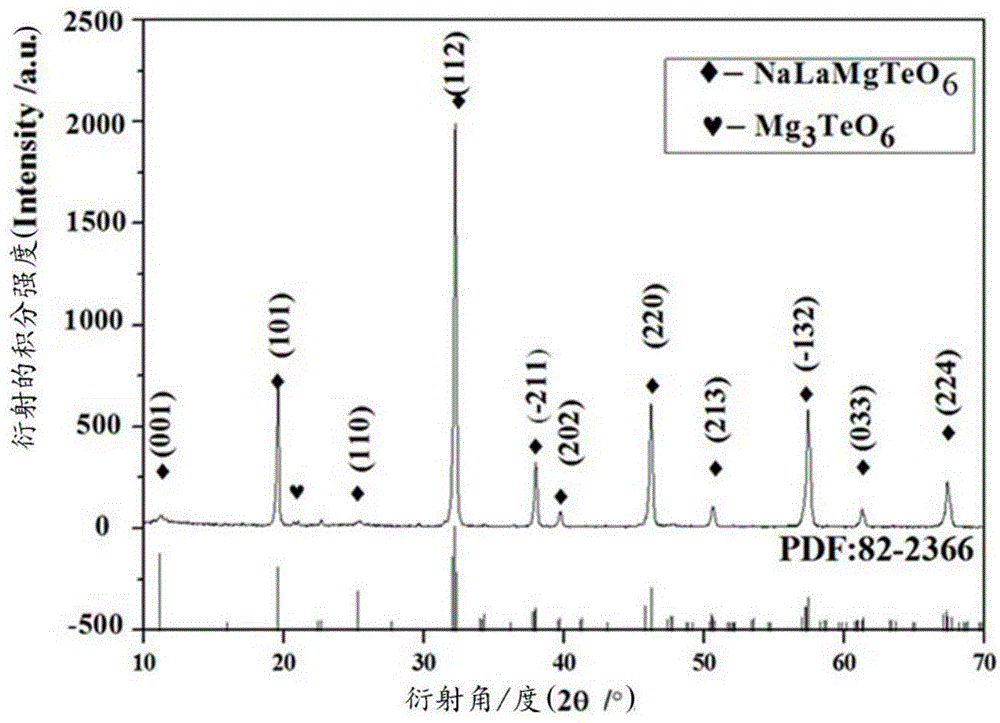

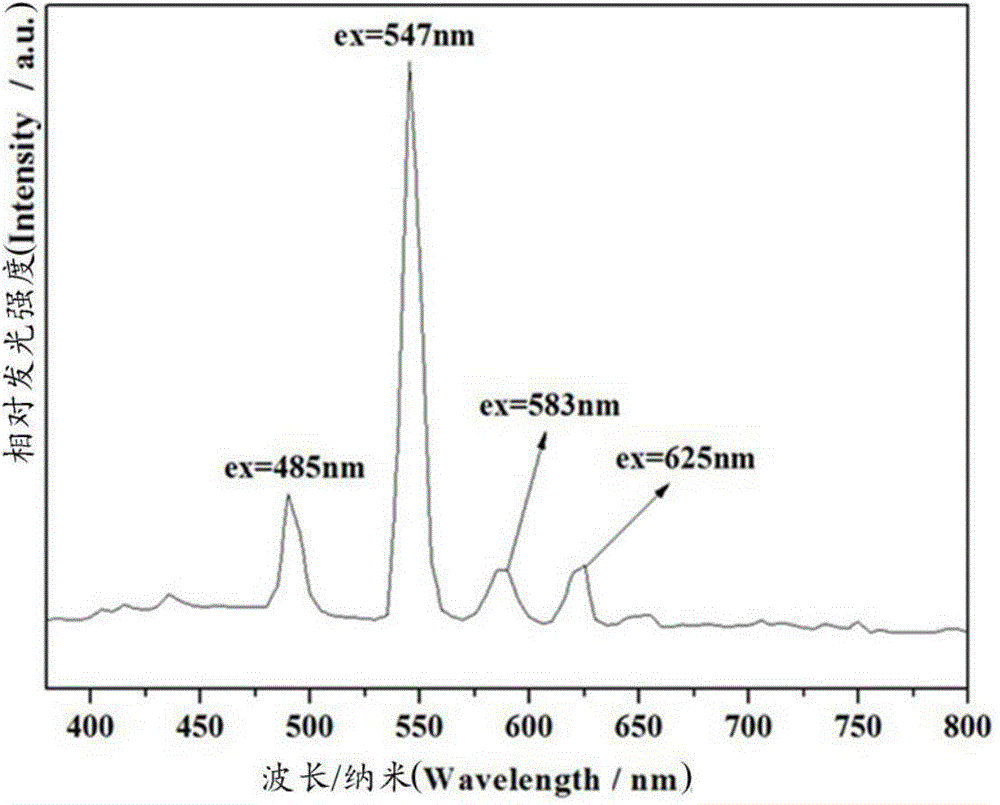

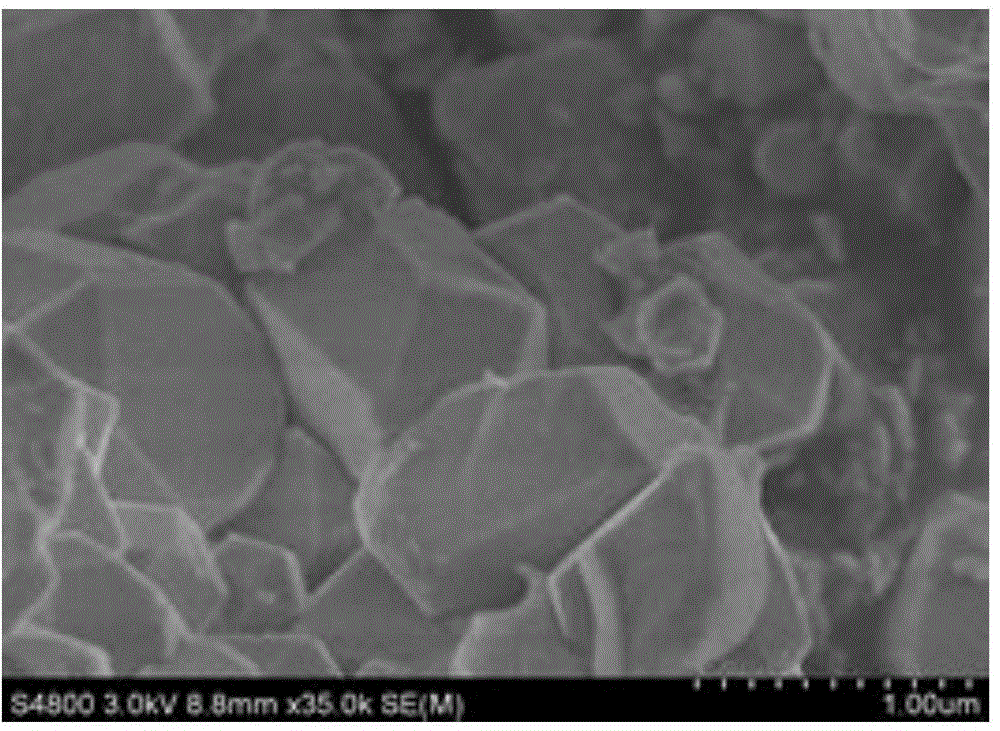

Rare earth-doped NaLaMgTeO6-based green fluorescent powder and preparation method thereof

A green phosphor, rare earth doping technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problem that the luminous intensity and color rendering of green powder cannot meet the needs of use well, and achieve easy availability of raw materials and sintering. The effect of low temperature and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Select commercially available Na 2 CO 3 , La 2 o 3 , TeO 2 , Mg(NO 3 ) 2 ·6H 2 O and Tb 4 o 7 As a reaction raw material, according to the chemical formula NaLa 0.99 MgTeO 6 : 0.01Tb 3+ The stoichiometric ratio of each raw material was weighed;

[0031] 2) Put the raw materials weighed in step 1) into the mortar, add ethanol to the mortar, the amount of ethanol can make the raw materials in the mortar fully grind and mix evenly;

[0032] 3) Co-precipitate the homogeneously mixed raw materials with the ethanol system, and dry the precipitate in an oven at 100°C for 3 hours;

[0033]4) Put the dried mixture into a corundum crucible, place the crucible in a high-temperature furnace, raise the temperature to 300°C at a rate of 2°C / min, then raise the temperature to 1100°C at a rate of 5°C / min, keep it warm for 4 hours, and then cool To room temperature promptly obtains green fluorescent powder NaLa of the present invention 0.99 MgTeO 6 : 0.01Tb 3+ .

Embodiment 2

[0035] 1) Select commercially available Na 2 CO 3 , La 2 o 3 , TeO 2 , Mg(NO 3 ) 2 ·6H 2 O and Tb 4 o 7 As a reaction raw material, according to the chemical formula NaLa 0.97 MgTeO 6 : 0.03Tb 3+ The stoichiometric ratio of each raw material was weighed;

[0036] 2) Put the raw materials weighed in step 1) into the mortar, add ethanol to the mortar, the amount of ethanol can make the raw materials in the mortar fully grind and mix evenly;

[0037] 3) Co-precipitate the homogeneously mixed raw materials with the ethanol system, and dry the precipitate in an oven at 120°C for 5 hours;

[0038] 4) Put the dried mixture into a corundum crucible, place the crucible in a high-temperature furnace, raise the temperature to 300°C at a rate of 3°C / min, then raise the temperature to 1200°C at a rate of 3°C / min, keep it warm for 4 hours, and then cool To room temperature promptly obtains green fluorescent powder NaLa of the present invention 0.97 MgTeO 6 : 0.03Tb 3+ .

Embodiment 3

[0040] 1) Select commercially available Na 2 CO 3 , La 2 o 3 , TeO 2 , Mg(NO 3 ) 2 ·6H 2 O and Tb 4 o 7 As a reaction raw material, according to the chemical formula NaLa 0.95 MgTeO 6 : 0.05Tb 3+ The stoichiometric ratio of each raw material was weighed;

[0041] 2) Put the raw materials weighed in step 1) into the mortar, add ethanol to the mortar, the amount of ethanol can make the raw materials in the mortar fully grind and mix evenly;

[0042] 3) Co-precipitate the homogeneously mixed raw materials with the ethanol system, and dry the precipitate in an oven at 120°C for 3 hours;

[0043] 4) Put the dried mixture into a corundum crucible, place the crucible in a high-temperature furnace, raise the temperature to 300°C at a rate of 3°C / min, then raise the temperature to 1200°C at a rate of 5°C / min, keep it warm for 5 hours, and then cool To room temperature promptly obtains green fluorescent powder NaLa of the present invention 0.95 MgTeO 6 : 0.05Tb 3+ .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com