Terpenyl ester hyperdispersant and preparation method for same

A technology of hyperdispersant and terpene-based ester, which is applied in chemical instruments and methods, transportation and packaging, and dissolution, and can solve problems such as large particles, thermodynamic instability, and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] A preparation method of terpene-based ester hyperdispersant, its processing steps are as follows:

[0029] (1) Preparation of terpene resin α, β-unsaturated compound adduct: In parts by weight, 100 parts of terpene resin, 25-50 parts of α, β-unsaturated compound, and 0.1-1.5 parts of catalyst are put into The reaction kettle is slowly heated to 160~200°C under the protection of nitrogen, and stirred for 4~6 hours to obtain terpene resin α, β-unsaturated compound adducts;

[0030] (2) Preparation of ester hyperdispersant: add 1~50 parts of modified carboxylation reagent and 20~60 parts of dihydric alcohol to the above-mentioned terpene resin α, β-unsaturated compound adduct, and continue the reaction for 3~ 4h, then gradually raise the temperature to 220~260℃, and then polycondense for 8~10h under the vacuum condition of 500~2000Pa;

[0031]The terpene resin is a product obtained by polymerizing one or more of turpentine, α-pinene, β-pinene, limonene and dipentene at -2...

PUM

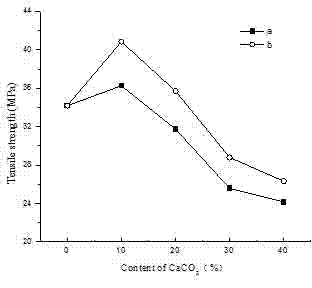

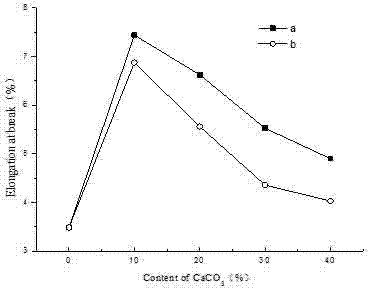

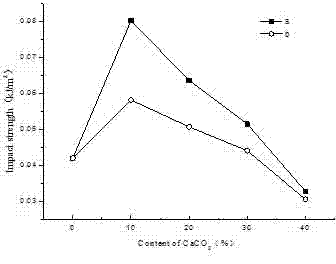

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com