Layered double hydroxide-molybdate ion modified graphene flame-retarding and smoke-inhibiting agent and preparation method of same

A technology of molybdate ion and hydroxide, which is applied in the field of flame retardant and smoke suppressant, can solve the problems of reduced flame retardant efficiency, poor dispersion, and decreased physical and mechanical properties of polymers, so as to improve the performance of flame retardant and smoke suppressor, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

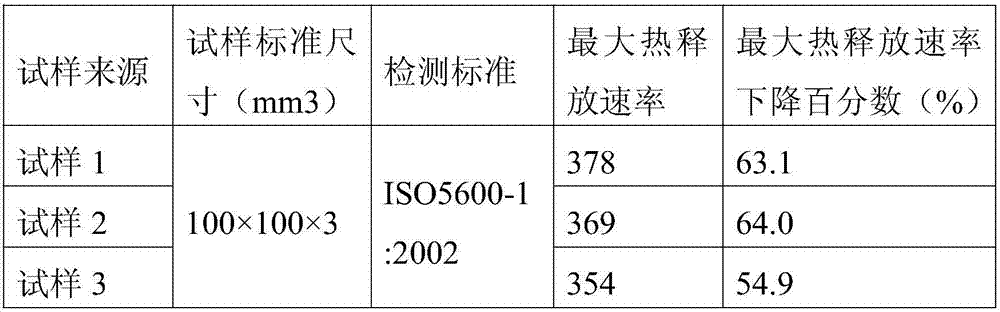

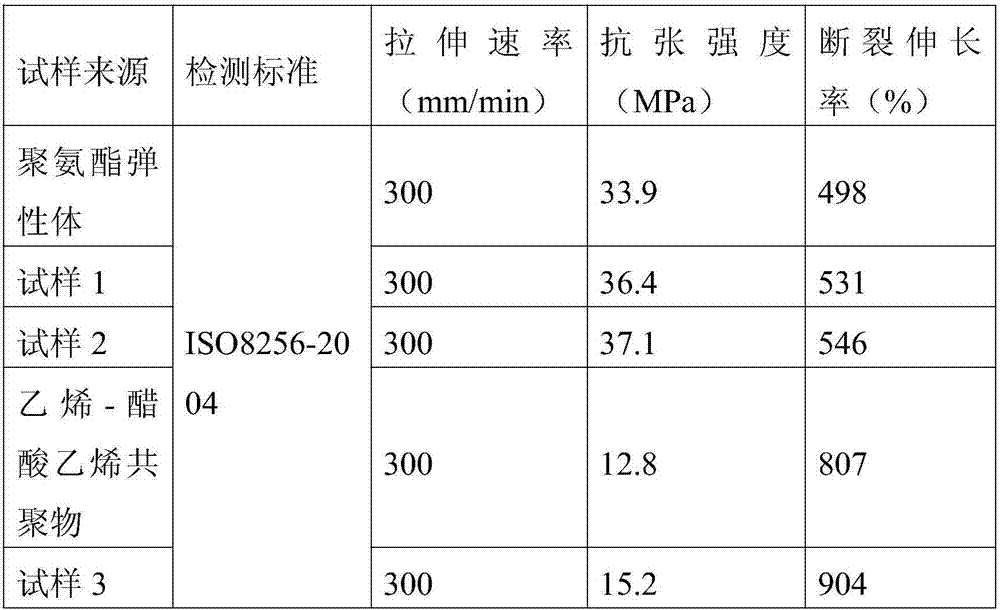

[0011] Example 1: Preparation and Application of Flame Retardant and Smoke Suppressant

[0012] 1. Preparation of Flame Retardant and Smoke Suppressant

[0013] (1) Weigh 7.5g of Al(NO 3 ) 3 9H 2 O and 25.6g of Mg(NO 3 ) 2 ·6H 2 O, dispersed and dissolved in 150ml deionized water to obtain a uniform salt solution;

[0014] (2) Take 0.64g graphene and be dispersed in 150ml alkaline solution (NaOH concentration is 0.20M, Na CO Concentration is 0.05M), ultrasonic 30 minutes, obtain the graphene dispersion liquid of uniform dispersion;

[0015] The salt solution prepared in step (1) is added dropwise in the above-mentioned graphene dispersion liquid, stirs rapidly while adding dropwise; (time, speed)

[0016] Use 0.2M NaOH solution to adjust the pH value of the mixture to 8, stir the mixture at 40°C for 36h, then add 0.75ml N 2 h 2 ·H 2 O, heat up to 100°C, react at constant temperature for 3 hours, wash the product twice with deionized water and absolute ethanol in turn...

Embodiment 2

[0021] Example 2: Preparation and Application of Flame Retardant and Smoke Suppressant

[0022] 1. Preparation of Flame Retardant and Smoke Suppressant

[0023] (1) Weigh 37.5g of Al(NO3)3.9H2O and 59.4g of Zn(NO3)2.6H2O, disperse and dissolve in 500ml deionized water to obtain a uniform salt solution;

[0024] (2) Weigh 1.2g graphene and disperse it into 150ml alkaline solution (NaOH concentration is 0.20M, NaOH 2 CO 3 Concentration is 0.05M), ultrasonic 20 minutes, obtain the graphene dispersion liquid of uniform dispersion;

[0025] The salt solution prepared in step (1) is added dropwise in the above-mentioned graphene dispersion liquid, stirs rapidly while adding dropwise; (time, speed)

[0026] Use 0.5M NaOH solution to adjust the pH value of the mixture to 11, stir the mixture at 60°C for 24h, then add 1.5ml N 2 h 2 ·H 2 O, heat up to 110°C, react at constant temperature for 2 hours, wash the product three times with deionized water and absolute ethanol in turn, a...

Embodiment 3

[0031] Example 3: Preparation and Application of Flame Retardant and Smoke Suppressant

[0032] 1. Preparation of Flame Retardant and Smoke Suppressant

[0033] (1) Weigh 14.0625g of Al(NO 3 ) 3 9H 2 O and 54.5625g of Co(NO 3 ) 2 ·6H 2 O, dispersed and dissolved in 150ml deionized water to obtain a uniform salt solution;

[0034] (2) Take 0.82g graphene and be dispersed in 150ml alkaline solution (NaOH concentration is 0.20M, Na CO Concentration is 0.05M), ultrasonic 30 minutes, obtain the graphene dispersion liquid of uniform dispersion;

[0035] The salt solution prepared in step (1) is added dropwise in the above-mentioned graphene dispersion liquid, stirs rapidly while adding dropwise; (time, speed)

[0036] Use 0.4M NaOH solution to adjust the pH value of the mixture to 10, stir the mixture at 80°C for 12h, then add 0.75ml N 2 h 2 ·H 2 O, heat up to 120°C, react at constant temperature for 1 hour, wash the product three times with deionized water and absolute et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com