Electrolytic water catalytic material of gold-copper twin structure

A catalytic material and water electrolysis technology, applied in the electrolysis process, electrolysis components, electrodes, etc., can solve problems such as high cost and scarcity, and limit practical applications, achieve high universality, good industrial application prospects, and improve hydrogen evolution active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

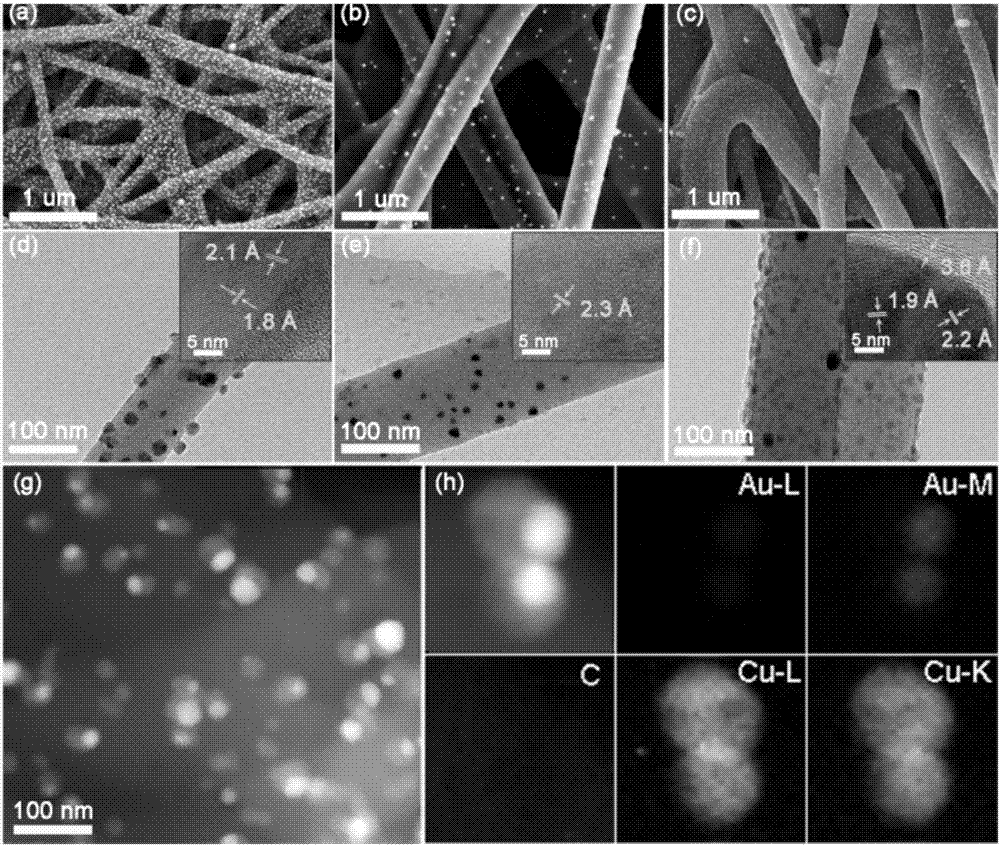

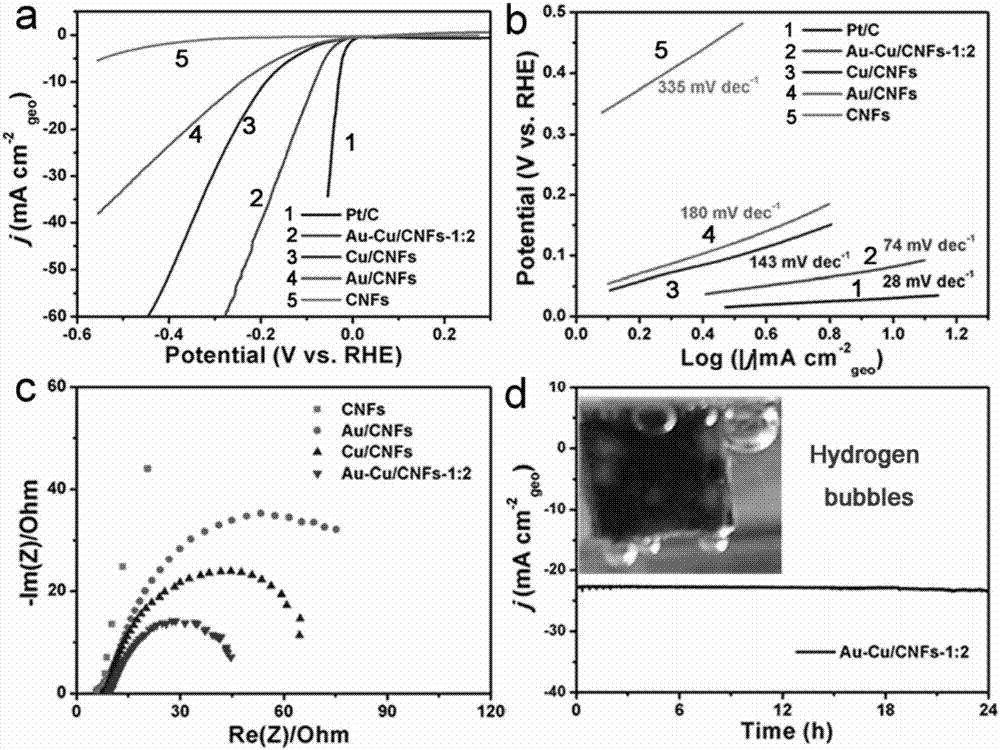

[0025] A gold-copper twin structure electrolytic water catalytic material, the electrolytic water catalytic material is a gold-copper twin structure nanoparticle / carbon nanofiber hybrid material, prepared through the following steps:

[0026] (1) Put deionized water into the container, slowly add the water-soluble polymer under stirring conditions, heat the oil bath to 80°C until the solution becomes transparent, then add water-soluble gold salt and water-soluble copper salt , stirring and mixing evenly to prepare a precursor solution; the fineness of the carbon nanofibers is 300-600 nm. The particle size of the gold-copper twin structure nanoparticles is 5-30 nm. The water-soluble high molecular polymer is one or more of polyvinyl alcohol, polyetherimide and polyvinylpyrrolidone. The mass concentration of each component in the precursor solution is as follows: 10-15% of water-soluble high molecular polymer, 1-10% of gold salt and copper salt in total, and the balance of deio...

Embodiment 1

[0031] Add a certain volume of deionized water to the three-necked flask, then slowly add 1.5 grams of polyvinyl alcohol (PVA) dissolved powder under stirring conditions, heat the oil bath to 80 ° C until the solution becomes transparent, and then add 0.05 grams of copper chloride and 0.025 g of chloroauric acid are slowly added to the above solution, and the precursor solution containing gold salt and copper salt can be obtained after 30 minutes. The mass concentration of each component in the precursor solution is as follows: polyvinyl alcohol 12%, chloroauric acid 0.2%, copper chloride 0.4%; transfer the obtained precursor solution to a 10mL syringe, then fix the syringe on the electrospinning syringe pump, the positive pole of the high-voltage DC power supply is connected to the needle tip of the syringe, the high-voltage DC power supply The negative electrode is connected to the receiving plate covered with aluminum foil, the distance between the collecting plate and the n...

Embodiment 2

[0033]Add a certain volume of deionized water to the three-necked flask, then slowly add 1.5 grams of polyetherimide (PEI) dissolved powder under stirring conditions, heat the oil bath to 80 ° C until the solution becomes transparent, and then add 0.025 grams of chlorine Copper chloride and 0.05 g of chloroauric acid are slowly added to the above solution, and a precursor solution containing gold salt and copper salt can be obtained after 30 minutes. The mass concentration of each component in the precursor solution is as follows: polyetherimide 12% , 0.4% chloroauric acid, 0.2% copper chloride; transfer the obtained precursor solution to a 10 mL syringe, then fix the syringe on the syringe pump for electrospinning, and connect the positive pole of the high-voltage DC power supply to the needle tip of the syringe, The negative pole of the high-voltage DC power supply is connected to the receiving plate covered with aluminum foil, the distance between the collecting plate and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com