Preparation method of lithium ion battery cathode slurry

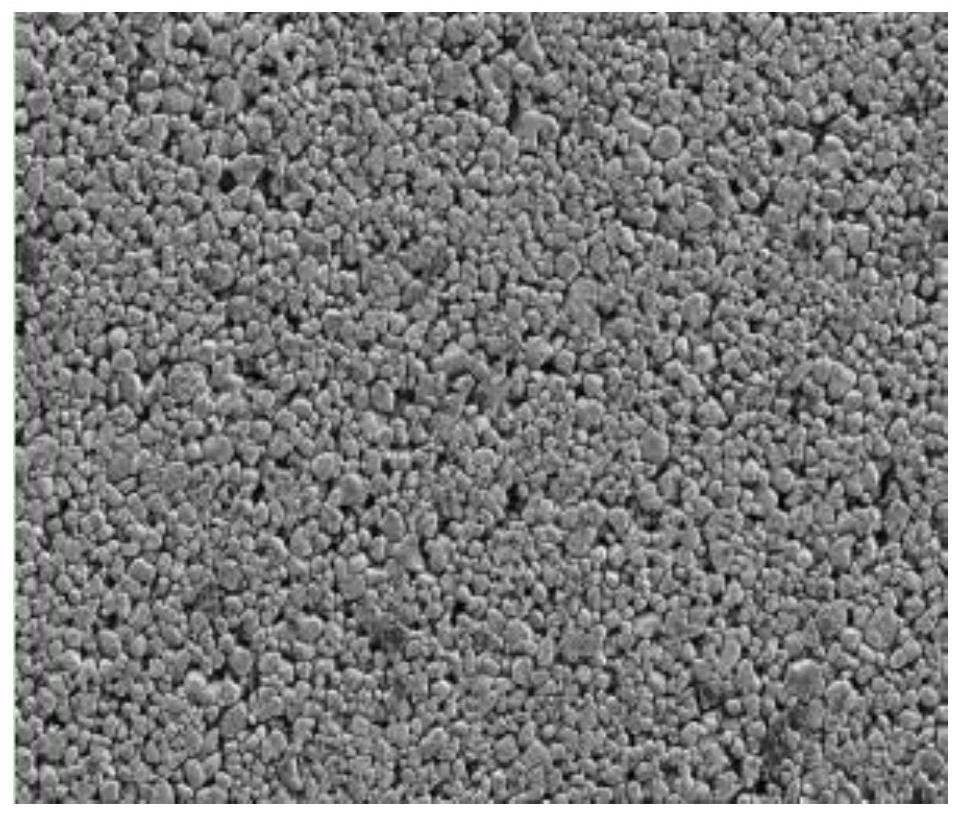

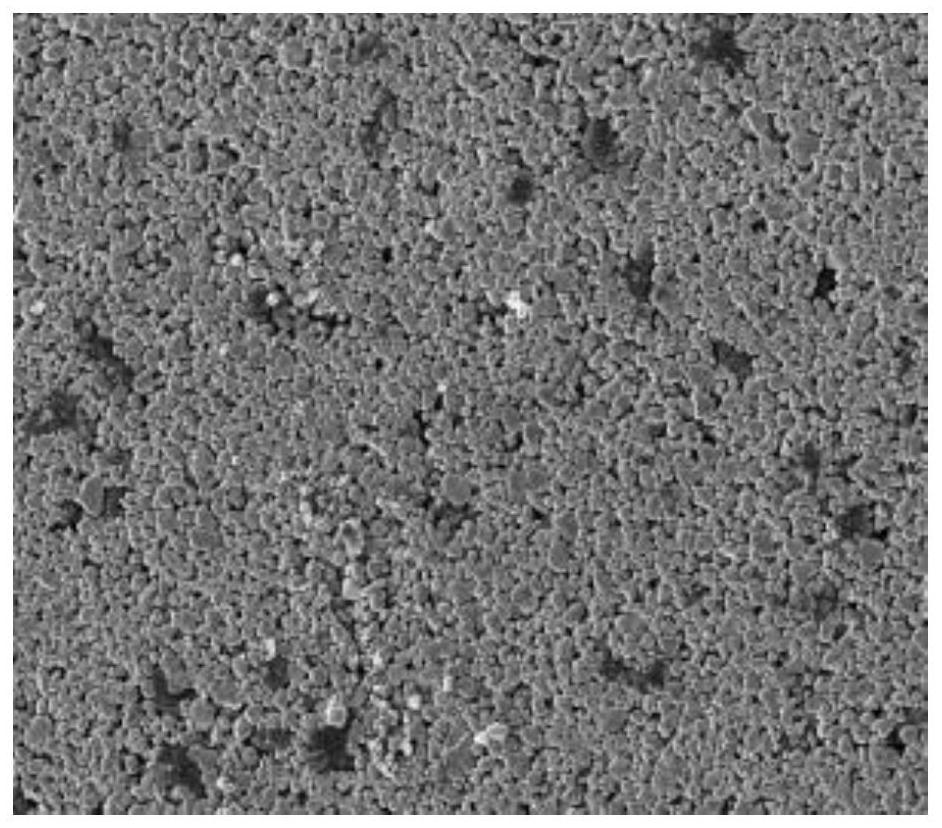

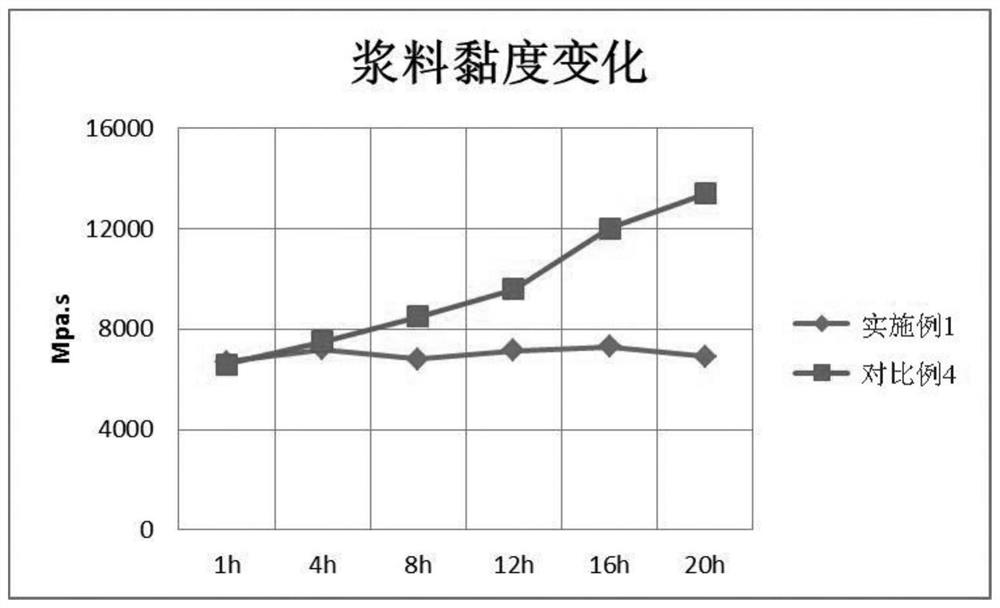

A lithium-ion battery, positive electrode slurry technology, used in electrode manufacturing, battery electrodes, positive electrodes, etc., can solve the problems of conductive agent and binder aggregation, uneven dispersion of slurry, and large viscosity rebound. Agglomeration, optimized dispersion effect, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment provides a preparation method of lithium-ion battery cathode slurry, comprising the following steps:

[0034] S1, add the conductive agent into the dispersant, stir and disperse at the revolution speed of 25-40r / min, the rotation speed of 300-800r / min, the stirring and dispersion time is 3-10min, and obtain the conductive agent with a solid content of 0.5-3%. agent dispersion;

[0035] S2, dissolving the adhesive in a solvent to obtain an adhesive solution with a solid content of 5-9%;

[0036] S3, add the adhesive solution to the conductive agent dispersion liquid, firstly carry out pre-stirring at a revolution speed of 25-40r / min, and an autorotation speed of 300-800r / min, the pre-stirring time is 3-8min, and then 25-40r / min The revolution speed of 40r / min and the rotation speed of 1000-1500r / min are fully stirred, and the stirring time is 60min to obtain a mixed slurry;

[0037] S4, add the positive electrode active material into the mixed sl...

Embodiment 2

[0042] This embodiment provides a method for preparing a positive electrode slurry for a lithium ion battery, which is different from Example 1 in that the positive active material includes a ternary positive electrode material and lithium manganate that are mechanically mixed at a mass ratio of 1:1.

[0043] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com