Method for preparing water-soluble ferroferric oxide nano particle

A technology of ferric tetroxide and nanoparticles, which is applied in the directions of iron oxide/iron hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of poor water solubility and limited application, and achieves low cost, simple method and good superparamagnetic properties. energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

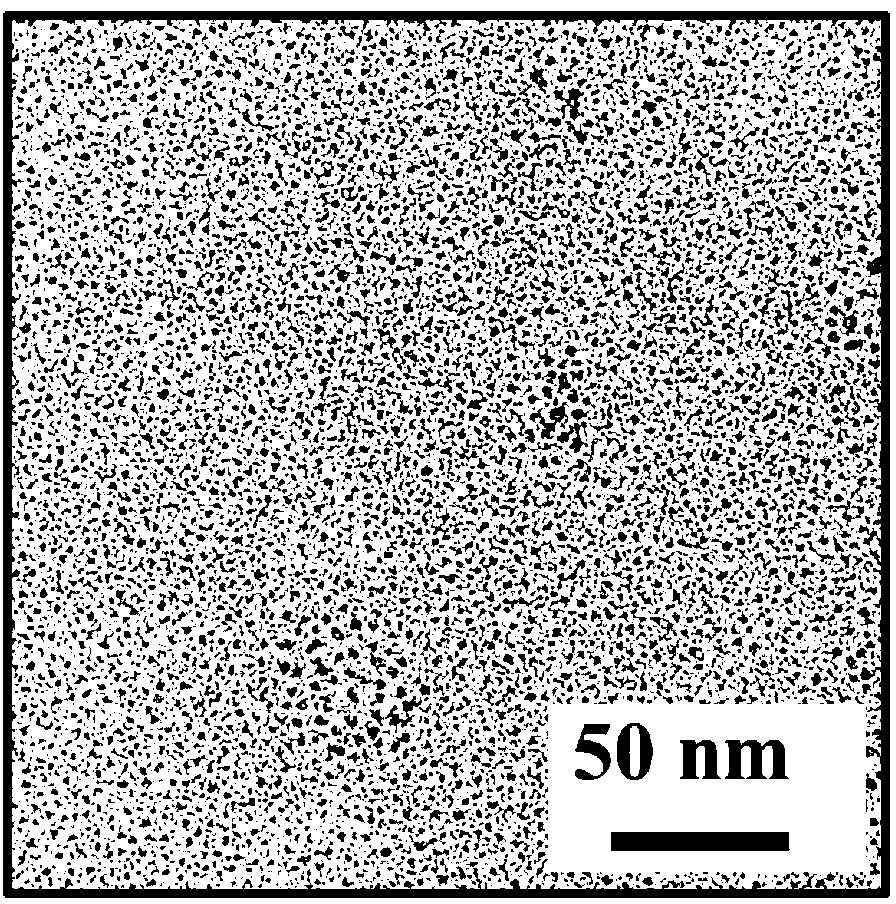

[0036] The preparation method of water-dispersible ferric oxide nanoparticles, the steps are as follows:

[0037] 1) Dissolve 0.648g (4mmol) of anhydrous ferric chloride and 0.48g (1.6mmol) of trisodium citrate in 40mL of diethylene glycol, heat to 70-80°C, and stir until it is completely dissolved;

[0038] 2) Add 1.0 g (12 mmol) of anhydrous sodium acetate to the mixed solution obtained in step 1), and wait until it is completely dissolved;

[0039] 3) The homogeneous mixed solution obtained in step 2) is placed in a stainless steel reaction kettle of polytetrafluoroethylene, the reaction kettle is closed, and the reaction is carried out at a constant temperature of 200 ° C for 6 hours. After the reaction is completed, it is naturally cooled to room temperature;

[0040] 4) The ferric oxide nanoparticles were separated from the reaction solution with a magnet, and the obtained product was washed three times with absolute ethanol and deionized water at room temperature, and t...

Embodiment 2

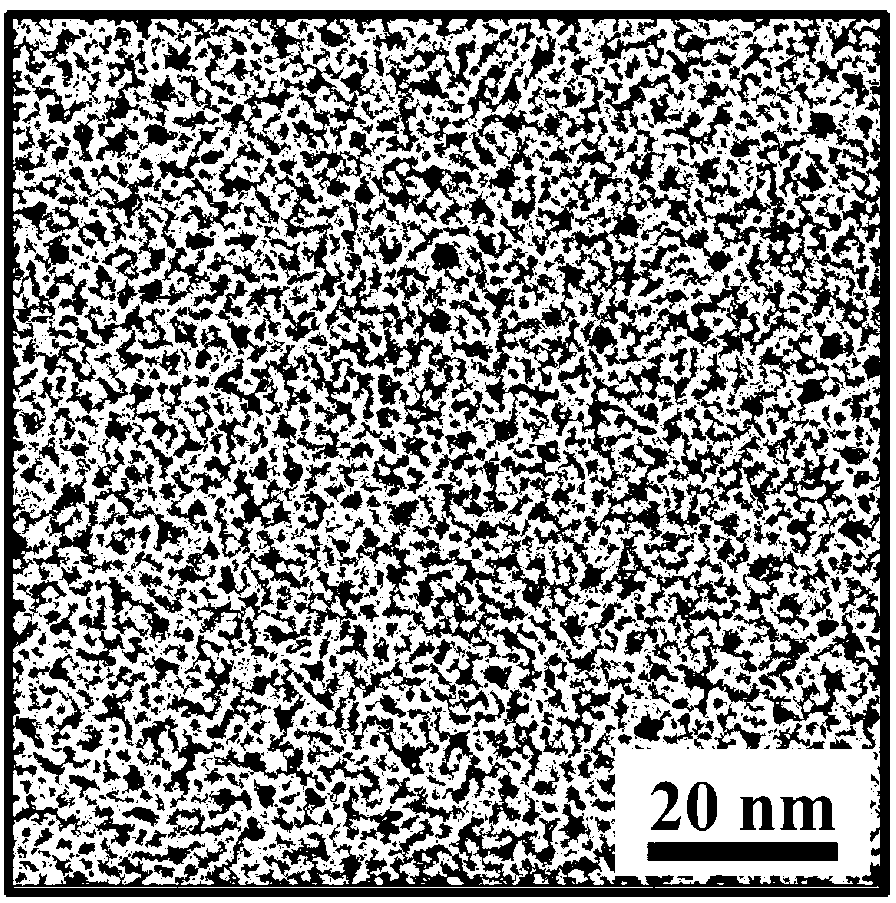

[0045] The preparation method of water-dispersible ferric oxide nanoparticles, the steps are the same as those in Example 1, the difference is that the reaction is carried out at a constant temperature of 200° C. for 4 hours. see figure 2 Transmission electron microscopy (TEM) topography pictures shown and Figure 5 X-ray diffraction (XRD) pattern shown in curve a.

Embodiment 3

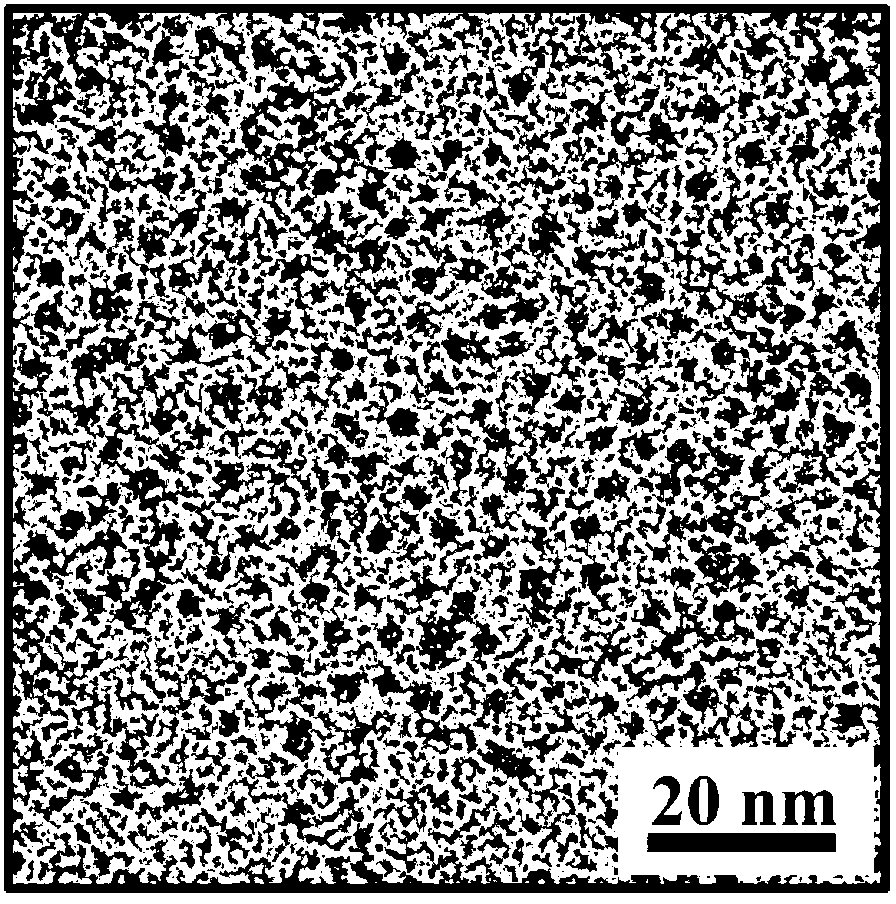

[0047] The preparation method of water-dispersible ferric oxide nanoparticles, the steps are the same as those in Example 1, the difference is that the reaction is carried out at a constant temperature of 200° C. for 10 hours. see image 3 Transmission electron microscopy (TEM) topography pictures shown and Figure 5 X-ray diffraction (XRD) pattern shown in curve c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com