good industrial application prospect.

Owner:ZHEJIANG SCI-TECH UNIV

Method for preparing nanometer titanium dioxide slurry through cellulose acidification process

ActiveCN102522211AGood film formingGood dispersionLight-sensitive devicesFinal product manufactureCelluloseSlurry

The invention provides a method for preparing nanometer titanium dioxide slurry through a cellulose acidification process. Raw materials comprise titanium dioxide powder, acid liquor dispersing agent, surface stabilizer and surfactant. The method comprises the steps of: firstly, using acid liquor to treat the titanium dioxide powder; then dissolving the treated titanium dioxide powder in solution prepared by using the surface stabilizer, the surfactant and the acid liquor dispersing agent; and finally agitating, heating and concentrating to obtain slurry with certain content. The invention aims at providing a new method which has the advantages that the manufacturing method is simple and convenient, the raw materials are easy to obtain, the manufacturing cost is low, the performance is stable, the output efficiency is high, the process is environmental-friendly, and the method is suitable for the large-scale industrial production of titanium dioxide slurry and is used for avoiding and overcoming the defects that the yield is low, the steps are complex, the performance of the prepared slurry is unstable and the like when the existing method is used for preparing the titanium dioxide slurry by using nanometer titanium dioxide powder.

Owner:NANJING UNIV OF TECH

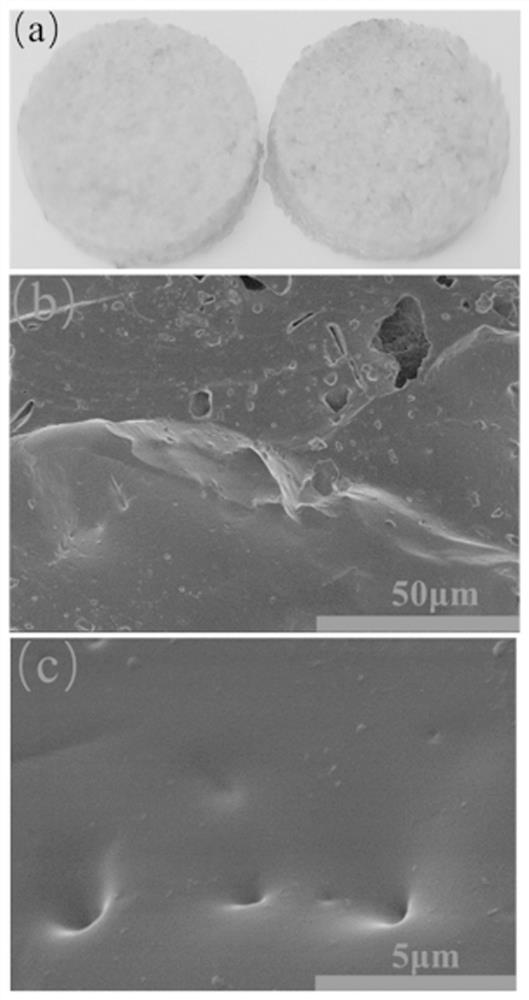

Compound adsorbent based on hippophae rhamnoides linn branches and trunks and preparation method of compound adsorbent

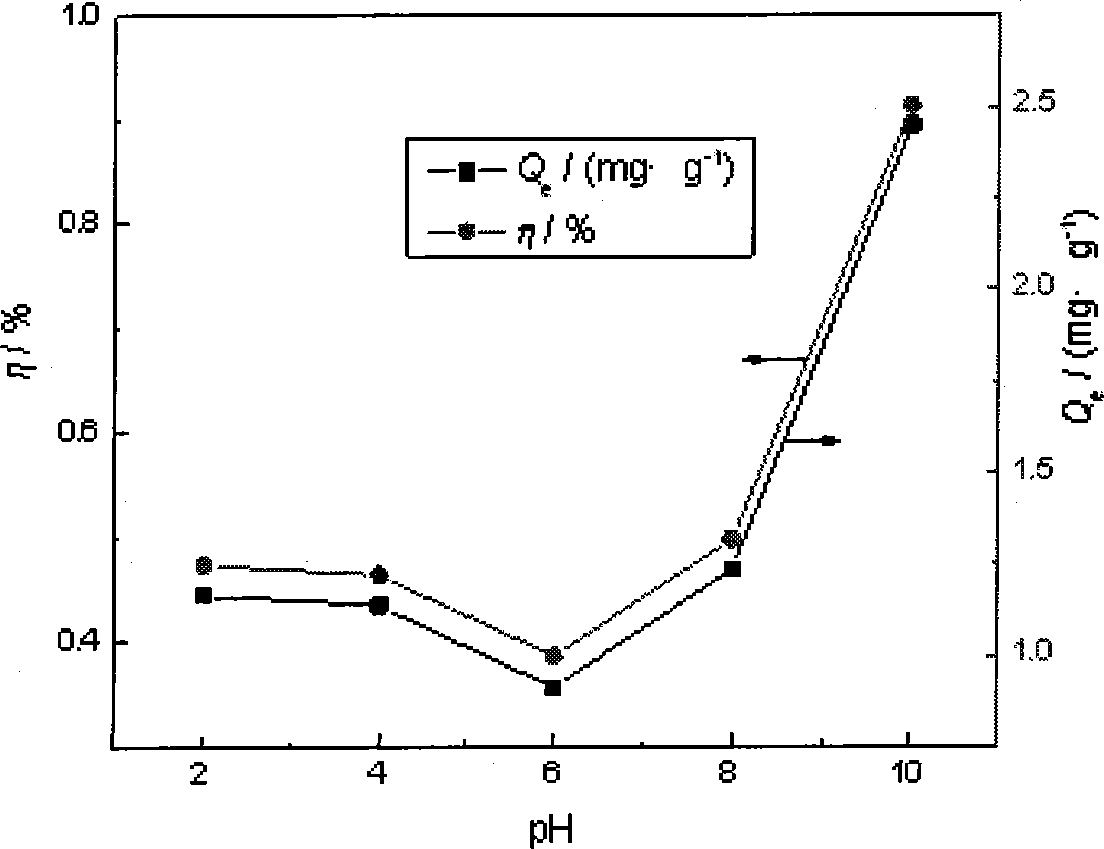

ActiveCN104368308AImprove adsorption capacityResidue reductionOther chemical processesWater contaminantsWastewaterHippophae rhamnoides

The invention relates to a compound adsorbent based on hippophae rhamnoides linn branches and trunks. The compound adsorbent is produced by the following steps: preparing hippophae rhamnoides linn charcoal by the hippophae rhamnoides linn branches and trunks, and loading nano Fe3O4 grains. The invention further provides a preparation method of the compound adsorbent. The national resource quantity of the hippophae rhamnoides linn branches and trunks is great; and the compound adsorbent is prepared by taking waste biological resources of the hippophae rhamnoides linn branches and trunks as raw materials so that the industrial chain of utilizing the hippophae rhamnoides linn branches and trunks is effectively lengthened. The obtained compound adsorbent can be used for treating doxycycline organic pollutant wastewater and can be regenerated.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST

Layered double hydroxide-molybdate ion modified graphene flame-retarding and smoke-inhibiting agent and preparation method of same

ActiveCN107163289AImprove flame retardant and smoke suppression performanceImprove mechanical propertiesMOLYBDATE IONCvd graphene

The invention belongs to the technical field of flame-retarding and smoke-inhibiting agents and particularly relates to a layered double hydroxide-molybdate ion modified graphene flame-retarding and smoke-inhibiting agent and a preparation method of same. The preparation method includes the steps of supporting LDH onto surface of graphene and intercalating molybdate ions between layers of the LDH. The flame-retarding and smoke-inhibiting agent not only improves the flame-retarding and smoke-inhibiting performances of a polymer but also improves physical and mechanical performances of the polymer.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

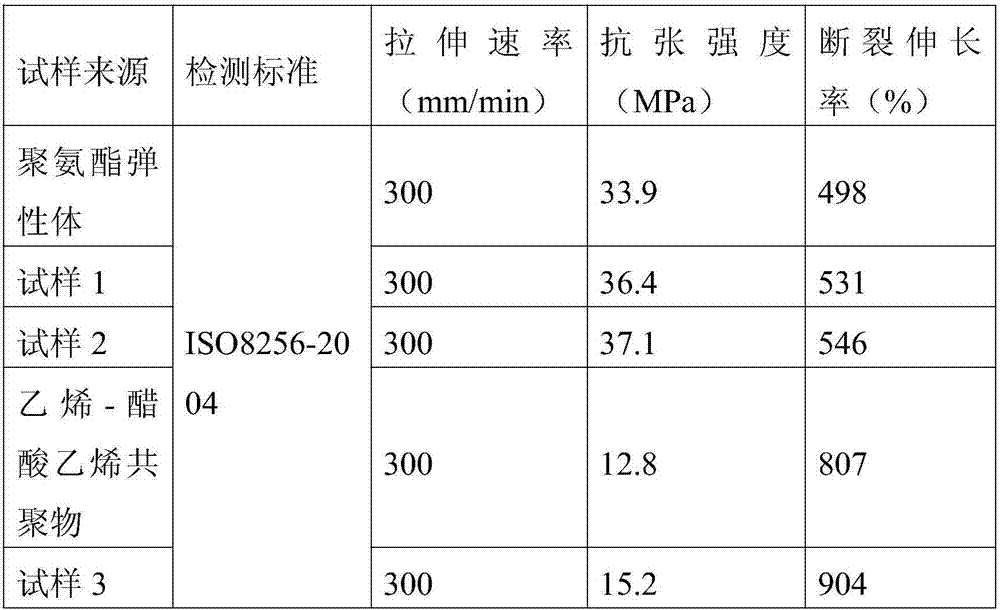

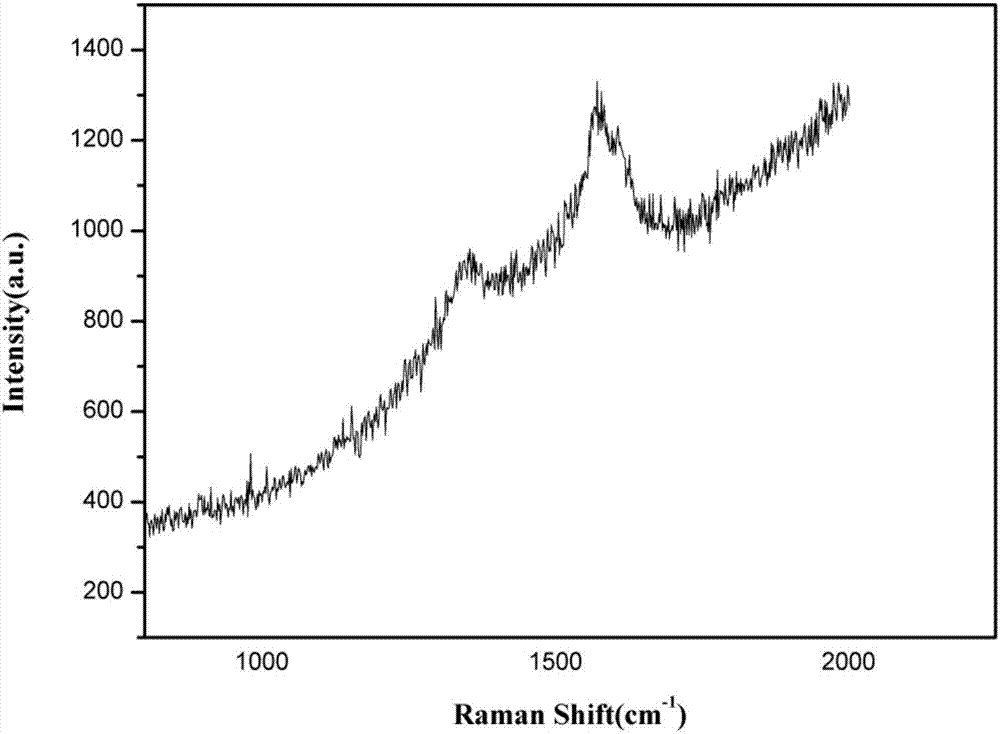

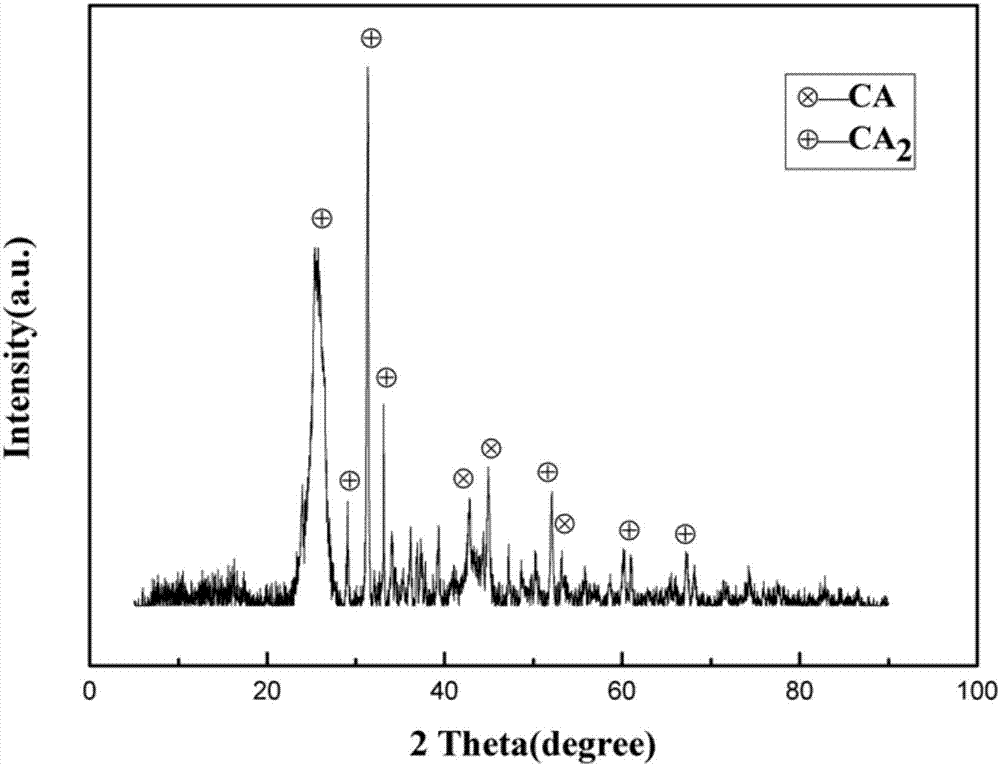

Carbon-calcium aluminate composite powder and preparation method thereof

The invention provides a preparation method of carbon-calcium aluminate composite powder. By the method, aluminium oxide is adopted as raw material, and organic acid calcium is adopted as raw material, in non-oxidizing atmosphere, carbon-calcium aluminate composite powder is obtained by high temperature sintering. The organic acid calcium has two effects, organic acid acts as a calcium source and a carbon source, by taking advantage of this characteristic, in high temperature non-oxidizing atmosphere, sintering is conducted on organic acid calcium and aluminum oxide, pyrolysis is conducted on organic acid calcium, carbon is reduced, new generated calcium oxide and aluminium oxide in the raw materials react to form a calcium aluminate, carbon / calcium aluminium powder is synthesized in one step by utilizing this characteristic. The method has the characteristic of in-situ synthesis, and carbon source is added by means of chemical reactions, carbon source after the chemical reactions gets into composite materials, the dispersity of carbon is greatly increased, far superior to the dispersity of the carbon added by means of physical penetration in the prior art.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Terpenyl ester hyperdispersant and preparation method for same

ActiveCN104844763AImprove performanceGood dispersionTransportation and packagingMixingPtru catalystAlcohol

The invention discloses a terpenyl ester hyperdispersant and a preparation method for the same. The preparation method comprises the following steps of feeding 100 parts by weight of terpene resin, 25 to 50 parts by weight of an alpha,beta-unsaturated compound and 0.1 to 1.5 parts by weight of a catalyst into a reaction kettle, slowly raising the temperature to 160 to 200 DEG C under the protection of nitrogen, performing reaction with stirring for 4 to 6h, adding 1 to 50 parts by weight of a modified carboxylation reagent and 20 to 60 parts by weight of dihydric alcohol, continuing performing reaction for 3 to 4h, then gradually raising the temperature to 220 to 260 DEG C, performing condensation polymerization reaction for 8 to 10h under the vacuum condition of 500 to 2,000Pa, and cooling to obtain the terpenyl ester hyperdispersant after reaction is finished. The hyperdispersant can be widely applied to the preparation and the dispersion of inorganic superfine powder.

Owner:GUANGXI UNIV FOR NATITIES

Preparation method of high-dispersity silk fibroin-chitosan-3-methylimidazole salt hexylthiophene-multiwalled carbon nanotube gel

InactiveCN109880184AGood biocompatibilityNo side effectsConjugated PolyelectrolytesEnvironmental resistance

The invention belongs to the field of functional material, and discloses a preparation method of a high-dispersity silk fibroin-chitosan-3-methylimidazole salt hexylthiophene-multiwalled carbon nanotube gel. According to the preparation method, the pi-pi bond effect not covalent bond effect of conjugate polyelectrolyte 3-methylimidazole salt hexylthiophene with acidified carbon nanotube surfaces is taken into utilization, so that the mutual attractive force of the modified carbon nanotube is reduced, the adhesiveness of the modified carbon nanotube is reduce, the dispersity is improved, the prepared material is high in stability and hydrophilic performance in solution, preparation speed is accelerated greatly, preparation cost is reduced, no influence on subsequent experiment steps or theperformance of particles to be prepared is caused, experiment result scientific performance is not influenced, experiment operation is simple, nontoxic, and harmless, and the preparation method is green, and is friendly to the environment.

Owner:ZHEJIANG SCI-TECH UNIV

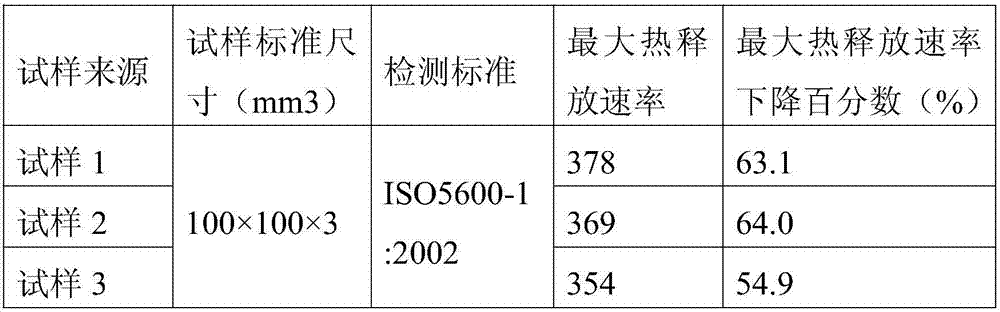

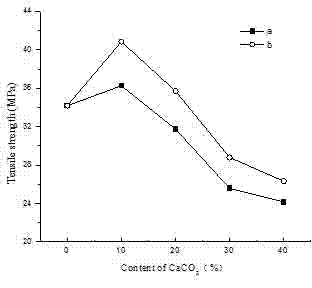

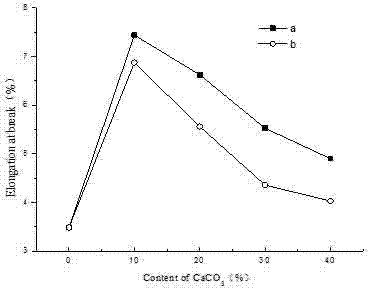

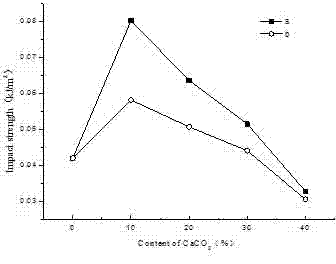

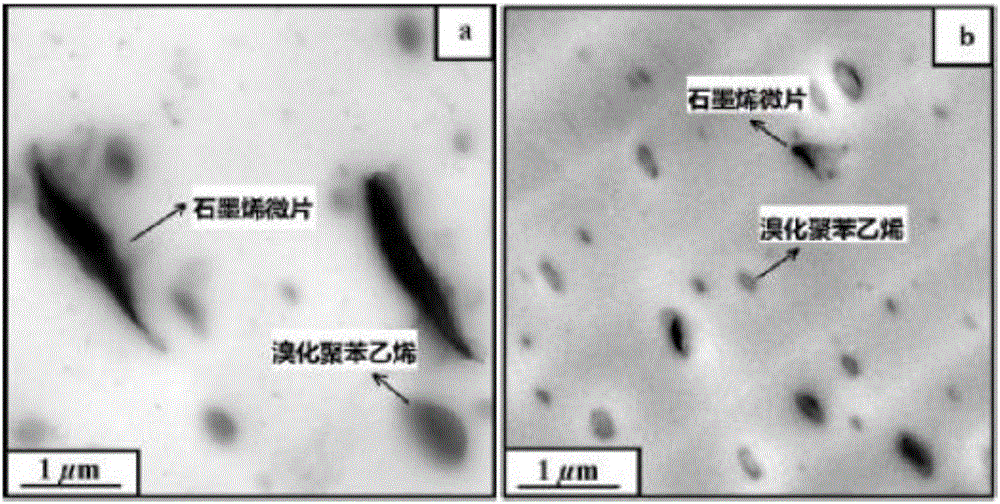

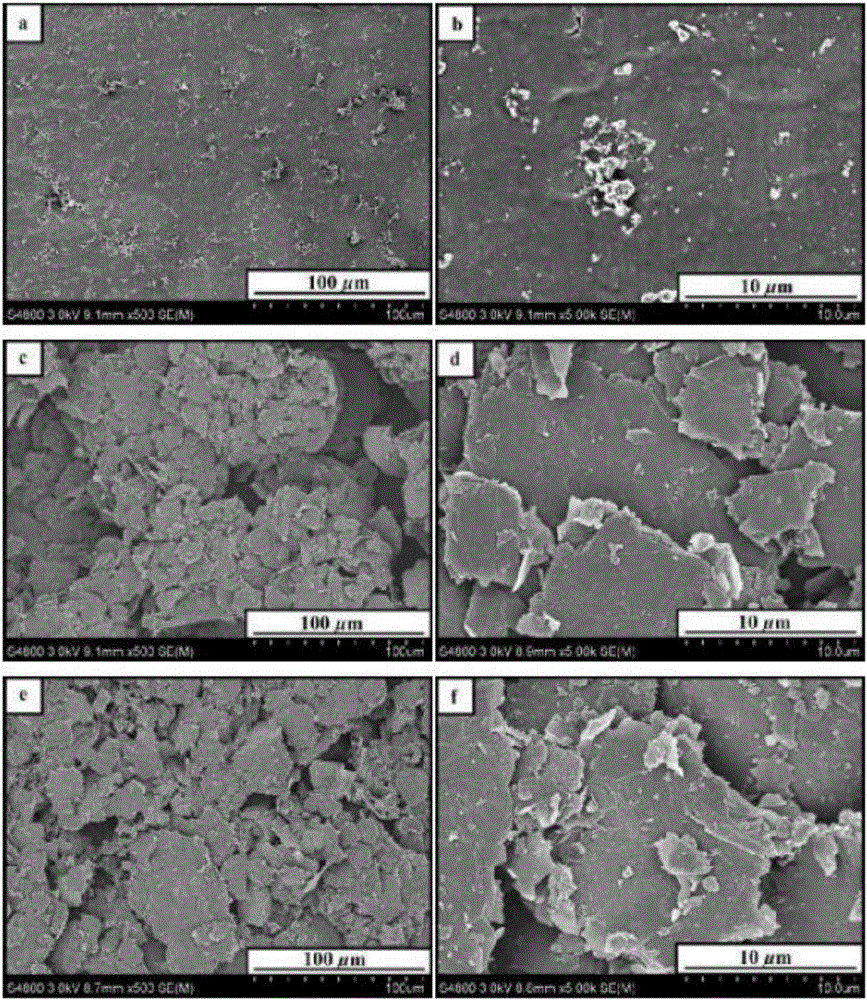

Flame-retardant high-polymer composite material and preparation method thereof

The invention provides a flame-retardant high-polymer composite material. The material is characterized by being prepared from an environment-friendly brominated flame retardant, graphene nano-platelets and an auxiliary dispersant, wherein the high-polymer material is polystyrene. The graphene nano-platelets are creatively added into the flame-retardant material and the adding mount is accurately limited; the graphene nano-platelets belong to condensed-phase flame retarding and a network structure is mainly formed in a combustion process, so that the material represents a solid-like behavior in a combustion process; the network structure can effectively inhibit thermal motion of a polymer molecular chain and the exchange of gas and heat is stopped. In view of the flame-retardant effect, only a few of graphene nano-platelets are added and the heat releasing speed and the smoke density of a polymer can be remarkably reduced; unpredicted technical effects are realized.

Owner:宁波福天新材料科技有限公司

Mixed initiating system for increasing the stability of gelatin casting molding ceramic slurry and use method thereof

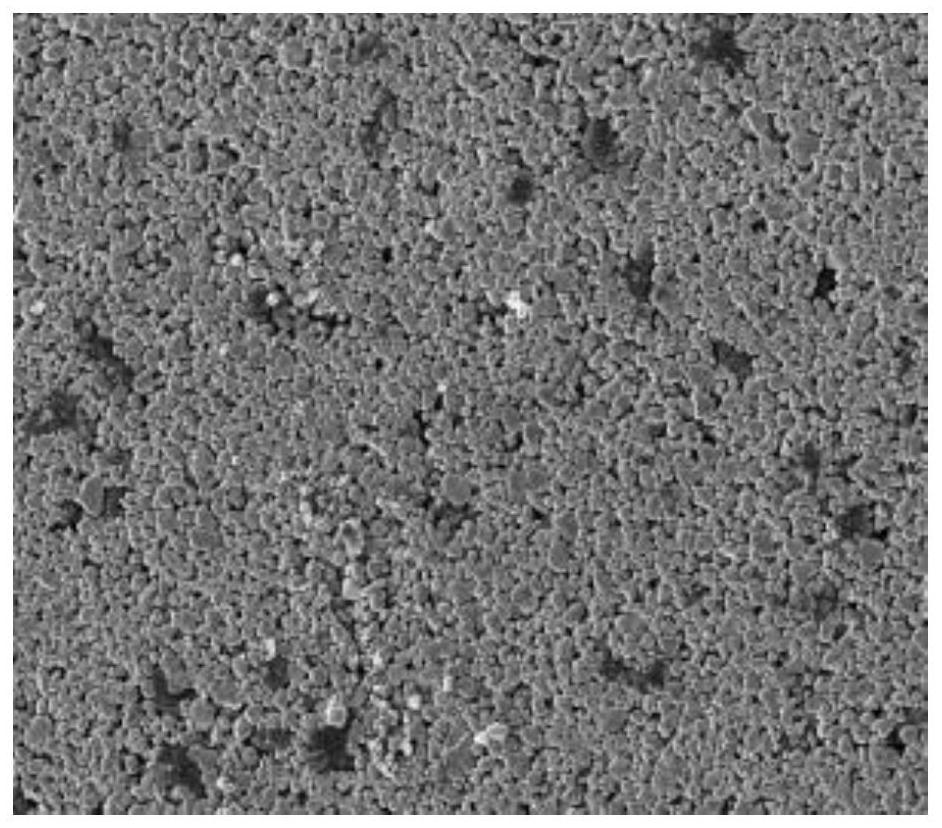

ActiveCN101514107AObvious reunion phenomenonSimple processCeramic shaping apparatusClay processing apparatusNon oxide ceramicsCasting mold

The invention relates to a mixed initiating system for increasing the stability of gelatin casting molding ceramic slurry and a use method thereof. The mixed initiating system comprises four components: in particular, deionized water, common used initiating agent, common used monomer and organic amine. The conventional gelatin casting molding technique can prepare stable ceramic slurry with about50-60 vol% of solid content and 300-600mPa.s of viscosity. The gelatin casting biscuit with uniform and compact structure can be obtained by further curing the ceramic slurry. The mixed initiating system can obtain the slurry with good stability, can prepare oxide and non-oxide ceramic materials with low cost, high performance and complex shape, and is suitable for the preparation of blocks or porous ceramics. And the technical process thereof can be easily realized.

Owner:中国科学院上海硅酸盐研究所苏州研究院

Electrolytic water catalytic material of gold-copper twin structure

The invention discloses an electrolytic water catalytic material of a gold-copper twin structure. The electrolytic water catalytic material is a nano-particle / carbon nanofiber hybrid material of the gold-copper twin structure. According to the electrolytic water catalytic material, the size of the gold-copper twin structure nanometer material is uniform, no obvious agglomeration phenomenon exists, a large number of nanometer interfaces of the electrolytic water catalytic material can effectively improve the catalytic activity, and good stability and repeatability are achieved.

Owner:ZHEJIANG SCI-TECH UNIV

Preparation method of catalyst for catalyzing hydrolysis of ammonia borane

PendingCN111389429AEasy to operateGood catalytic activityPhysical/chemical process catalystsReversible hydrogen uptakeAmmonia boraneMaterials science

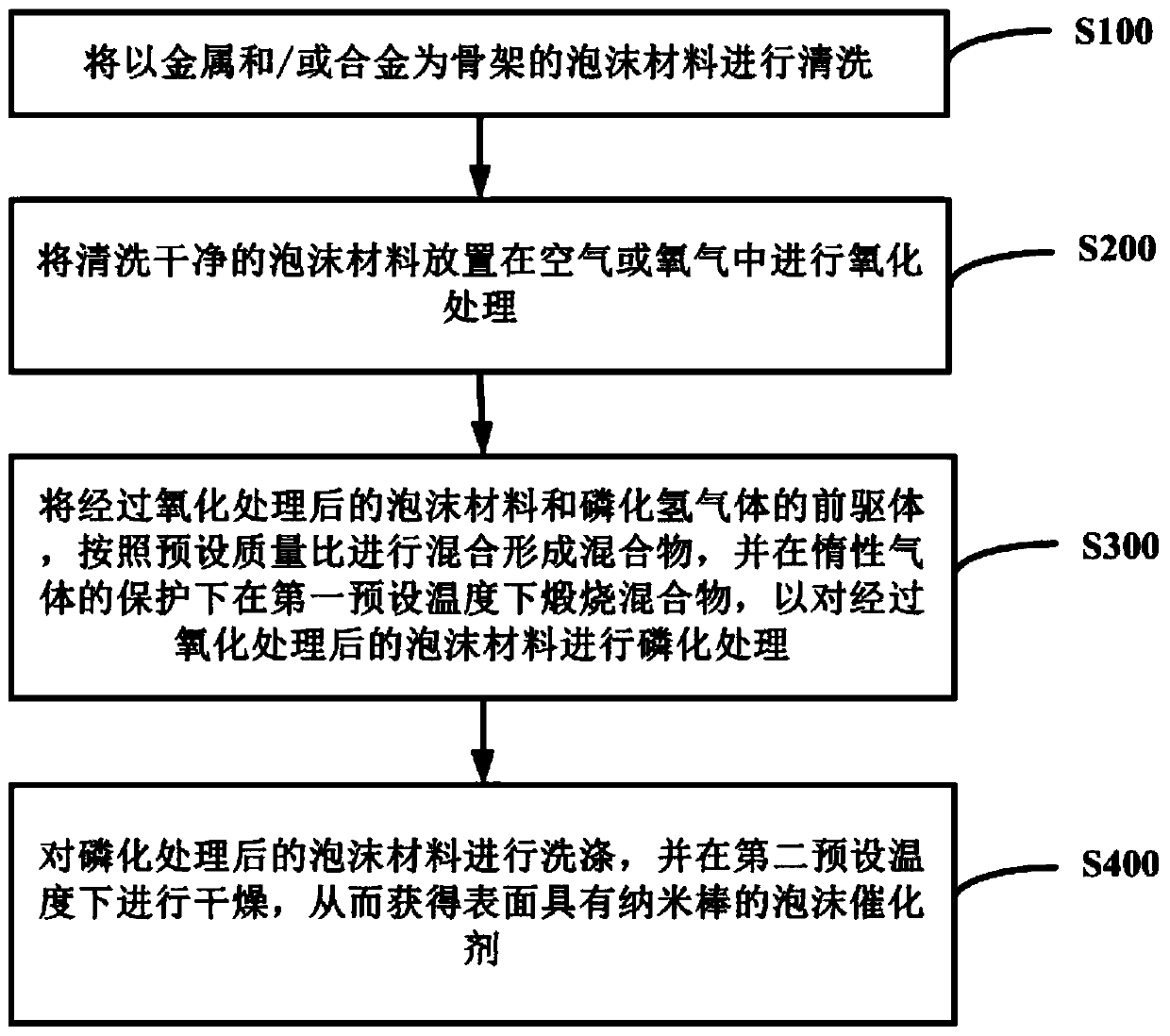

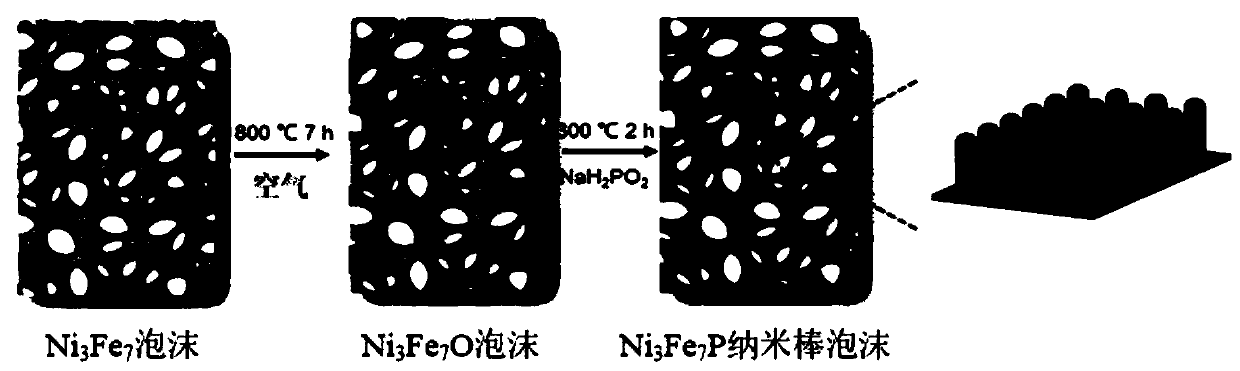

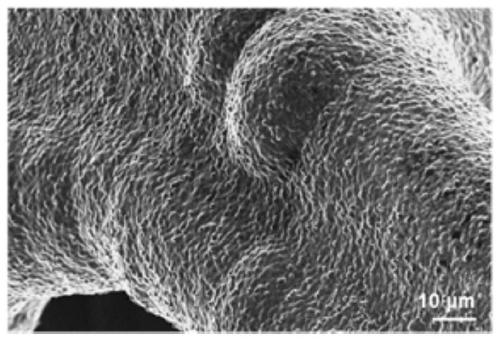

The invention provides a preparation method of a catalyst for catalyzing hydrolysis of ammonia borane. The preparation method comprises the following steps: cleaning a foam material taking metal and / or alloy as a framework; placing the cleaned foam material in air or oxygen to be subjected to oxidation treatment; mixing the foam material subjected to oxidation treatment and a precursor of phosphine gas according to a preset mass ratio to form a mixture, and calcining the mixture at a first preset temperature under the protection of inert gas so as to perform phosphating treatment on the foam material subjected to oxidation treatment; and washing the phosphatized foam material, and drying at a second preset temperature to obtain the foam catalyst with the nanorods on the surface. The preparation method is simple to operate, low in cost and easy for mass production, the nanorod prepared by the method has very good catalytic activity, 65mL of H2 can be generated per minute by only needing1cm < 2 > of Ni3Fe7P nanorod foam, and the nanorod has ultrahigh stability.

Owner:SUZHOU UNIV

Preparation method of porphyrin coupled silicon dioxide organic-inorganic nonlinear optical material

InactiveCN101840124BIncrease the doping concentrationMaintain structural propertiesNon-linear opticsPorphyrin moleculeSilicon dioxide

The invention discloses a preparation method of a porphyrin coupled silicon dioxide organic-inorganic nonlinear optical material, which comprises the following steps: 1. heating and reflowing a mixed solution of Msco-tetra-(4-carbomethoxyphenyl) porphyrin copper and gamma-aminopropyltriethoxysilane at the temperature of 160 to 250 DEG C for 10 to 60 hours to obtain a transparent deep red liquid; 2. dissolving a reaction product of step 1 and metal alkoxide into anhydrous ethanol, and stirring at room temperature for 1 to 2 hours; 3. dropwise adding a (H2O) / (C2H5OH) mixed liquid into the reaction product of step 2 at the room temperature for hydrolysis and polymerization reaction for 1 to 5 hours; and 4. pouring the obtained transparent sol into a glass or plastic utensil, sealing with a thin film, ageing at the room temperature for 35 to 45 days, and pricking a hole on the thin film every day to finally prepare compound dried gel. The invention has the advantages that the monomer doping concentration of porphyrin molecules in a gel solid medium can be greatly improved, and the molecular energy level structure and the spectral characteristic of the porphyrin molecules in the gel medium are kept.

Owner:NINGBO UNIV

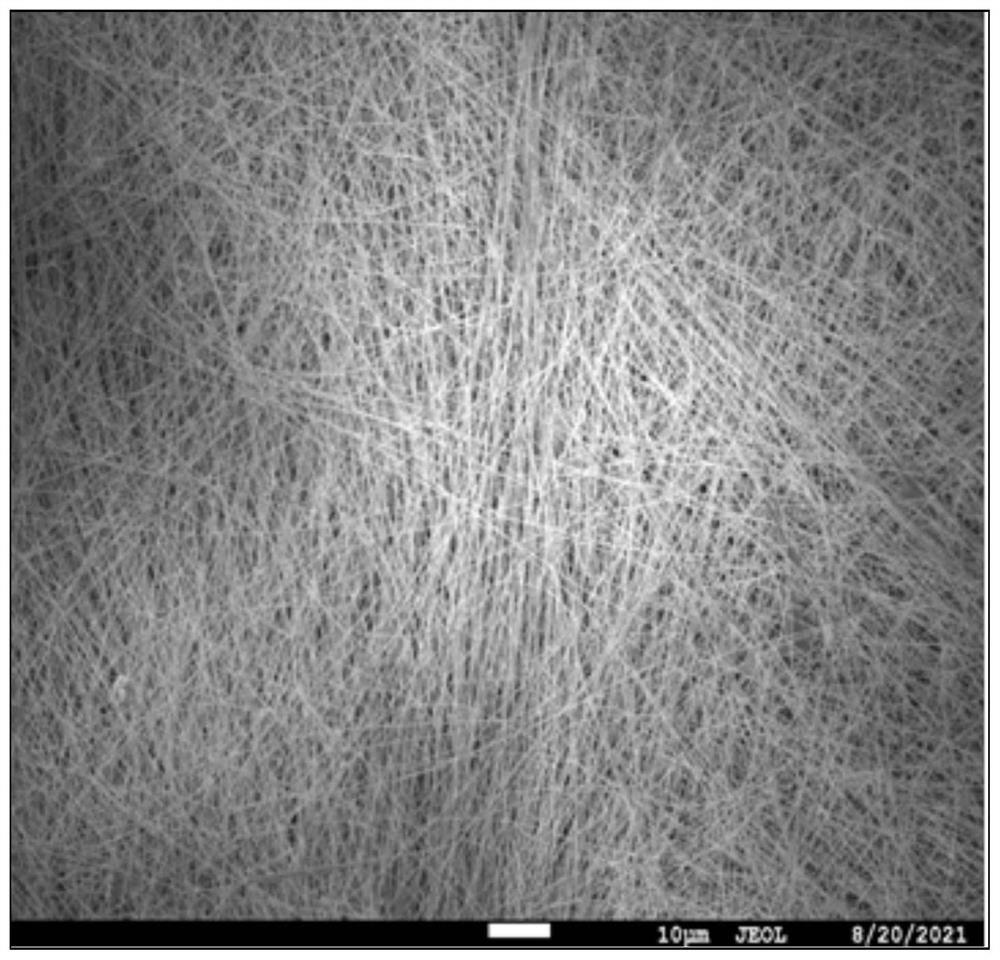

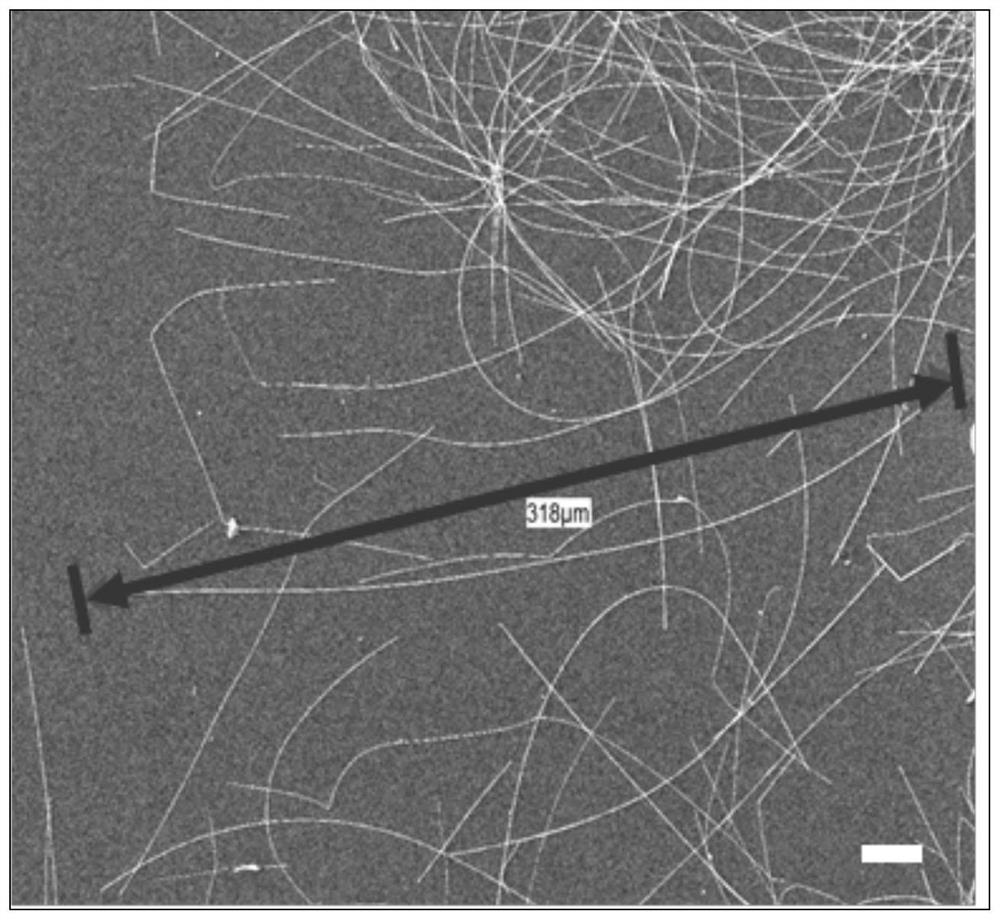

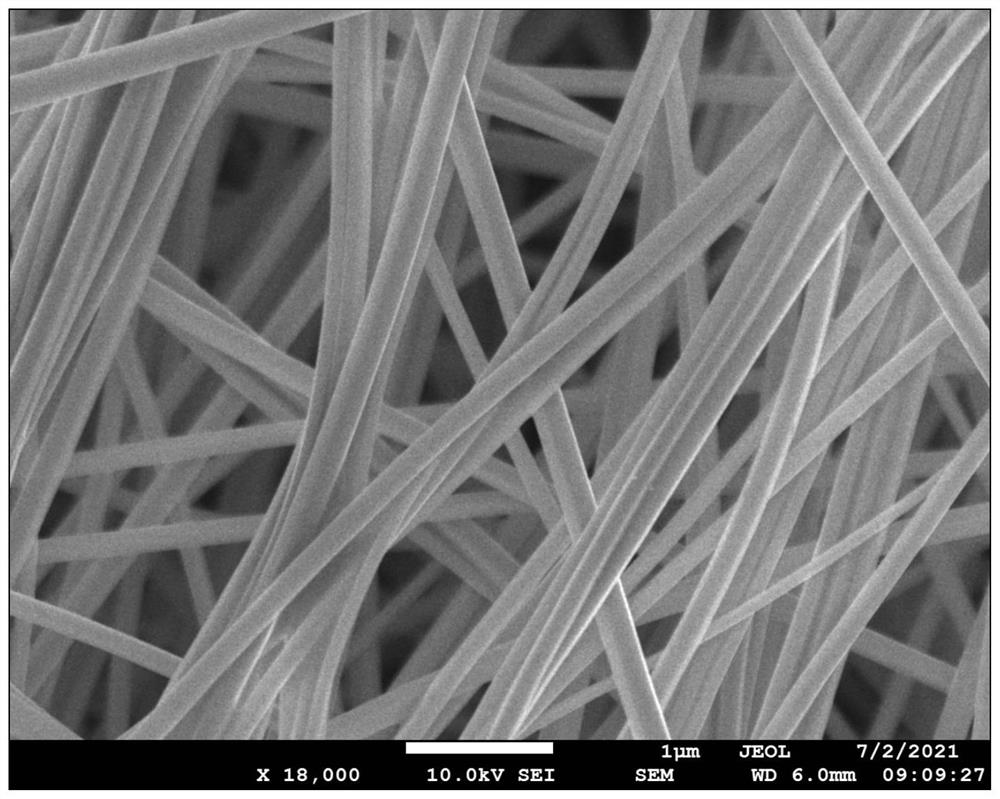

Preparation method of ultra-long nano silver wire material

ActiveCN114029499ALow costEase of industrial productionMaterial nanotechnologyTransportation and packagingNanowirePyrrolidinones

The invention discloses a preparation method of an ultra-long nano silver wire material. The preparation method comprises the following steps: 1, adding glucose and polyvinylpyrrolidone into deionized water; 2, adding a copper sulfate solution into a clarified solution; 3, adding a sodium chloride solution into a mixed solution A; 4, dropwise adding a silver nitrate solution into a mixed solution B, and carrying out a hydrothermal reaction; and 5, settling and washing a flocculent product to obtain the ultra-long nano silver wire material. According to the method, silver nitrate is used as a raw material, the glucose is used as a reducing agent, a hydrothermal reaction is adopted, and the ultra-long silver nanowire material is prepared in an aqueous solution system, so that a common process for preparing the ultra-long silver nanowire material through a polyhydric alcohol organic system at present is broken through, and the technical limitations that the ultra-long silver nanowire material is difficult to wash and harsh in reaction condition are broken through; and the novel method is developed under an aqueous solution system, does not need inert atmosphere protection, is low in cost, is green and environment-friendly, and is easy for industrial production and preparation of the ultra-long nano silver wire material.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

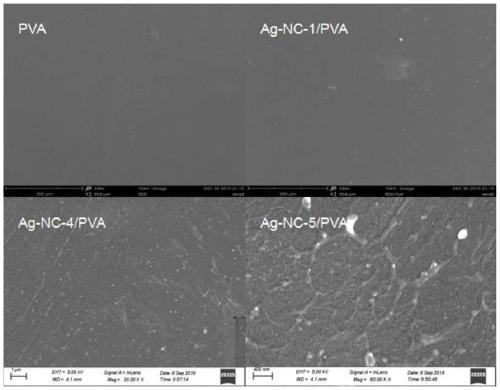

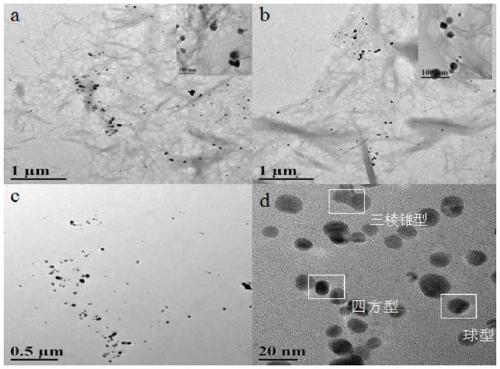

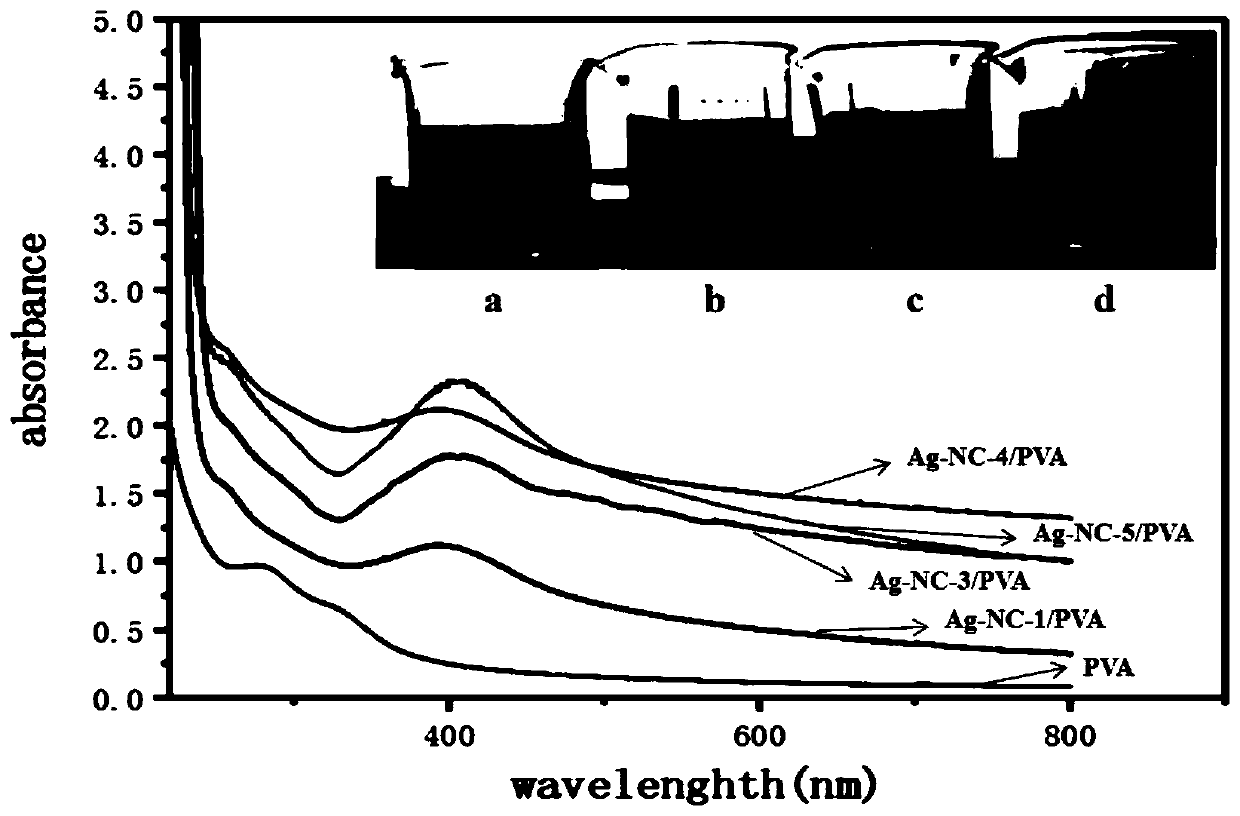

Silver-loaded nano cellulose, preparation method thereof and antibacterial composite material

ActiveCN111471312AGood antibacterial effectImprove water resistanceBiocideDisinfectantsSilver NanoCarboxylic group

The invention provides a silver-loaded nano cellulose, a preparation method thereof and an antibacterial composite material, and belongs to the technical field of functional materials. The preparationmethod comprises the following steps: mixing nano lignocellulose, tetramethyl piperidine oxide, NaBr and a Na2CO3-NaHCO3 buffer solution to obtain a nano lignocellulose suspension; mixing the nano lignocellulose suspension with a NaClO water solution, carrying out an oxidation reaction to obtain carboxylated nano lignocellulose; and mixing carboxylated nano lignocellulose, AgNO3, NaBH4 and water,and carrying out a reduction reaction under a dark condition to obtain the silver-loaded nano cellulose. By adopting the provided method, silver nano particles can be uniformly dispersed on the surface of the nano cellulose, the problem that silver nano particles are easy to agglomerate is solved; the silver-loaded nano cellulose is doped into a base material, and thus the obtained antibacterialcomposite material has an excellent antibacterial performance and also has excellent water resistance and mechanical properties.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

Preparation method of hollow mesoporous silica\APS\graphene oxide nano container

ActiveCN111057442AWork around the limitation of only providing passive protectionGood dispersionAnti-corrosive paintsEpoxy resin coatingsEpoxyMesoporous silica

The invention provides a preparation method of a hollow mesoporous silica\APS\graphene oxide nano container. According to the invention, hollow mesoporous silica and aminopropyltrimethoxysilane are mixed for modification, then the modified hollow mesoporous silica is grafted to the surface of graphene oxide, and the hollow mesoporous silica\APS\graphene oxide nano container which has good dispersity in an epoxy coating and can load a corrosion inhibitor is prepared. According to the preparation method, the dispersity of the graphene oxide in the epoxy coating is improved, so that the service life of the graphene oxide epoxy coating is greatly prolonged. The limitation that graphene oxide can only provide a passive protection function in an epoxy coating is also solved, the graphene oxide is prepared into a nano container capable of loading a corrosion inhibitor, and the active corrosion protection function can provide long-acting corrosion protection for a metal substrate.

Owner:HARBIN ENG UNIV

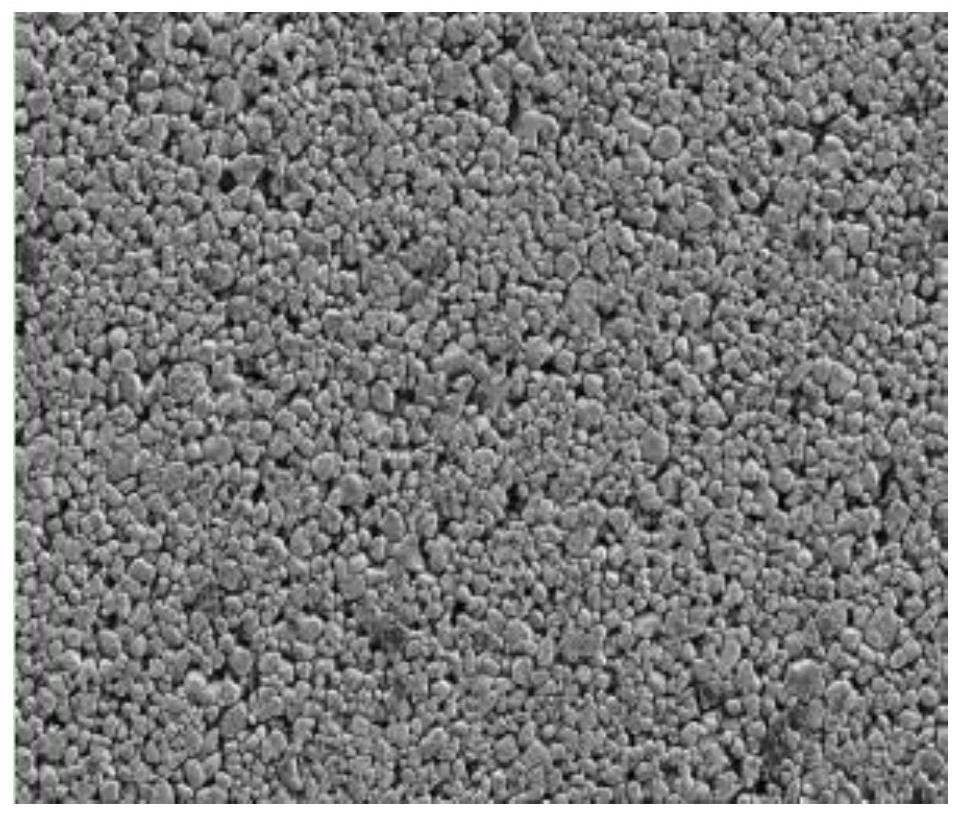

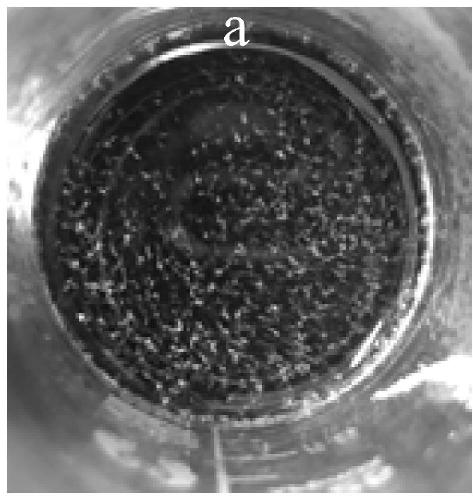

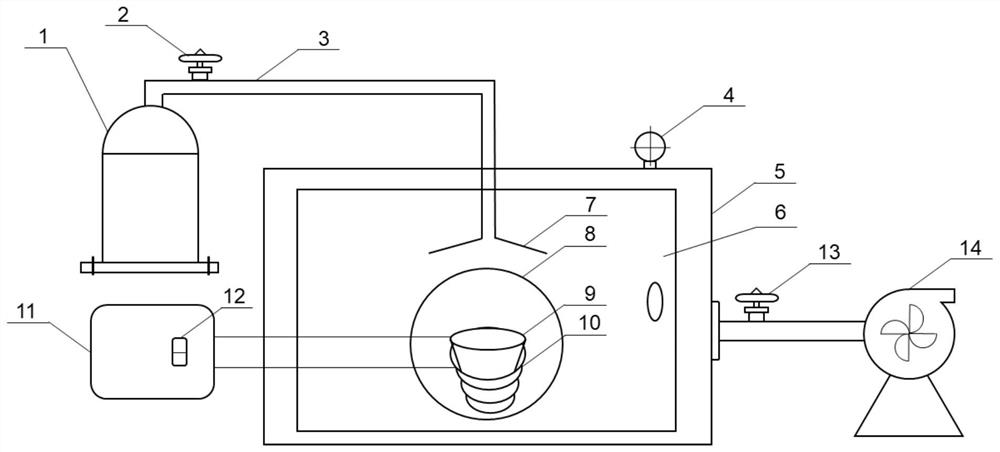

Method for preparing high-purity nano indium oxide powder

InactiveCN112062150AHigh purityImprove protectionMaterial nanotechnologyGallium/indium/thallium compoundsIndiumGas cylinder

The invention discloses a method for preparing high-purity nano indium oxide powder, which comprises a reaction box body for providing a purification reaction place, a bin gate is arranged on the reaction box body, a crucible for containing indium powder is arranged in the reaction box body, and a high-frequency induction coil for heating the crucible is arranged below the crucible. The O2 gas cylinder is connected with the reaction box body through a pipeline provided with a ball valve switch, the vacuum pump is connected with the reaction box body through a pipeline provided with a ball valve switch, and the reaction box body is further provided with a vacuum degree meter. By adopting the scheme, a special high-temperature reaction chamber and an atomizer do not need to be specially arranged. Compared with a precipitation method, the method does not generate waste liquid, does not need a washing and centrifuging process, does not need a high-temperature calcining link, and is beneficial to environmental protection and saving of water resources and energy. Compared with a solid-phase method, the indium vapor is oxidized with oxygen at high temperature, and the nano indium oxide powder with high purity, uniform particle size and high sintering activity can be prepared.

Owner:中山智隆新材料科技有限公司

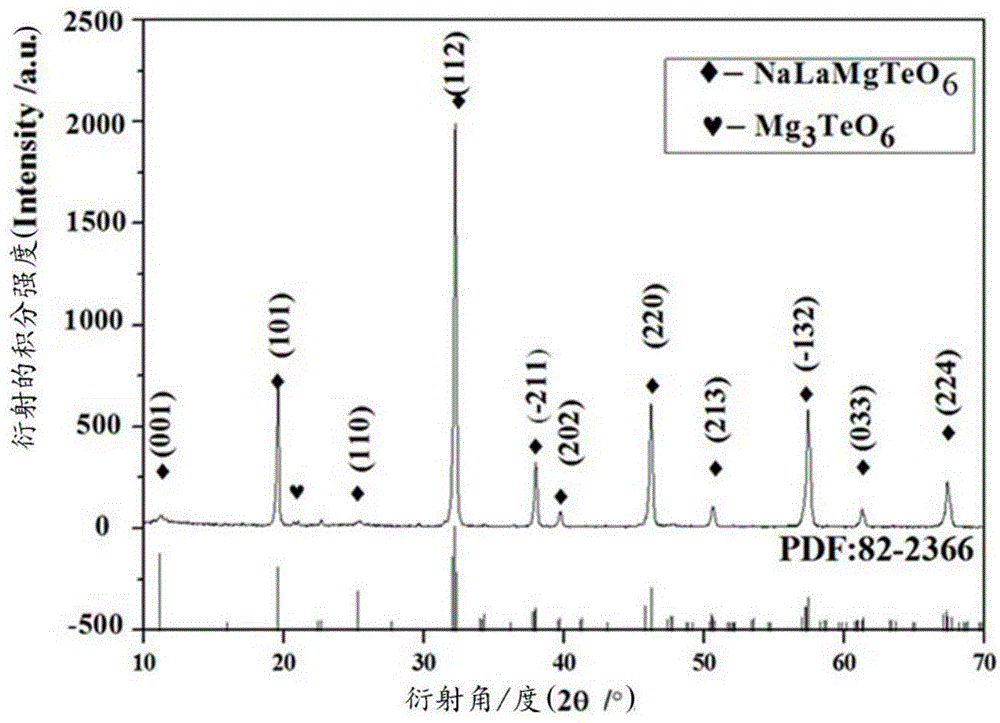

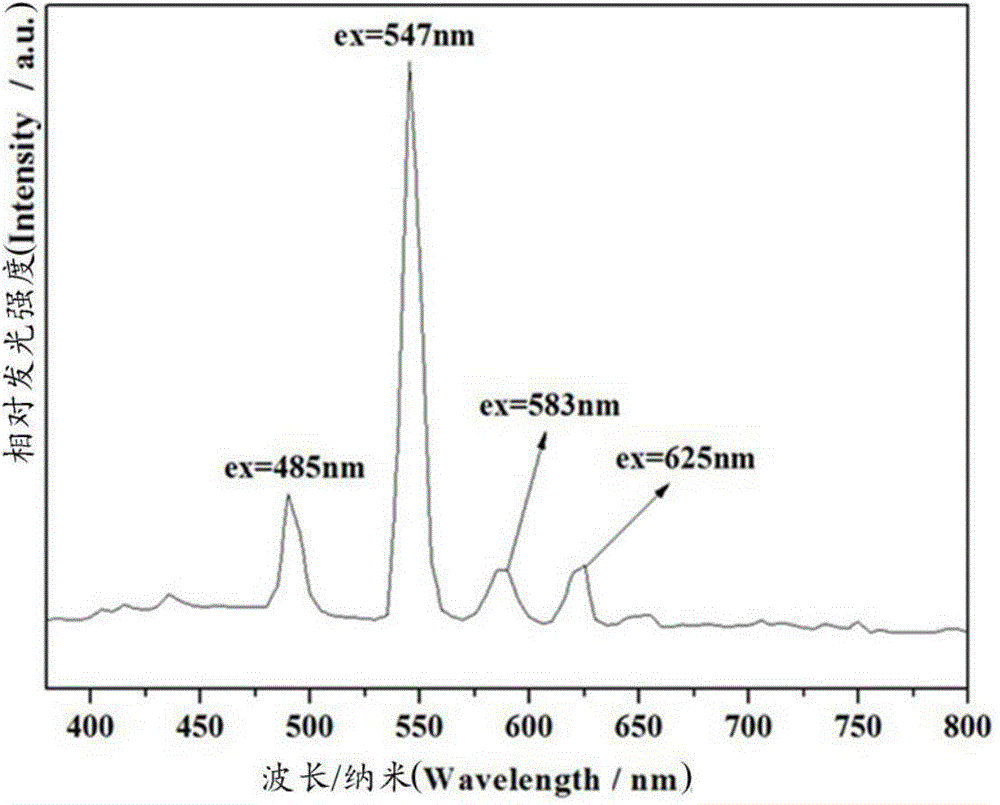

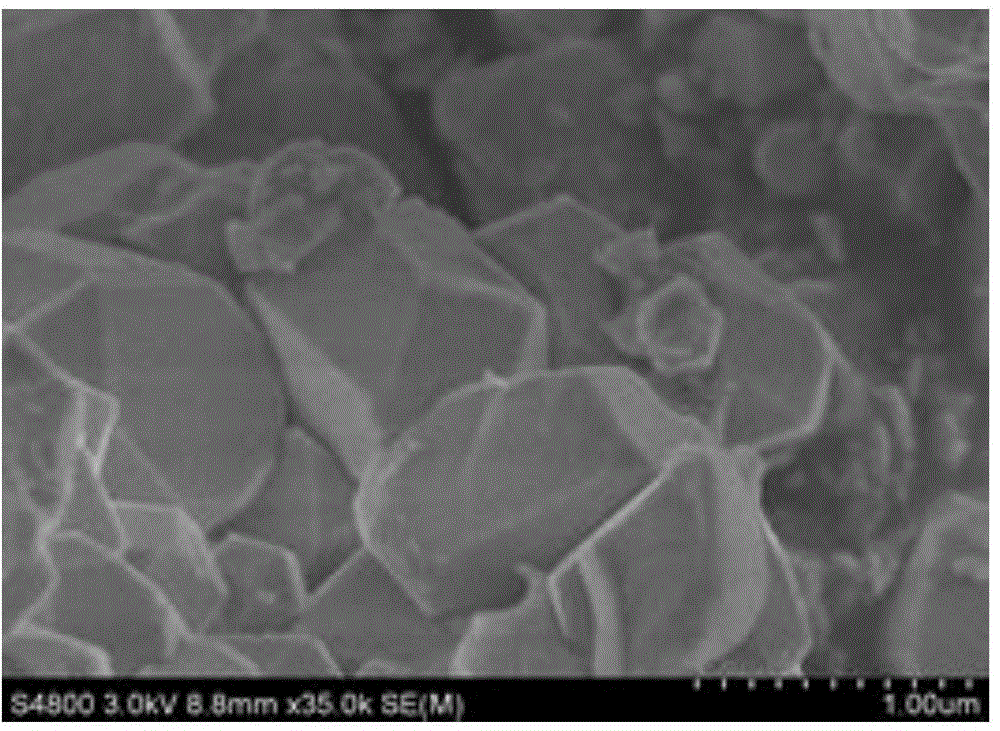

Rare earth-doped NaLaMgTeO6-based green fluorescent powder and preparation method thereof

InactiveCN104694126ALower sintering temperatureRaw materials are easy to getLuminescent compositionsWide areaUltraviolet

The invention discloses rare earth-doped NaLaMgTeO6-based green fluorescent powder and a preparation method thereof. By adopting a high-temperature solid phase method, by taking a compound containing Na<+>, a compound containing La<3+>, a compound containing Te<4+>, a compound containing Mg<2+>, a compound containing Dy<3+> and a compound containing Tb<3+> as reaction raw materials, the raw materials are weighed in a stoichiometric ratio of a chemical formula NaLa(1-x)MgTeO6:xTb<3+>, wherein x is equal to 0.01-0.10. The NaLa(1-x)MgTeO6:xTb<3+> crystal prepared by the invention is good in development and good in powder morphology. The crystal excited by 365nm ultraviolet rays emits green characteristic light, is high in light emitting intensity and emits light in a wide spectrum and multiple peaks. The emission peak covers red, green and blue wide areas of 485-625nm and green emission at the main peak of 547nm is represented.

Owner:SHAANXI UNIV OF SCI & TECH

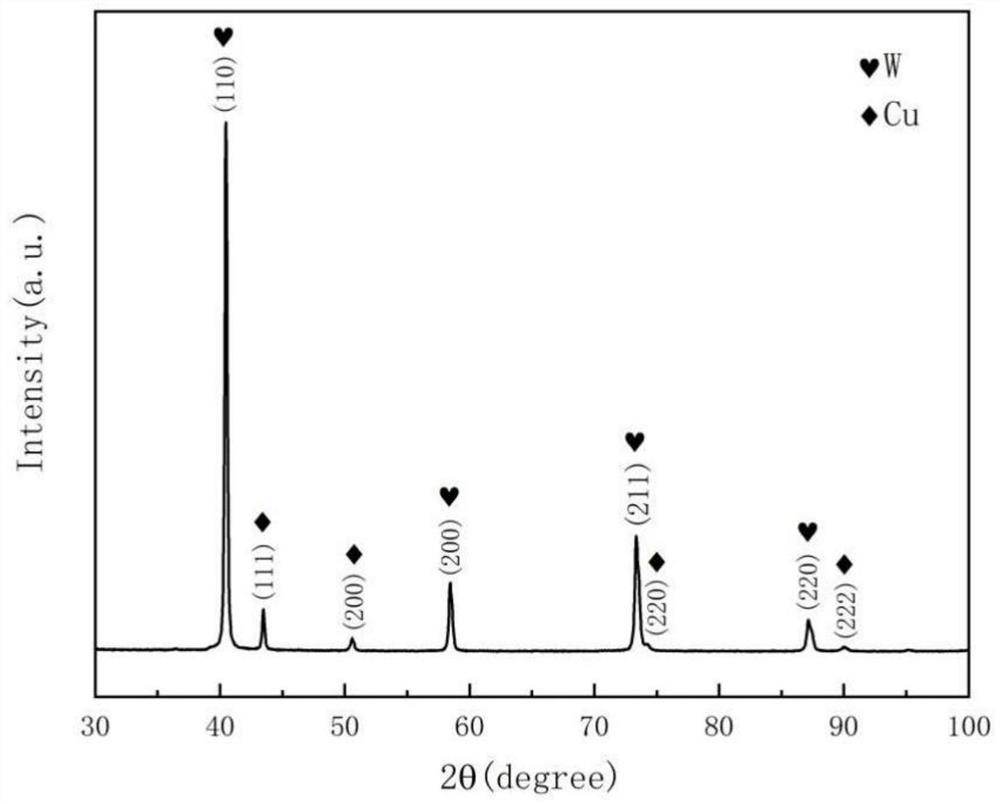

W-Cu composite powder with high thermal conductivity and low thermal expansion coefficient and preparation method thereof

PendingCN113909484AHigh sintering activityImprove density and physical propertiesSemiconductor/solid-state device detailsSolid-state devicesThermal conductivityThermal transmittance

The invention discloses W-Cu composite powder with high thermal conductivity and low thermal expansion coefficient. The thermal conductivity is 200-235W / (m.K), and the thermal expansion coefficient is (5.6-9.3) * 10<-6> / K. The invention further discloses a preparation method of the W-Cu composite powder with high thermal conductivity and low thermal expansion coefficient. The preparation method comprises the following steps of: preparing a W-Cu precursor by adopting a wet chemical method; carrying out pyrolysis reduction on the W-Cu precursor in a hydrogen environment; and carrying out compression molding on the reduced W-Cu composite powder, then heating to 1100-1300 DEG C in a hydrogen atmosphere, carrying out heat preservation for 100-140 minutes, and cooling to obtain the W-Cu composite powder. According to the preparation method, the W-Cu composite precursor is prepared by adopting the wet chemical method, the W-Cu composite powder with high sintering activity is obtained through different reduction process combinations, and then the W-Cu composite powder with high density, high thermal conductivity, low thermal expansion coefficient and uniform tissue distribution is prepared through subsequent liquid phase sintering.

Owner:安徽亿恒新材料科技有限公司

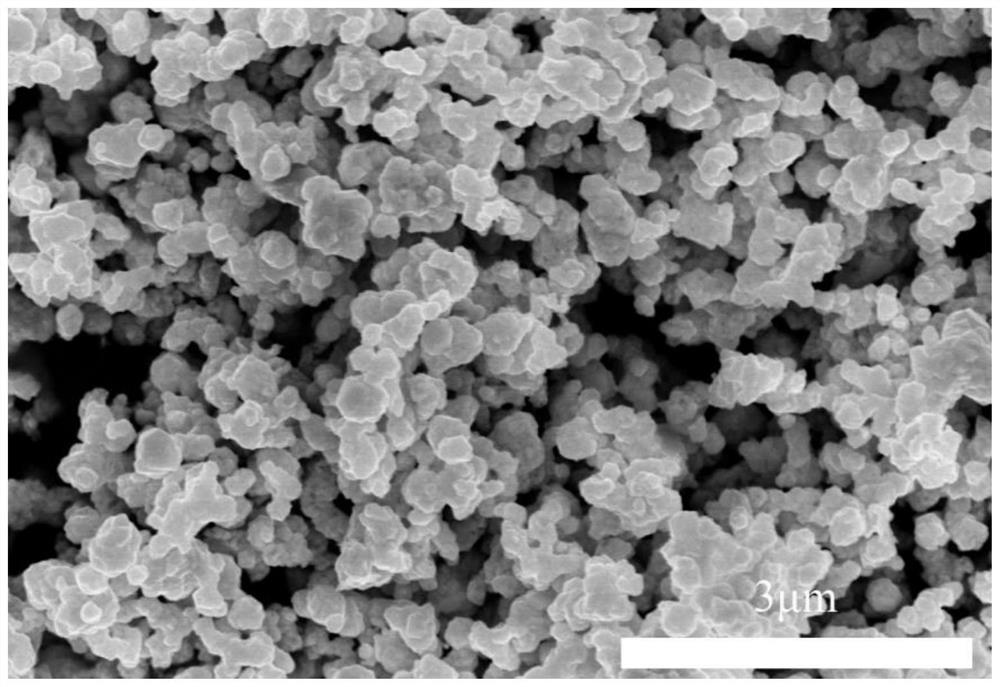

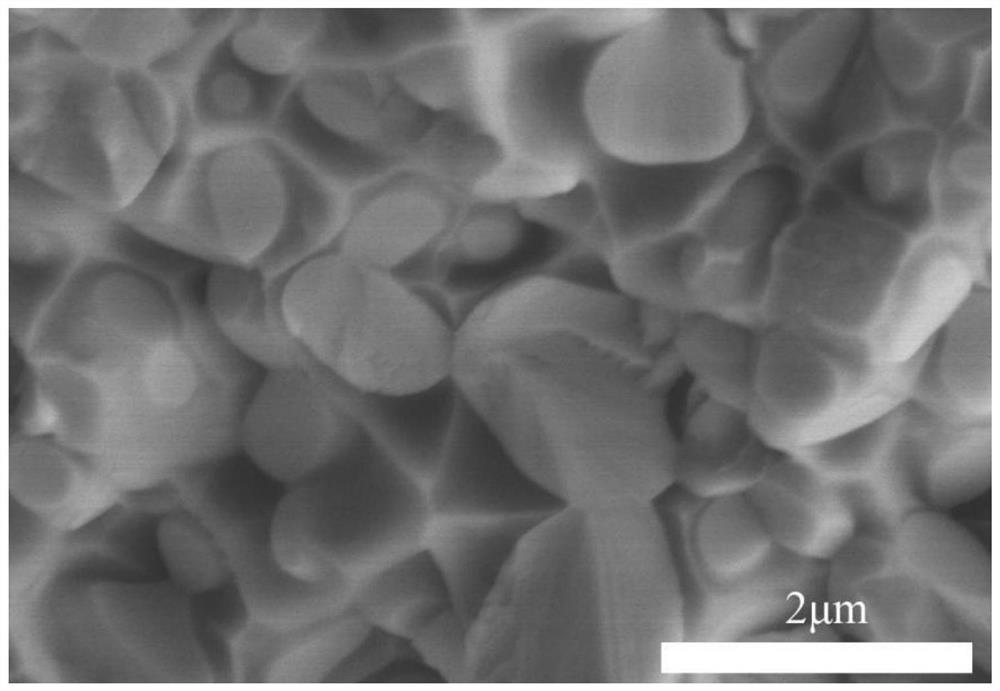

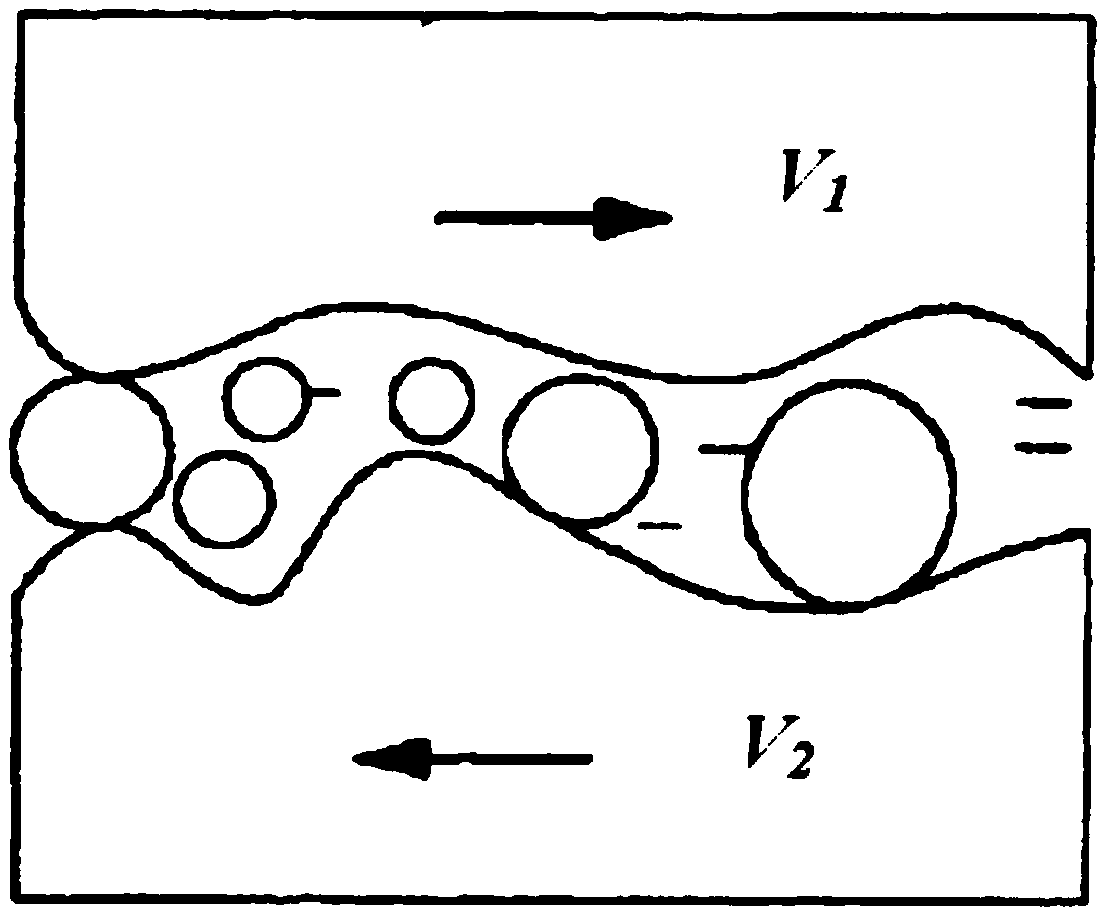

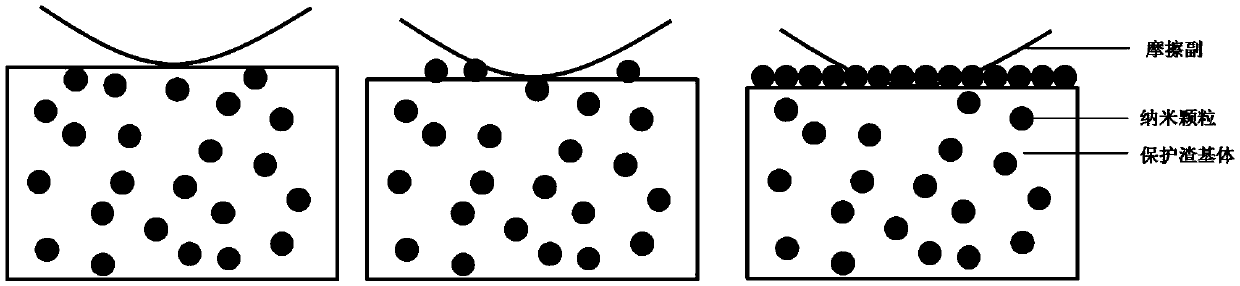

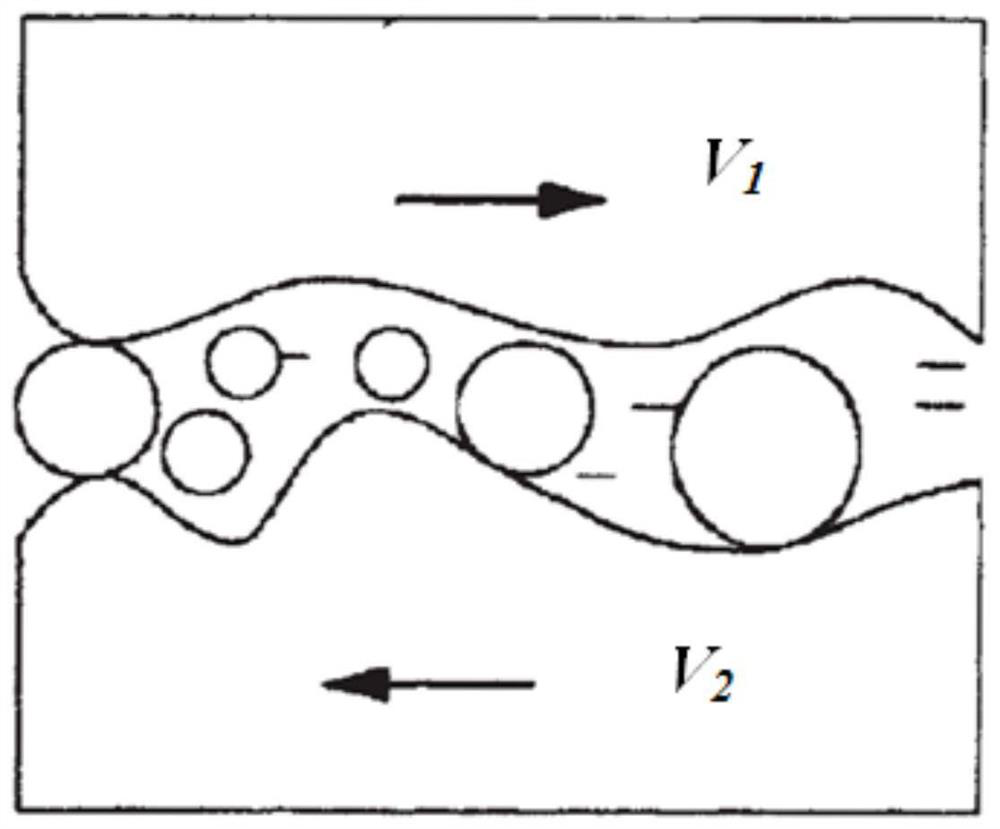

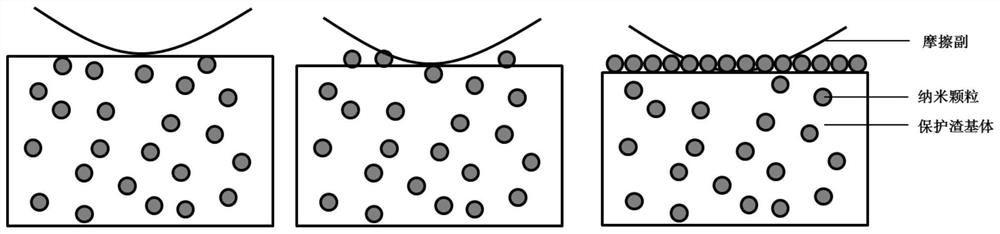

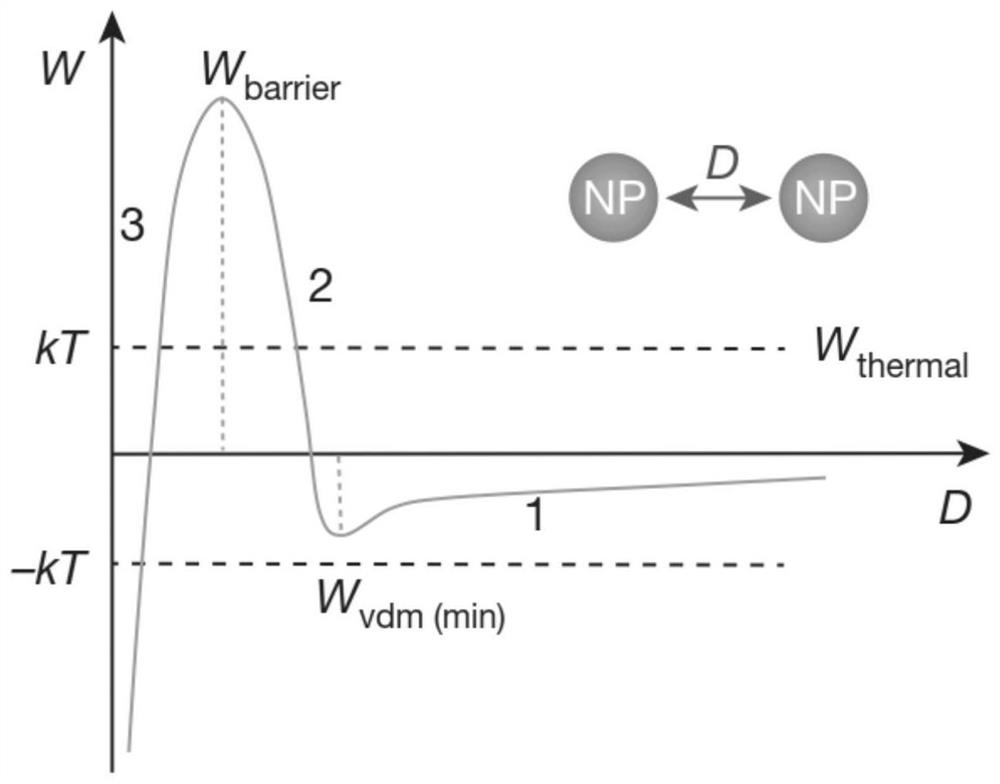

Continuous casting crystallizer nano protection slag and preparing method thereof

The invention discloses continuous casting crystallizer nano protection slag and a preparing method thereof. Spherical nanoparticles with the volume ratio being 0.1 to 50% are doped in the protectionslag, due to the fact that that the spherical nanoparticles have the advantages of being high in heat conduction coefficient, good in sphericility degree, proper in grain size and the like, uniform and stable nanofluid is formed in the liquid protection slag, nano particles with the enough high interfaces between the particles and the enough low Van der Waals' effect potential can be formed in solid protection slag, the nano particles can be kept uniform distribution in the liquid-state protection slag, the obvious agglomeration does not exist, after the protection slag is added, the continuous casting crystallizer nano protection slag is formed, the excellent heat transfer property and the lubricating property can be achieved, the casting blank surface and the inner quality can be improved, and the method is suitable for producing products (like a super-thick plate) of the special requirement and products (like super-high pulling rate) of the particular continuous casting process.

Owner:CISDI ENG CO LTD +1

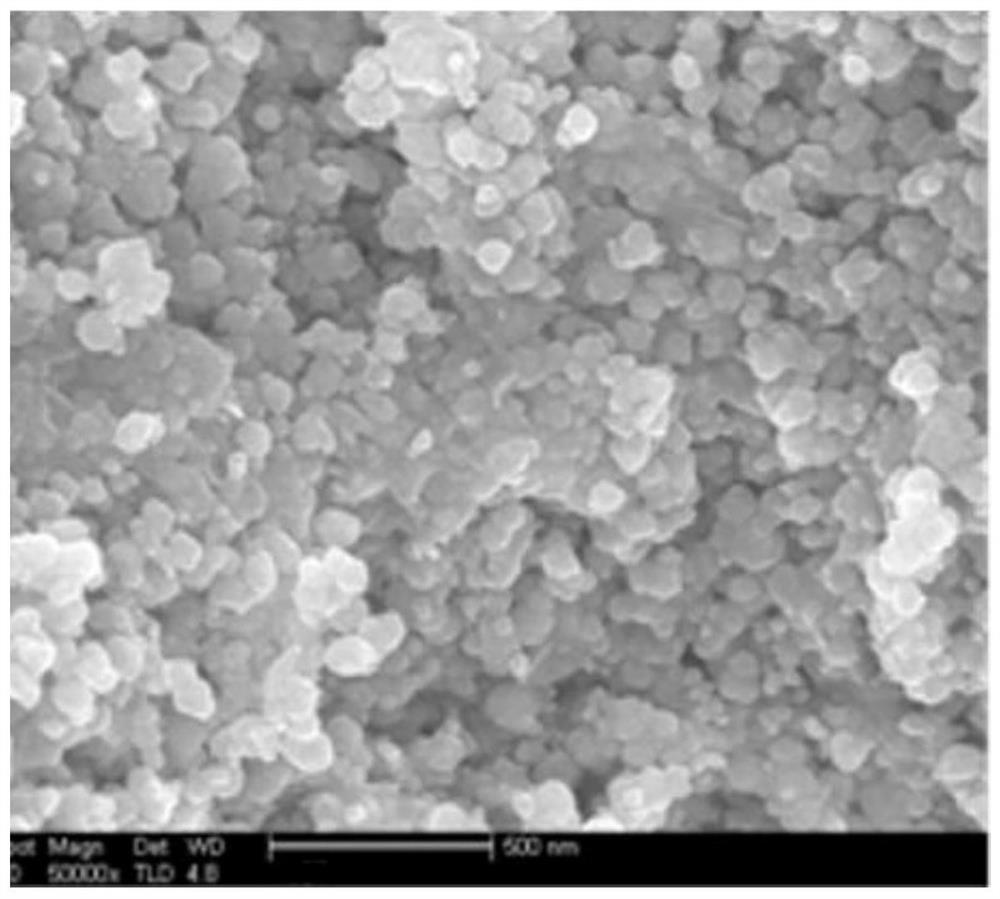

Lithium iron phosphate anode active material preparation method and lithium iron phosphate anode active material prepared therethrough

ActiveCN103633323AIncrease compaction densityHigh specific capacityCell electrodesLithium iron phosphateActive agent

The invention provides a lithium iron phosphate anode active material and a preparation method thereof. The preparation method of the lithium iron phosphate anode active material comprises the following steps: allowing a first phosphorus source, a first iron source and a cationic surfactant to contact with a first lithium source to obtain a solution A, allowing a second phosphorus source, a second iron source and an anionic surfactant to contact with a second lithium source to obtain a solution B, and reacting the solution A with the solution B at a high temperature under a high pressure to obtain lithium iron phosphate. The method is simple and can be easily realized, and the prepared anode active material has the advantages of high compacted density, high specific capacity and high volume energy.

Owner:BYD CO LTD

Magnetic biomimetic catalyst and preparation method and application method thereof

InactiveCN106669674AHigh fixed carbon contentHigh strengthMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationChemical oxygen demandWater quality

The invention relates to a magnetic biomimetic catalyst and a preparation method and an application method thereof. The preparation method adopts the technical scheme that the preparation method comprises the following steps of uniformly mixing coal-based carbon and a KOH (potassium hydroxide) solution, and treating for 1 to 2h under the vacuum atmosphere at the temperature of 105 DEG C; putting into a microwave generation device, and activating at the temperature of 300 to 700 DEG C; cooling, adding deoxidizing and deionizing water, stirring, standing, and obtaining an upper KOH recycling liquid and a lower precipitate; washing the lower precipitate, and drying, so as to obtain the modified coal-based carbon; uniformly mixing FeSO4.7H2O (ferrous sulfate), the modified coal-based carbon and the deoxidizing and deionizing water, so as to obtain suspension liquid; uniformly mixing NaNO3 (sodium nitrate), NaOH (sodium hydroxide) and the deoxidizing and deionizing water, dripping into the suspension liquid, stirring, and standing; washing the lower magnetic precipitate to neutral state, and drying, so as to obtain the magnetic biomimetic catalyst; uniformly mixing the magnetic biomimetic catalyst and organic wastewater, adding H2O2 (hydrogen peroxide), stirring, and treating, so that the COD (chemical oxygen demand) and chroma of the organic wastewater can reach the national industrial regeneration water quality standard. The preparation method has the characteristics that the technology is simple, the operability is high, the cost is low, the yield is high, and the environment-friendly effect is realized.

Owner:WUHAN UNIV OF SCI & TECH

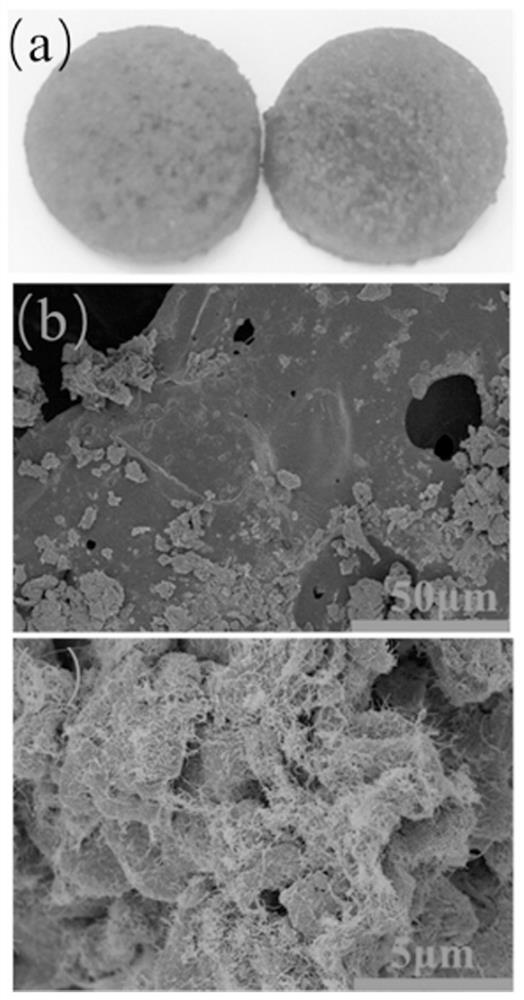

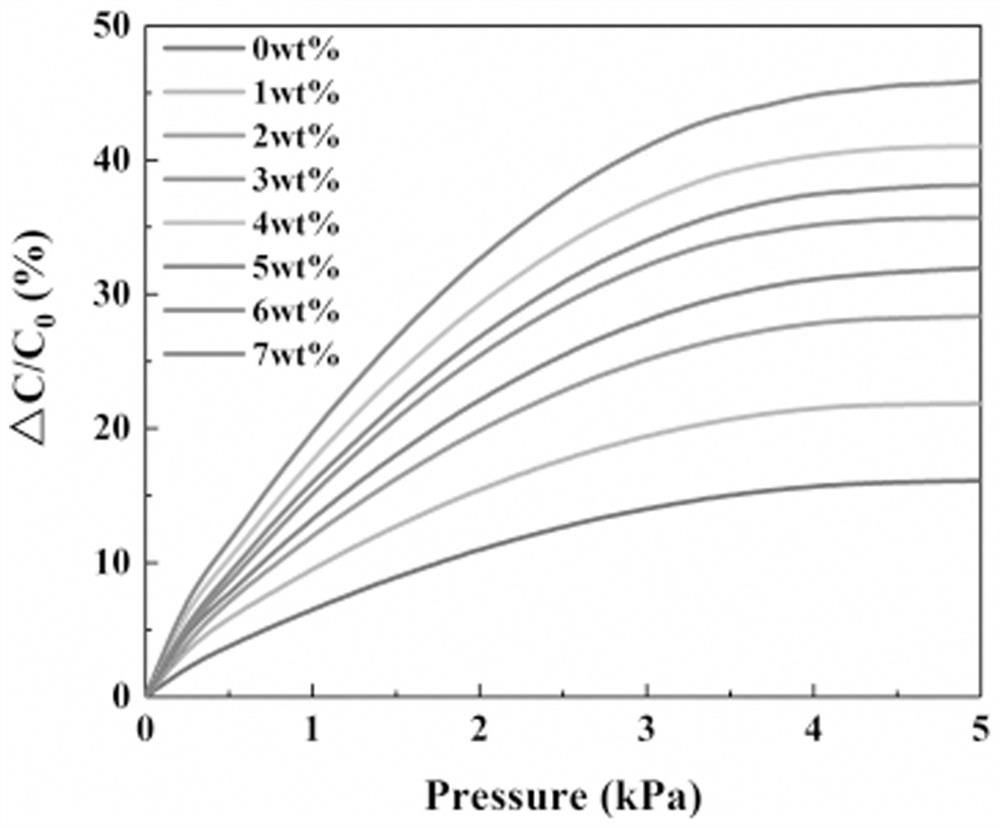

Preparation method of CNT/PDMS flexible composite material and capacitive pressure sensor

PendingCN114479468ASolve permeabilitySolve the problem of easy falling offCarbon compoundsForce measurementCapacitive pressure sensorFirming agent

The invention discloses a preparation method of a CNT / PDMS flexible composite material, which comprises the following steps: fully mixing CNT modified by a strong acid oxidation method with sugar particles, adding PDMS sponge and a curing agent, fully stirring, tabletting by using a tabletting machine, putting a sample into a drying oven, heating and curing for a certain time, and taking out the sample to obtain the CNT / PDMS flexible composite material. And taking out the sample, and putting the sample into water to melt the sugar, thereby preparing the CNT / PDMS flexible composite material. The carbon nanotubes are brought into the PDMS matrix through the sugar particles, so that the phenomenon of agglomeration among the nanotubes is reduced, the carbon nanotube particles are favorably combined with the polymer matrix and are uniformly dispersed in the flexible matrix PDMS, the sensitivity and durability are good, and stable capacitance response is ensured.

Owner:SUZHOU UNIV

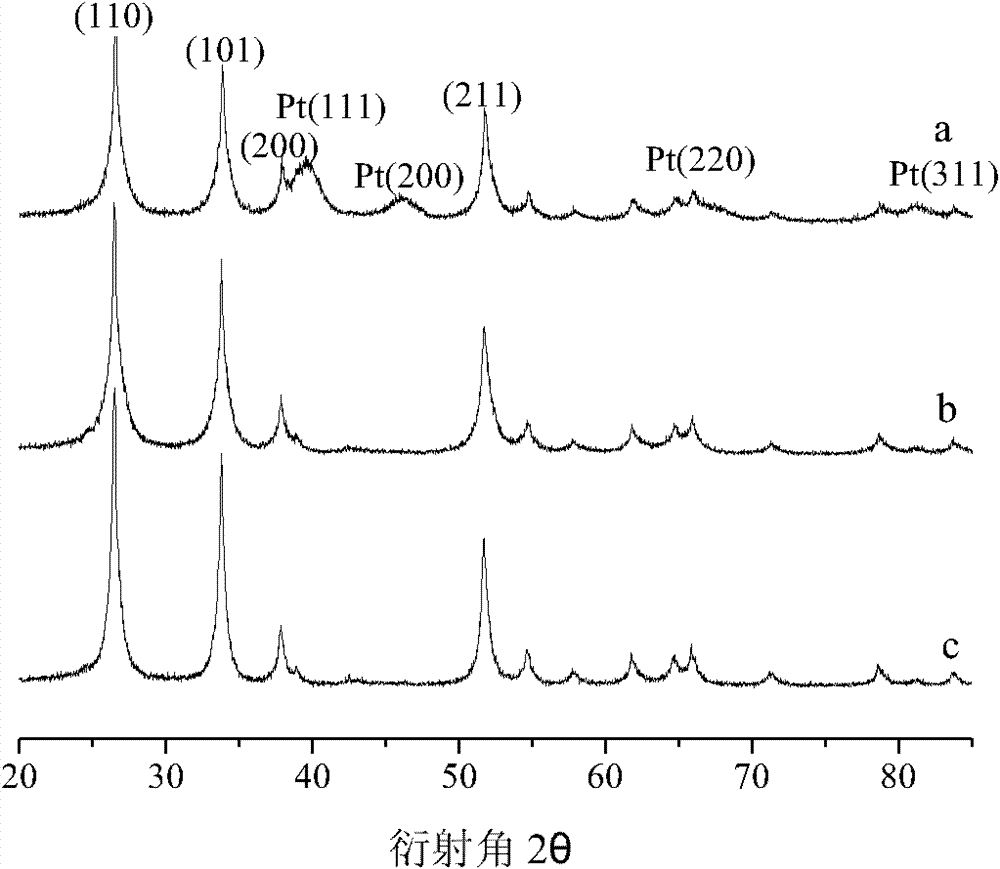

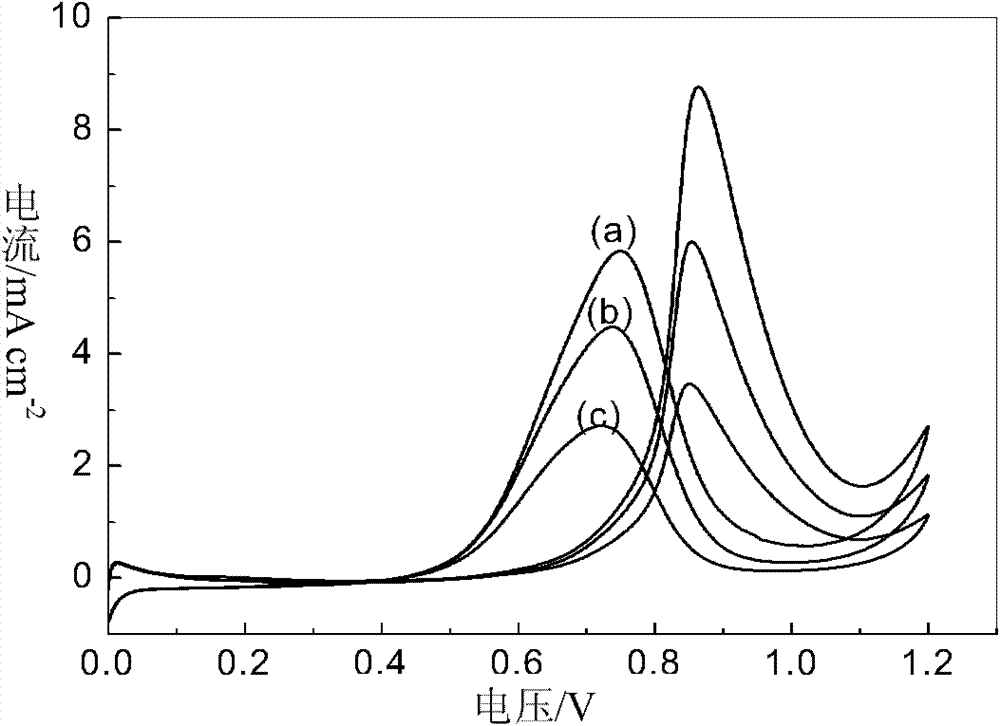

Method for preparing anode catalyst of direct methanol fuel cell

InactiveCN102074712BImprove dispersion uniformityImprove consistencyCell electrodesMetal/metal-oxides/metal-hydroxide catalystsHigh current densityCatalytic oxidation

The invention relates to a method for preparing an anode catalyst of a direct methanol fuel cell. The method comprises the following steps of: dispersing and dissolving carbon black, SnCl4.5H2O and SbCl3 in absolute ethanol; filtering, washing, drying, grinding and calcining to obtain an antimony tin oxide / carbon (ATO / C) carrier, which has a uniform size, is uniformly dispersed and is hardly agglomerated, by taking ammonia water or sodium hydroxide solution as a precipitator; dissolving H2PtCl6.6H2O in ethylene glycol; heating in the atmosphere of inert gas to obtain platinum (Pt) sol; and mixing the PT sol and ethanol suspension of the ATO / C to obtain a Pt-ATO / C catalyst. The method has a simple process and is low in cost; and the prepared Pt-ATO / C catalyst is highly dispersed, has a uniform particle size, does not have obvious agglomeration phenomenon, has a lower starting potential and higher current density, shows excellent electro-catalytic oxidation activity and efficiency and has a good application prospect.

Owner:DONGHUA UNIV

Nano mold flux for continuous casting crystallizer and preparation method thereof

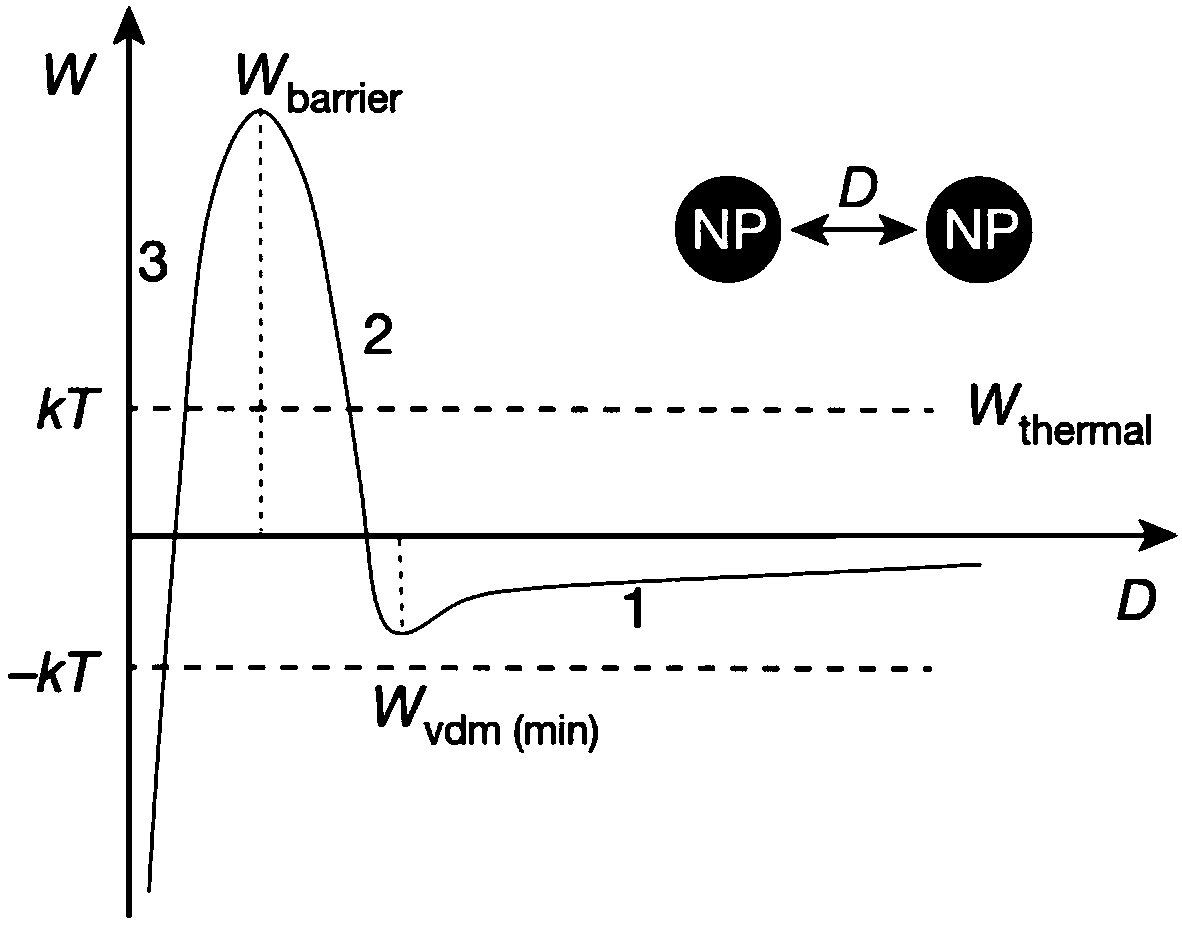

The invention discloses a continuous casting crystallizer nano mold flux and a preparation method thereof. The mold flux is doped with spherical nanoparticles with a volume ratio of 0.1 to 50%. The spherical nanoparticles have high thermal conductivity and good sphericity. , suitable particle size and other advantages, uniform and stable nanofluid can be formed in liquid mold flux, and nanoparticles with sufficiently high interfacial energy and sufficiently low van der Waals action potential in solid mold flux can make nanoparticles The liquid mold flux can maintain a uniform distribution without obvious agglomeration phenomenon, so after adding the mold flux, it forms a continuous casting crystallizer nano-molten flux, which has excellent heat transfer performance and lubricating performance, and can improve the surface and interior of the slab. Quality, suitable for the production of products with special specifications (such as extra-thick plates) and products with special continuous casting processes (such as ultra-high casting speed).

Owner:CISDI ENG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com