Preparation method of high-dispersity silk fibroin-chitosan-3-methylimidazole salt hexylthiophene-multiwalled carbon nanotube gel

A technology of multi-walled carbon nanotubes and methyl imidazolium salt, which is applied in the field of functional materials, can solve problems such as limitations in the scope of application, and achieve the effects of stable dispersion, high water solubility, and no toxic side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

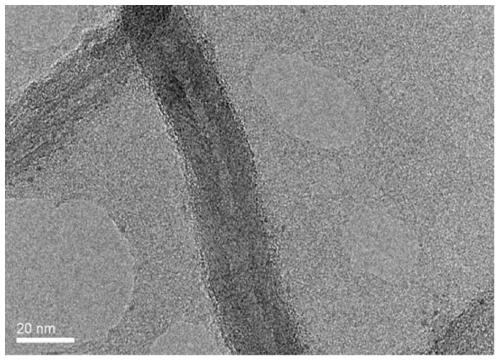

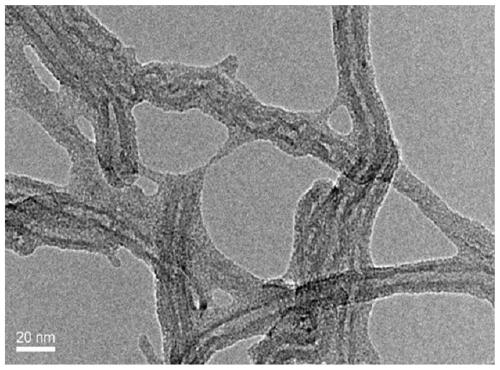

Image

Examples

Embodiment 1

[0039] 1) Measure 10 mg of acidified multi-walled carbon nanotubes in 20 ml of deionized water for 30 minutes to disperse completely. Methylaminopropyl) carbodiimide hydrochloride (0.1 mmol) 10 ml, after stirring for 10 min, slowly add 10 ml N-hydroxysuccinimide (0.1 mmol) dropwise, and react for 30 min.

[0040] 2) Prepare 3-methylimidazolium hexylthiophene by a two-step method. Dissolve 20 mg of the prepared 3-methylimidazolium hexylthiophene in 20 ml deionized water, heat and ultrasonicate at 40°C for 30 minutes to dissolve completely.

[0041] 3) Add 10mg of chitosan to 10ml of deionized water, add 1% acetic acid, and sonicate for 30min until completely dissolved.

[0042] 4) Slowly add the chitosan solution obtained above into the dispersion obtained in step 1) drop by drop, and react for 24 h.

[0043] 5) Measure 20 ml of ultrasonicated 3-methylimidazolium hexylthiophene and slowly add it to the solution obtained in step 4), and ultrasonicate for 30 minutes to make it c...

Embodiment 2

[0051] 1) Measure 15 mg of acidified multi-walled carbon nanotubes in 20 ml of deionized water for 30 minutes until the dispersion is complete. After the ultrasound is completed, place the solution on a magnetic stirrer and slowly add 1-ethyl-(3-di Methylaminopropyl) carbodiimide hydrochloride (0.1 mmol) 10 ml, after stirring for 10 min, slowly add 10 ml of N-hydroxysuccinimide (0.1 mmol) dropwise, and react for 30 min.

[0052] 2) Prepare 3-methylimidazolium hexylthiophene by a two-step method. Dissolve 30 mg of 3-methylimidazolium hexylthiophene in 20 ml of deionized water, heat and sonicate at 40°C for 30 minutes to dissolve completely.

[0053] 3) Add 15mg of chitosan to 10ml of deionized water, add 1% acetic acid, and sonicate for 30min until completely dissolved.

[0054] 4) Slowly add the above chitosan solution dropwise into the dispersion obtained in step 1), and react for 24 h.

[0055] 5) Slowly add 30 ml of ultrasonicated 3-methylimidazolium hexylthiophene into th...

Embodiment 3

[0063] 1) Measure 10 mg of acidified multi-walled carbon nanotubes in 20 ml of deionized water for 30 minutes to disperse completely. Methylaminopropyl) carbodiimide hydrochloride (0.1 mmol) 10 ml, after stirring for 10 min, slowly add 10 ml N-hydroxysuccinimide (0.1 mmol) dropwise, and react for 30 min.

[0064] 2) Prepare 3-methylimidazolium hexylthiophene by a two-step method. Dissolve 20 mg of 3-methylimidazolium hexylthiophene in 20 ml of deionized water, heat and sonicate at 40°C for 30 minutes to dissolve completely.

[0065] 3) Add 10mg of chitosan to 10ml of deionized water, add 1% acetic acid, and sonicate for 30min until completely dissolved.

[0066] 4) Slowly add the above chitosan solution dropwise into the dispersion obtained in step 1), and react for 24 h.

[0067] 5) Take 20ml of ultrasonicated 3-methylimidazolium hexylthiophene and slowly add it to the solution obtained in step 4), and ultrasonicate for 30 minutes to make it composite with chitosan-multi-wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com