Nanometer platinum-copper alloy catalytic material for electrolysis of water

A technology of platinum-copper alloys and catalytic materials, which is applied in metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc., and can solve the problems of expensive precious metals and inability to use them on a large scale , to achieve the effect of many active sites, small size and large aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

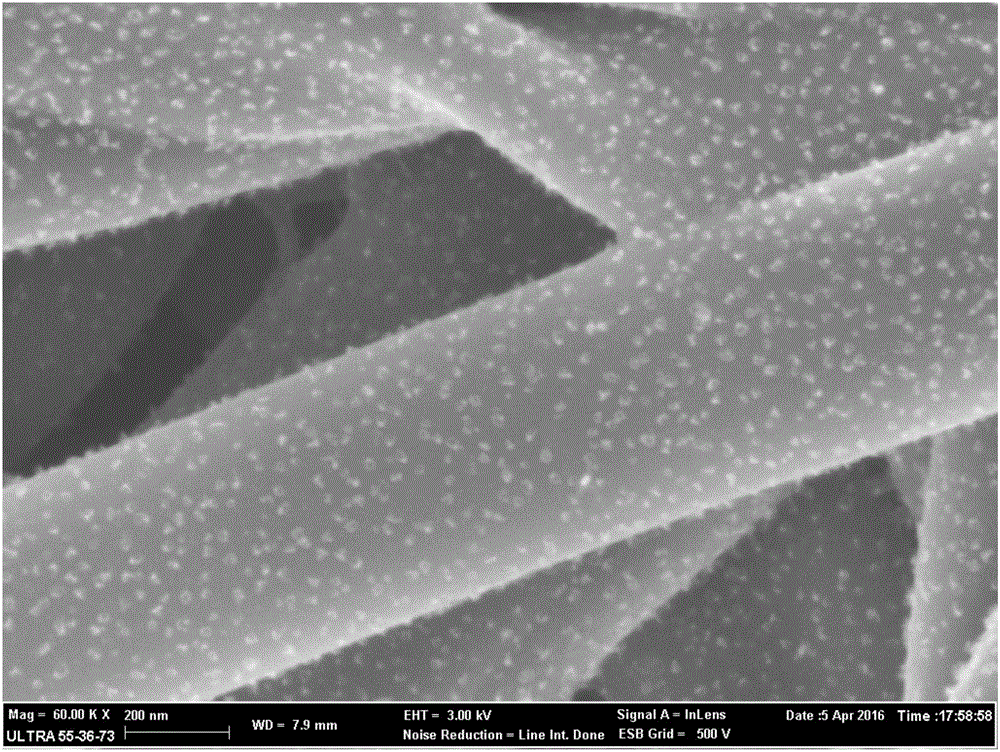

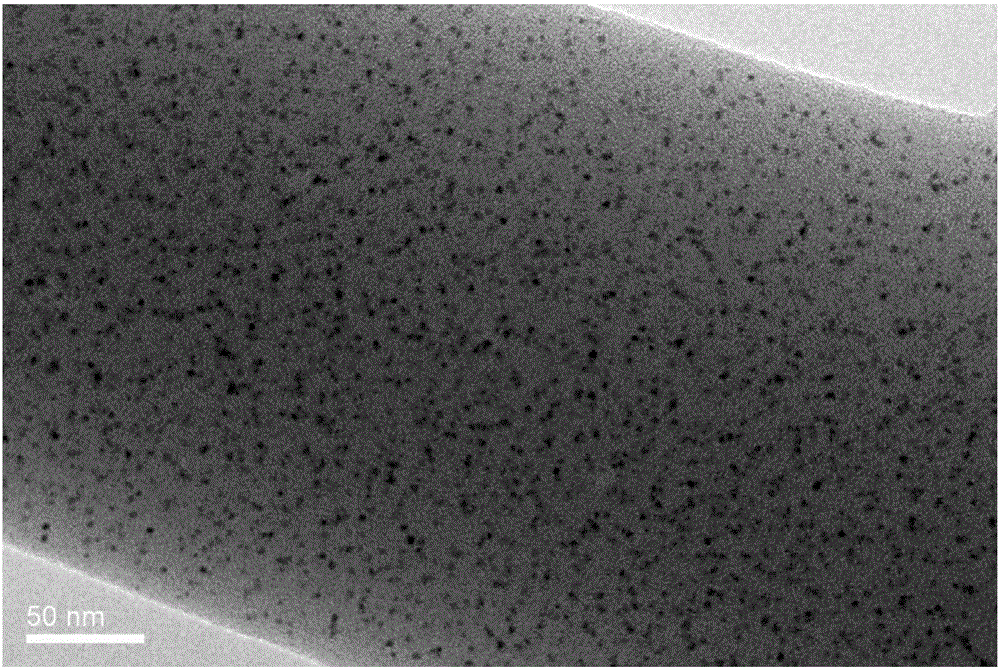

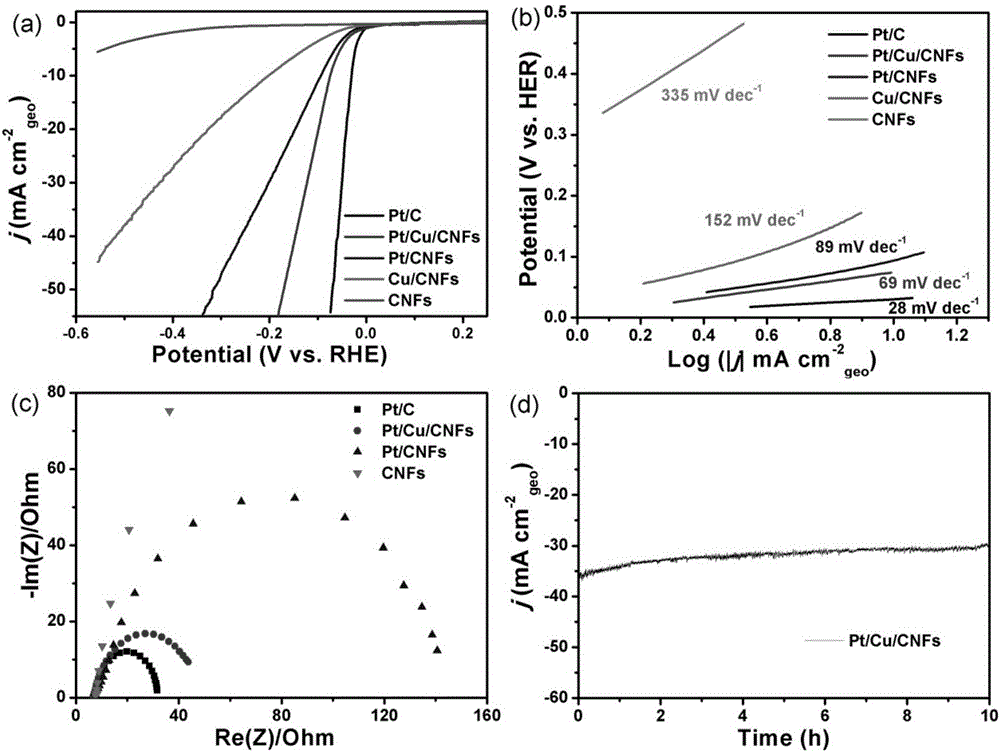

[0031] A nano-sized platinum-copper alloy electrolytic water catalytic material, the nano-sized platinum-copper alloy electrolytic water catalytic material is a platinum-copper alloy nanoparticle / carbon nanofiber hybrid material, which is prepared by the following steps:

[0032] (1) Put the solvent into the container, then slowly add the polymer, stir continuously until it is completely dissolved, then add the water-soluble platinum source and water-soluble copper source, stir and mix evenly, and prepare the precursor solution; The mass concentration of each component in the precursor solution is as follows: high molecular polymer 8-20%, platinum source 1-50%, copper source 1-50%, solvent balance; the solvent is deionized water or DMF . Preferably, the mass concentration of each component in the precursor solution is as follows: high molecular polymer 8-20%, platinum source 10-30%, copper source 10-30%, solvent balance; the solvent is deionized water or DMF. The high molecu...

Embodiment 1

[0037] Dissolve polyvinyl alcohol (PVA) powder in deionized water to make an aqueous solution with a mass concentration of 12%, then slowly add copper chloride and chloroplatinic acid to the above solution, and keep stirring until the solution is evenly mixed. A precursor solution was obtained, and the mass concentration of each component in the precursor solution was as follows: 12% polyvinyl alcohol, 25% chloroplatinic acid, 5% copper chloride, and the balance of deionized water. Move the prepared precursor solution to a 10mL syringe, and fix the syringe on the electrospinning syringe pump. The needle of the syringe is connected to the positive pole of the high-voltage direct current power supply, and the collecting plate covered with aluminum foil is connected to the negative pole of the high-voltage direct current power supply. Adjust the distance between the collection plate and the needle to 12 cm, the injection speed of the syringe pump to 0.3 mL / h (flow rate), set the p...

Embodiment 2

[0039]Dissolve polyacrylonitrile (PAN) powder in N,N-dimethylformamide solution, then slowly add copper chloride and chloroplatinic acid into the above solution, and keep stirring until the solution is evenly mixed to obtain the precursor The mass concentration of each component in the precursor solution is as follows: 10% polyacrylonitrile, 25% chloroplatinic acid, 5% copper chloride, and the balance of N,N-dimethylformamide. Move the prepared precursor solution to a 10mL syringe, and fix the syringe on the electrospinning syringe pump. The needle of the syringe is connected to the positive pole of the high-voltage direct current power supply, and the collecting plate covered with aluminum foil is connected to the negative pole of the high-voltage direct current power supply. Adjust the distance between the collection plate and the needle to 15 cm, the injection speed of the syringe pump to 0.6 mL / h (flow rate), set the positive voltage to 12 kV, and the negative voltage to 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com