Preparation method of catalyst for catalyzing hydrolysis of ammonia borane

A technology for catalyzing ammonia borane and catalysts, which is applied in the directions of physical/chemical process catalysts, chemical instruments and methods, hydrogen production, etc., can solve the problems of poor catalyst stability, high cost, complicated preparation methods, etc., and achieves good catalytic activity, High stability and simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

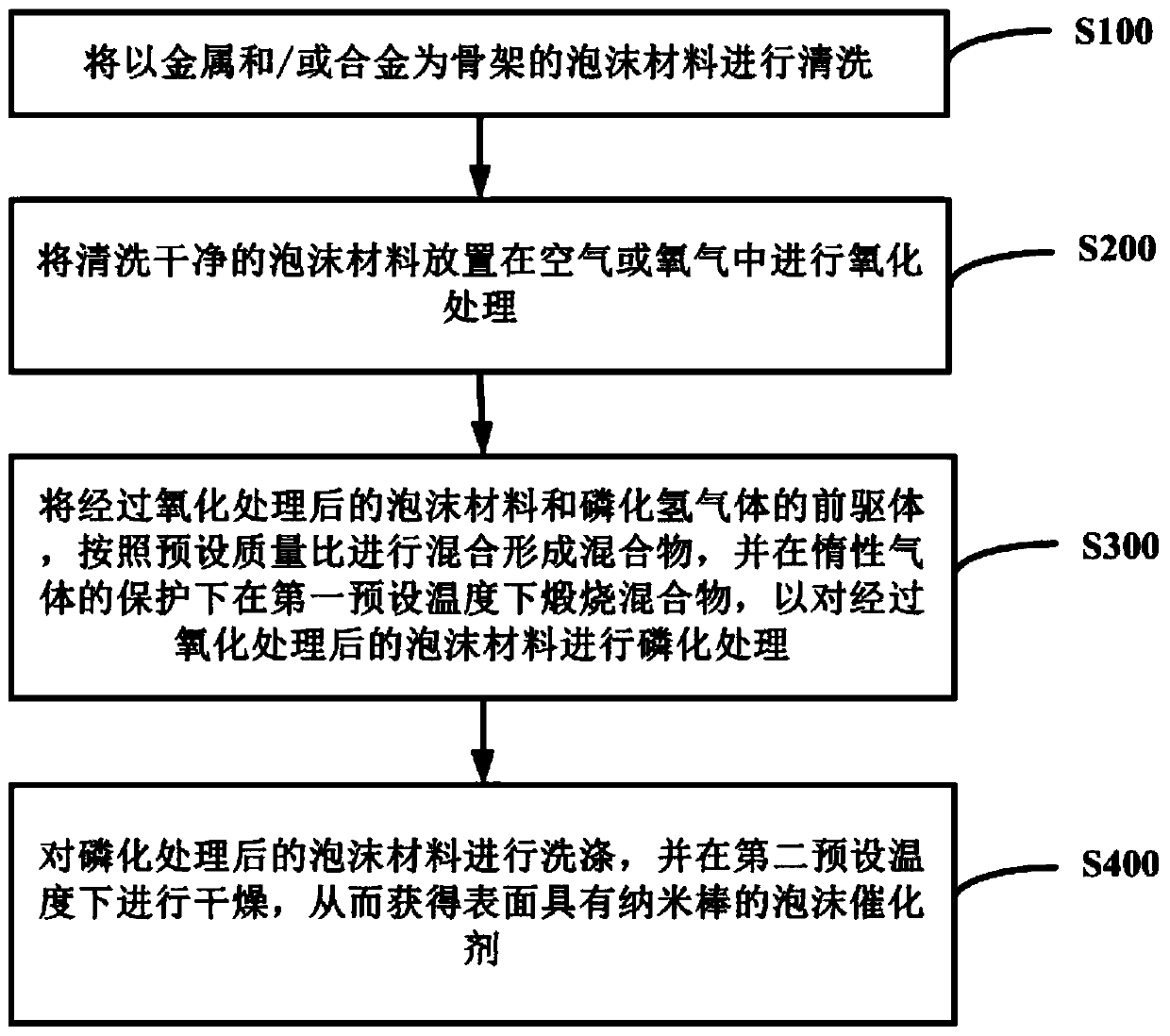

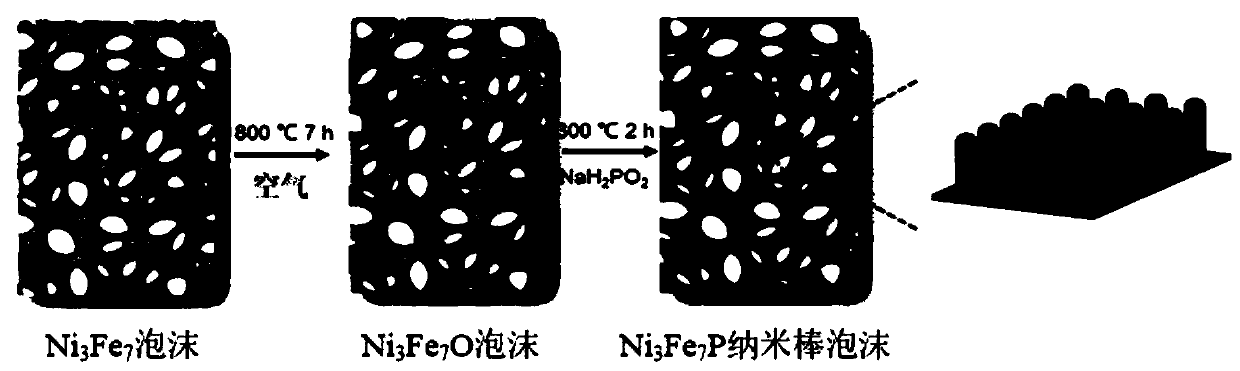

[0049] figure 1 A schematic flowchart of a preparation method of a catalyst for catalyzing the hydrolysis of ammonia borane according to an embodiment of the present invention is shown. like figure 1 As shown, the preparation method comprises the following steps:

[0050] Step S100, cleaning the foam material with metal and / or alloy as the skeleton;

[0051] Step S200, placing the cleaned foam material in air or oxygen for oxidation treatment;

[0052] Step S300, mixing the oxidized foam material and the precursor of phosphine gas according to a preset mass ratio to form a mixture, and calcining the mixture at a first preset temperature under the protection of an inert gas to Phosphating treatment is carried out on the treated foam material;

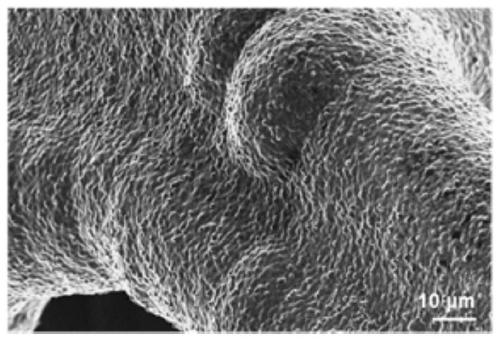

[0053] Step S400, washing the phosphating foam material and drying it at a second preset temperature, so as to obtain a foam catalyst with nanorods on its surface.

[0054] In step S100, the foam material is preferably a foam materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com