Flame-retardant high-polymer composite material and preparation method thereof

A technology of flame retardant polymer and polymer material, applied in the field of flame retardant polymer composite material and its preparation, to achieve the effects of reducing heat release rate, reducing smoke density and easy heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

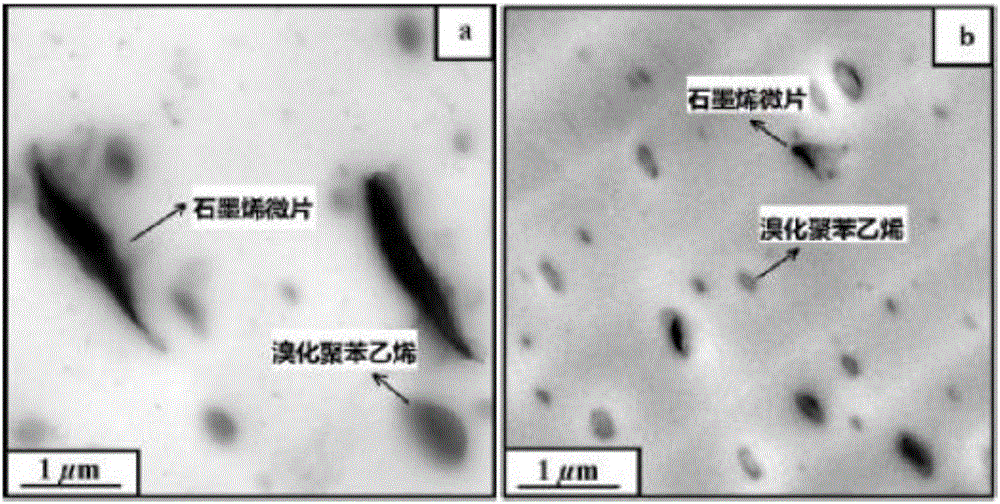

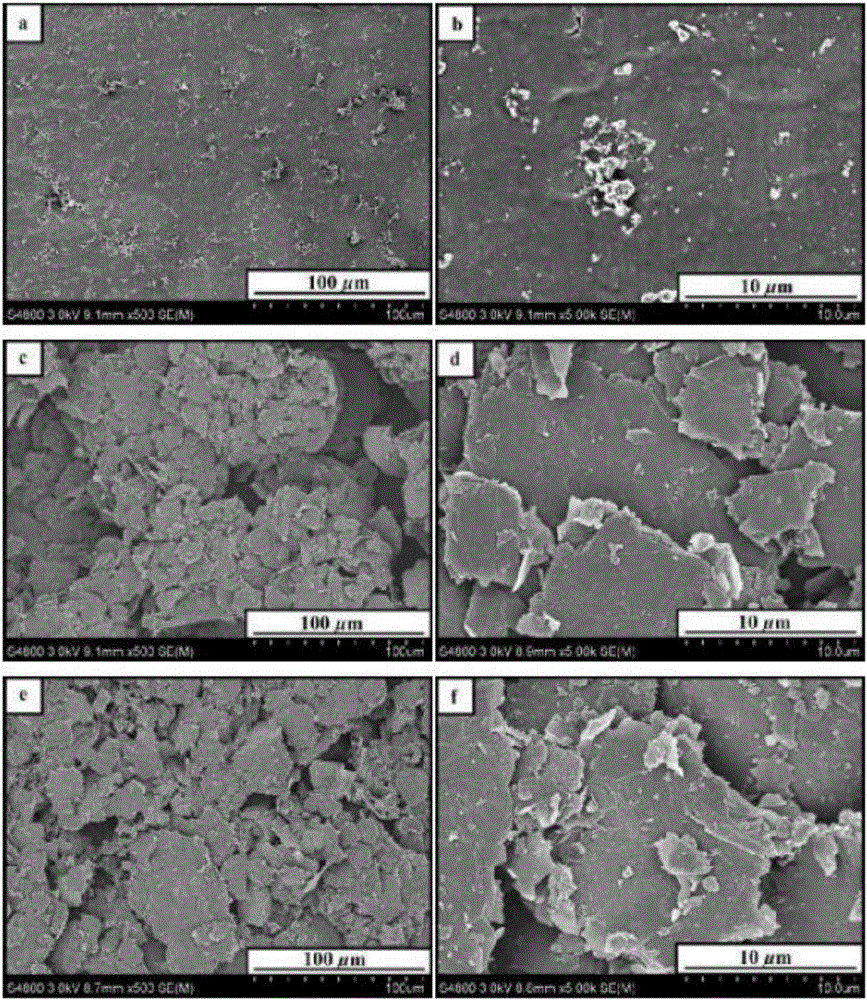

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below through specific examples, but the present invention is not limited only to the following examples. Some non-essential improvements and adjustments made by those skilled in the art according to the content of the present invention still belong to the protection scope of the present invention.

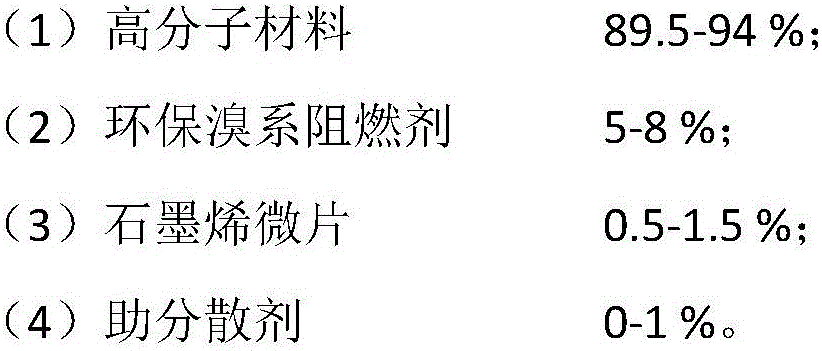

[0029] Embodiment formula is as shown in table 1 below:

[0030] Various raw materials used in the following examples of the present invention are commercially available products unless otherwise specified.

[0031] The formula of table 1. embodiment and sample number

[0032]

[0033] Samples of the various examples were compounded and melt blended at the weight percentages (wt %) in the table above.

[0034] Examples Flame retardant properties

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com