Preparation method of high-flame-retardant smoke-suppression LVT floor wear-resistant layer

A high flame retardant and wear-resistant layer technology, applied in insulation layers, flat products, applications, etc., can solve the problems of reducing the light transmittance and flexibility of the wear-resistant layer, reducing the excellent performance of LVT composite floors, and achieving good light transmission. performance, excellent flame retardant and smoke suppression performance, the effect of improving light transmission and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

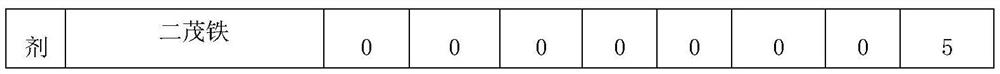

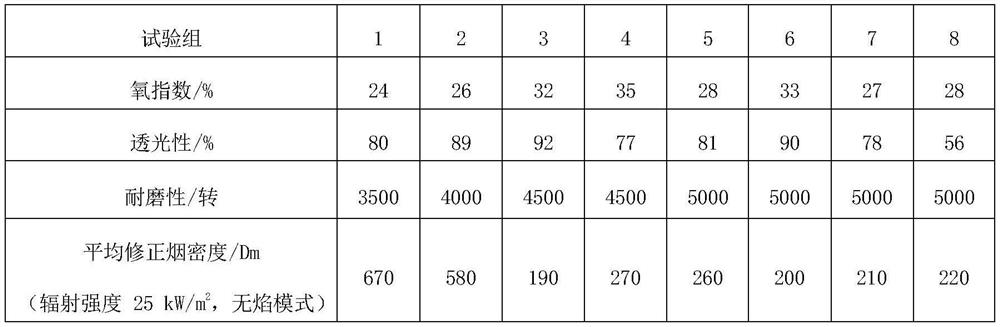

[0041] The weight parts of each component of embodiment 1-10 are as shown in table 3:

[0042] Table 3 embodiment 1-10 raw material formula

[0043]

[0044]

[0045] The preparation method specifically comprises the following steps:

[0046](1) Mixing: According to the raw material formula, put the production raw materials into the mixer and mix evenly, wherein the mixing temperature is 130°C, the mixing time is 4min, and the speed of the mixer is 200r / min;

[0047] (2) Banbury mixing: send the uniformly mixed materials into the banbury mixer for banbury mixing, the banbury time is 10min, and the banbury temperature is 120°C;

[0048] (3) Open refining: send the materials after banbury mixing into the open mill for open refining, the opening temperature is 160°C, and the time is 4 minutes;

[0049] (4) Calendering: Send the refined material into a calender, and form a sheet after roller calendering at a temperature of 170°C;

[0050] (5) Cooling: The resulting sheet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com