Method for preparing high-purity nano indium oxide powder

A technology of nano-indium oxide and indium oxide, which is applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve problems such as difficulty in guaranteeing the purity of indium oxide powder, difficulty in achieving nanoscale reactions, and complex process control, etc., to achieve beneficial The effect of environmental protection, uniform particle size, and simple temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with embodiment.

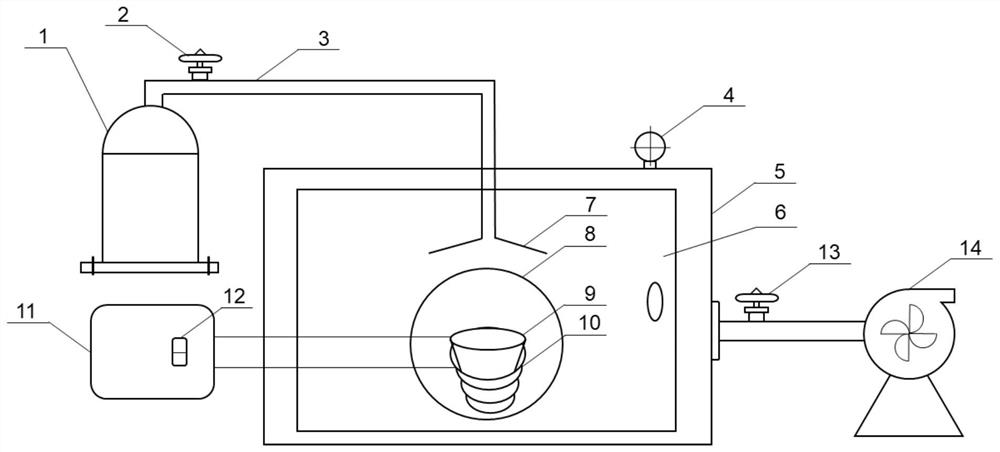

[0023] Such as figure 1 , 2 As shown, a kind of method for preparing high-purity nano-indium oxide powder provided by the present invention, at first a reaction box 5 is provided, the reaction box 5 is equipped with a door 6 with an observation window 8, and the reaction box 5 is provided with a useful In the crucible 9 containing indium powder, a high-frequency induction coil 10 for heating the crucible 9 is provided below the crucible 9. 2 The gas cylinder 1 is connected to the reaction box 5 through a pipeline provided with a ball valve switch 2, a vacuum pump 14 is connected to the reaction box 5 through a pipeline provided with a ball valve switch 13, and the reaction box 5 is also provided with a vacuum gauge 4 .

[0024] Specific preparation steps: ball mill the indium powder of the reaction raw material for 1 to 2 hours, and pass through a mesh of 60, 100, 150, and 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com