Patents

Literature

57 results about "Solid like" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid Basics. What is one physical characteristic of a solid? Solids can be hard like a rock, soft like fur, a big rock like an asteroid, or small rocks like grains of sand. The key is that solids hold their shape and they don't flow like a liquid. A rock will always look like a rock unless something happens to it.

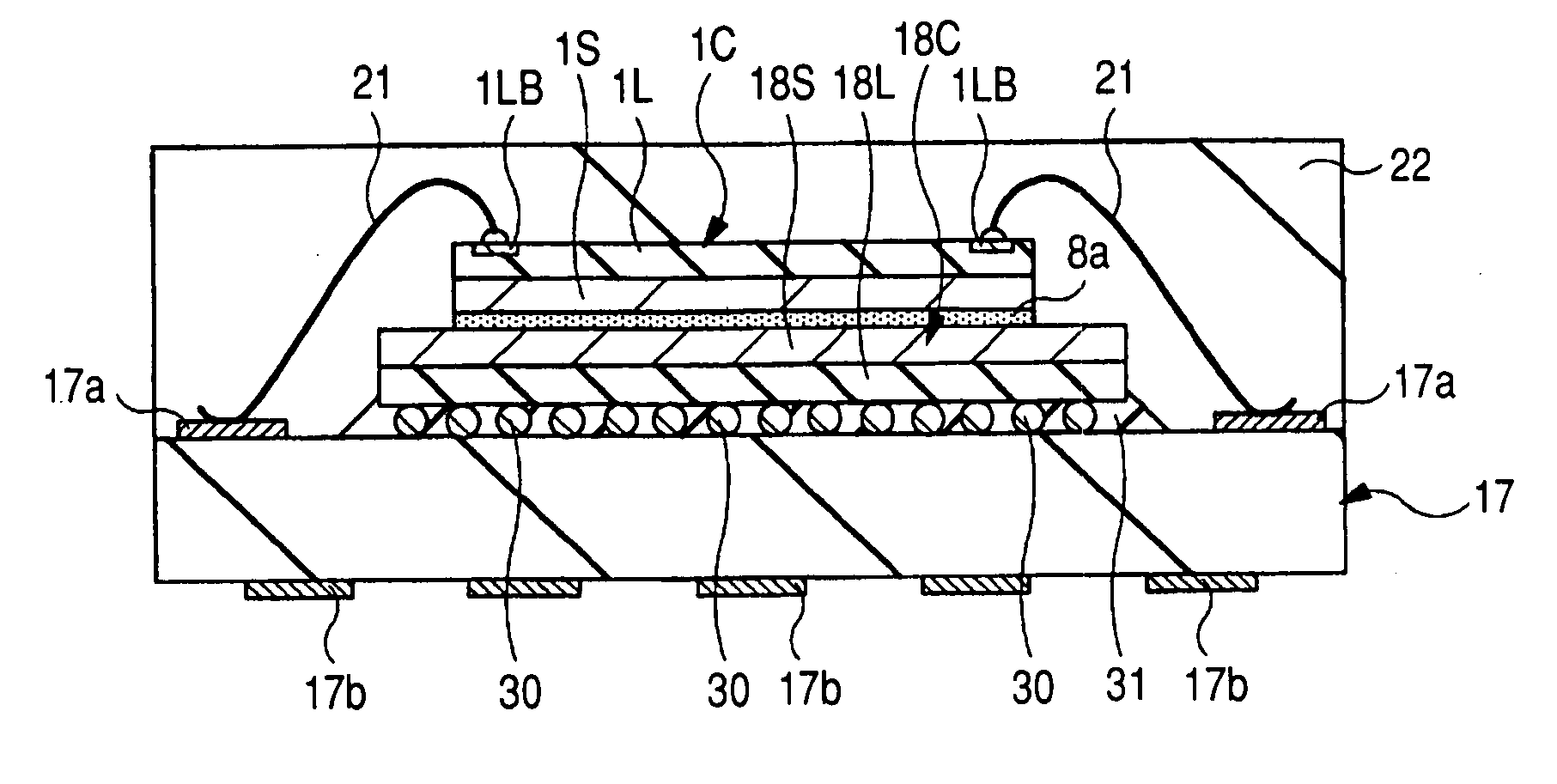

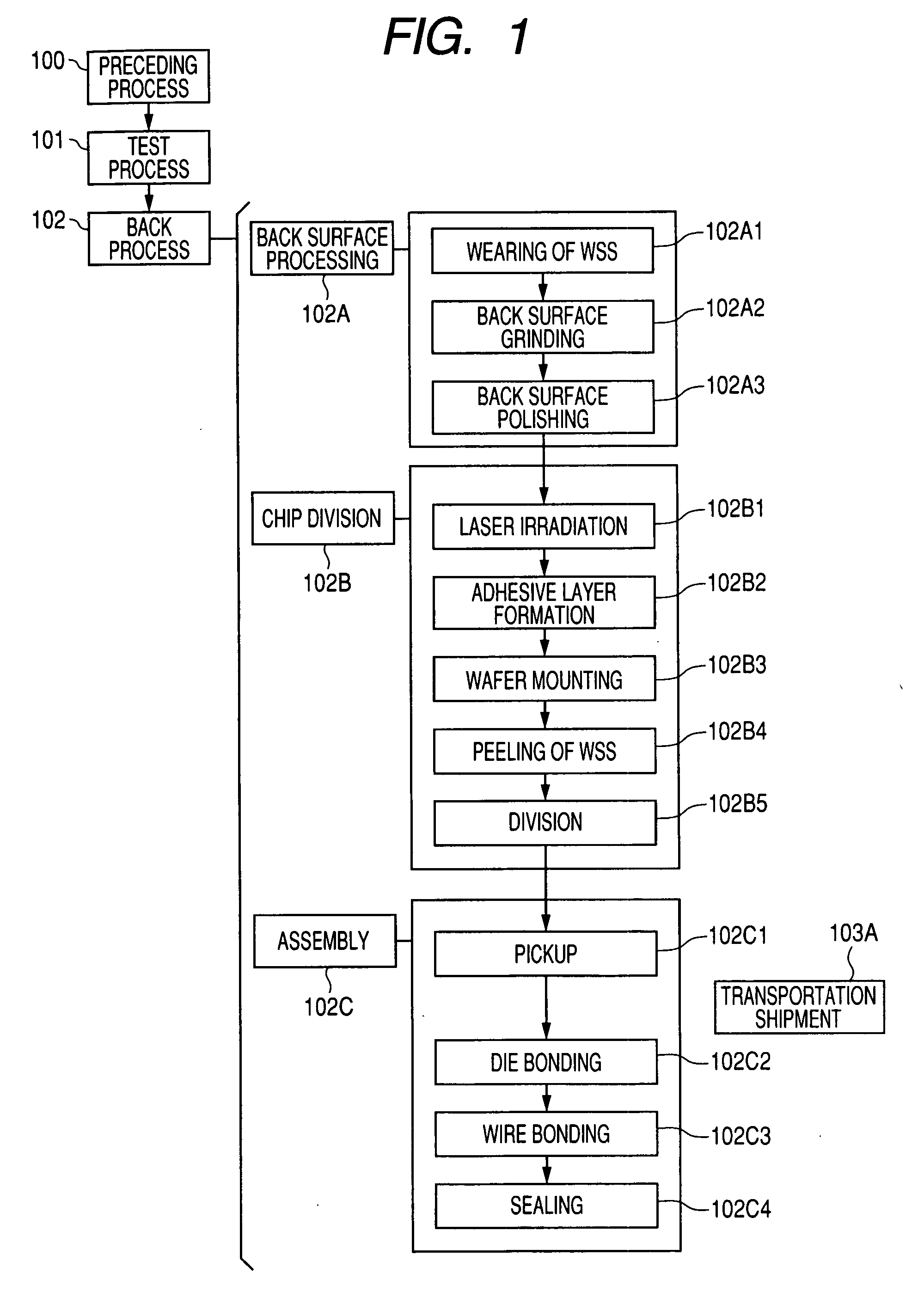

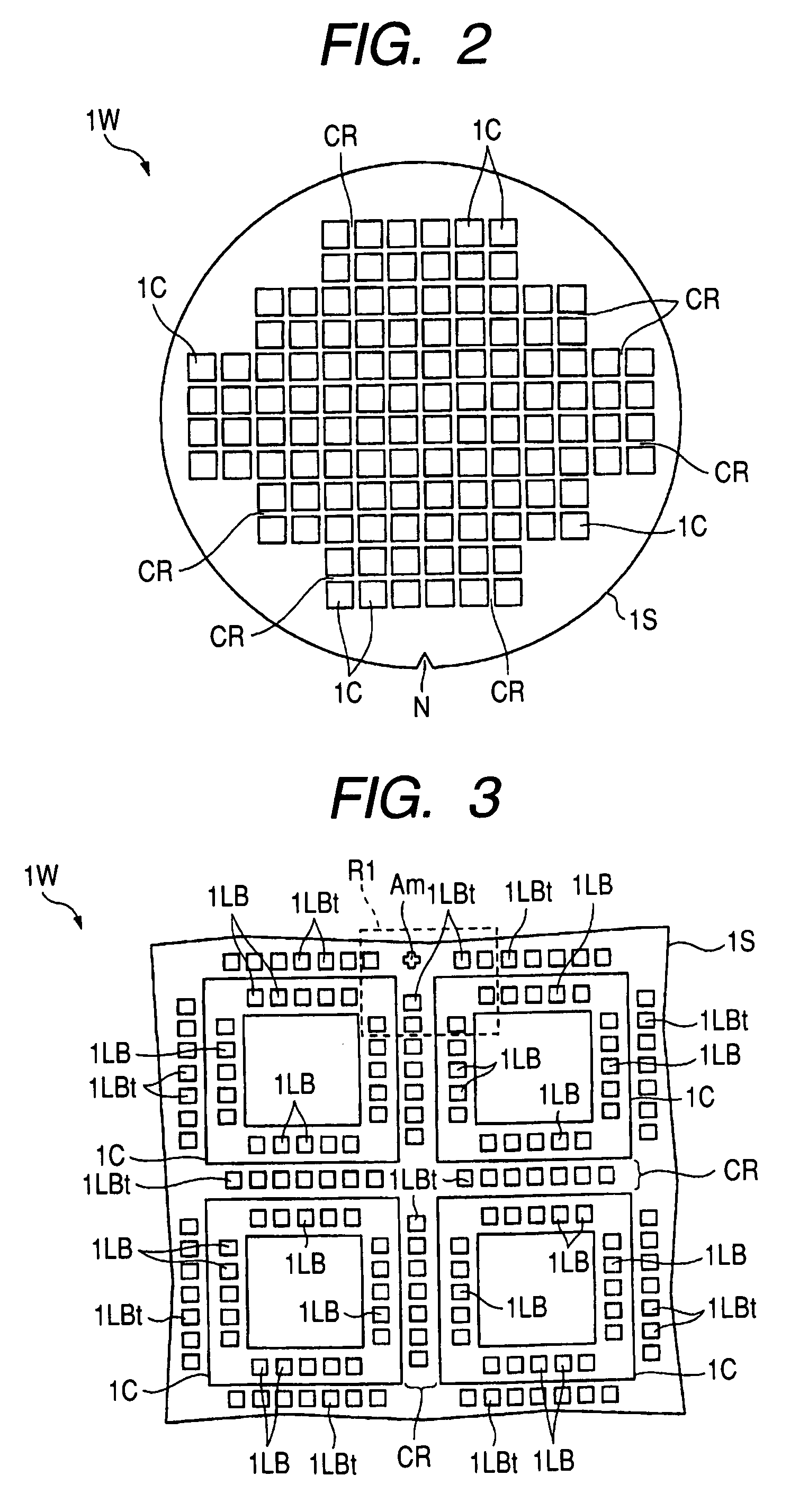

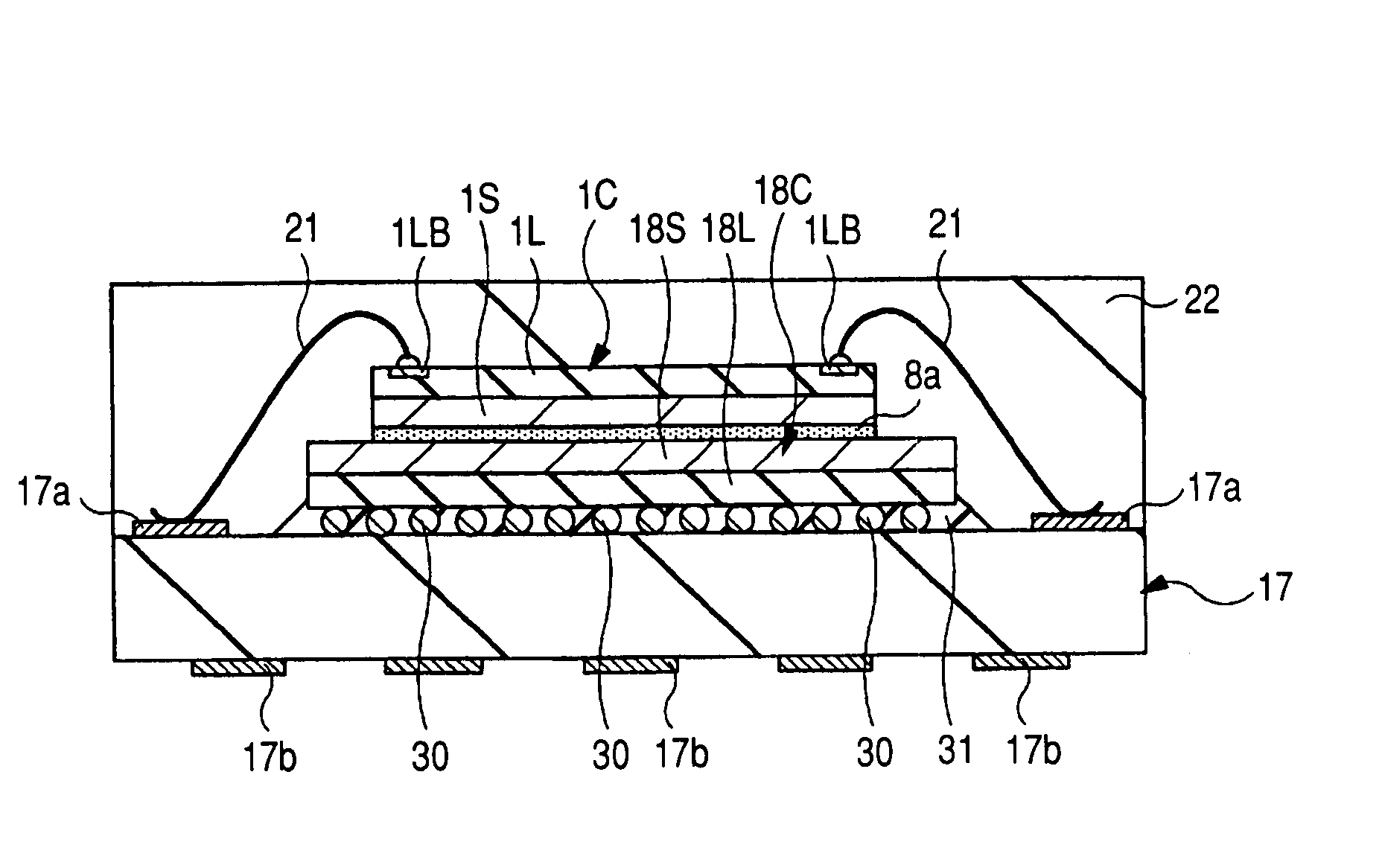

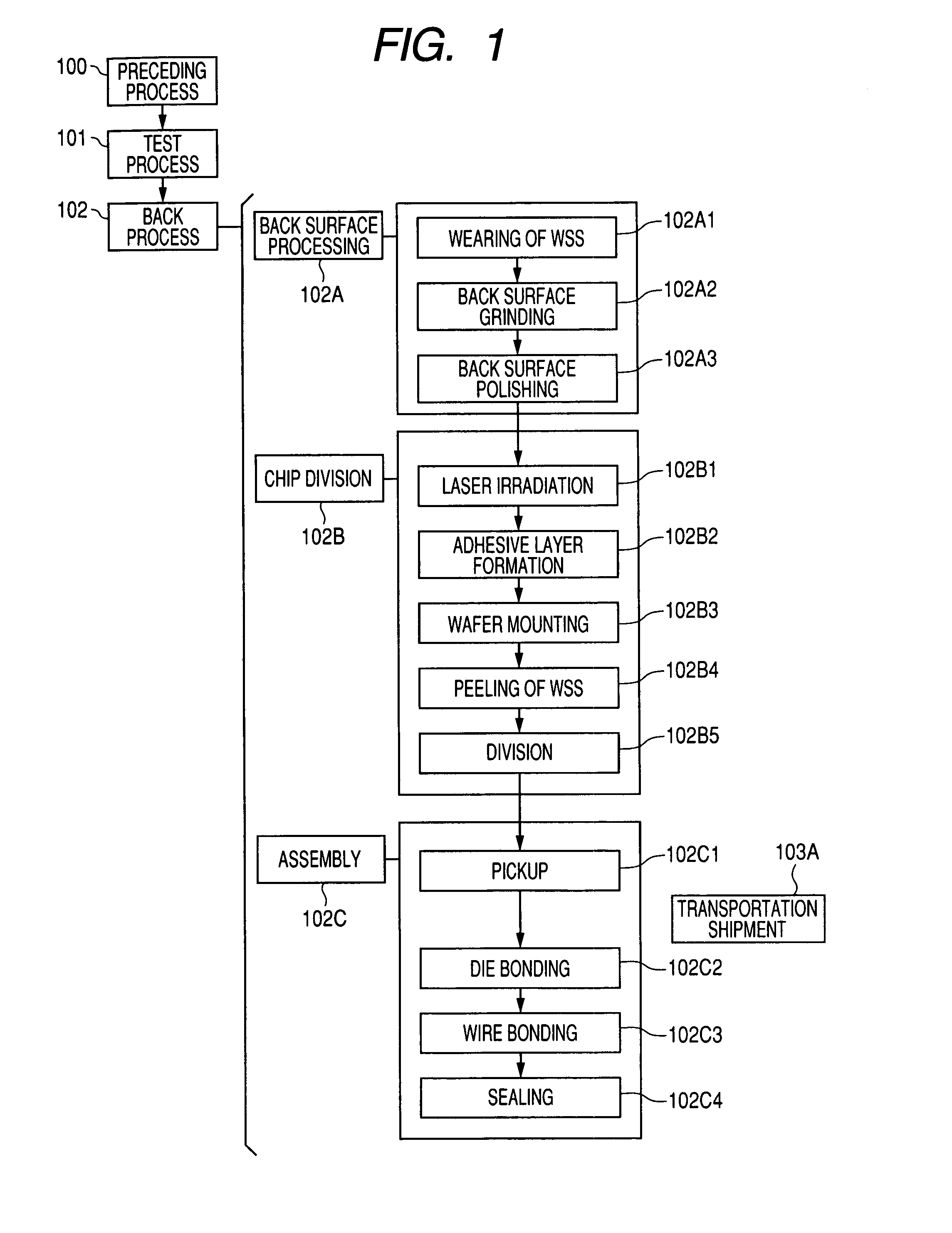

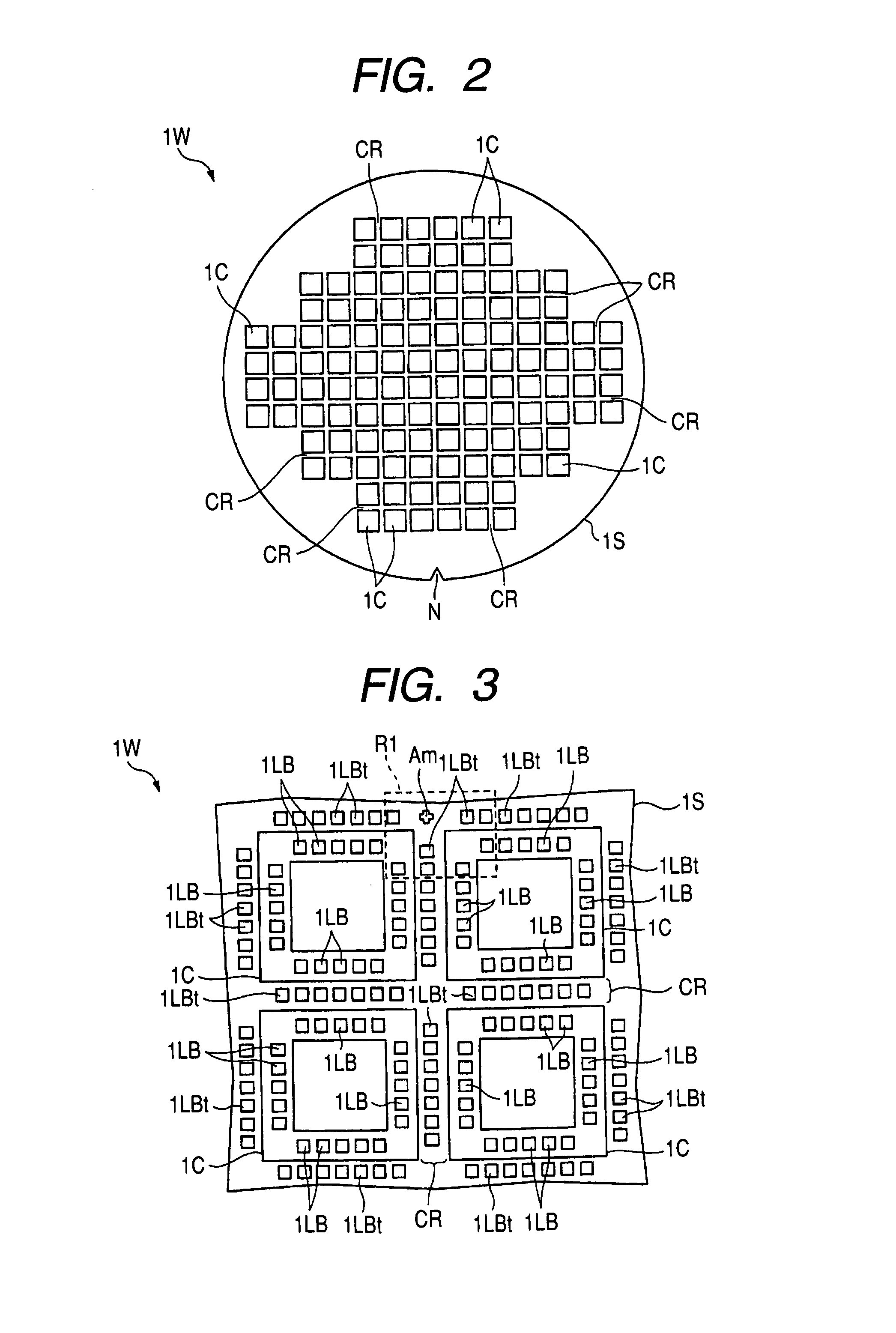

Semiconductor device and a manufacturing method of the same

InactiveUS20070037321A1Semiconductor/solid-state device detailsSolid-state devicesDevice materialLiquid state

The semiconductor device having the structure which laminated the chip in many stages is made thin. A reforming area is formed by irradiating a laser beam, where a condensing point is put together with the inside of the semiconductor substrate of a semiconductor wafer. Then, after applying the binding material of liquid state to the back surface of a semiconductor wafer by a spin coating method, this is dried and a solid-like adhesive layer is formed. Then, a semiconductor wafer is divided into each semiconductor chip by making the above-mentioned reforming area into a division origin. By pasting up this semiconductor chip on the main surface of an other semiconductor chip by the adhesive layer of the back surface, the semiconductor device having the structure for which the semiconductor chip was laminated by many stages is manufactured.

Owner:RENESAS ELECTRONICS CORP

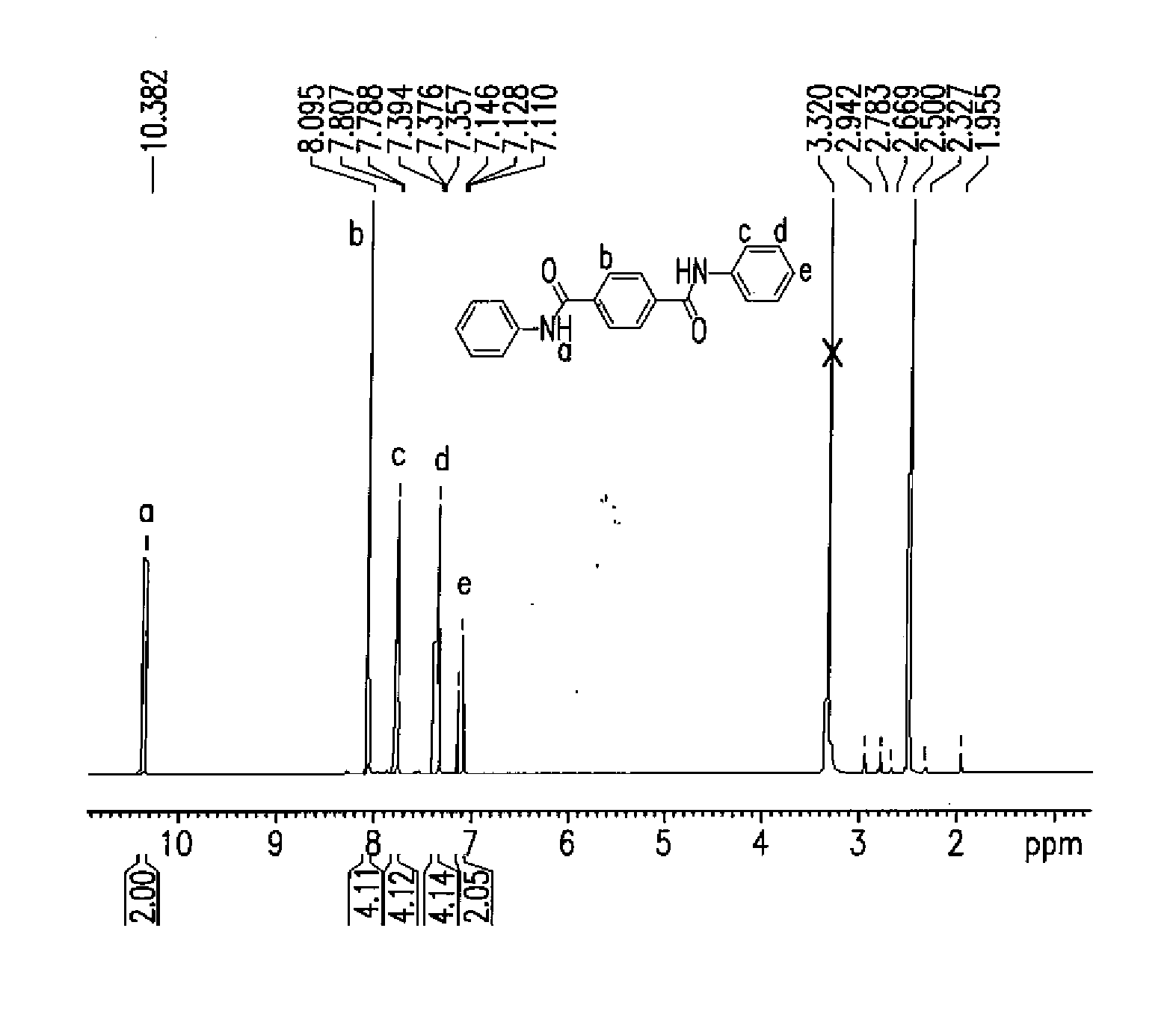

Liquid Crystalline Polymer Composition Containing a Fibrous Filler

InactiveUS20130052447A1Liquid crystal compositionsSynthetic resin layered productsLiquid crystallineFiber

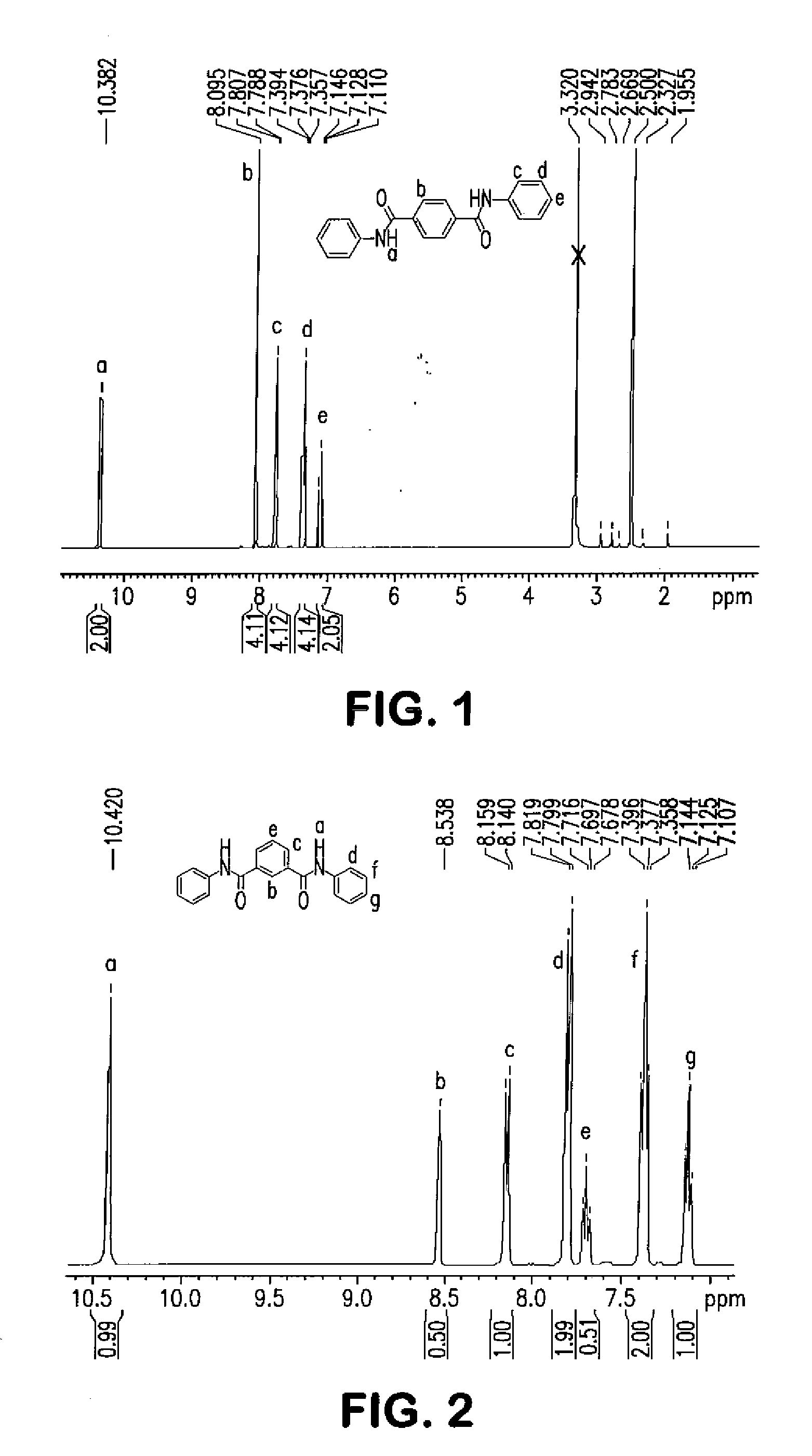

A polymer composition that contains a thermotropic liquid crystalline polymer, fibrous filler (e.g., glass fibers), and a flow aid is provided. The flow aid is in the form of an aromatic amide oligomer which, due to its unique nature and properties, has the ability to dramatically reduce melt viscosity with only a minimal degree of blending with the polymer. More particularly, the fibrous filler is supplied to an extruder in conjunction with the polymer and / or at a location downstream thereof so that the polymer is still in a solid or solid-like state when it initially contacts the filler. In this manner, the fibrous filler and polymer are allowed to mix together while the composition still has a relatively high melt viscosity, which helps to uniformly disperse the fibrous filler within the polymer matrix. After a certain period of time, the aromatic amide oligomer is then supplied to the extruder at a location downstream from the fibrous filler to reduce the melt viscosity of the composition.

Owner:TICONA LLC

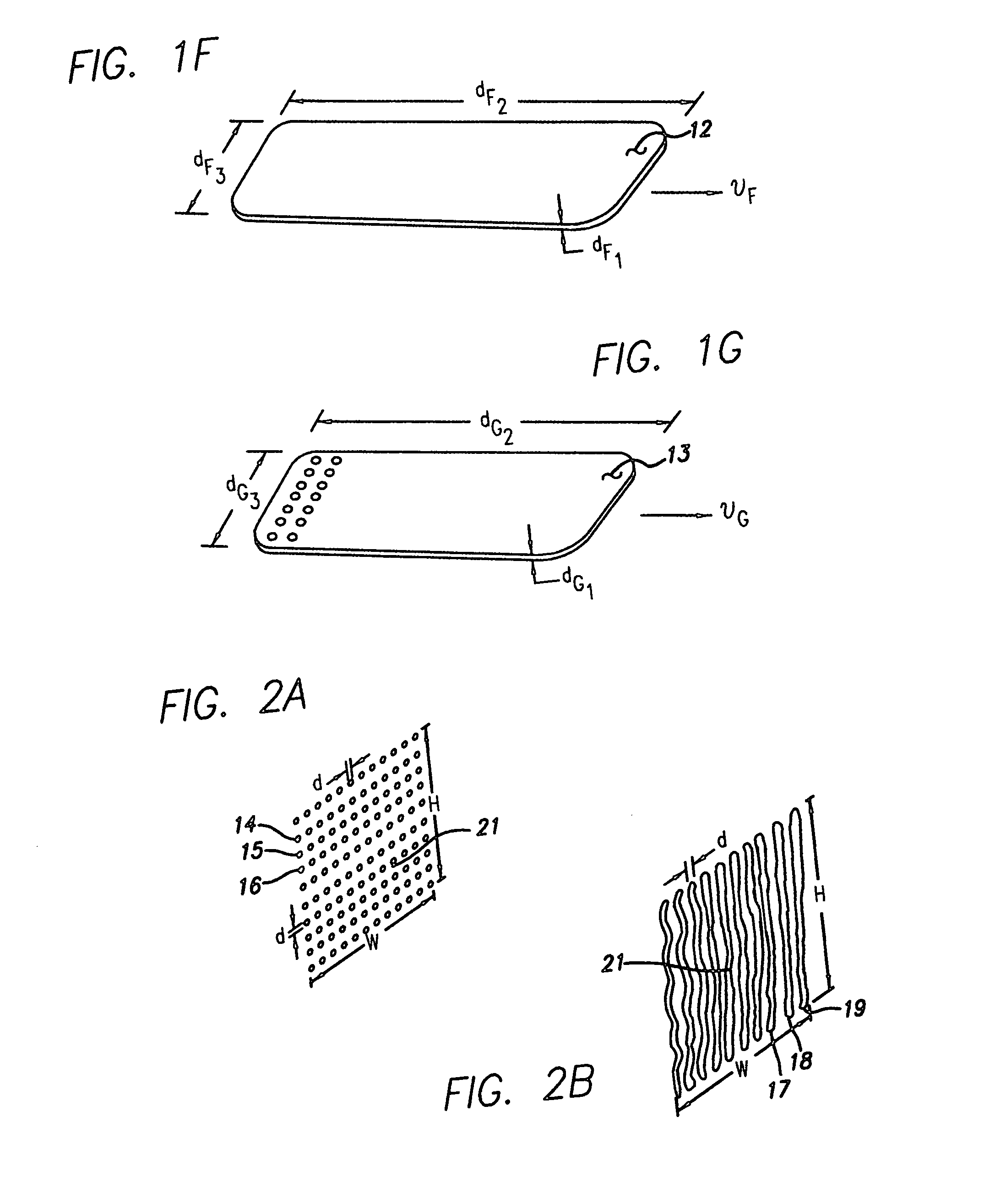

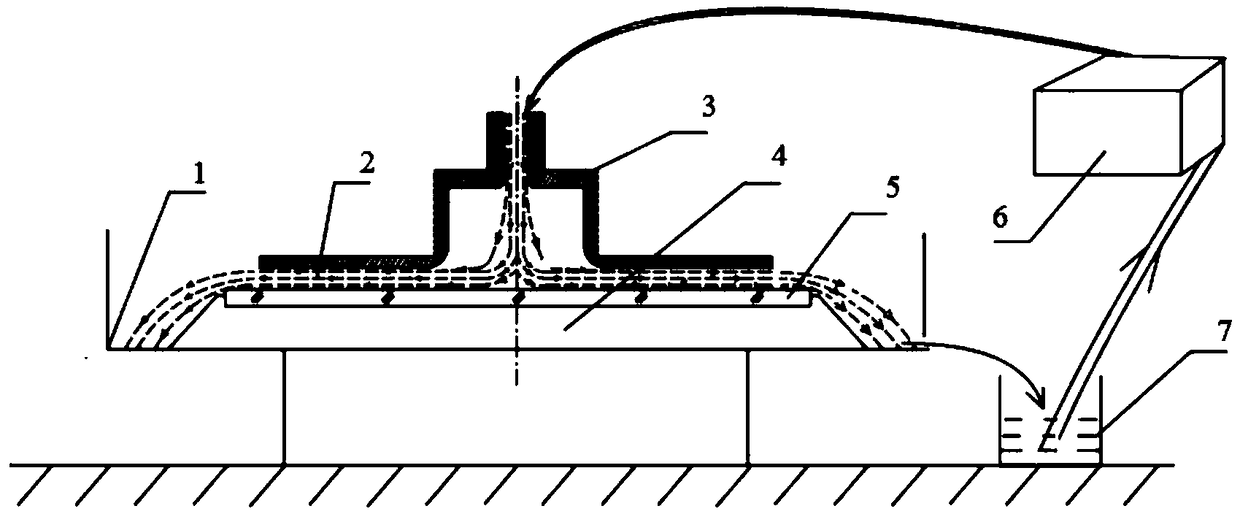

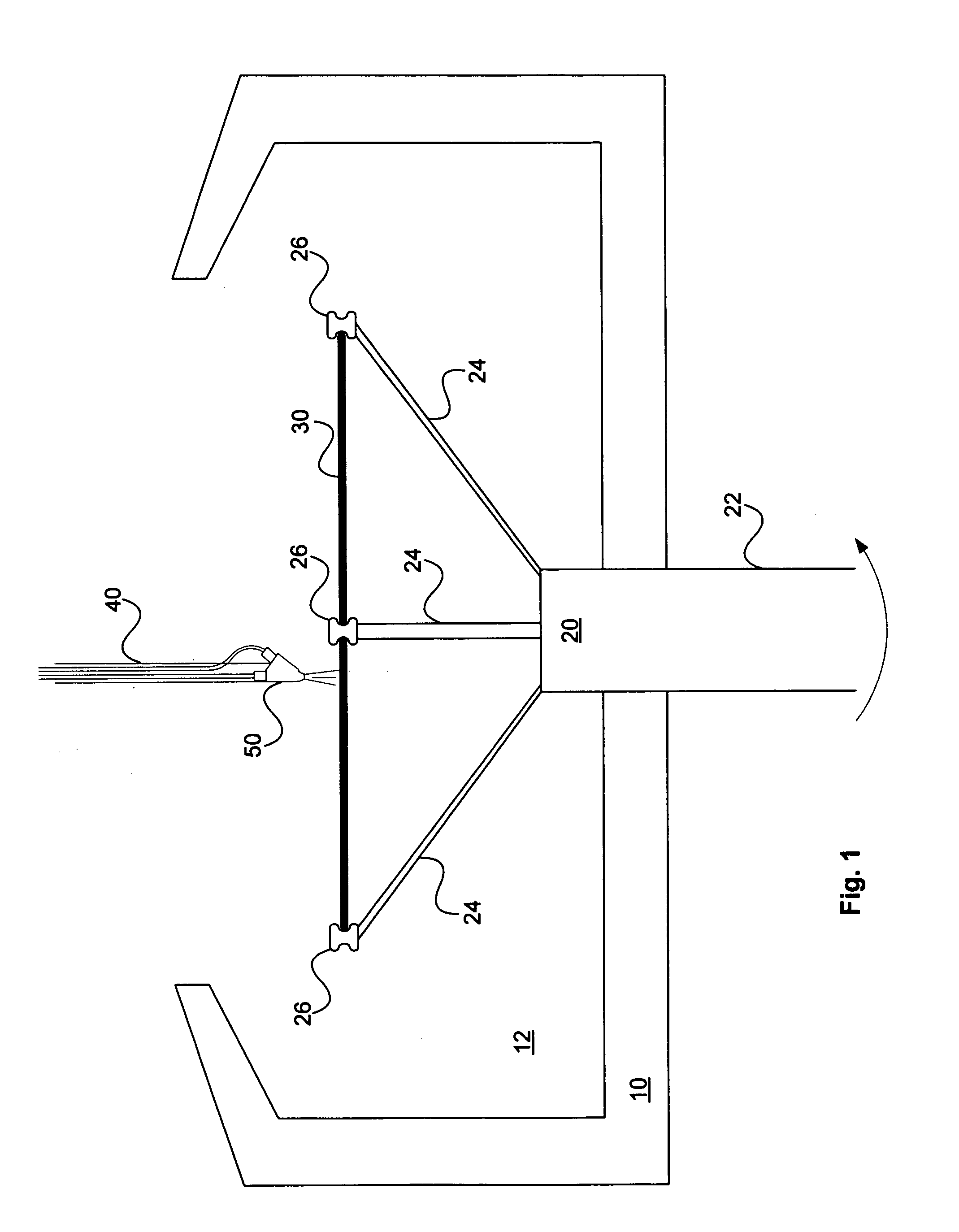

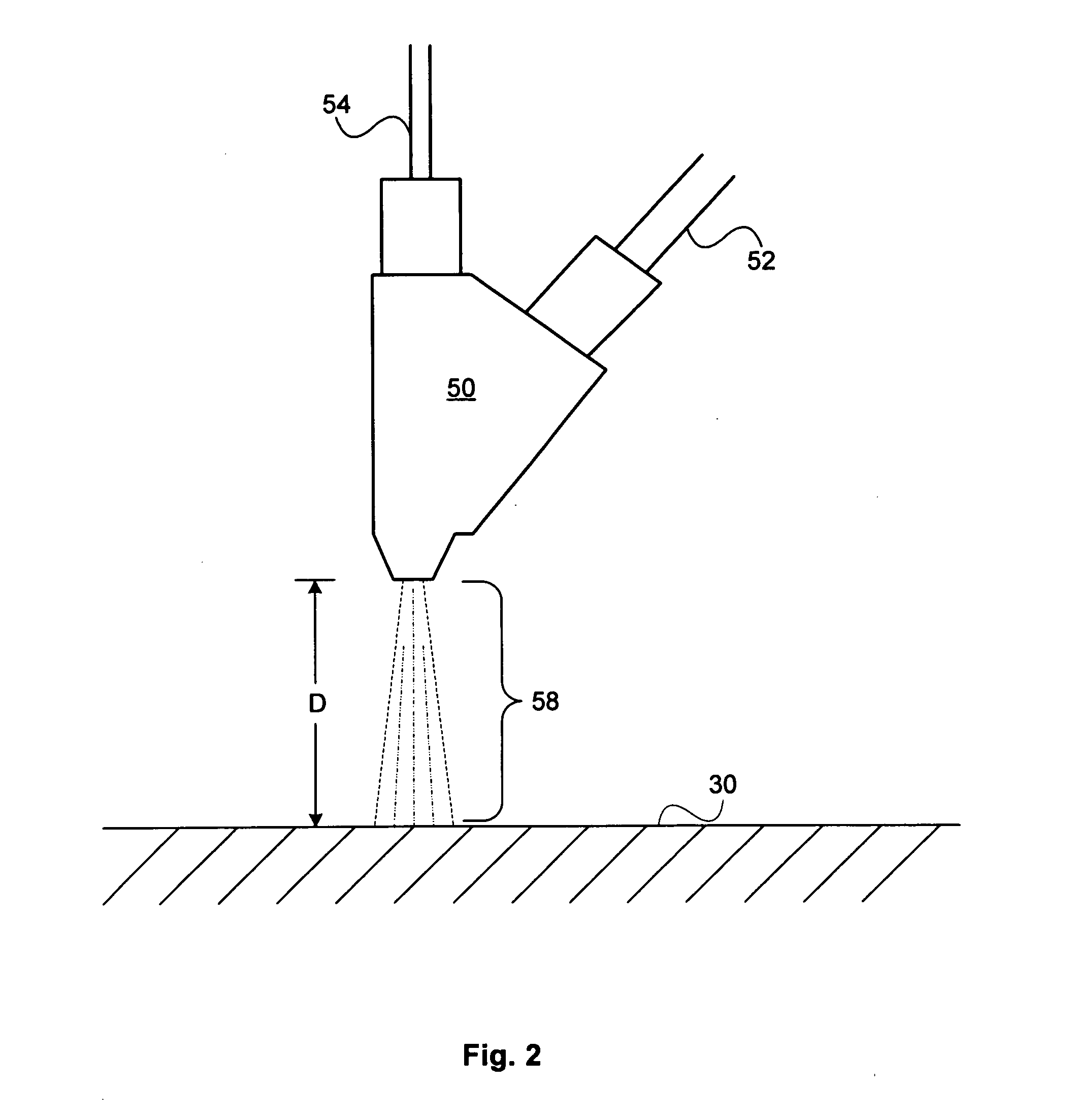

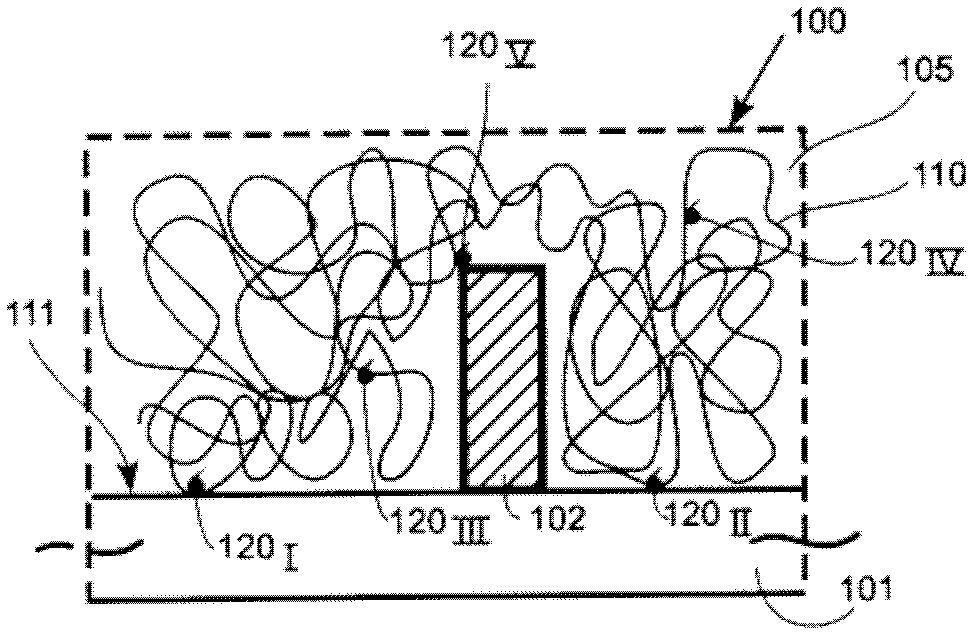

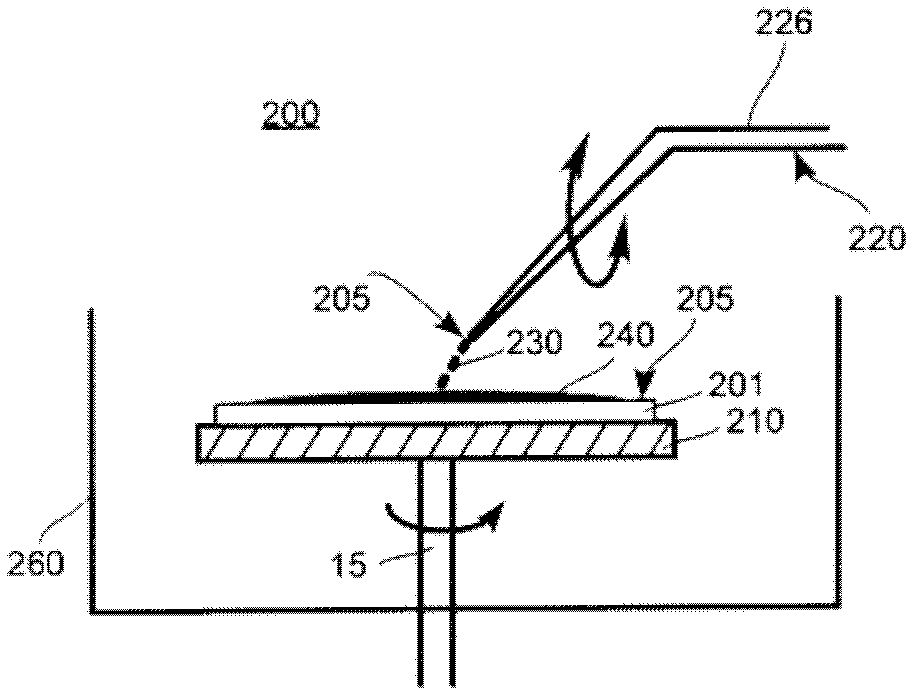

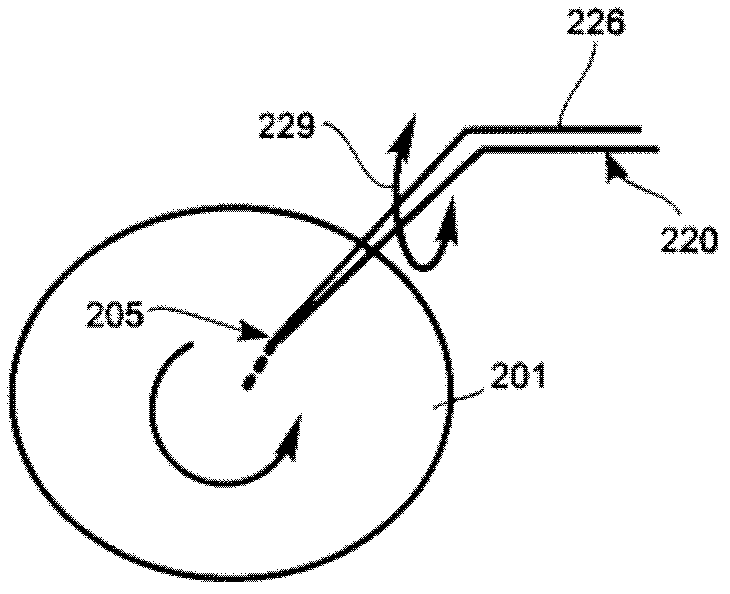

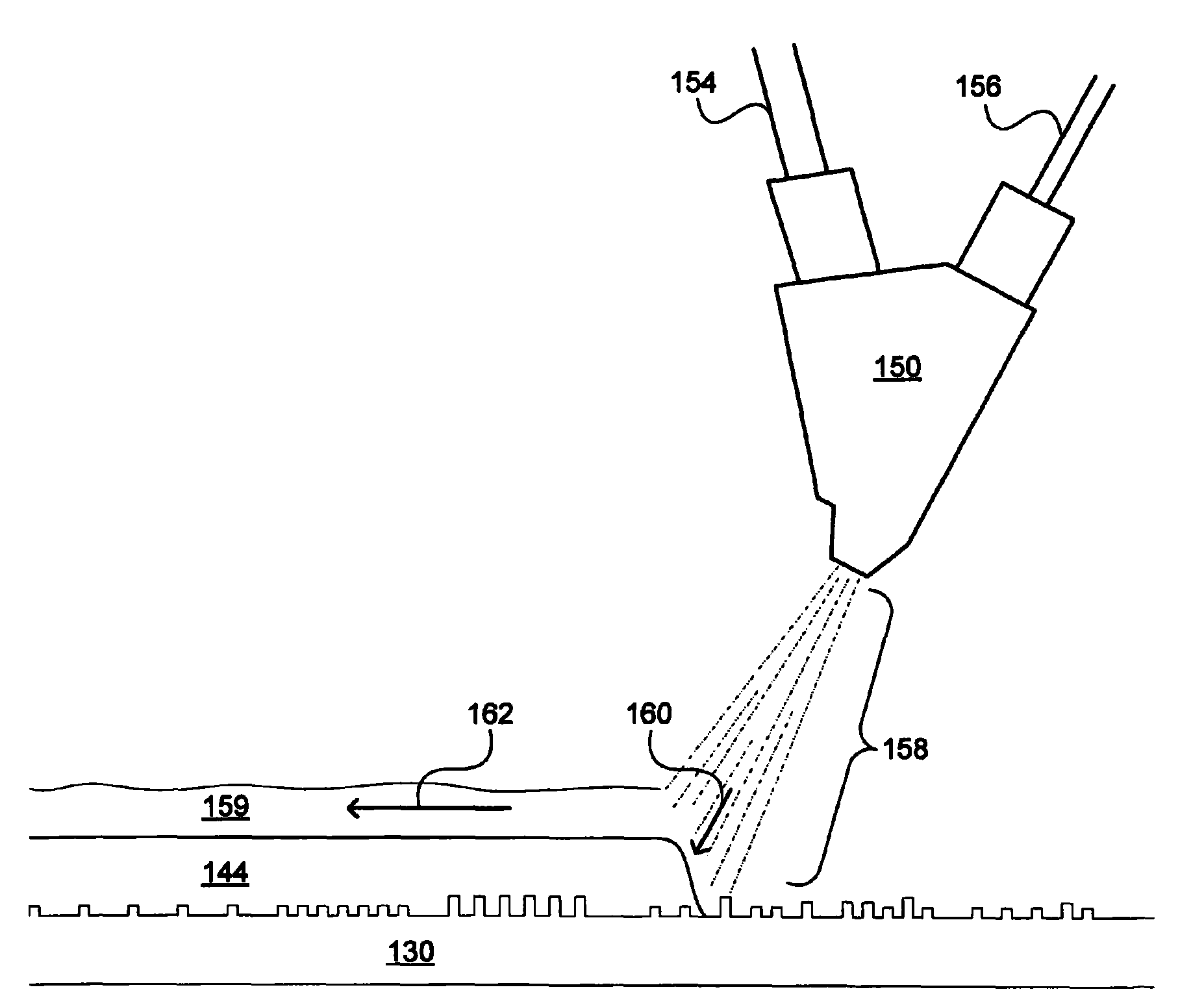

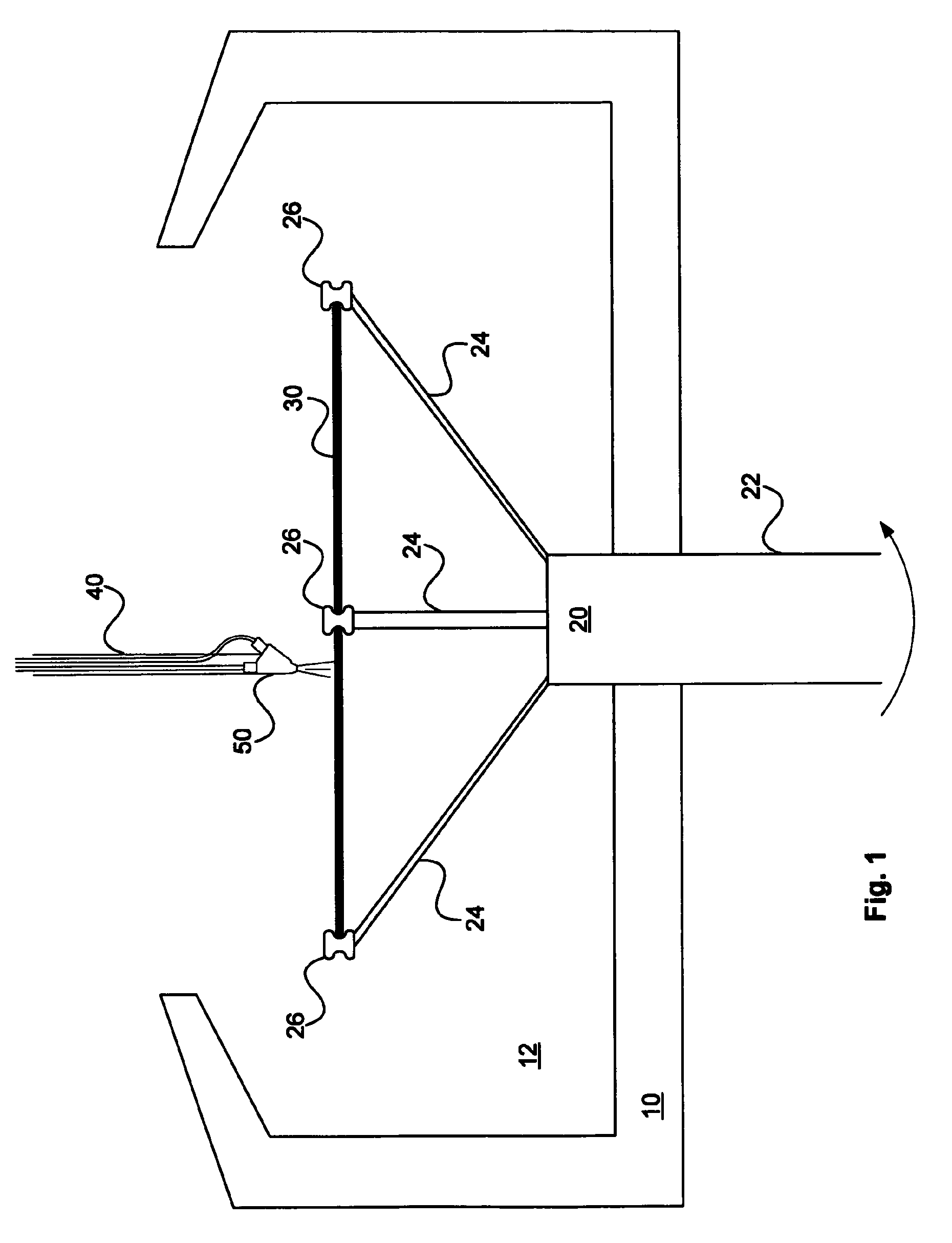

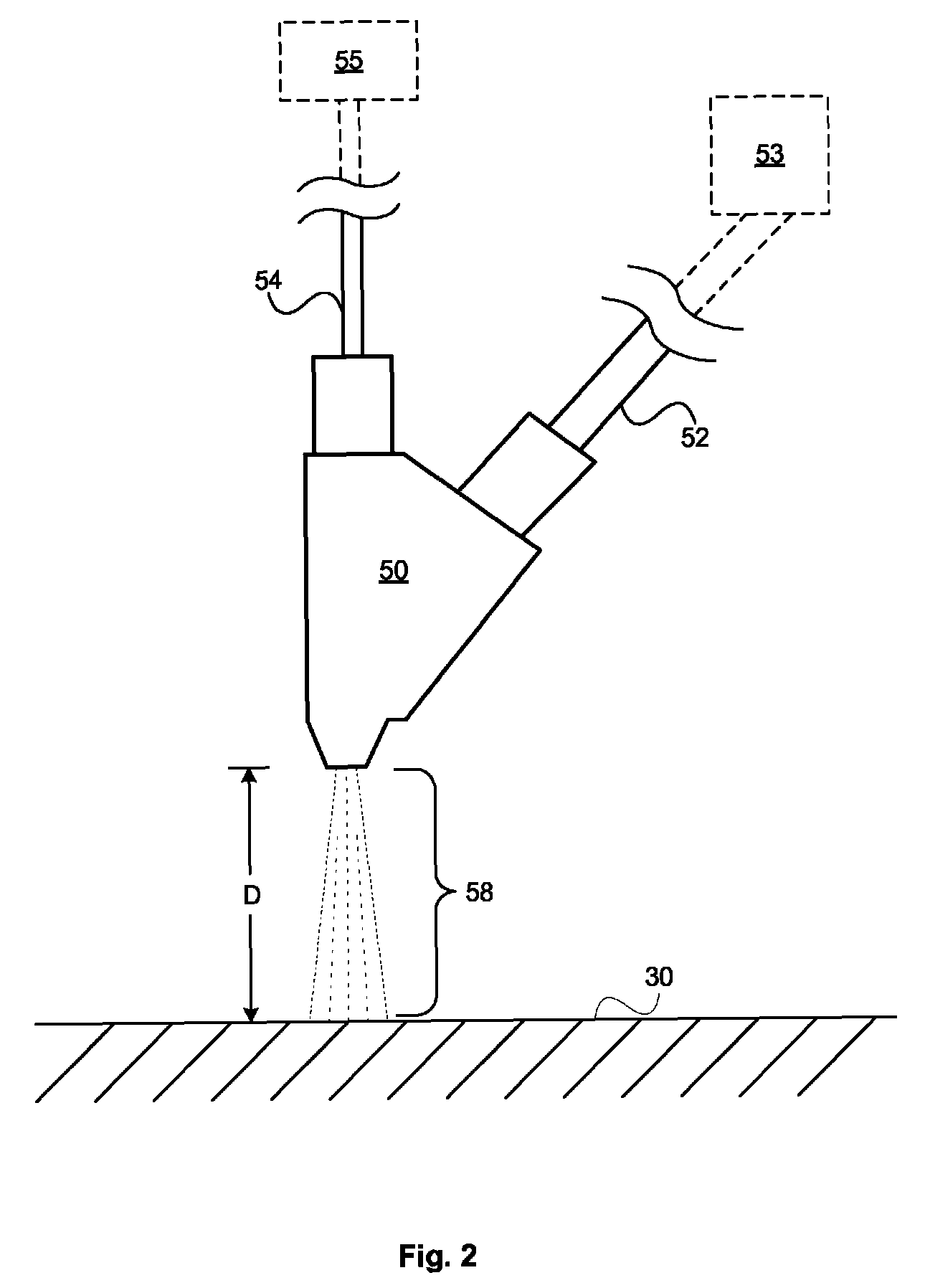

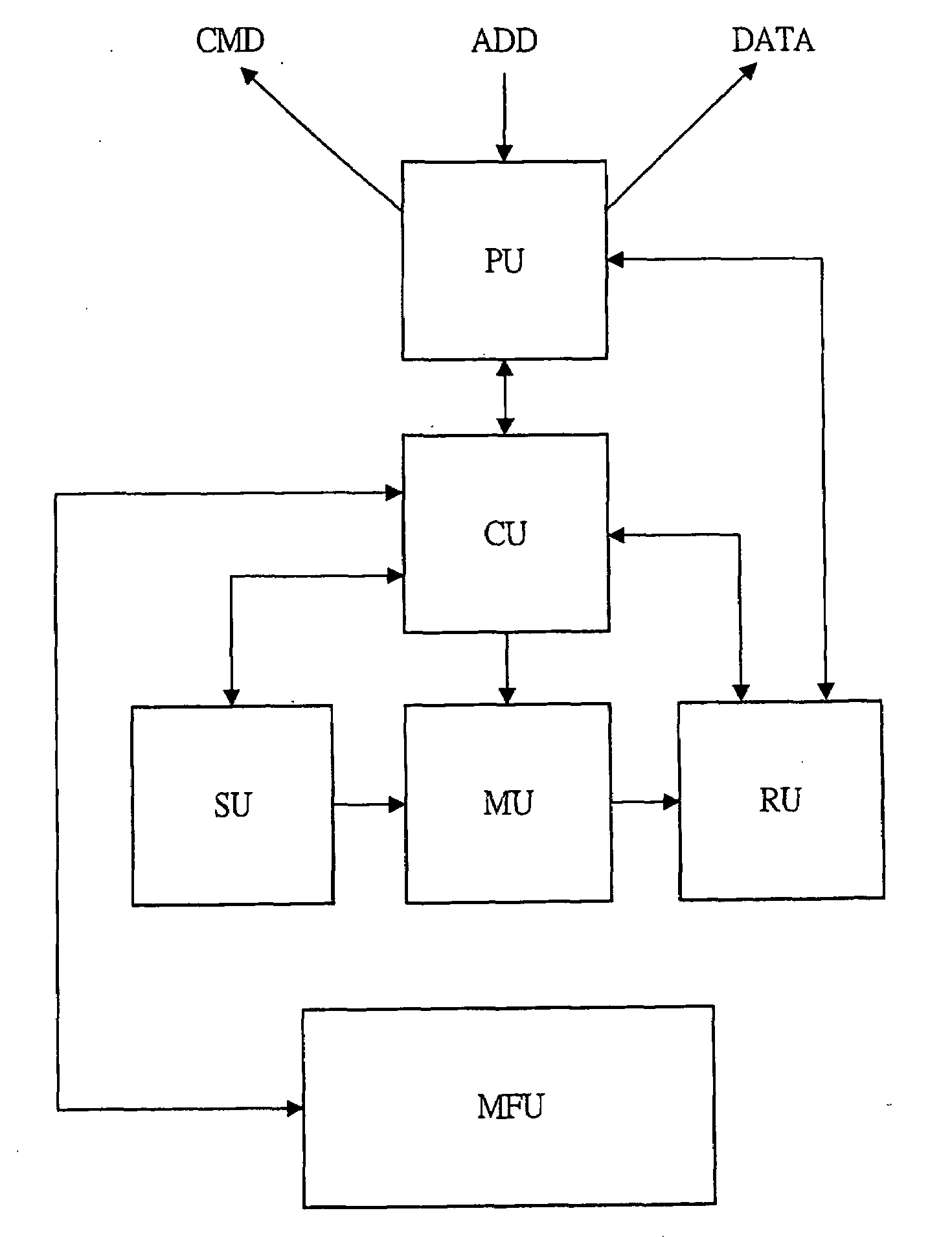

Microdroplet-based 3-D volumetric displays utilizing emitted and moving droplet projection screens

ActiveUS8289274B2Reduce complexityReduce consumptionViewersStatic indicating devicesParticulatesGraphics

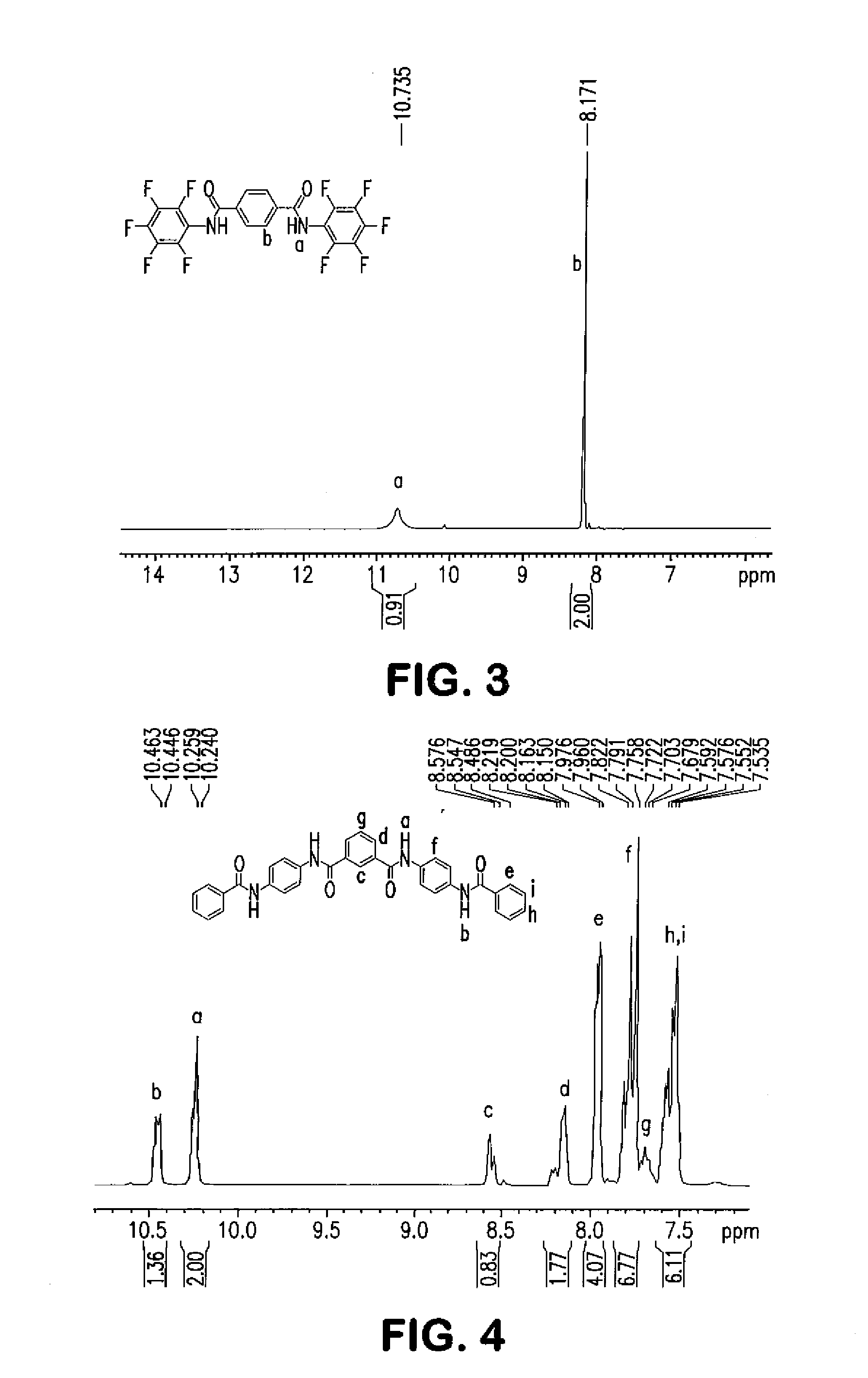

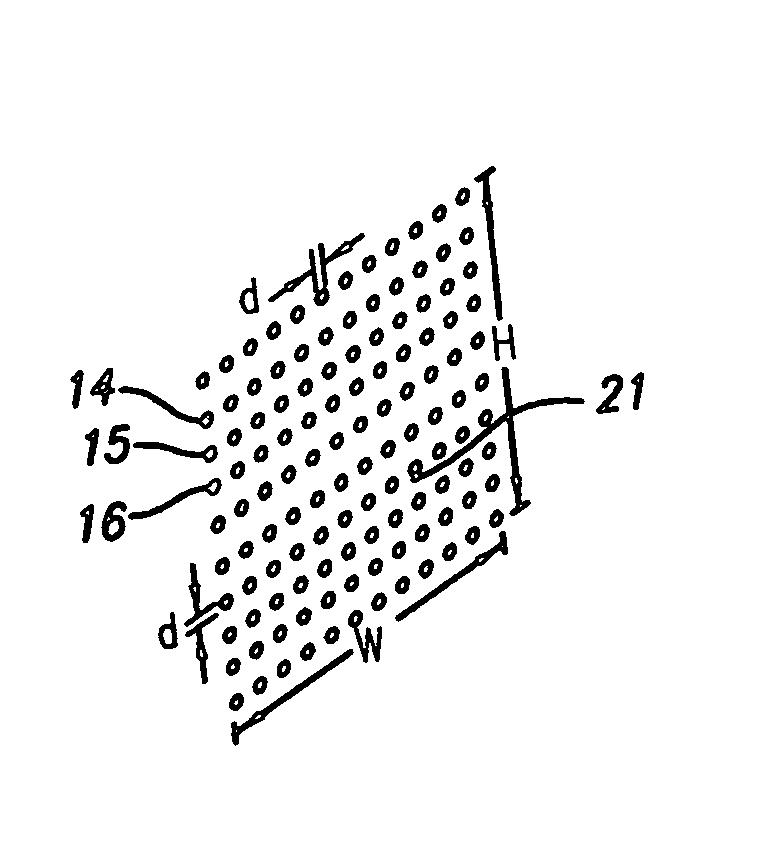

Volumetric three-dimensional (3-D) graphical or computer displays are disclosed herein that are capable of presenting objects, data, scenes or other visual information in a realistic or solid-like manner, allowing for an unaided observer to observe such static or moving objects from multiple perspectives with natural depth-cues and superior image quality. We utilize in this refined approach moving-screens formed from particulate-arrays and we preferably optically project multiple image sub-slices on each such flying-screen as it passes through the image-volume thereby minimizing particulate mass-flow since only once screen per image-volume is needed to present the several or many necessary slices of each volumetric frame.

Owner:I P FOUNDRY

A method of synthesizing a NaY molecular sieve and the synthesized NaY molecular sieve

InactiveCN104692412AEvenly dispersedHigh solid contentFaujasite aluminosilicate zeoliteMolecular sieveFiltration

The invention relates to a method of synthesizing a NaY molecular sieve and the synthesized NaY molecular sieve. The method includes following steps: a step of synthesizing a directing agent, namely a step of subjecting a silicon source and NaOH to mixing pretreatment, adding water and an aluminum source, mixing uniformly and ageing to obtain the directing agent, with the mole ratio of Na2O, Al2O3, SiO2 and H2O being 15-25:1:10-30:250-450; a step of preparing reactive gel, namely a step of adding a solid silicon source into a NaOH solution, pretreating to prepare hydrous silica gel, adding an aluminum source, mixing uniformly, adding the directing agent, stirring and mixing uniformly to obtain flow type solid-like reactive gel, with the total adding mole ratio of the Na2O, the Al2O3, the SiO2 and the H2O being 2-6:1:5.5-10.5:50-150; and a step of crystallizing, performing suction filtration and drying, namely a step of crystallizing the prepared solid-like reactive gel, filtering after crystallization is finished, washing and drying to obtain a product.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

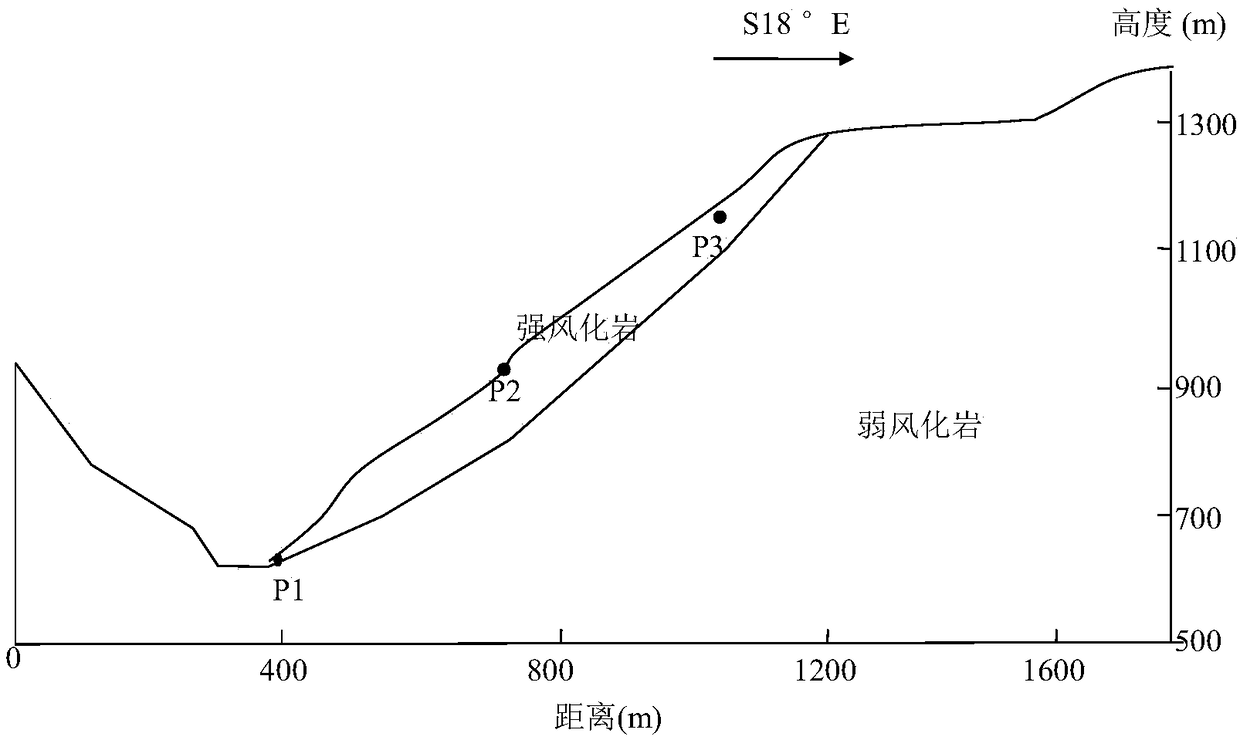

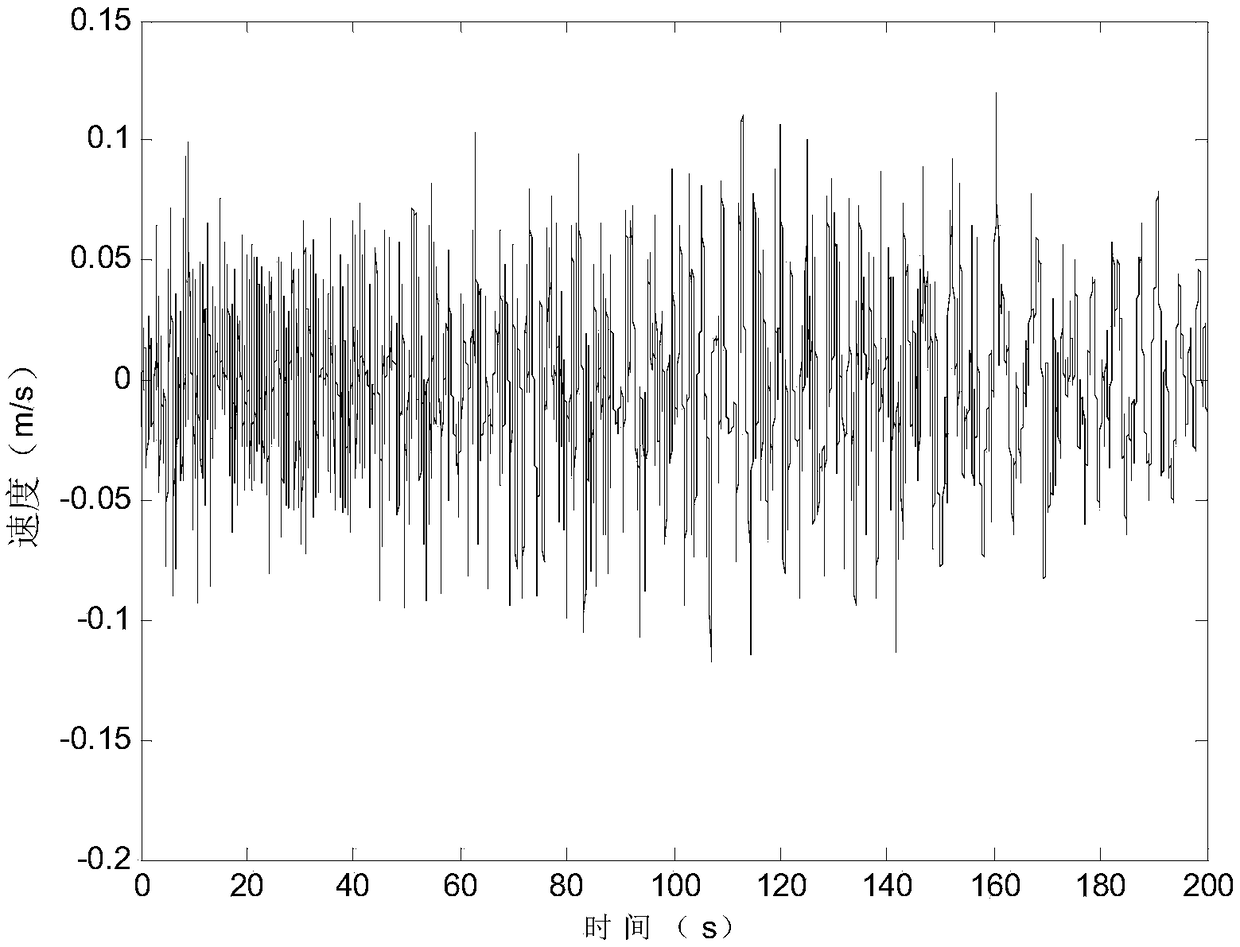

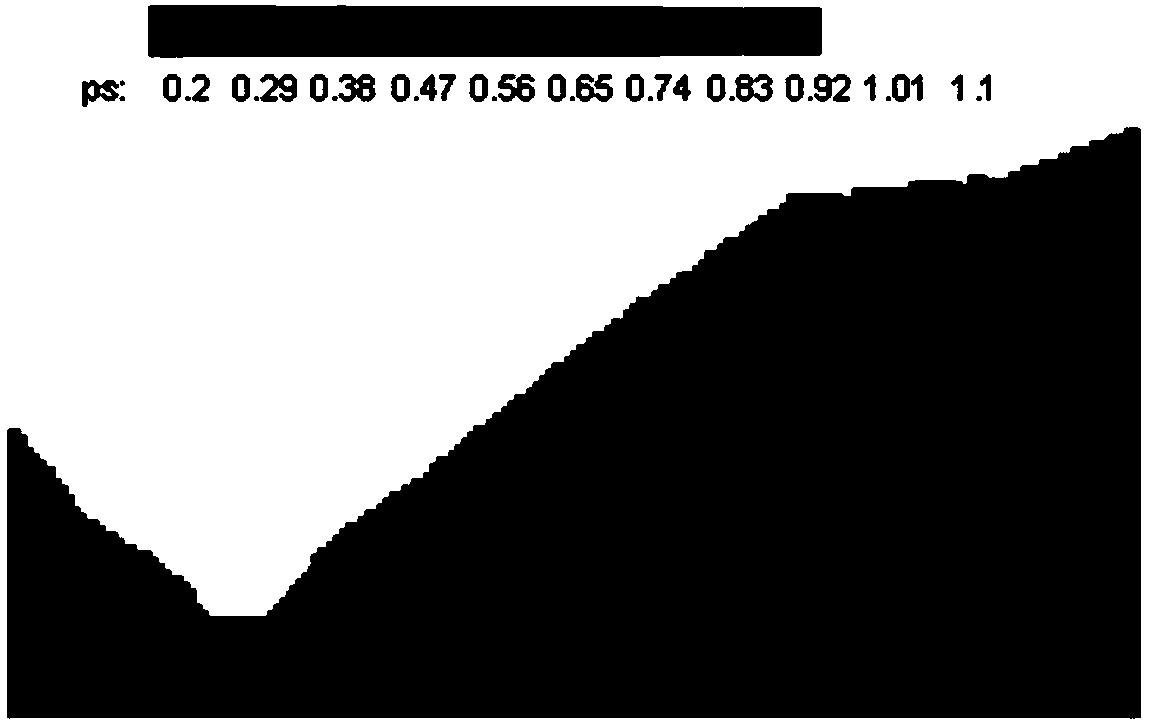

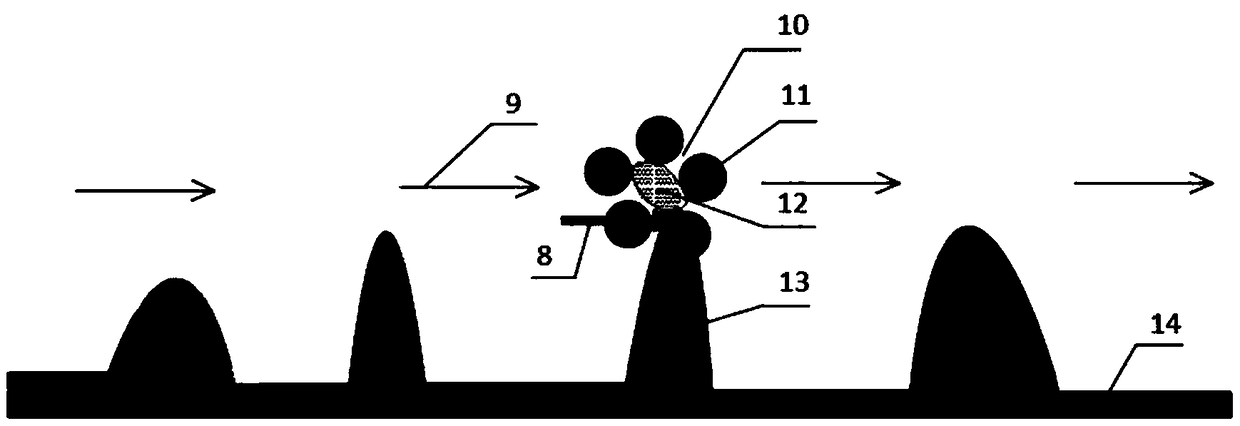

A method for simulating progressive failure, like solid-liquid phase transformation behavior of rock and soil media

InactiveCN109284523AAccurate predictionReasonable assessment of hazardsGeometric CADDesign optimisation/simulationStart upNewtonian fluid

The invention relates to a rock-soil medium progressive failure, solid-like. The smooth particle dynamics (SPH) method is improved from three aspects: boundary condition, constitutive relation and artificial stress, so that the SPH can reproduce the progressive failure of rock and soil media under strong earthquake dynamic condition, solid-like-liquid phase change behavior, constructing slip-freeboundary modified by seismic wave velocity to apply seismic wave, creating free-field boundary to prevent seismic wave reflection, using particle rheology for reference, combining Drucker-Prager constitutive model and Newtonian fluid constitutive model construct a new unified constitutive model, which can describe the phase from sliding (solid-like) to flowing (liquid-like) in geotechnical media.The invention effectively reproduces the kinematic characteristics of the start-up, high-speed flow and accumulation process of the landslide, analyzes the progressive failure of the rock and soil medium and the penetration process of the sliding surface under the action of the strong earthquake, thereby accurately predicting the sliding distance, and reasonably assesses the earthquake-triggered landslide. The hazard caused by debris flow provides scientific basis for the planning and design of earthquake prevention and disaster reduction.

Owner:TONGJI UNIV

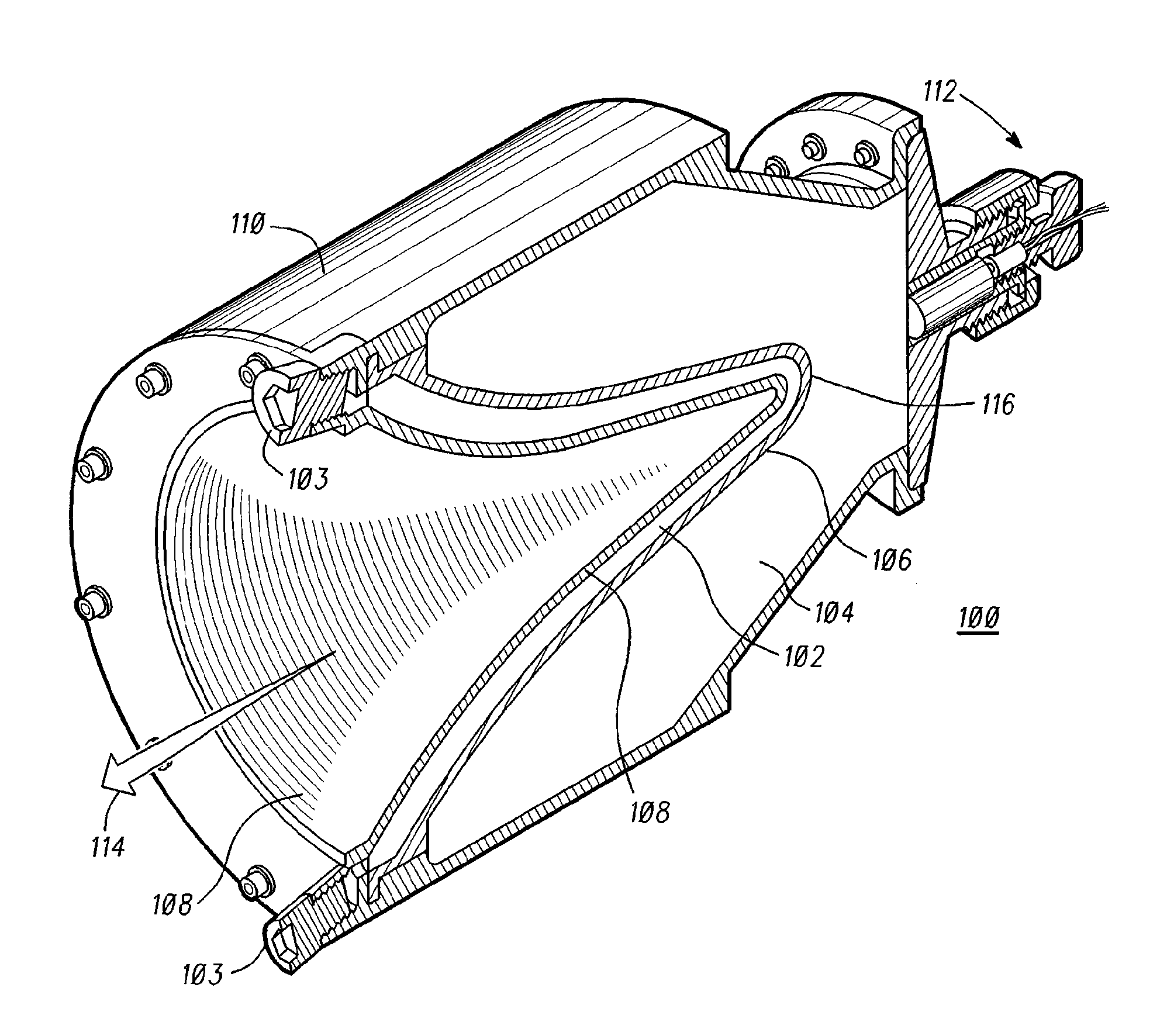

Reactive shaped charge, reactive liner, and method for target penetration using a reactive shaped charge

Embodiments of a reactive shaped charge, a reactive liner, and a method for penetrating a target are generally described herein. The reactive shaped charge comprises a reactive liner having a matrix of reactive metal particles in a hydrocarbon fuel, a high explosive, and an inner barrier separating the reactive liner from the high explosive. The hydrocarbon fuel fills the interstitial spacing between the reactive metal particles, and the matrix is tightly packed or compresses to exhibit a solid like property.

Owner:RAYTHEON CO

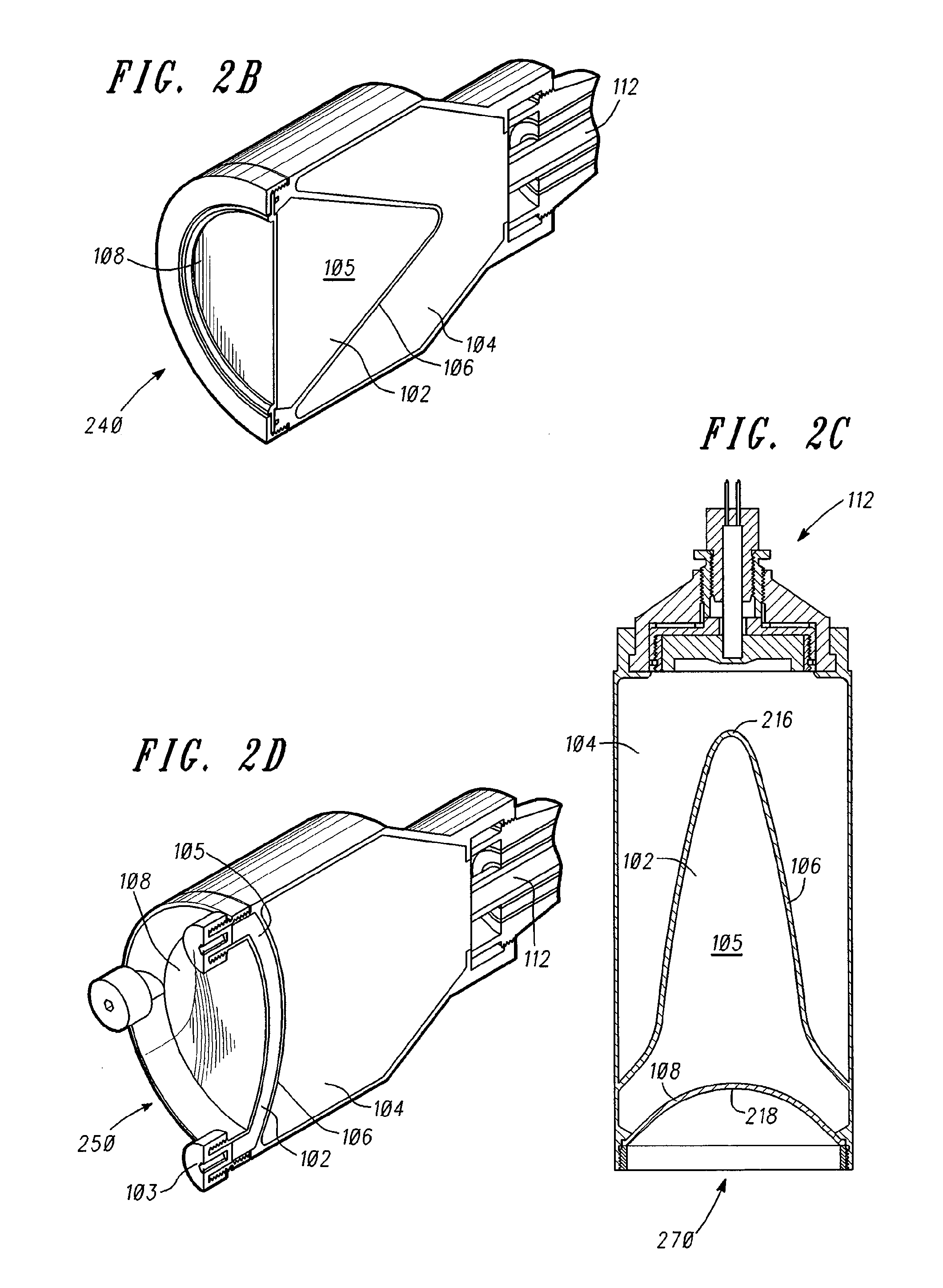

Liquid float polishing method taking non Newtonian power law fluid as polishing medium

The invention relates to the technical field of polishing of super smooth surfaces of optical elements, in particular to a liquid float polishing method taking a non Newtonian power law fluid as a polishing medium. Optical glass is processed with high efficiency, high quality and low cost. According to the technical scheme, the device comprises a pipeline, a polishing head which supplies a liquidin the middle and a worktable. The pipeline conveys a polishing liquid to the center of the polishing head, the polishing liquid is guided into the polishing head through a hydraulic pump and flows through a polishing area between the polishing head polishing surface and a processed workpiece on the worktable, a liquid film formed by the fluid in the polishing area supports the polishing head, thepolishing head achieves a self-balanced state under the action of the liquid, the liquid flows at a certain speed in the polishing area, the fluid has a shear thickening phenomenon under the action of the shearing force, solid particles wrap the polishing particles therein to form a flexible solid abrasive material so as to form a solid-like shape to shear a protruding peak on the processed workpiece, so that the surface of the workpiece is removed.

Owner:XIAN TECHNOLOGICAL UNIV

Enzyme method degumming method

Provided is an enzyme method degumming method. The method comprises the following steps: firstly, an enzyme solution with a phospholipase concentration of 1-30000U / mL is prepared, soluble salts, a hydrophilic solvent and lipids rich in phosphatide are added in the enzyme solution, a three-liquid-phase system is prepared, and the mass ratios of the soluble salts, the hydrophilic solvent and the lipids to the enzyme solution are 0.1-0.9, 0.1-5 and 0.1-10; secondly, the three-liquid-phase system is placed in a reactor, a shaking-table reaction is carried out at a constant temperature, after the reaction is finished, the mixture is allowed to stand or centrifuged until the mixture is divided into four layers which are an upper liquid layer, a solid-like layer, a middle liquid layer and a lower liquid layer in order from top to bottom, phosphatide is mainly enriched in the solid-like layer, the upper liquid layer product is collected and a lipid product without phosphatide is obtained. The method has advantages of low energy consumption, high raw material utilization rate, mild reaction conditions and the like, and the technical problems are solved that synchronous removal and recovery of phosphatide in oil through present enzyme methods are difficult for industrialization.

Owner:SOUTH CHINA UNIV OF TECH

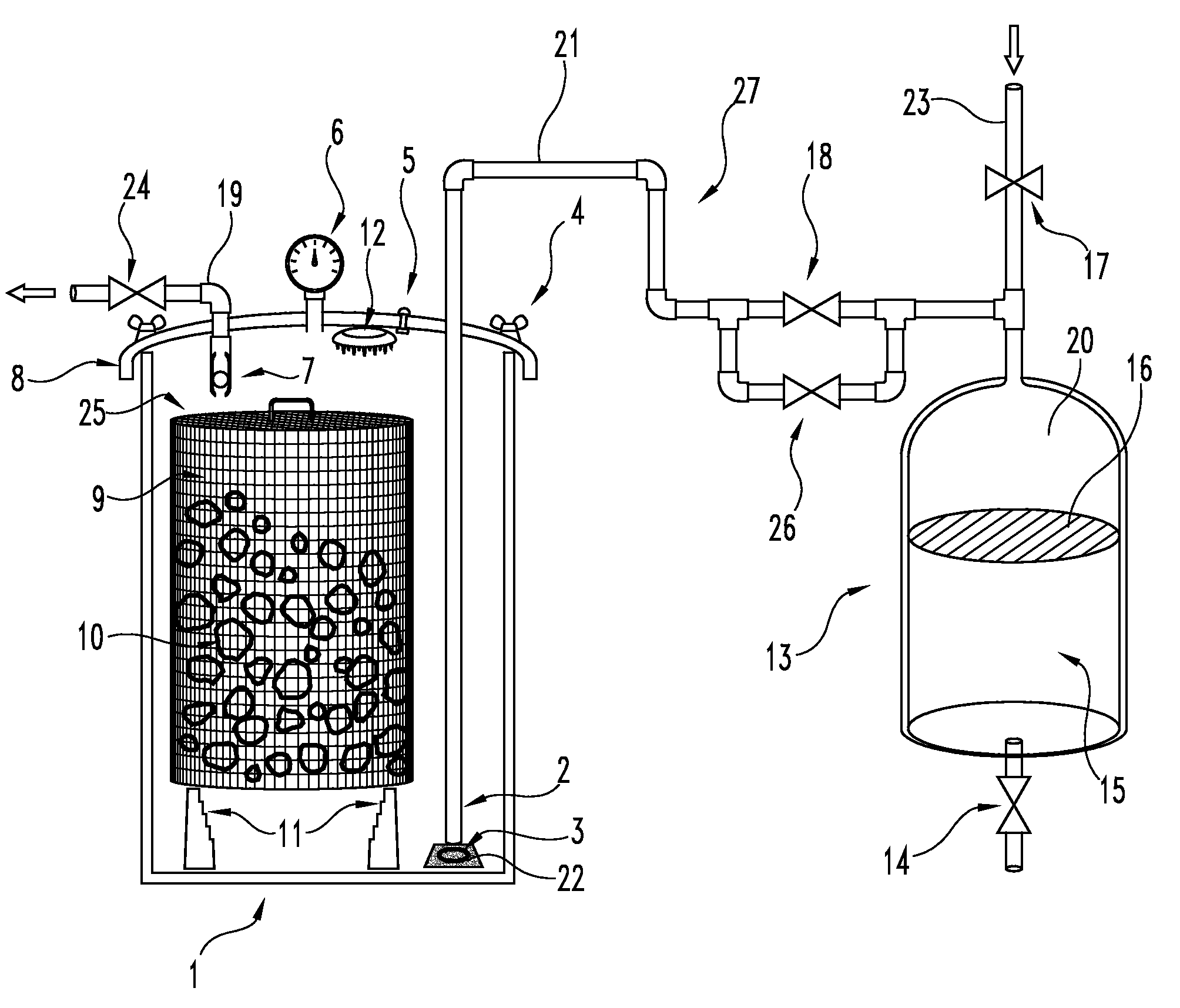

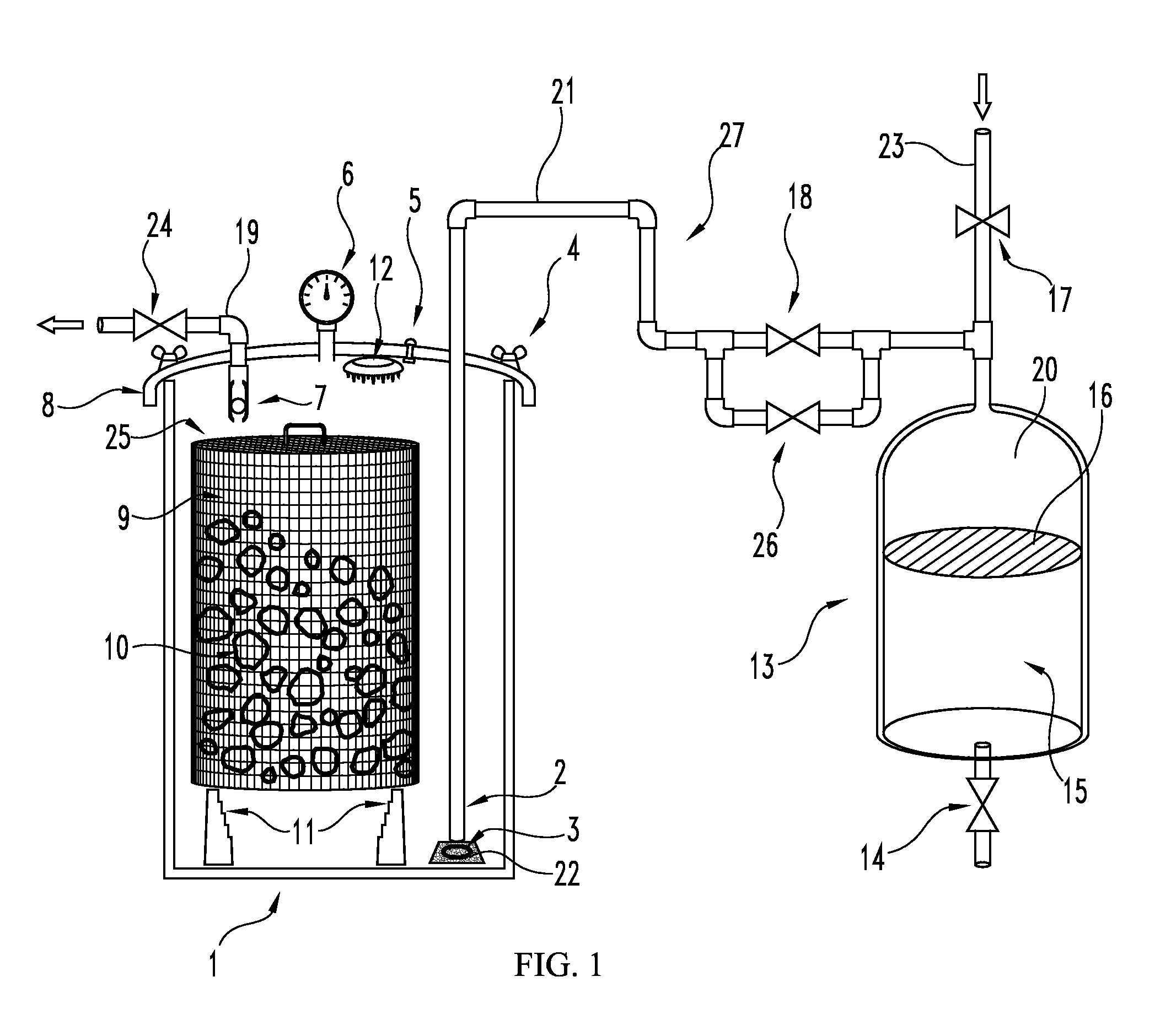

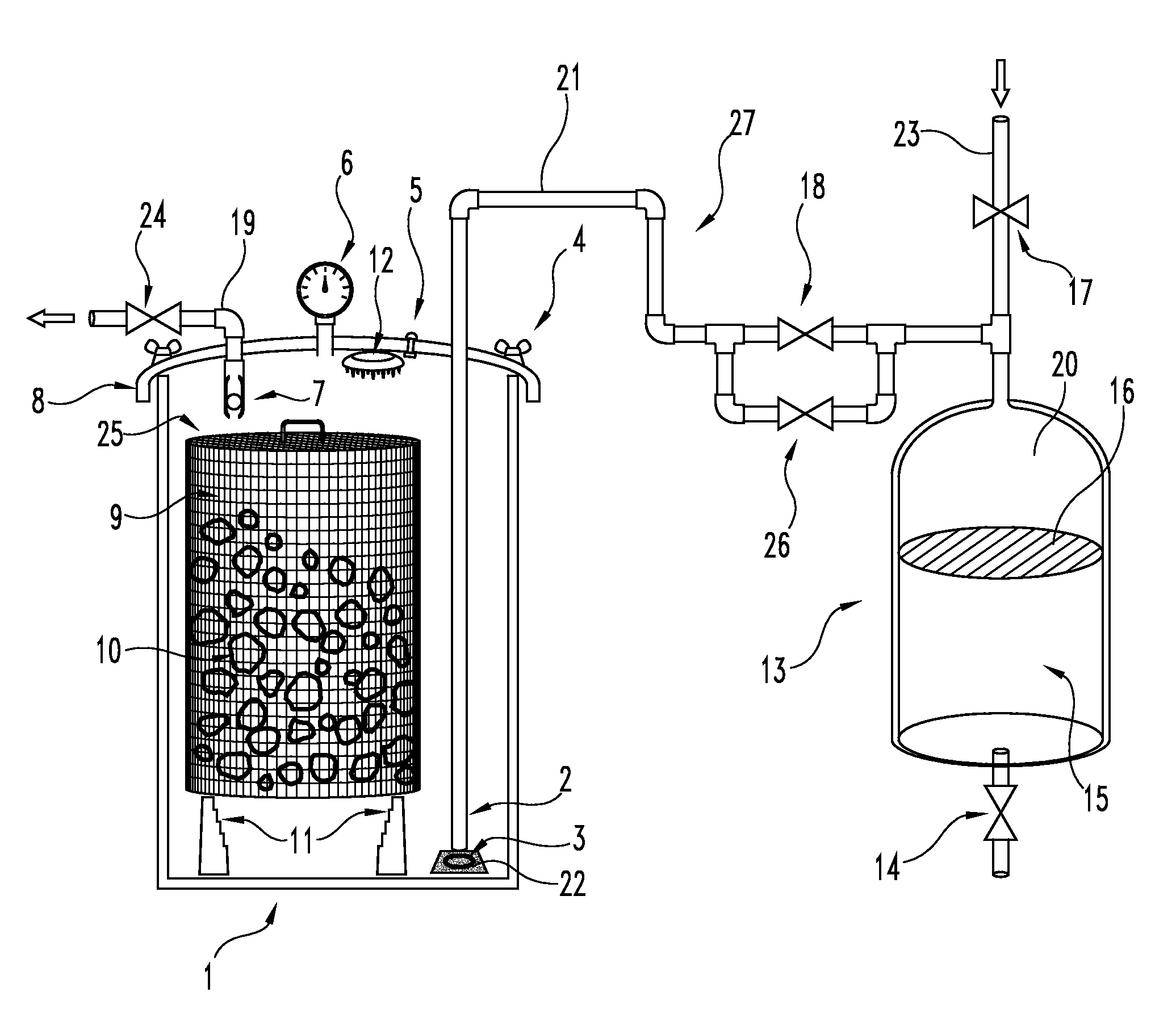

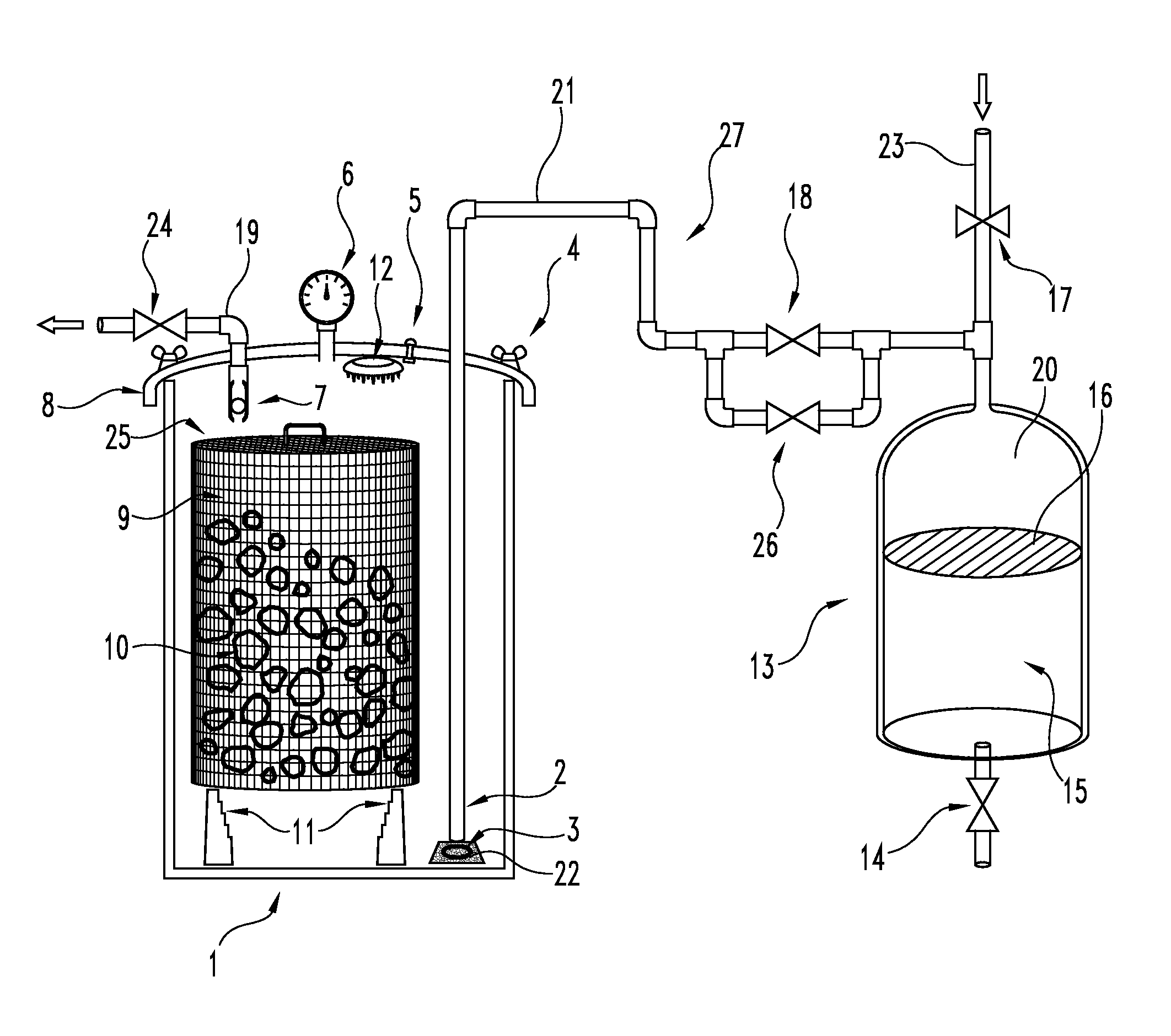

Control system for an on-demand gas generator

InactiveUS20090035214A1Reduce exposureReaction is slowPressurized chemical processPhysical/chemical process catalystsControl systemEngineering

A self-regulating on-demand gas generator. Generation of gas produced from a reaction is selectively, variably, and spontaneously controlled. A variable volume liquid chamber in communication with the pressure pot allows the volume of liquid reactant in the pressure pot to be varied. The amount of product gas generated in the pressure pot depends on the degree of contact between the solid-like reactant and the liquid reactant. The pressure of the product gas regulates the level of liquid in the pressure pot and thereby regulates the degree of contact between the solid-like reactant and the liquid reactant. A sealed gas chamber sharing a flexible diaphragm with the liquid chamber controls the expandability of the liquid chamber. Manipulating the pressure in the sealed gas chamber or the volume of the liquid reactant affects the pressure at which contact by the reactants will be initiated or terminated and thereby provides the ability to control the reaction.

Owner:PURDUE RES FOUND INC

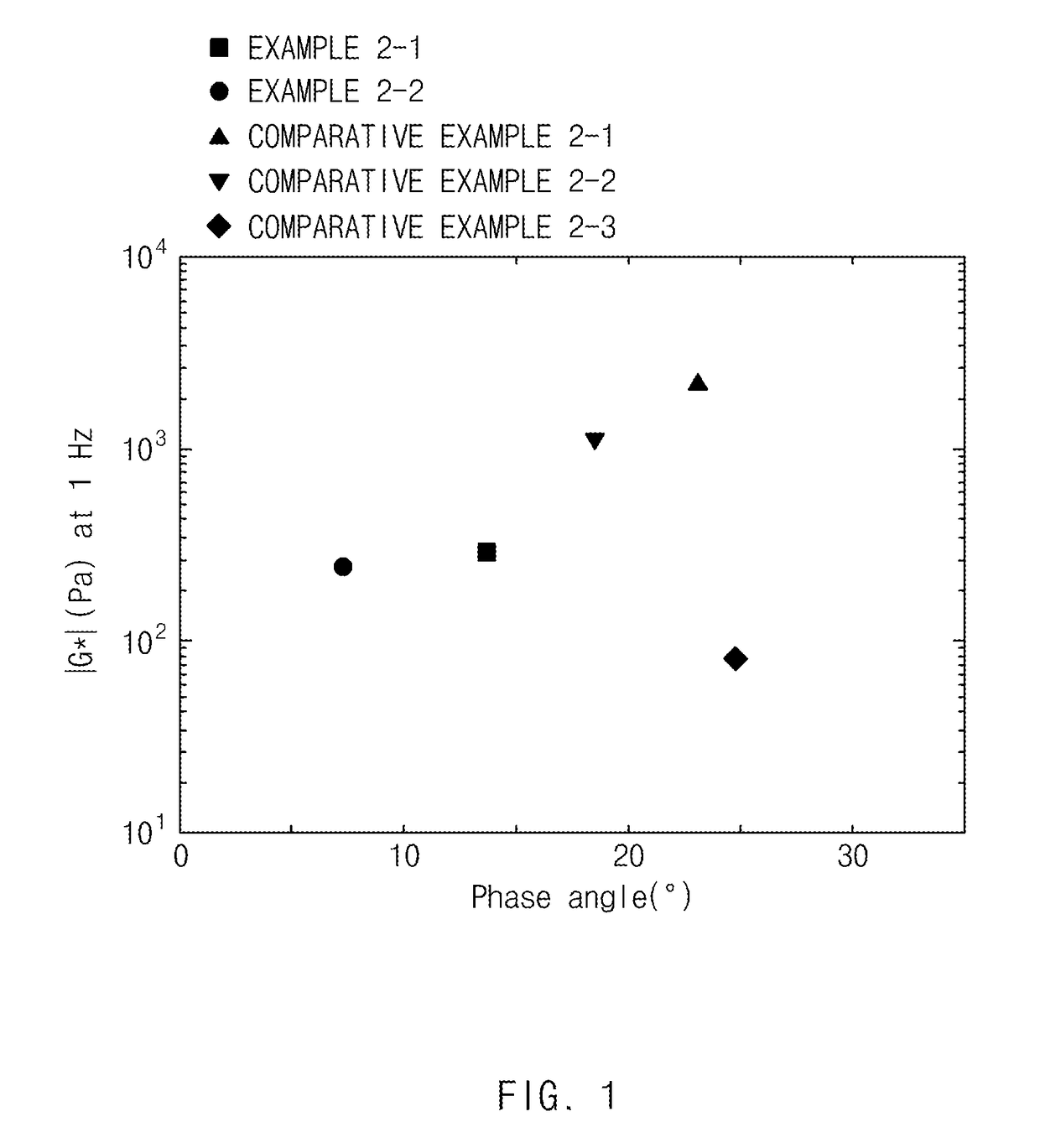

Conductive material dispersed liquid and lithium secondary battery manufactured using same

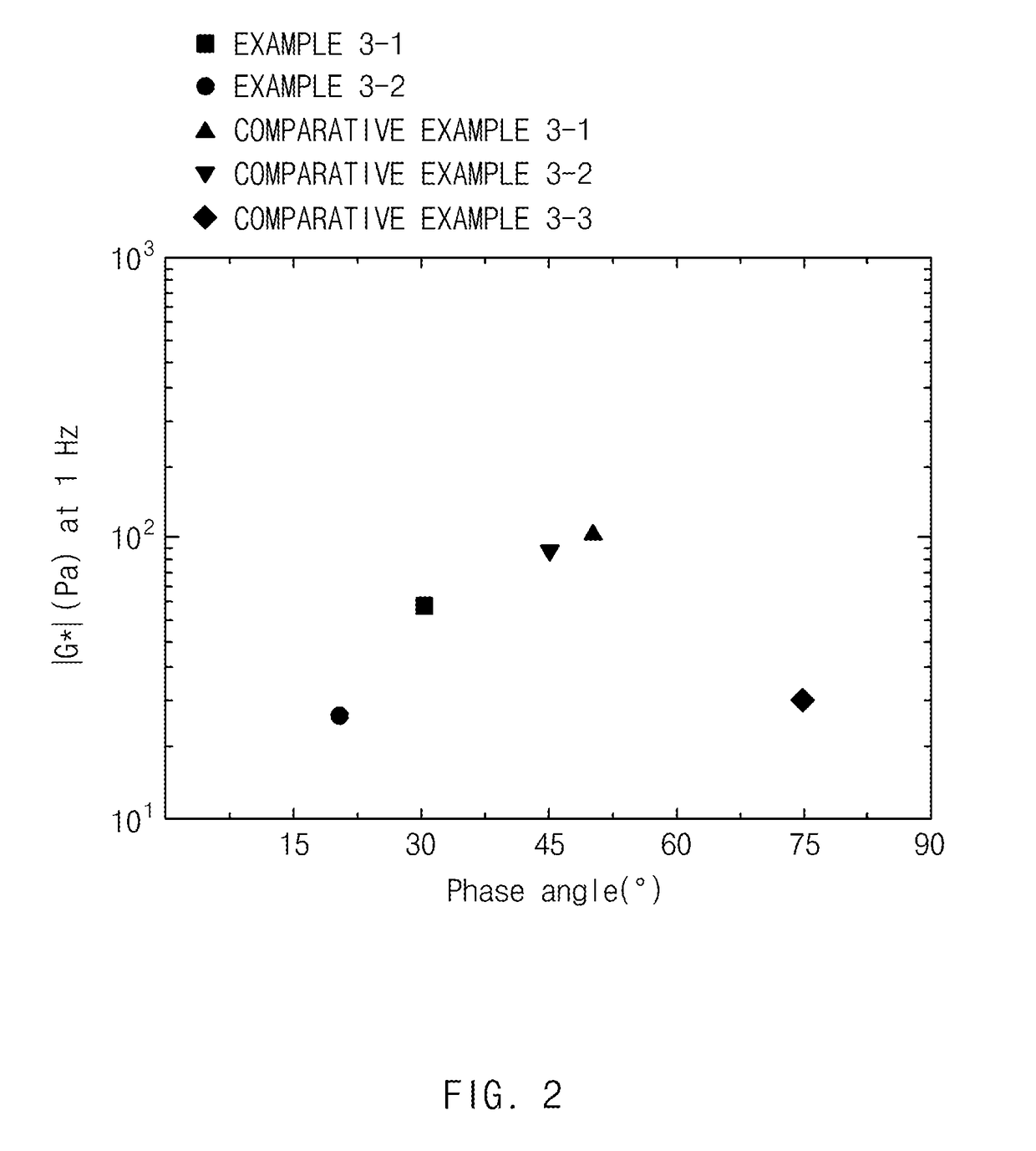

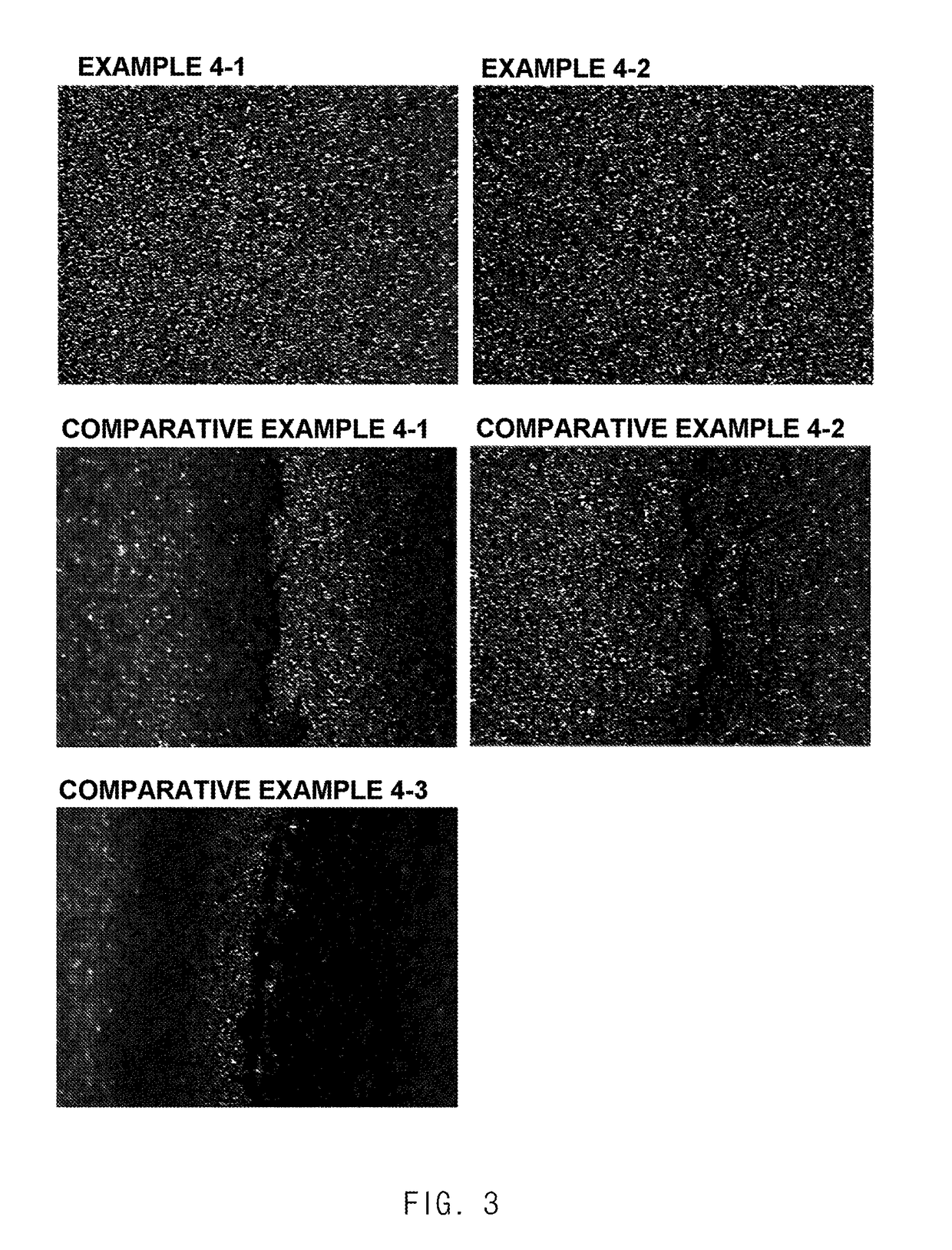

ActiveUS20180175370A1High solid-like propertyImprove performanceElectrode manufacturing processesFinal product manufactureTO-18Carbon nanotube

The present invention provides a conductive material dispersed liquid, including: a conductive material which includes bundle-type carbon nanotubes; a dispersant; a dispersion medium, where a phase angle is in a range of 3° to 18° when measured by a rheometer at a frequency of 1 Hz; and a lithium secondary battery manufactured using the conductive material dispersed liquid. The conductive material dispersed liquid has high solid-like properties, and thus allows the formation of an electrode active material layer having a uniform thickness with no concern for collapse or occurrence of cracks during manufacture of an electrode, and thereby can improve the performance characteristics, particularly capacity characteristics, of a battery.

Owner:LG ENERGY SOLUTION LTD

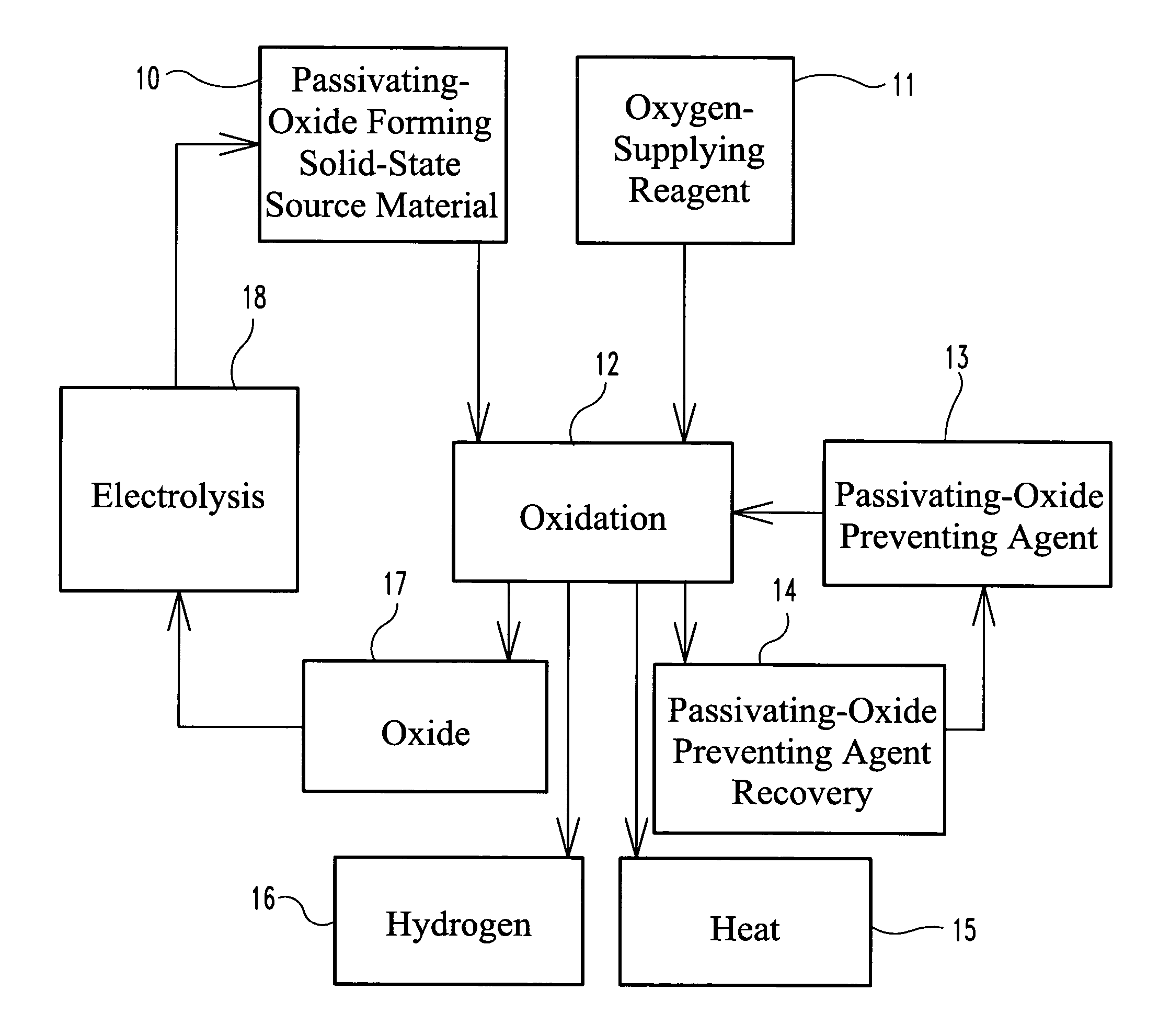

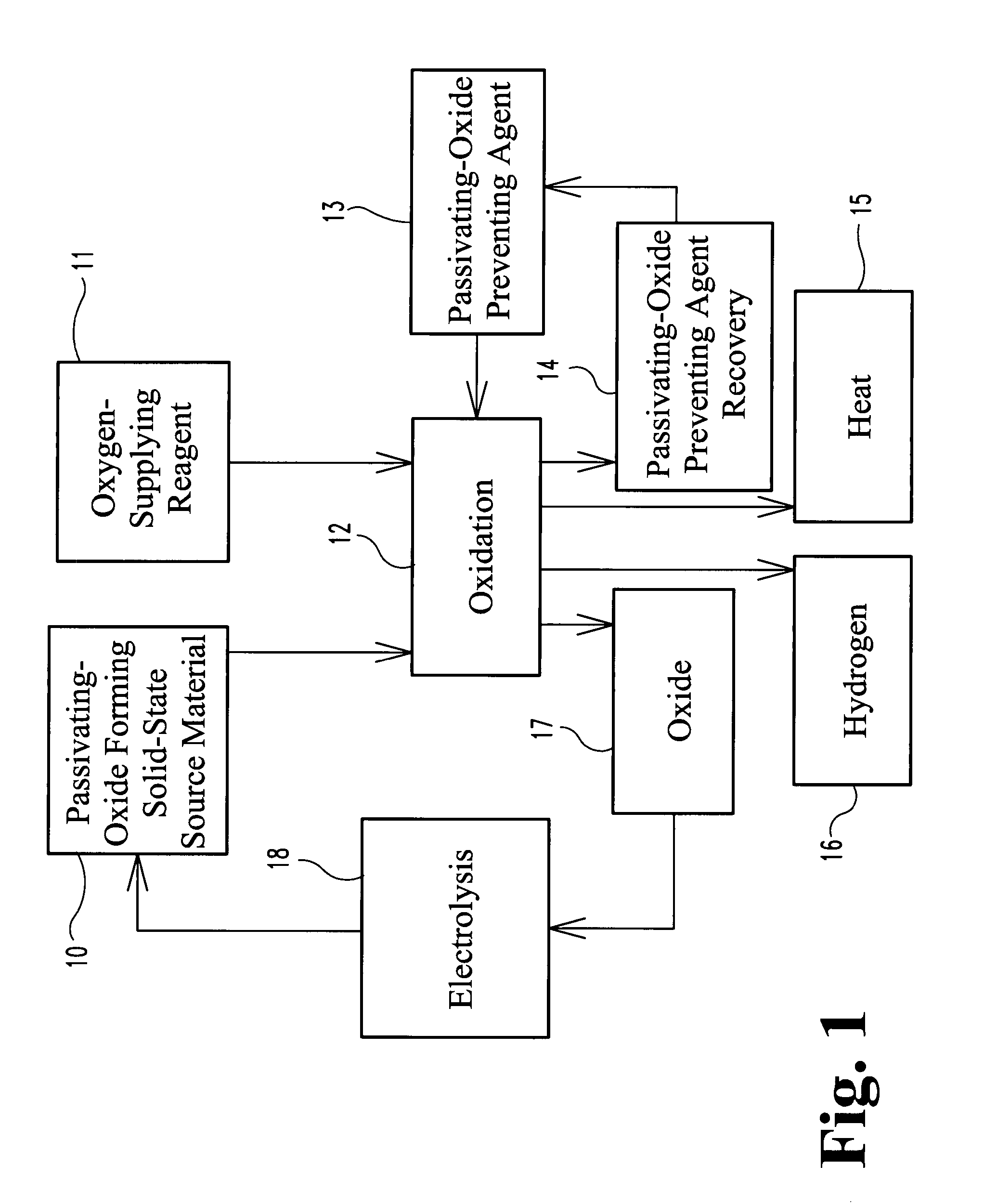

Power generation from solid aluminum

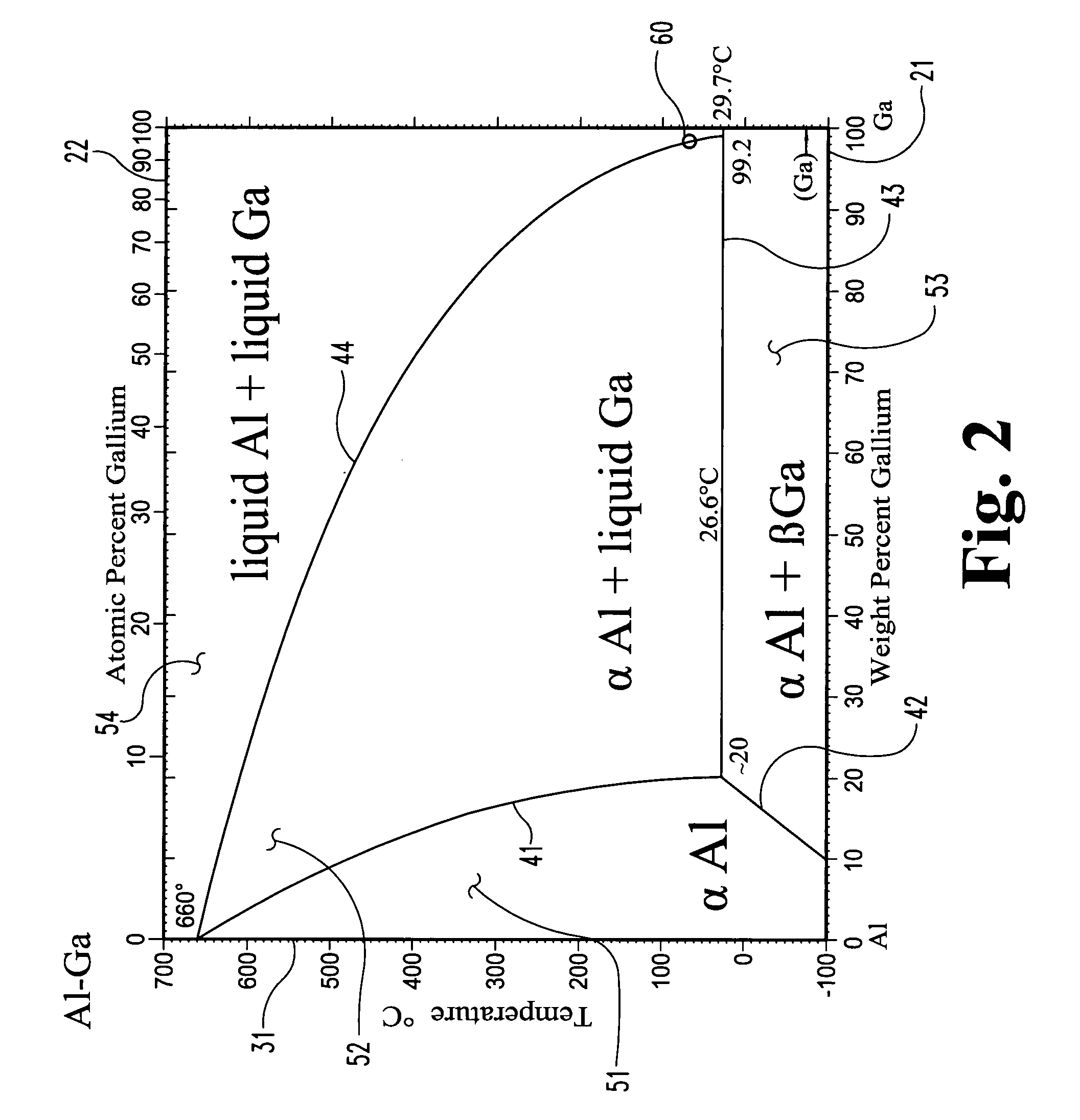

InactiveUS7938879B2Improve abilitiesLow temperature requirementEnergy inputBlast furnace detailsHydrogenSurface layer

A fuel for splitting water into hydrogen and an oxide component comprises a substantially solid pellet formed from a solid-like mixture of a solid-state source material capable of oxidizing in water to form hydrogen and a passivation surface layer of the oxide component, and a passivation preventing agent that is substantially inert to water in an effective amount to prevent passivation of the solid-state material during oxidation. The pellets may be introduced into water or other suitable oxidizer in a controlled rate to control the rate of reaction of the source material with the oxidizer, and thereby control the rate of formation of hydrogen. Methods are described for producing the solid-like mixture in varying weight percent of source material to passivation preventing agent.

Owner:PURDUE RES FOUND INC

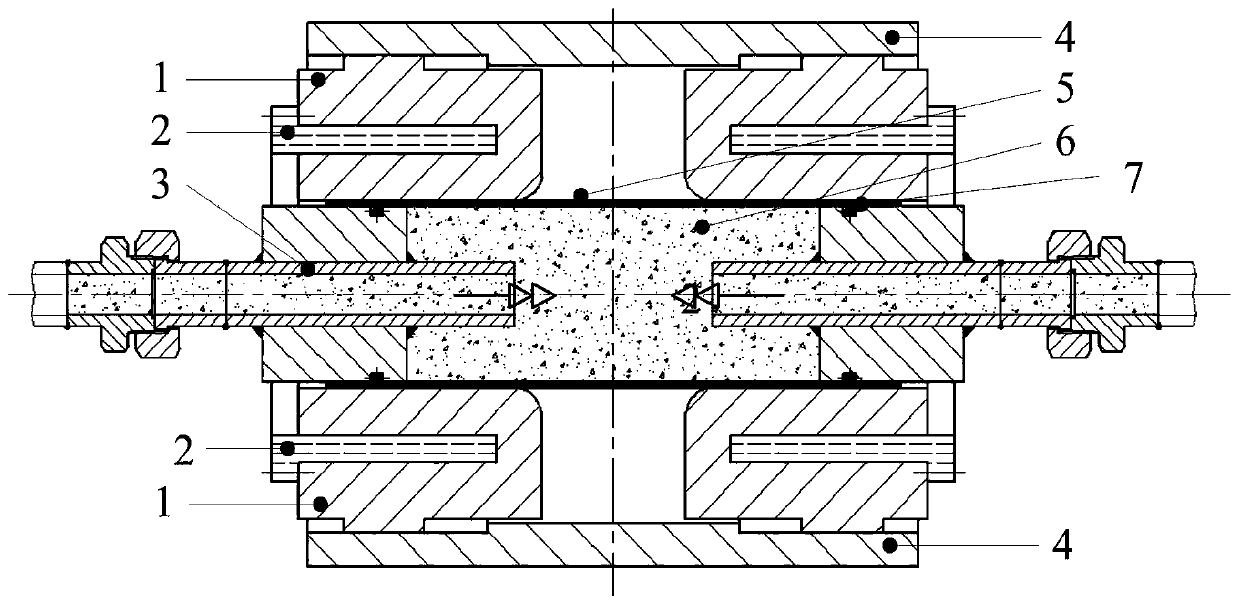

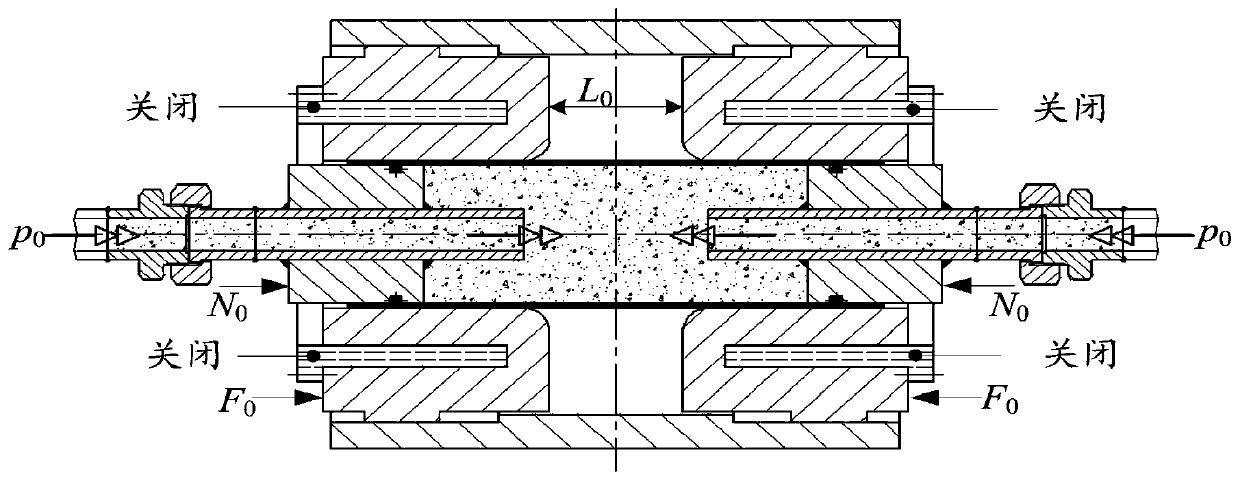

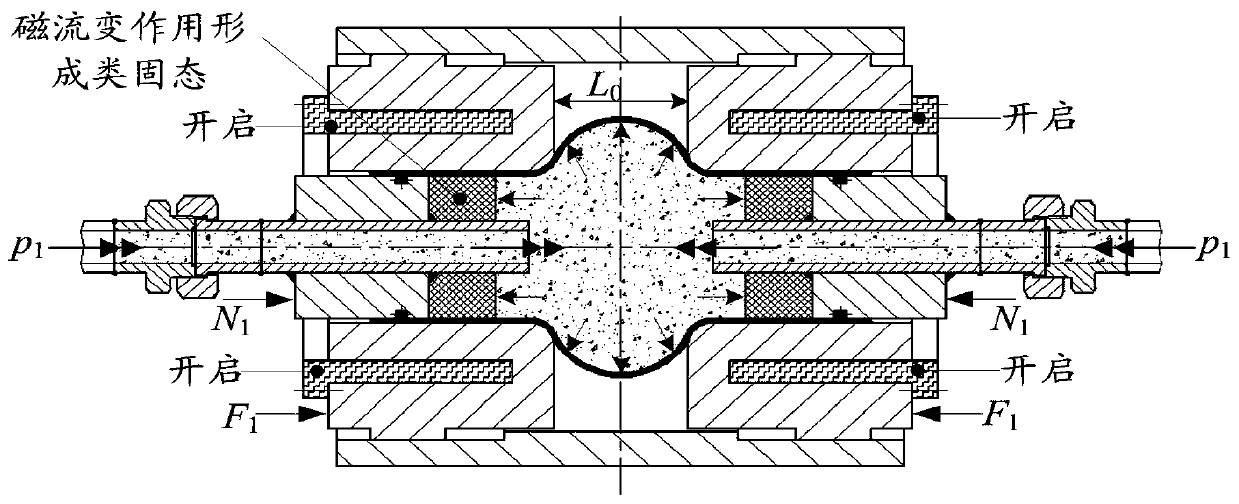

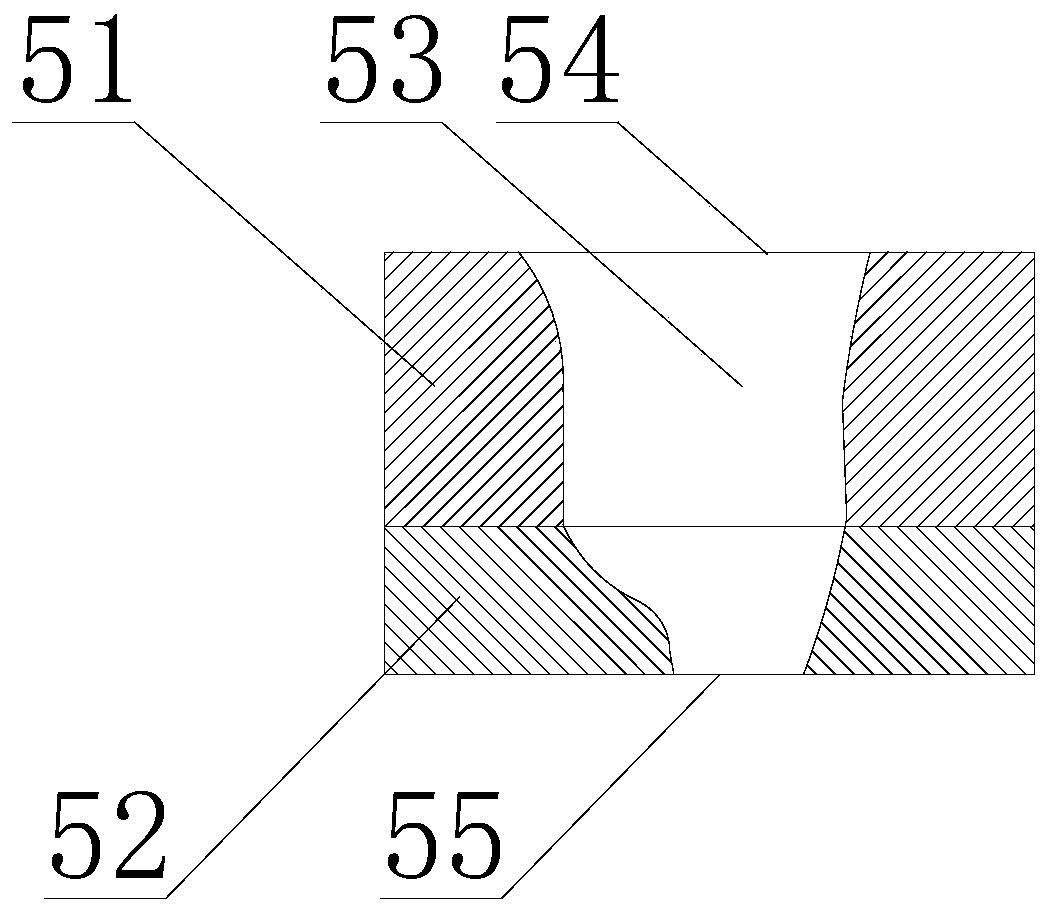

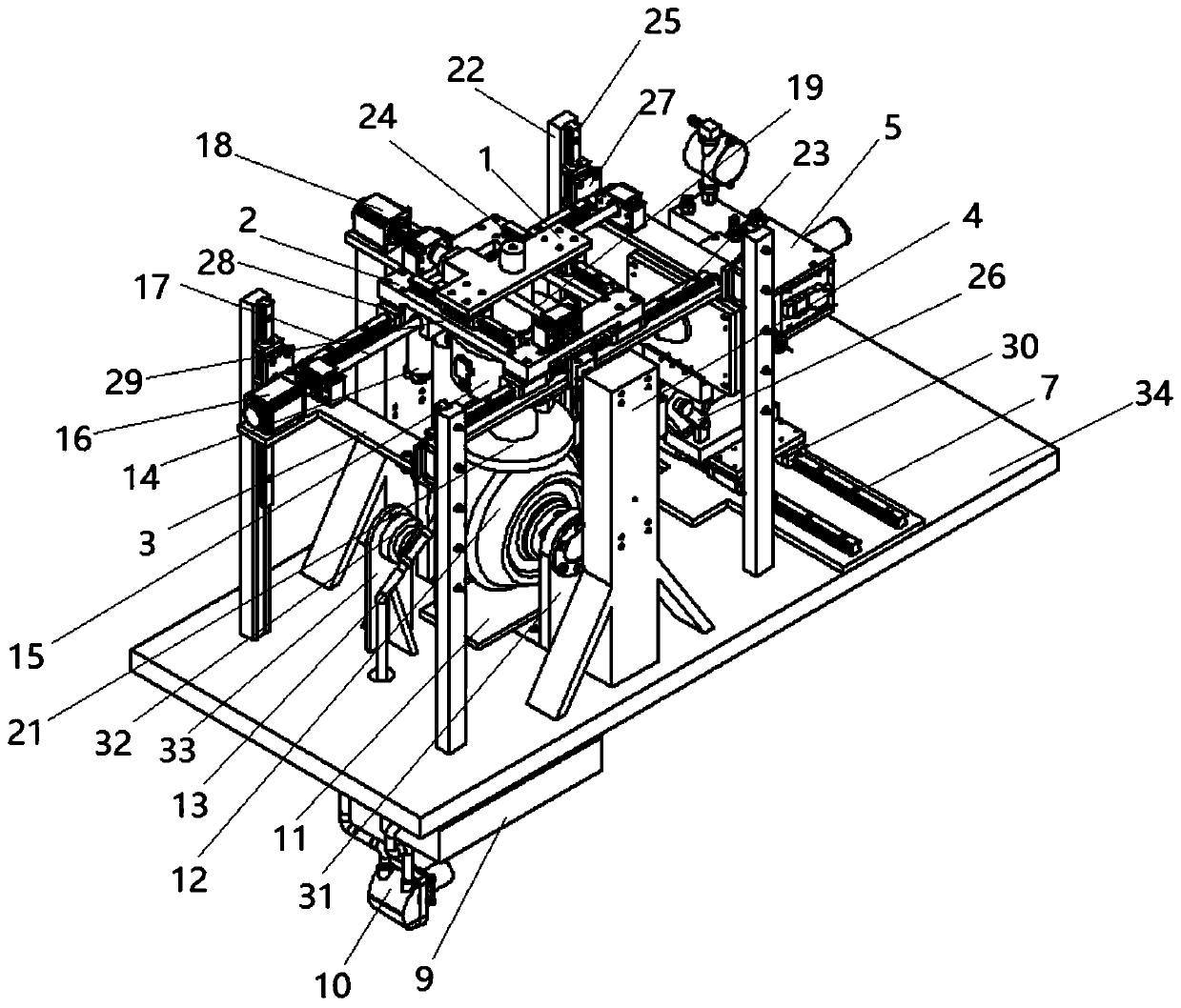

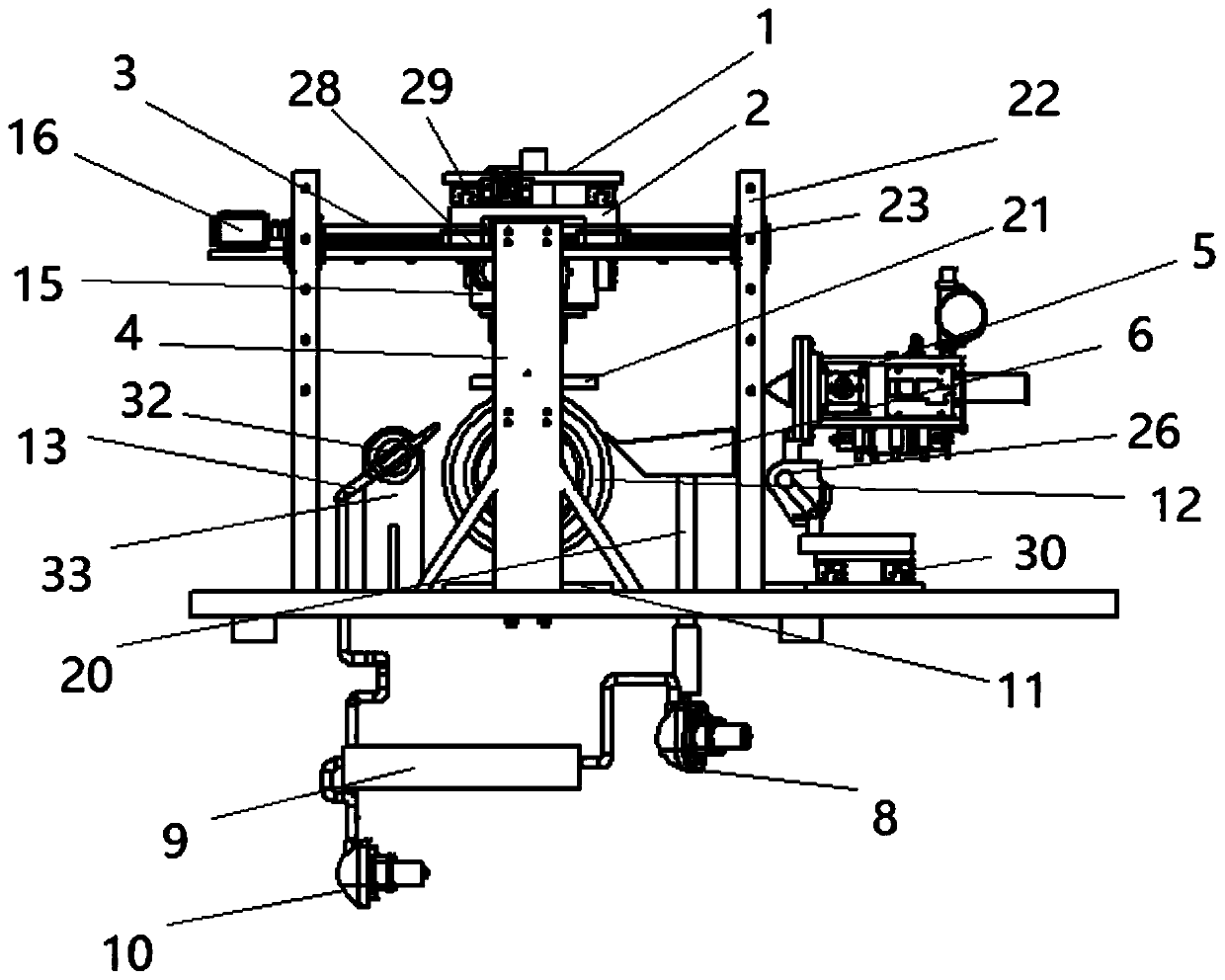

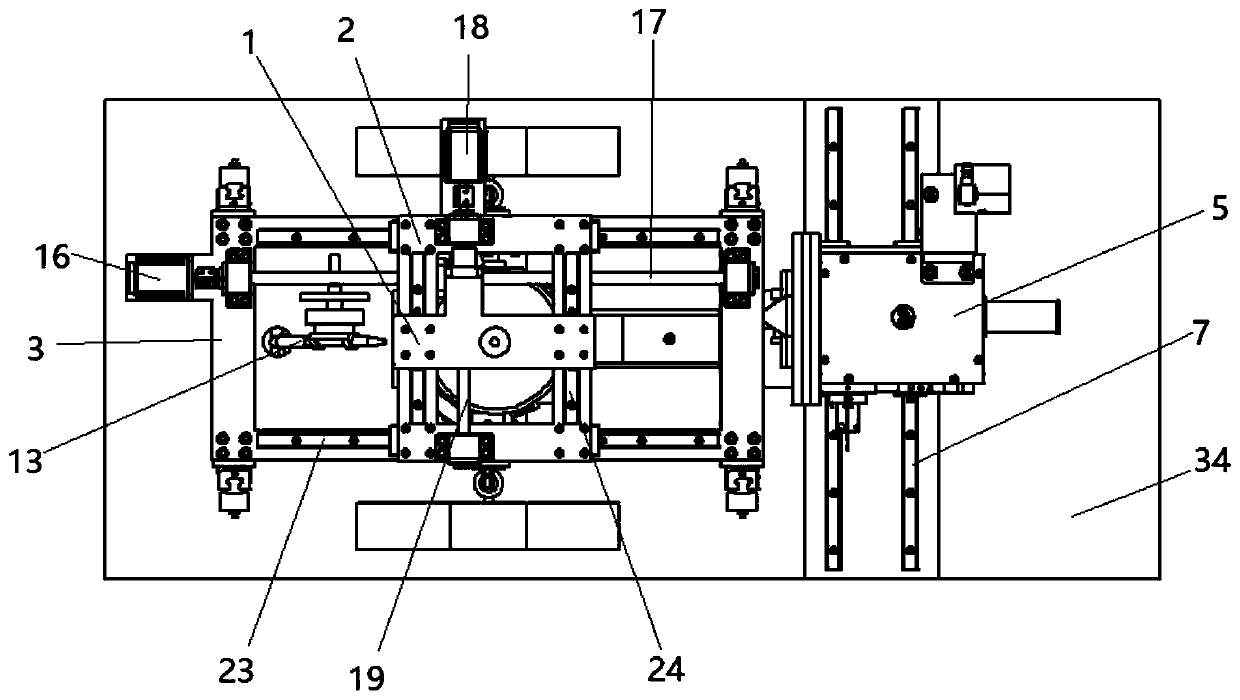

Magnetorheological fluid-assisted tube expansion and compression forming device and processing technique, and relates to the technical field of tube high-pressure forming

ActiveCN109759491AReduced sealing requirementsSolve the sealing problemMagnetorheological fluidEngineering

The invention discloses a magnetorheological fluid-assisted tube expansion and compression forming device and a processing technique, and relates to the technical field of tube high-pressure forming.The device comprises a casing film of an annular structure, pressing dies, electromagnetic devices, an initial tube blank and diamagnetic fluid filling tubes filled with magnetorheological fluid; thepressing dies are embedded at the two ends of the casing film; the end ports of the outer sides of all the pressing dies are each provided with the electromagnetic device; the initial tube blank is embedded in the pressing dies; and the diamagnetic fluid filling tubes are embedded in the two ends of the initial tube blank correspondingly. The areas of the two end ports of the initial tube blanks each internally forms a solid-like self-sealing plug under the action of magnetorheological fluid and a magnetic field, and the sealing problem of existing internal high-pressure forming technologies is solved; and through the diamagnetism of the diamagnetic fluid filling tubes, in the expansion process, liquid is continuously charged into an inner cavity of the initial tube blank, internal high pressure is formed, an overflow passage is formed in the pressure-maintaining step in the tube forming process, and the effects that fluid is charged for expansion at first and then forming pressing iscarried out under constant pressure support condition can be achieved.

Owner:YANSHAN UNIV

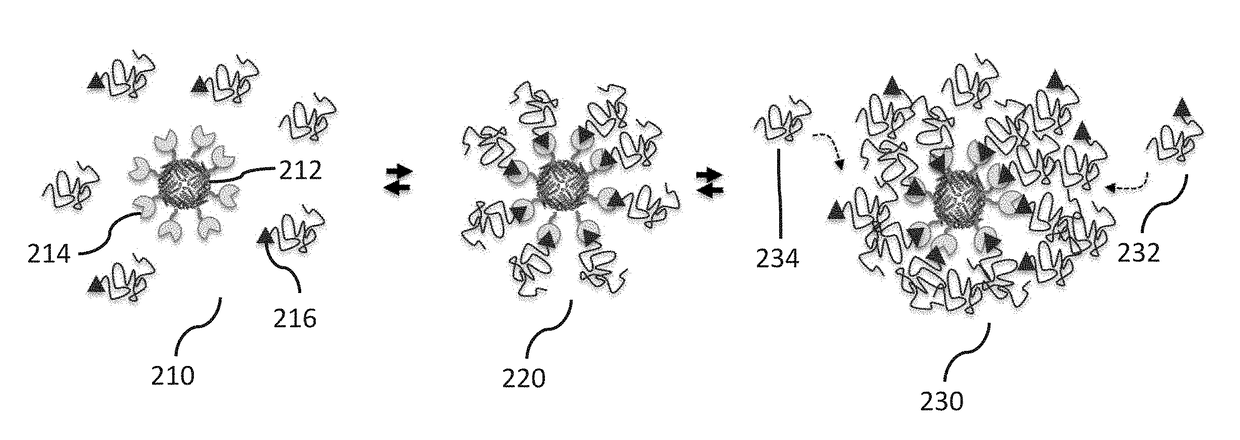

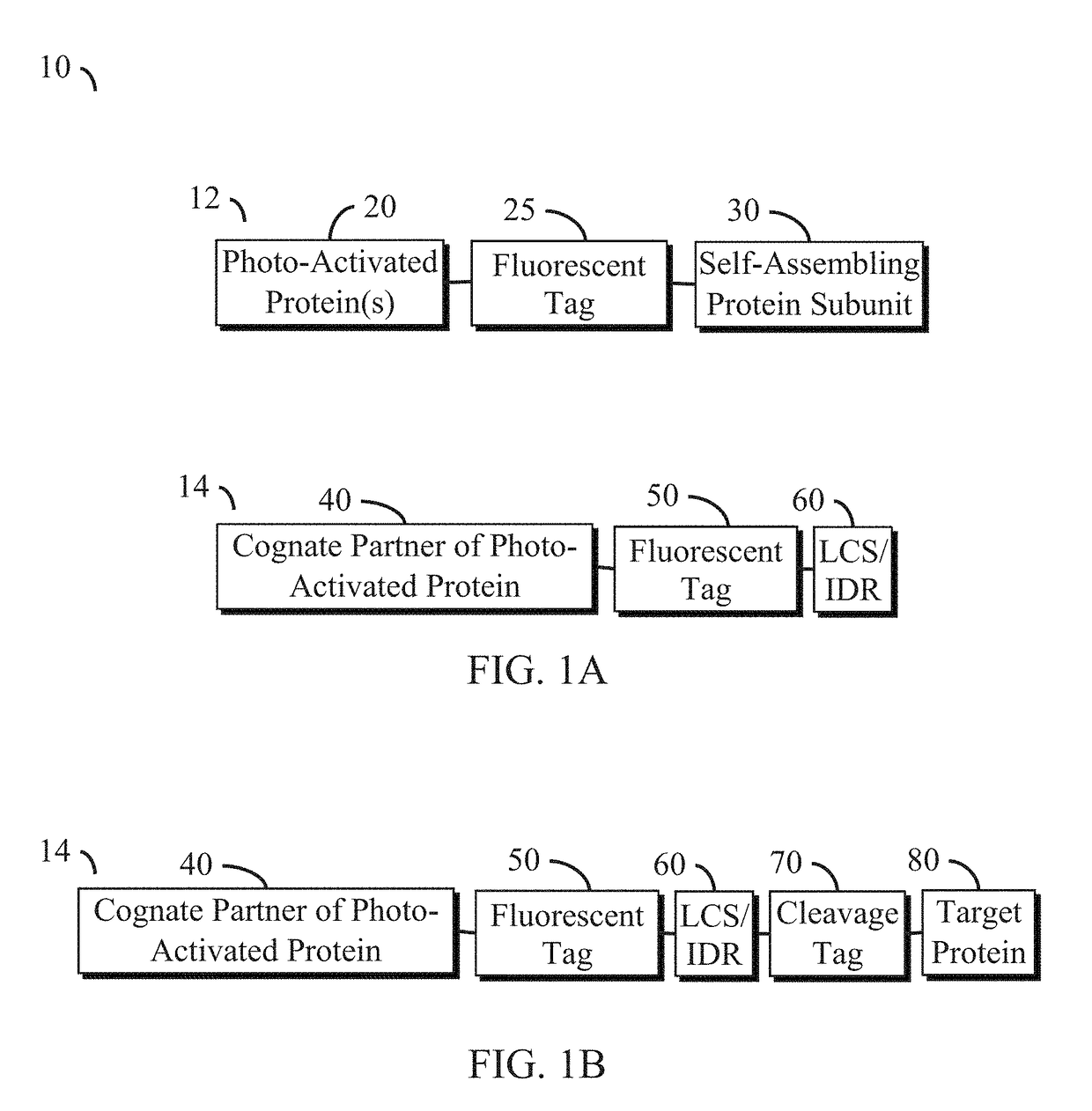

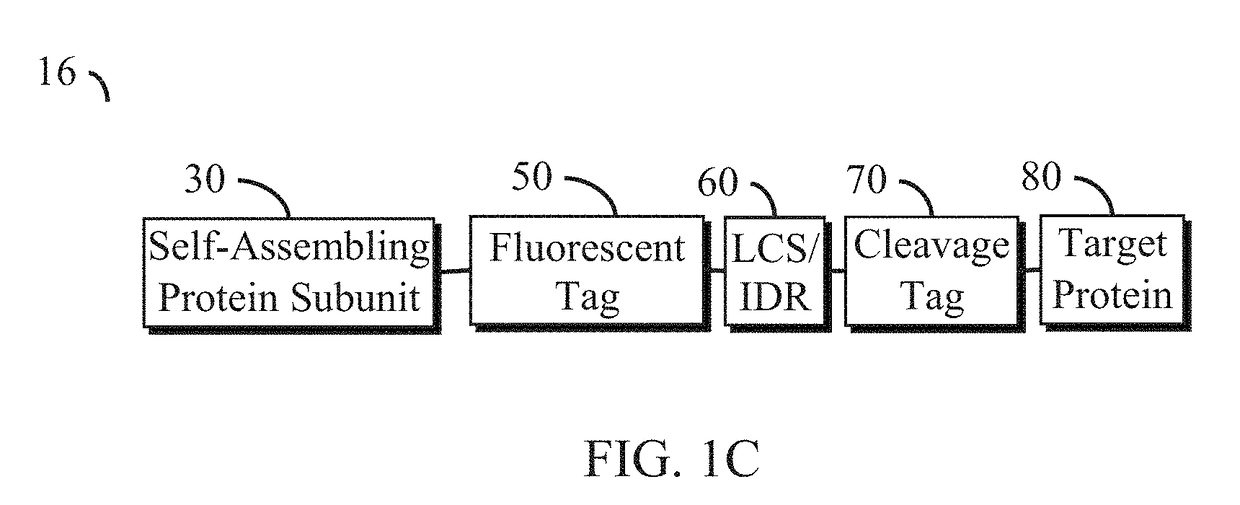

Disordered protein-based seeds for molecular clustering

ActiveUS20180251497A1Rapid and reversible clusteringEasy and rapid purificationAntibody mimetics/scaffoldsDepsipeptidesLight activationTransgenesis

A system and method for reversibly controlling clustering of proteins around an engineered multivalent nucleus is disclosed. The system and method utilize clustering, which may be controlled by light activation or deactivation. The system and method enable the spatiotemporal control of protein supramolecular assemblies, including liquid-like droplets under some conditions, and solid-like gels under other conditions. The system and method can be utilized for segregating or locally concentrating desired proteins and / or RNA in cells or cell lysate, which may be useful for protein purification purposes, or for assembling single or multiple membraneless bodies within specific sub-regions of the cells. These synthetically assembled bodies may recruit both transgenic and endogenic proteins and other biomolecules, thus can be linked to affect and even trigger a plethora of cellular processes.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Method of particle contaminant removal

ActiveUS20100313917A1Thin layerEasy to disassembleOrganic detergent compounding agentsNon-surface-active detergent compositionsHigh velocitySolid surface

Apparatus and methods for removing particle contaminants from a solid surface includes providing a layer of a viscoelastic material on the solid surface. The viscoelastic material is applied as a thin film and exhibits substantial liquid-like characteristics. The viscoelastic material at least partially binds with the particle contaminants. A high velocity liquid is applied to the viscoelastic material, such that the viscoelastic material exhibits solid-like behavior. The viscoelastic material is thus dislodged from the solid surface along with the particle contaminants, thereby cleaning the solid surface of the particle contaminants.

Owner:LAM RES CORP

Control system for an on-demand gas generator

InactiveUS8323364B2Reduce exposureReaction is slowMultiple metal hydridesHydrogen productionControl systemEngineering

Owner:PURDUE RES FOUND INC

Semiconductor device and a manufacturing method of the same

InactiveUS7514294B2Semiconductor/solid-state device detailsSolid-state devicesElectrical conductorLiquid state

The semiconductor device having the structure which laminated the chip in many stages is made thin. A reforming area is formed by irradiating a laser beam, where a condensing point is put together with the inside of the semiconductor substrate of a semiconductor wafer. Then, after applying the binding material of liquid state to the back surface of a semiconductor wafer by a spin coating method, this is dried and a solid-like adhesive layer is formed. Then, a semiconductor wafer is divided into each semiconductor chip by making the above-mentioned reforming area into a division origin. By pasting up this semiconductor chip on the main surface of an other semiconductor chip by the adhesive layer of the back surface, the semiconductor device having the structure for which the semiconductor chip was laminated by many stages is manufactured.

Owner:RENESAS ELECTRONICS CORP

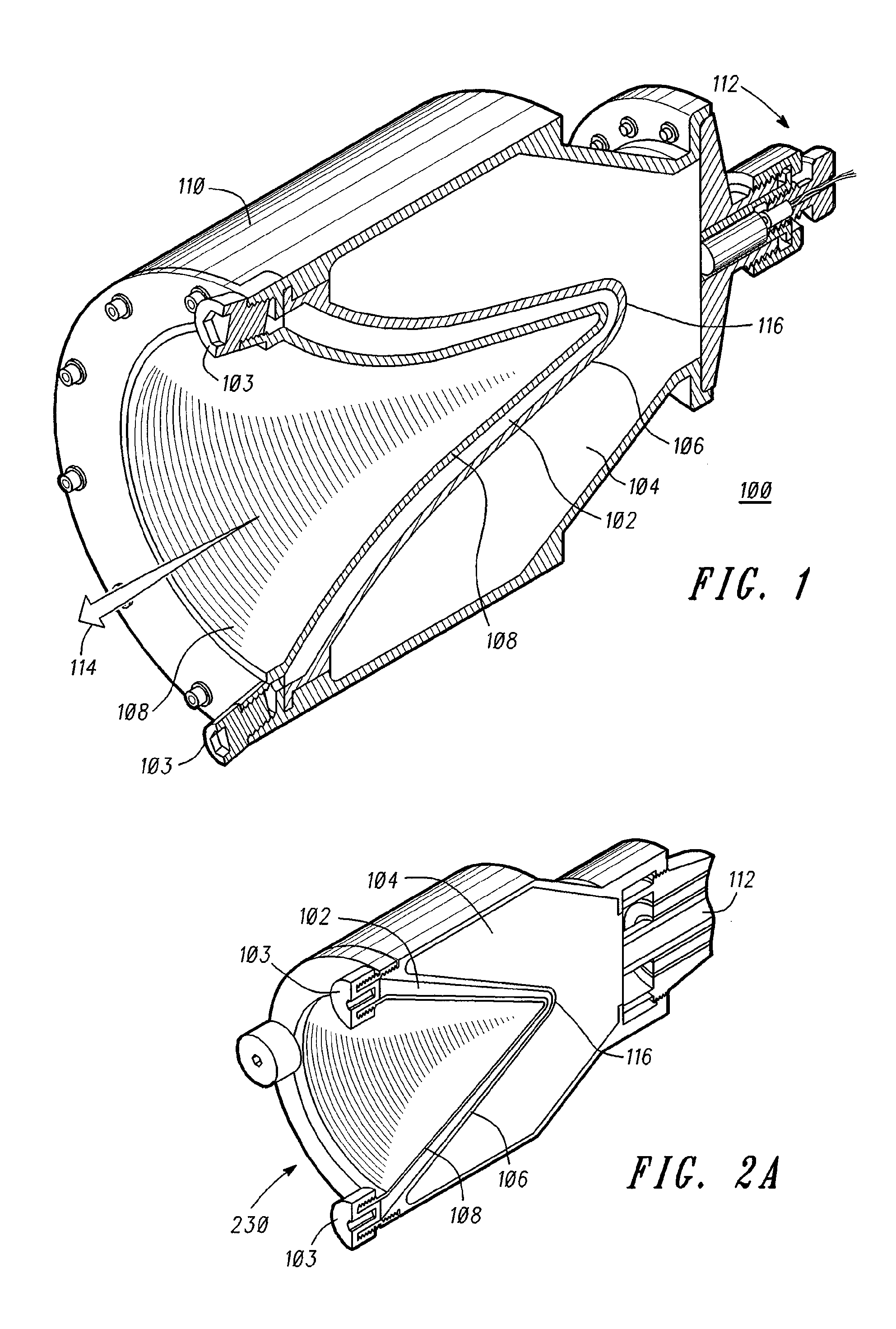

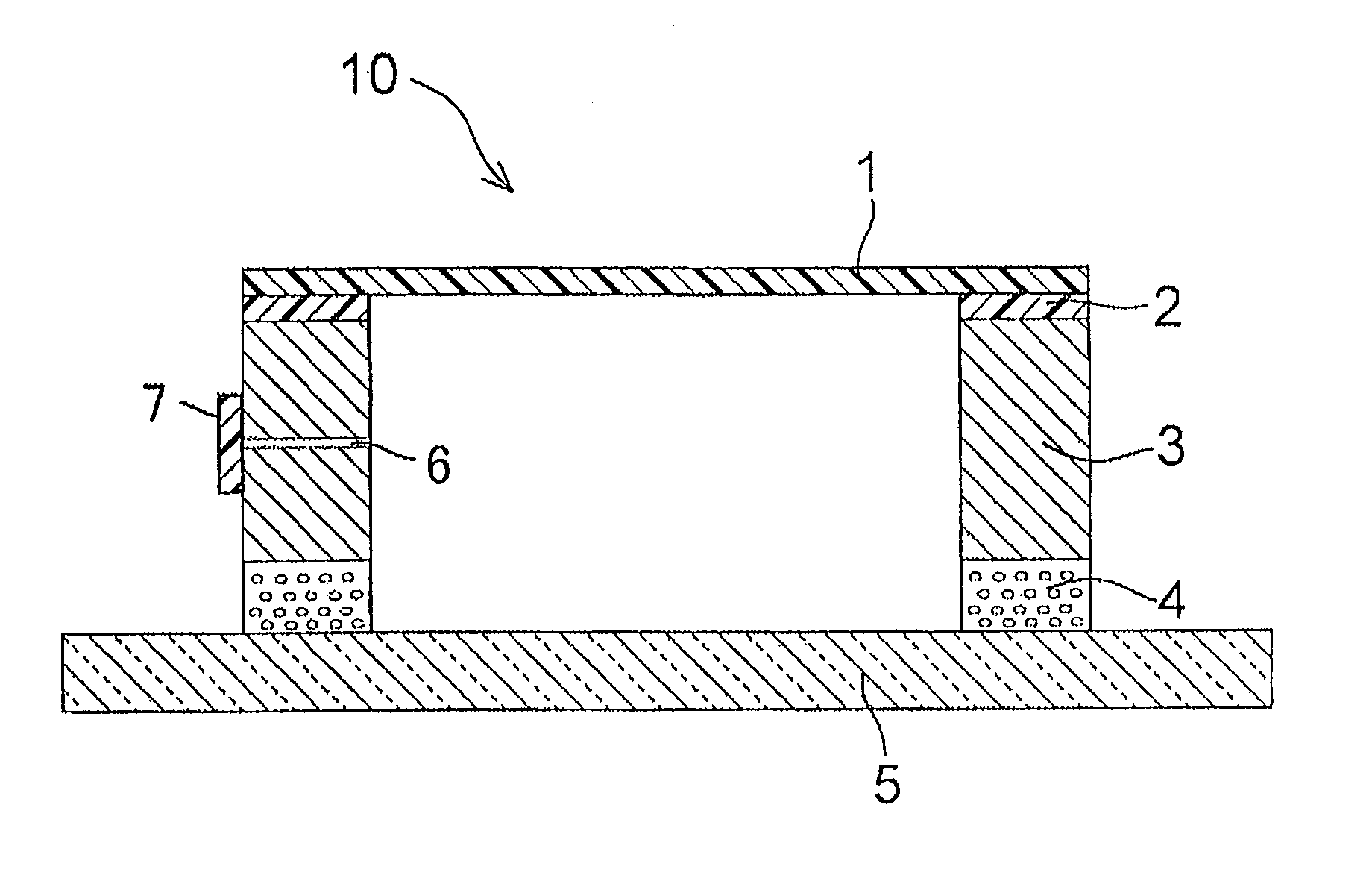

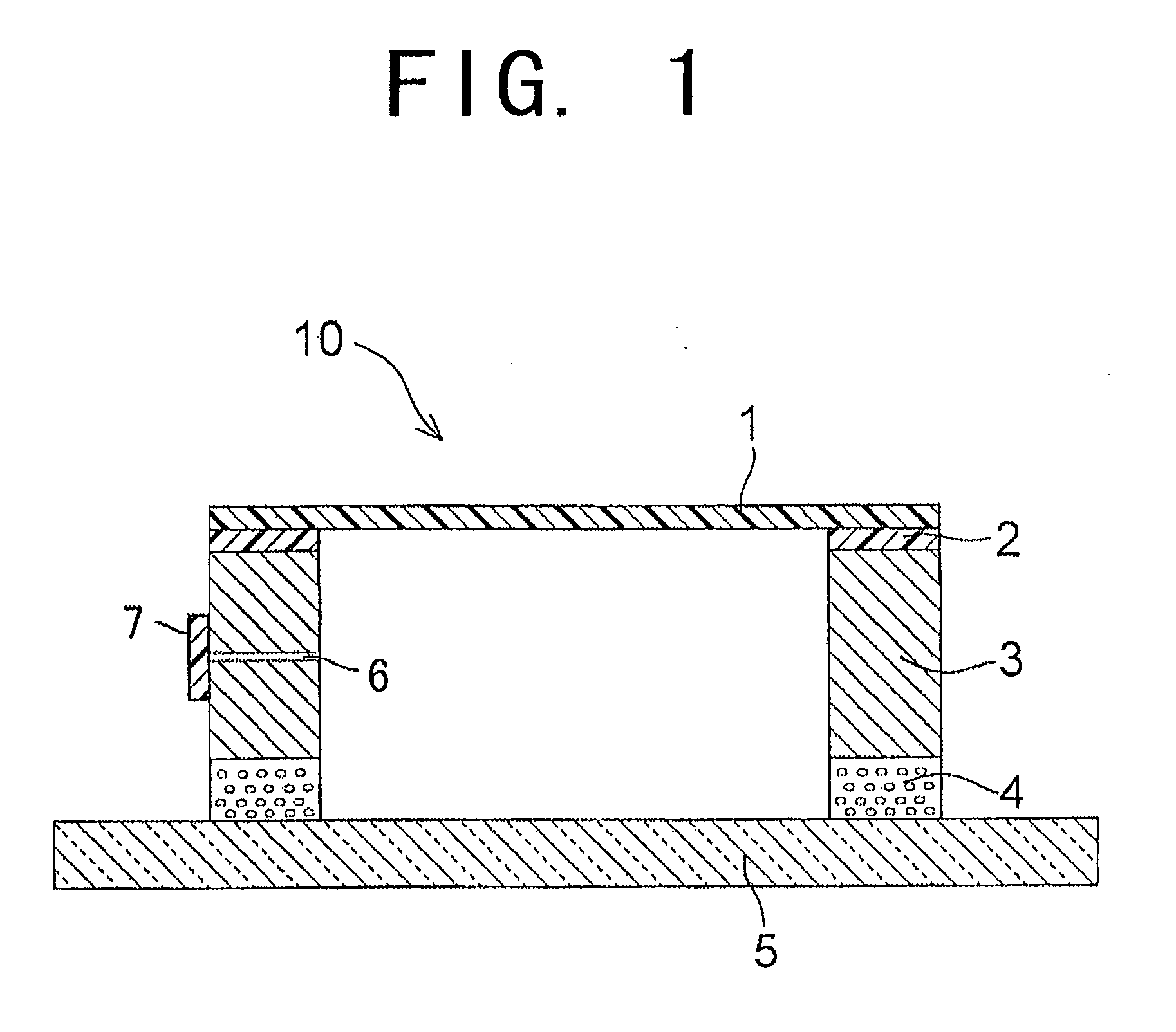

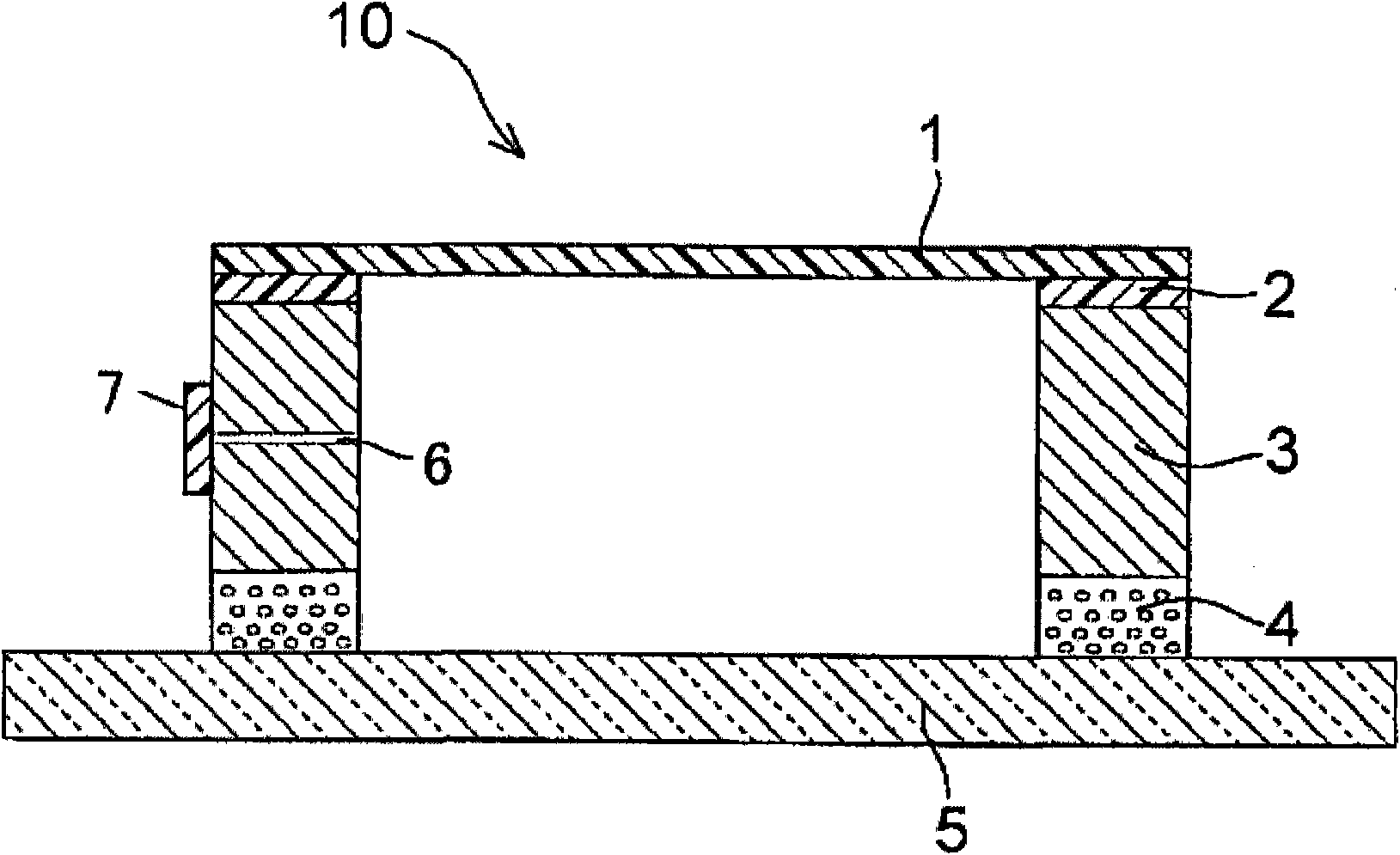

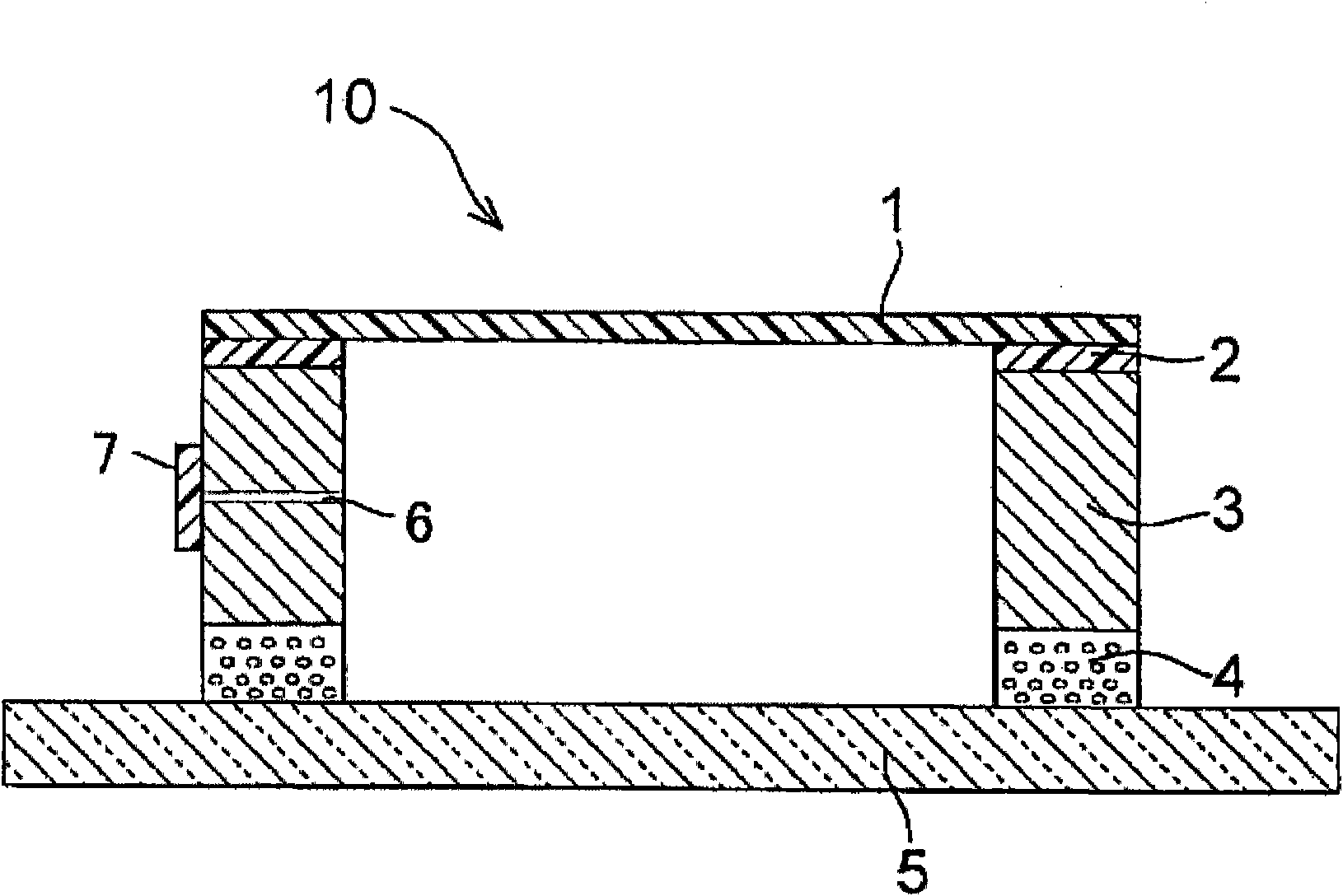

Pellicle for lithography

ActiveUS20110129767A1Prevent degradationEasy to peelSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentLithographic artistDecomposition

A pellicle 10 for lithography includes a pellicle frame 3, a pellicle membrane 1 adhered onto the upper end surface of the pellicle frame 3 and an agglutinant layer 4 formed on the lower surface of the pellicle frame 3 and the agglutinant layer 4 is formed by hardening a curable composition containing a straight chain perfluoro compound having a perfluoro structure in a main chain. The thus constituted pellicle 10 generates only a small amount of a decomposition gas even when it is used for a long time, thereby preventing solid-like foreign materials from separating out on a pattern region of a photomask 5 and can suppress degradation of an the agglutinant agent contained in an agglutinant layer 4 to be used for fixing a photomask 5 to the pellicle frame 3. Further, this pellicle 10 can be easily peeled off from a photomask 5 and replaced with a new one.

Owner:SHIN ETSU CHEM IND CO LTD

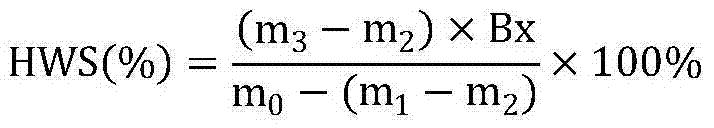

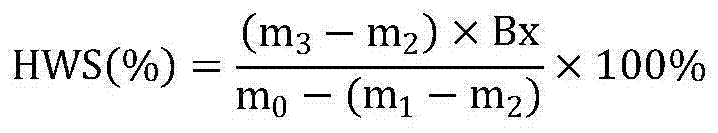

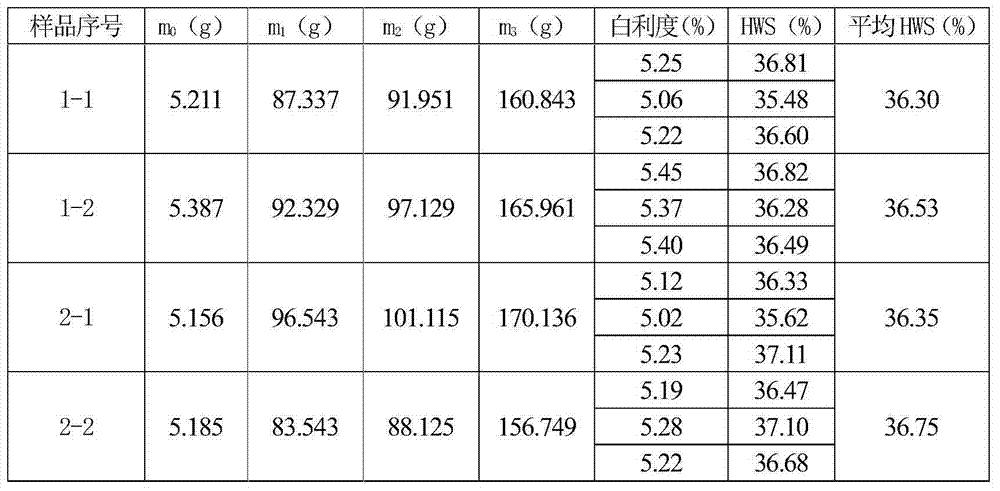

Rapid determination method for content of hot water-soluble substances in paper-making reconstituted tobacco

InactiveCN104777061AUndisturbedSimple and fast operationWeighing by removing componentWater solubleTobacco product

The invention provides a rapid determination method for the content of hot water-soluble substances in paper-making reconstituted tobacco. The method comprises the following steps: grinding a tobacco raw material used for production of paper-making reconstituted tobacco, a paper-making reconstituted tobacco sheet base or a finished paper-making reconstituted tobacco product into particles, sieving the particles, weighing a sample, drying the sample with an oven, then adding water, boiling the sample and calculating hot water-soluble substances in the sample by calculating hot water-soluble substances transferred to an aqueous solution. The method is applicable to solids like the raw material, the sheet base and the finished product related to the paper-making reconstituted tobacco and has the advantages of simple operation, short determination time and accurate determination results.

Owner:CHINA TOBACCO YUNNAN REMFG TOBACCO CO LTD

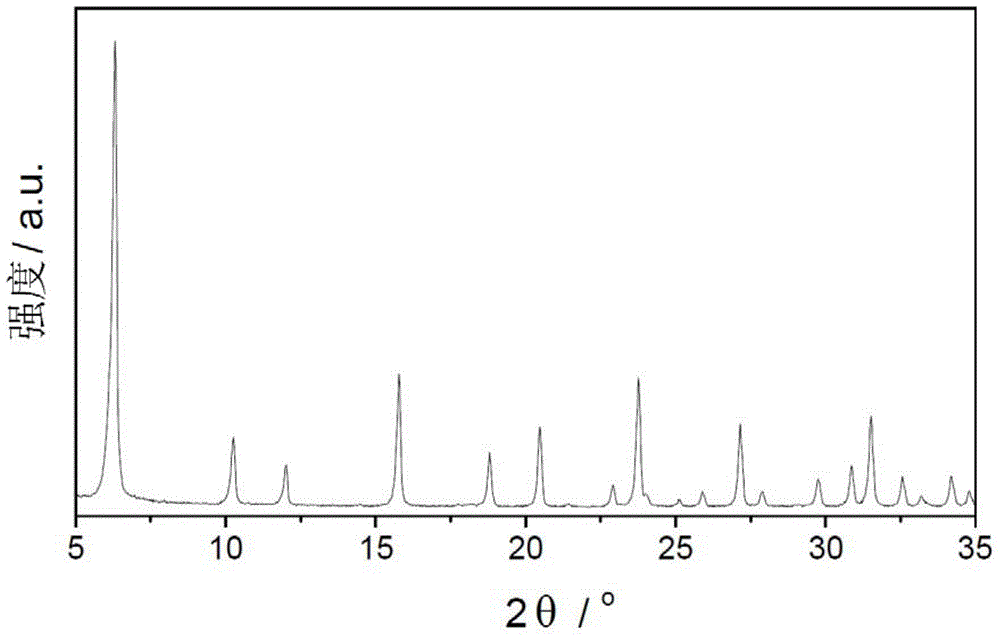

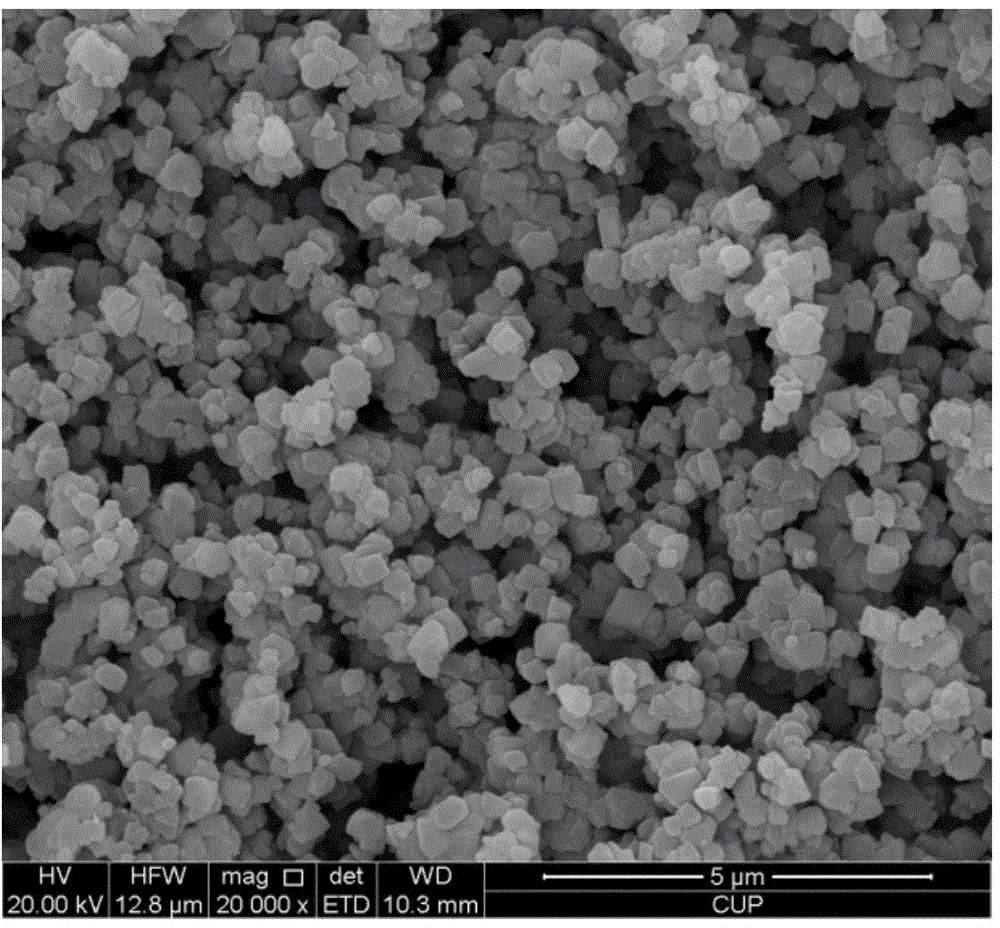

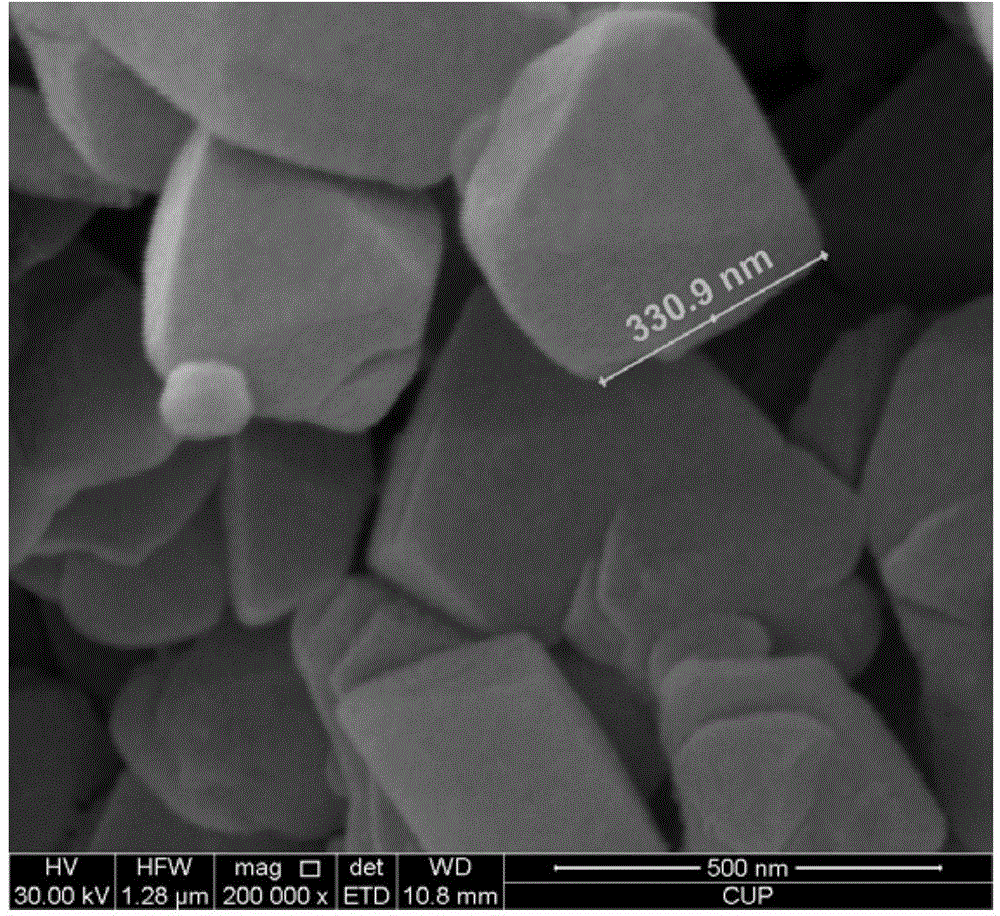

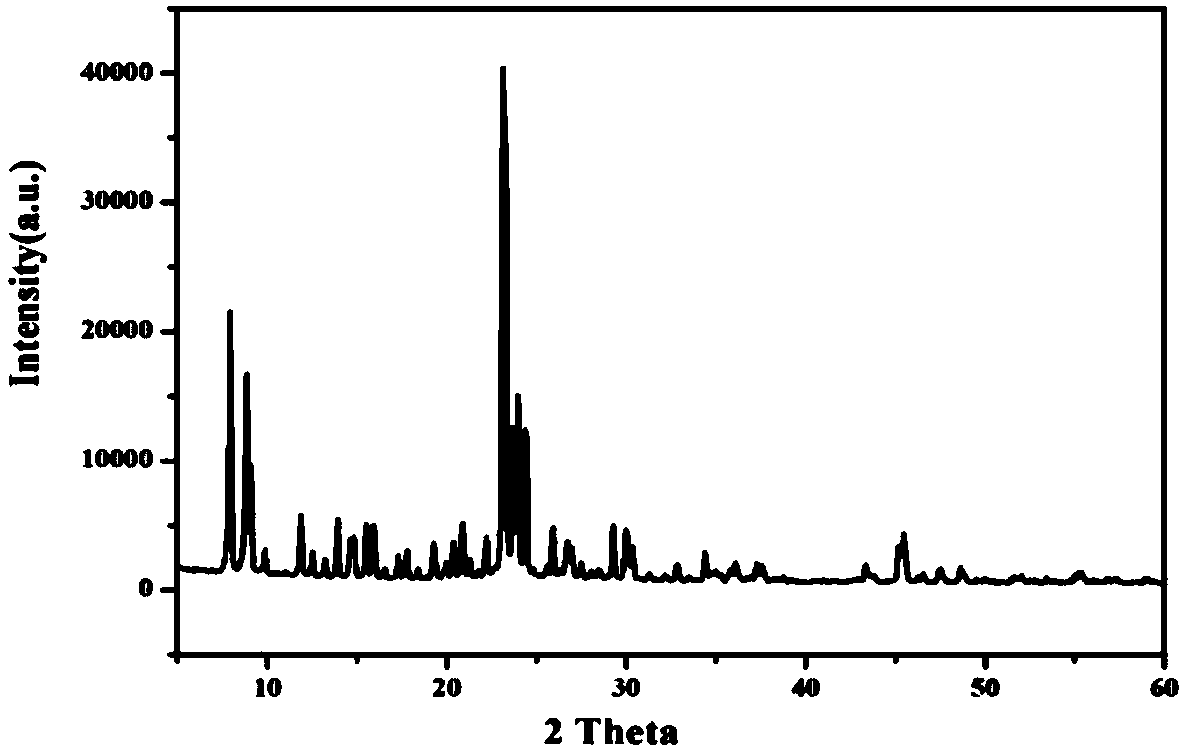

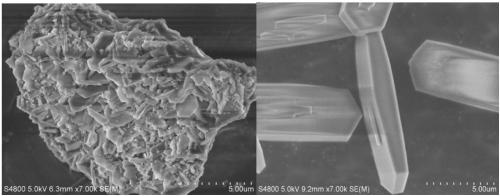

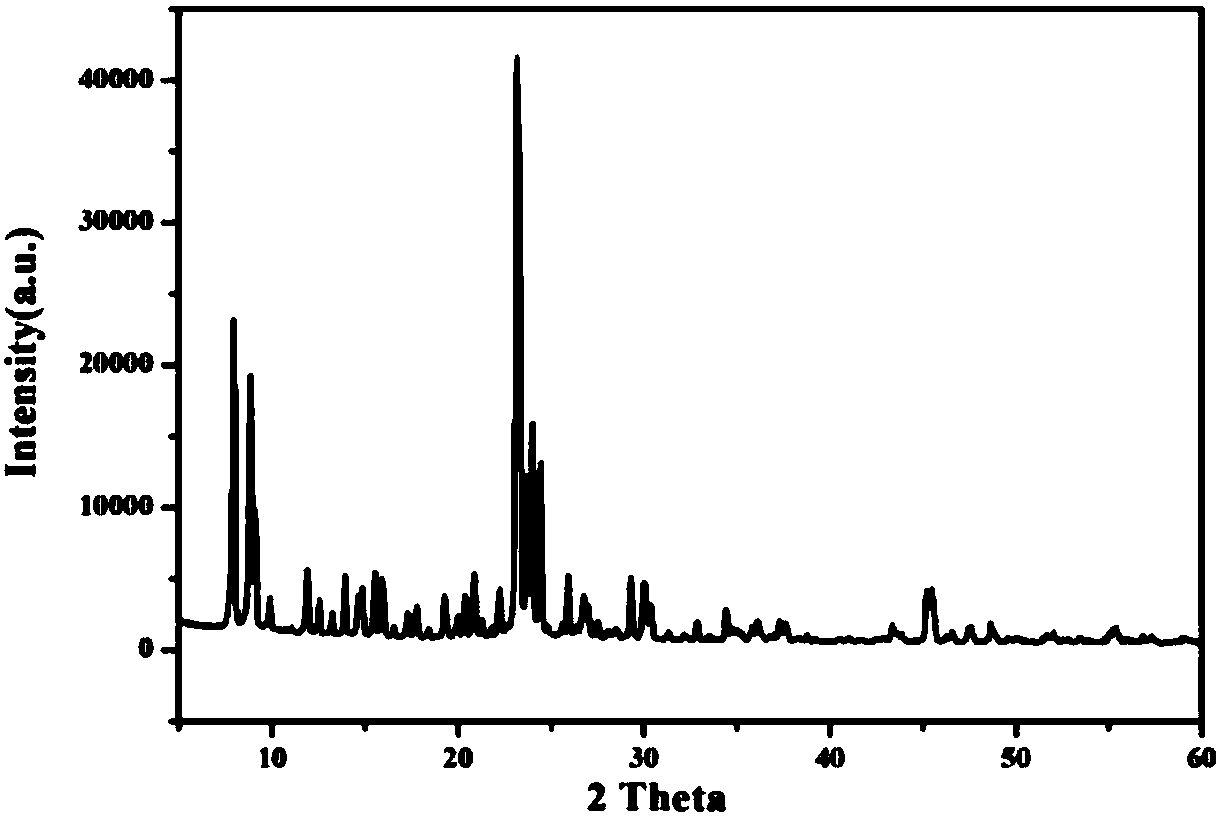

ZSM-5 molecular sieve and preparation method thereof

InactiveCN110156040ANot easy to reuniteAvoid easy cloggingPentasil aluminosilicate zeoliteCrystallinitySolid like

The invention provides a preparation method of a sheet ZSM-5 molecular sieve. The method includes: in a gel preparation process, mixing a silicon source, an aluminum source, a template agent and an additive, and performing stirring at 10-50DEG C for 1-20h; conducting standing aging for 10-30h at 10-90DEG C; putting the prepared gel reaction mixture into a reaction kettle, then putting the reactionkettle into an oven, conducting crystallization at 100-220DEG C for 4-30h, then taking the product out, and carrying out filtering, washing and drying to obtain the ZSM-5 molecular sieve product. Themethod provided by the invention synthesizes the ZSM-5 molecular sieve under a solid like phase condition, and the obtained ZSM-5 molecular sieve product is sheet shaped, and has a relative crystallinity of 90-110%, and an SiO2 / Al2O3 molar ratio of less than or equal to 100.

Owner:PETROCHINA CO LTD

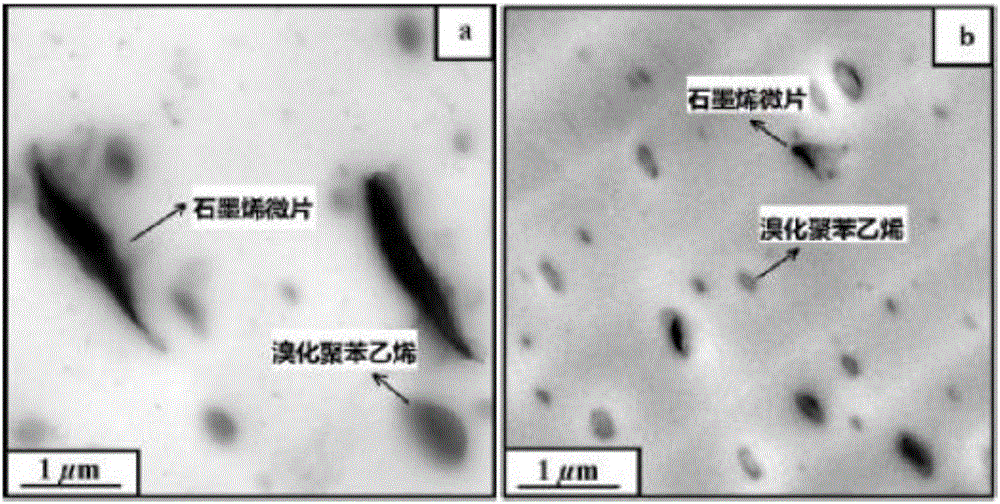

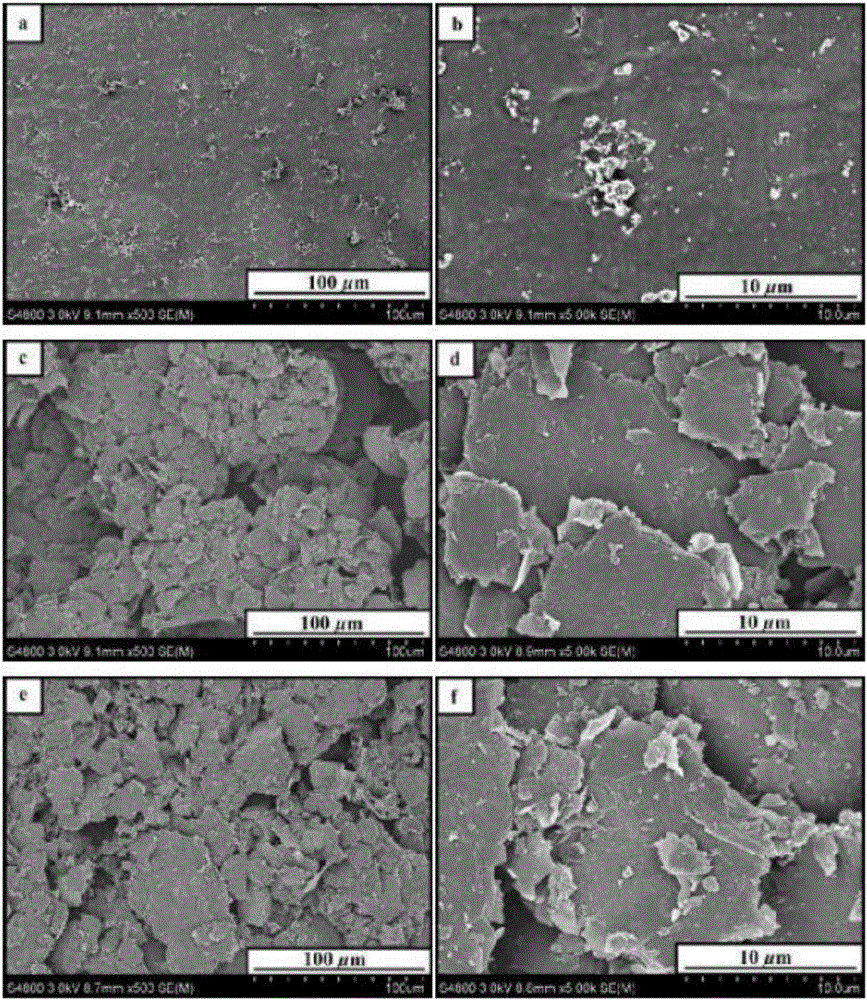

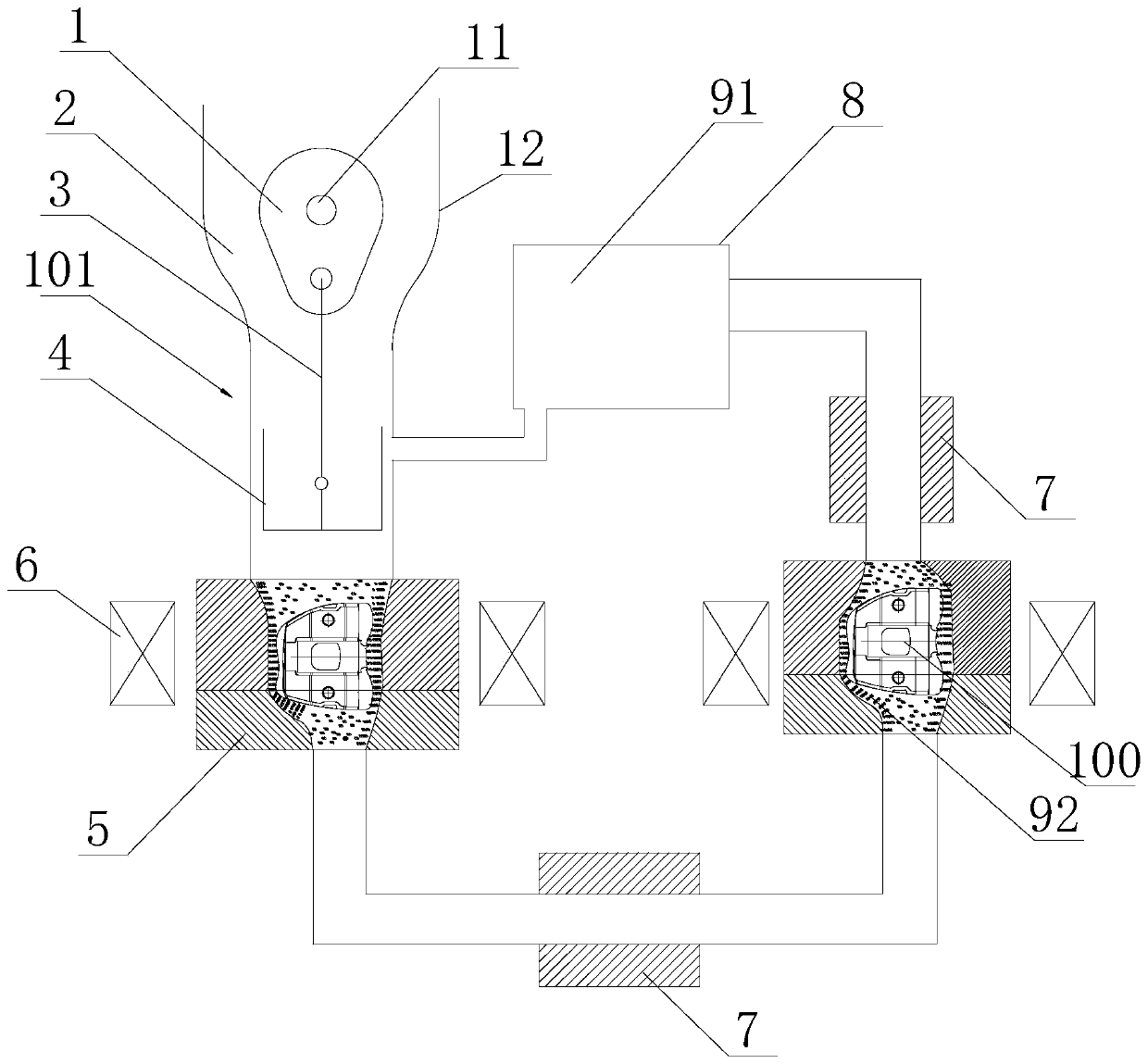

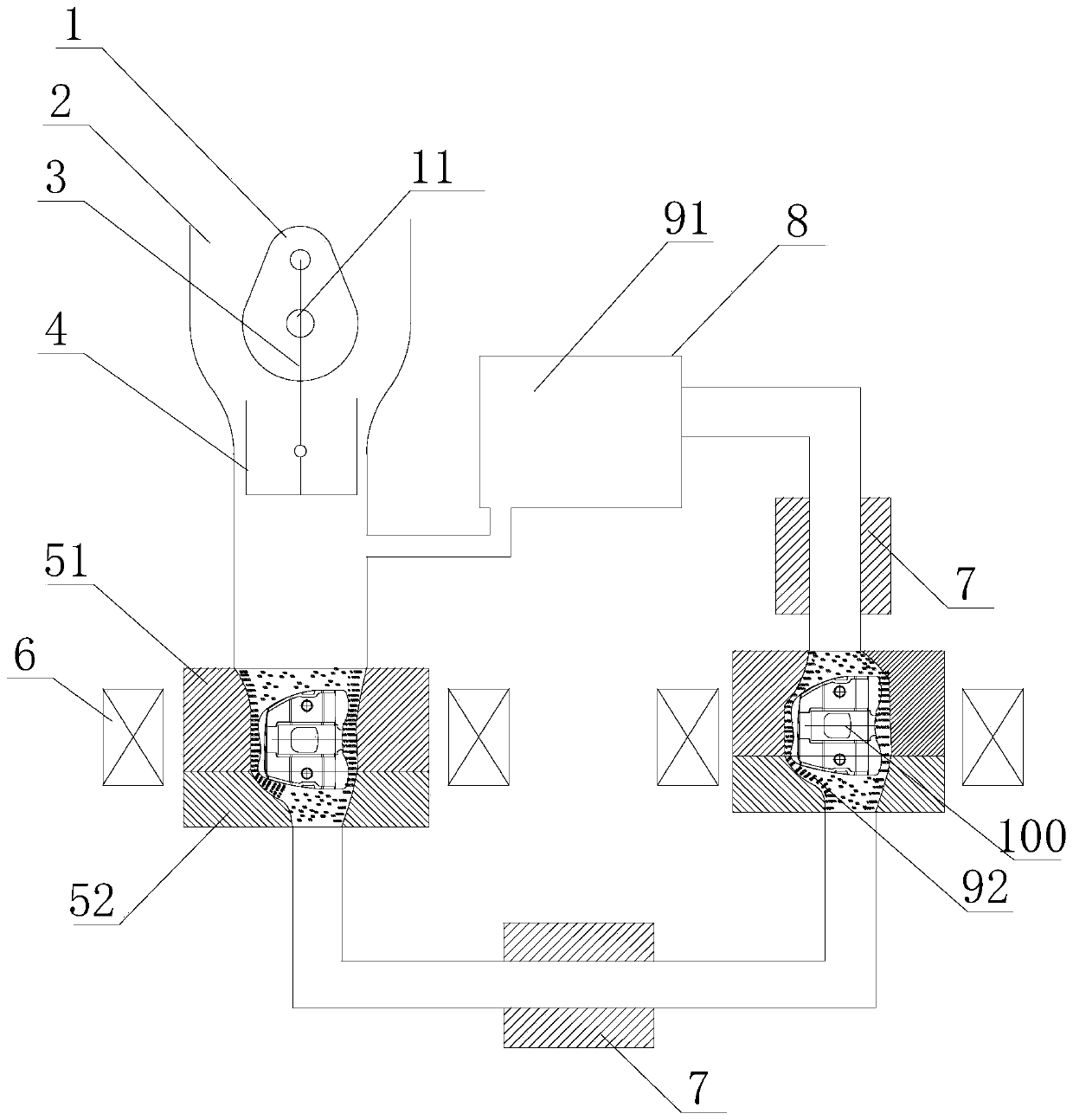

Flame-retardant high-polymer composite material and preparation method thereof

The invention provides a flame-retardant high-polymer composite material. The material is characterized by being prepared from an environment-friendly brominated flame retardant, graphene nano-platelets and an auxiliary dispersant, wherein the high-polymer material is polystyrene. The graphene nano-platelets are creatively added into the flame-retardant material and the adding mount is accurately limited; the graphene nano-platelets belong to condensed-phase flame retarding and a network structure is mainly formed in a combustion process, so that the material represents a solid-like behavior in a combustion process; the network structure can effectively inhibit thermal motion of a polymer molecular chain and the exchange of gas and heat is stopped. In view of the flame-retardant effect, only a few of graphene nano-platelets are added and the heat releasing speed and the smoke density of a polymer can be remarkably reduced; unpredicted technical effects are realized.

Owner:宁波福天新材料科技有限公司

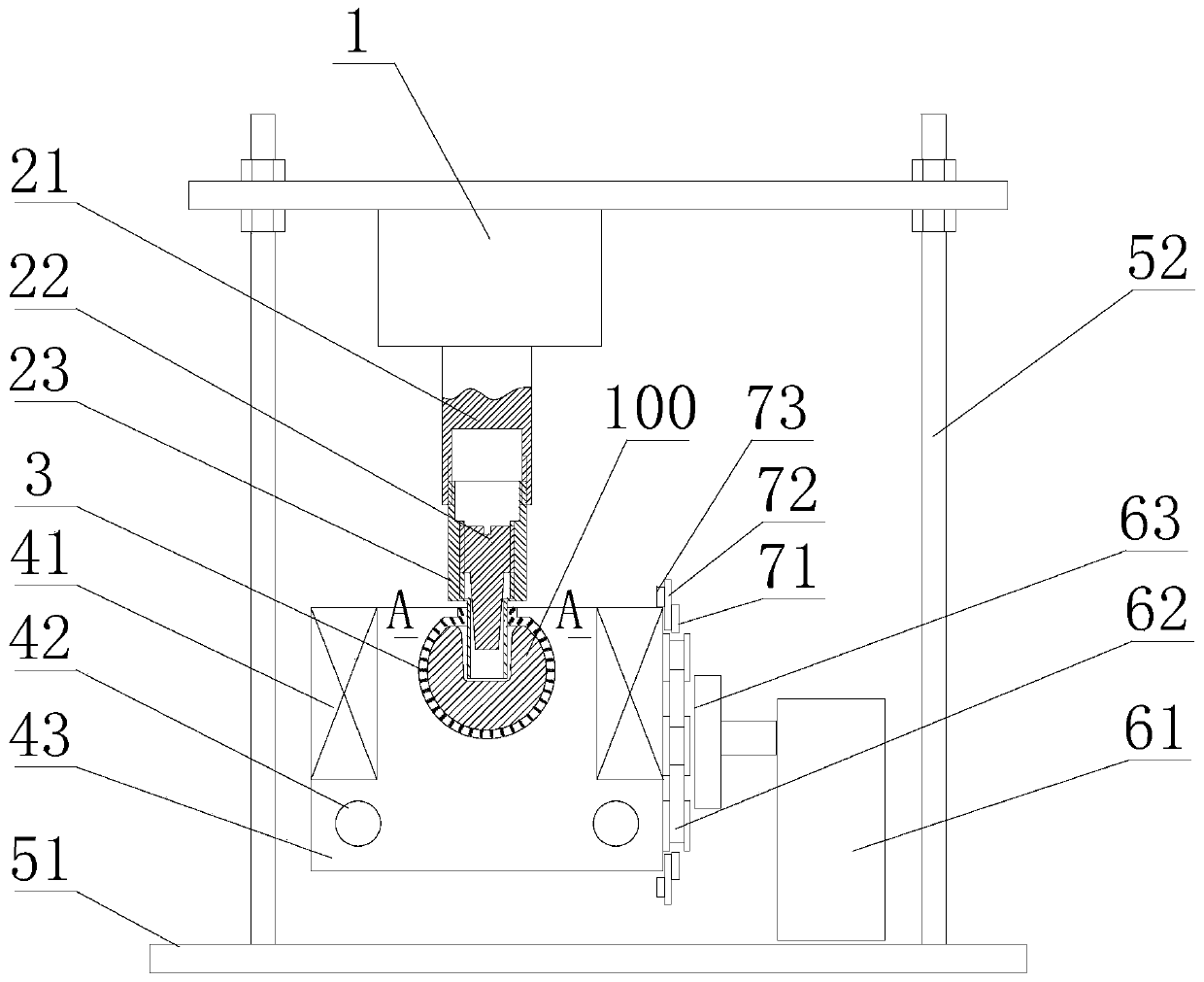

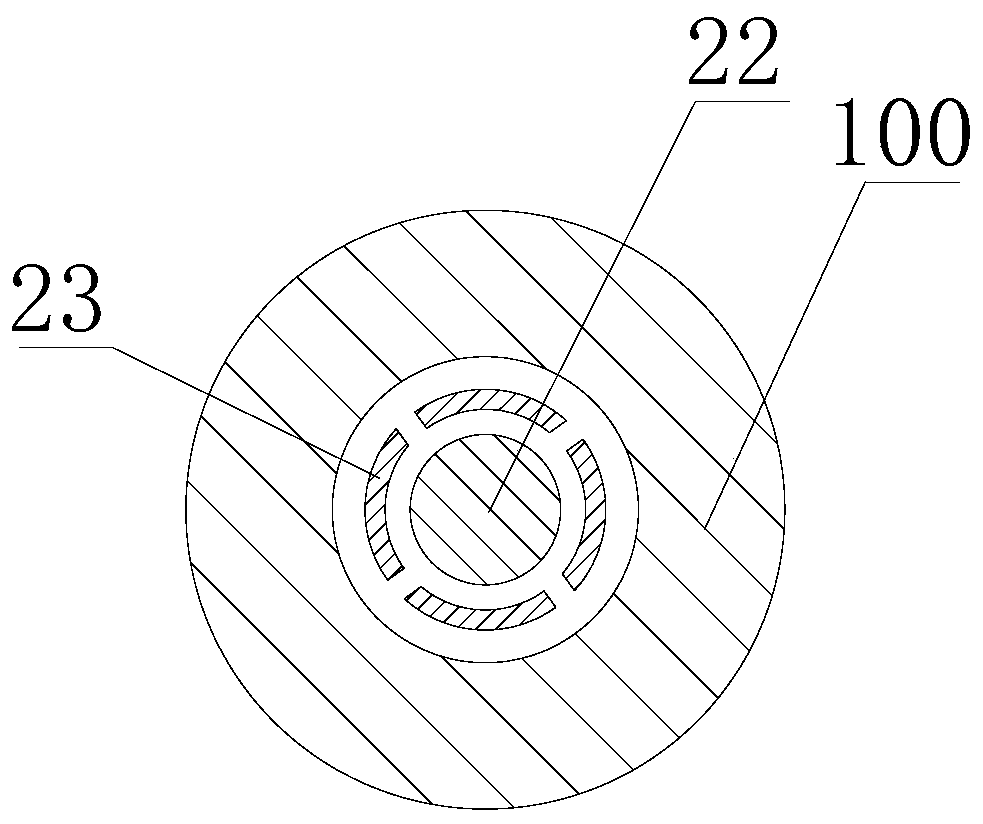

Polisher for artificial knee joint femoral condyle

PendingCN110340741AImprove surface roughnessEasy to GrindPolishing machinesSurface roughnessEngineering

The invention discloses a polisher for an artificial knee joint femoral condyle. The polisher comprises a fixed die, a pressure pump, a magnetic field generator, magnetorheological polishing fluid andstorage. The pressure pump, the fixed die and the storage are connected through pipelines to form a cycle. The magnetorheological polishing fluid is located in the storage and the pipelines. The magnetic field generator is arranged on the fixed die. A holding cavity for fixing a polished part is arranged in the fixed die. An upper channel and a lower channel are further formed in the fixed die and both communicate with the holding cavity. The upper channel communicates with the pressure pump through a pipeline. The lower channel communicates with the storage through a pipeline. The polisher has the advantages that the magnetorheological polishing fluid with pressure is injected, due to the influence of a magnetic field generated by the magnetic field generator on the fixed die, the magnetorheological polishing fluid is converted into a solid-like form, the polished part is polished with pressure, thus fine polishing is achieved, surface roughness of the polished part is improved to ahigh level, and the requirement of human body implantation is met.

Owner:ZHEJIANG CANWELL MEDICAL DEVICES CO LTD

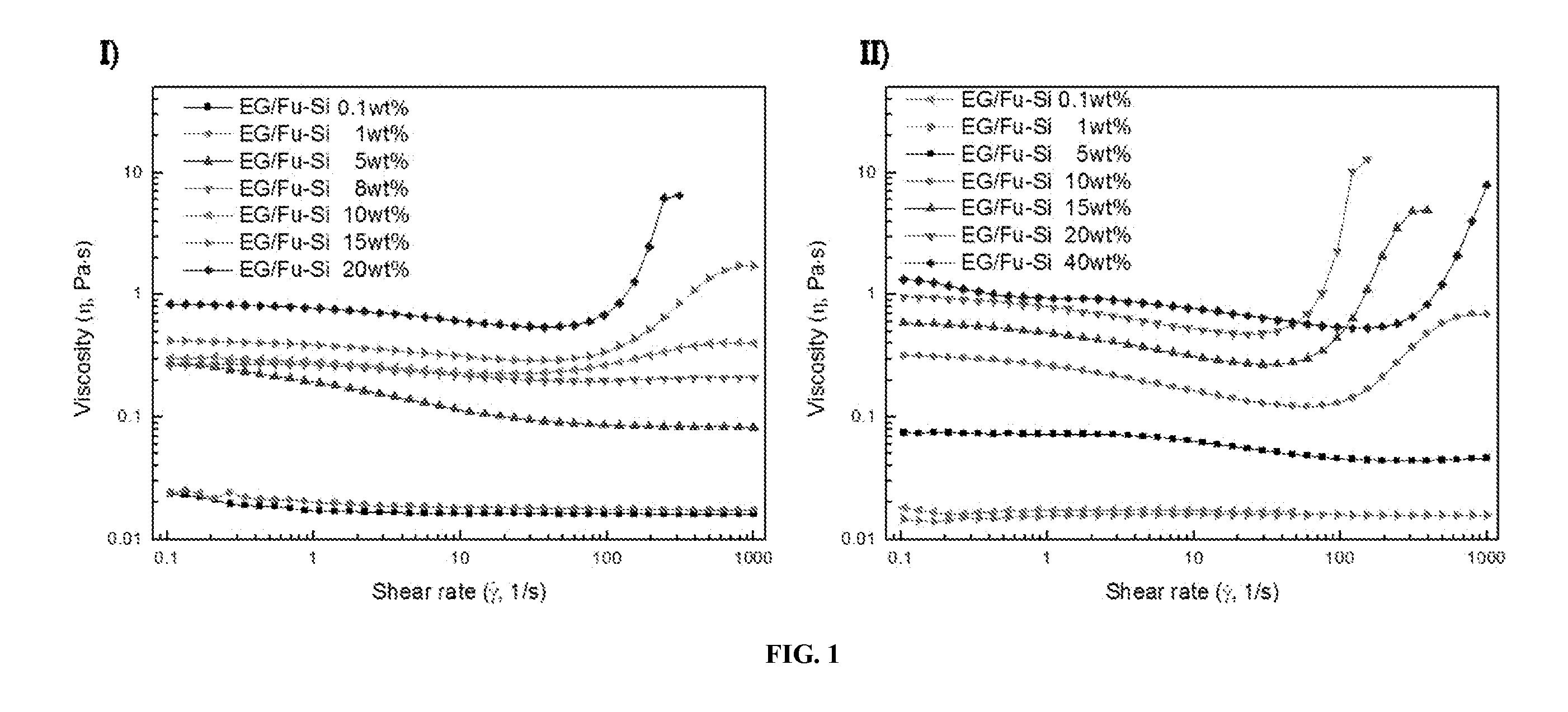

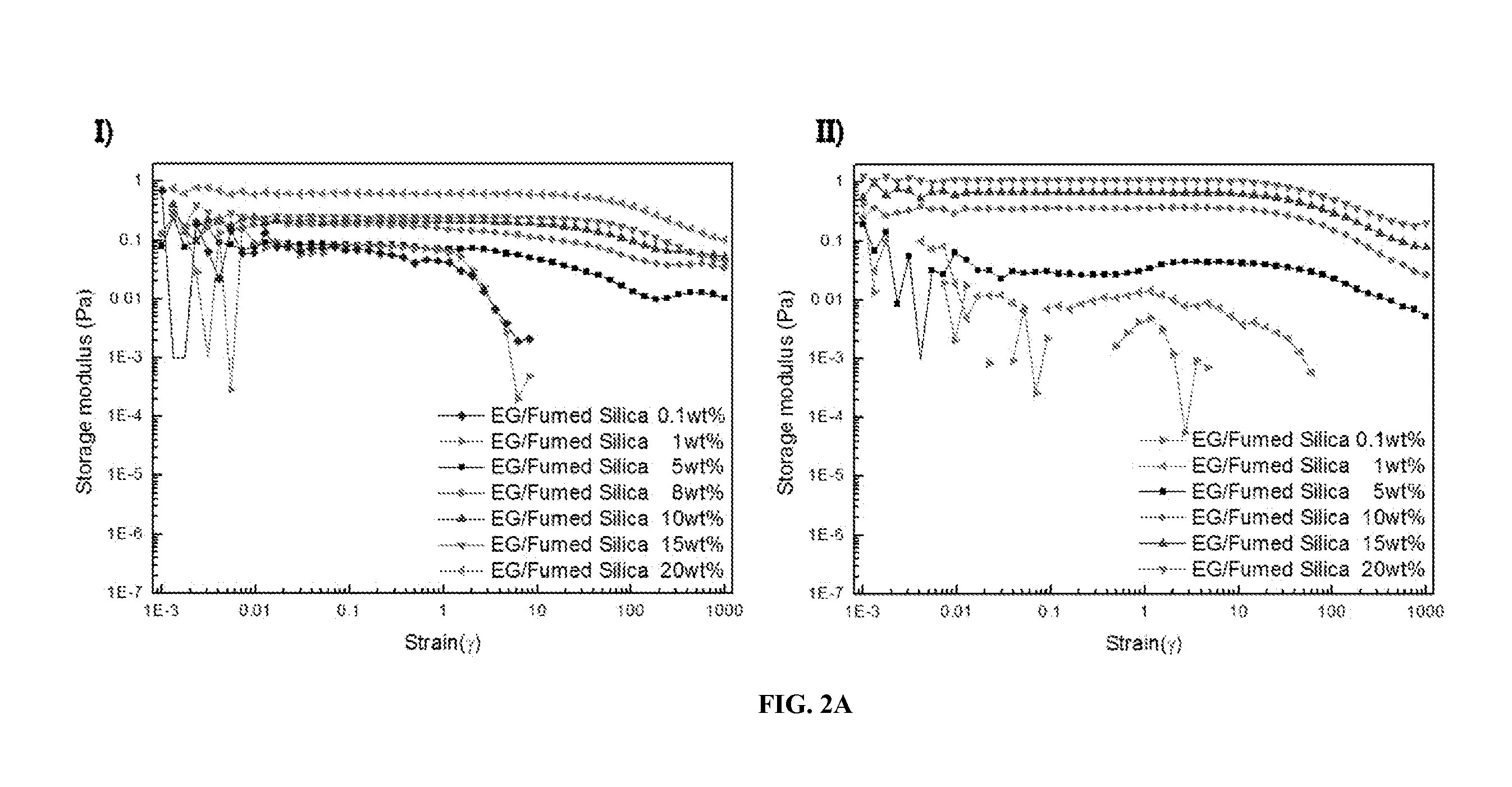

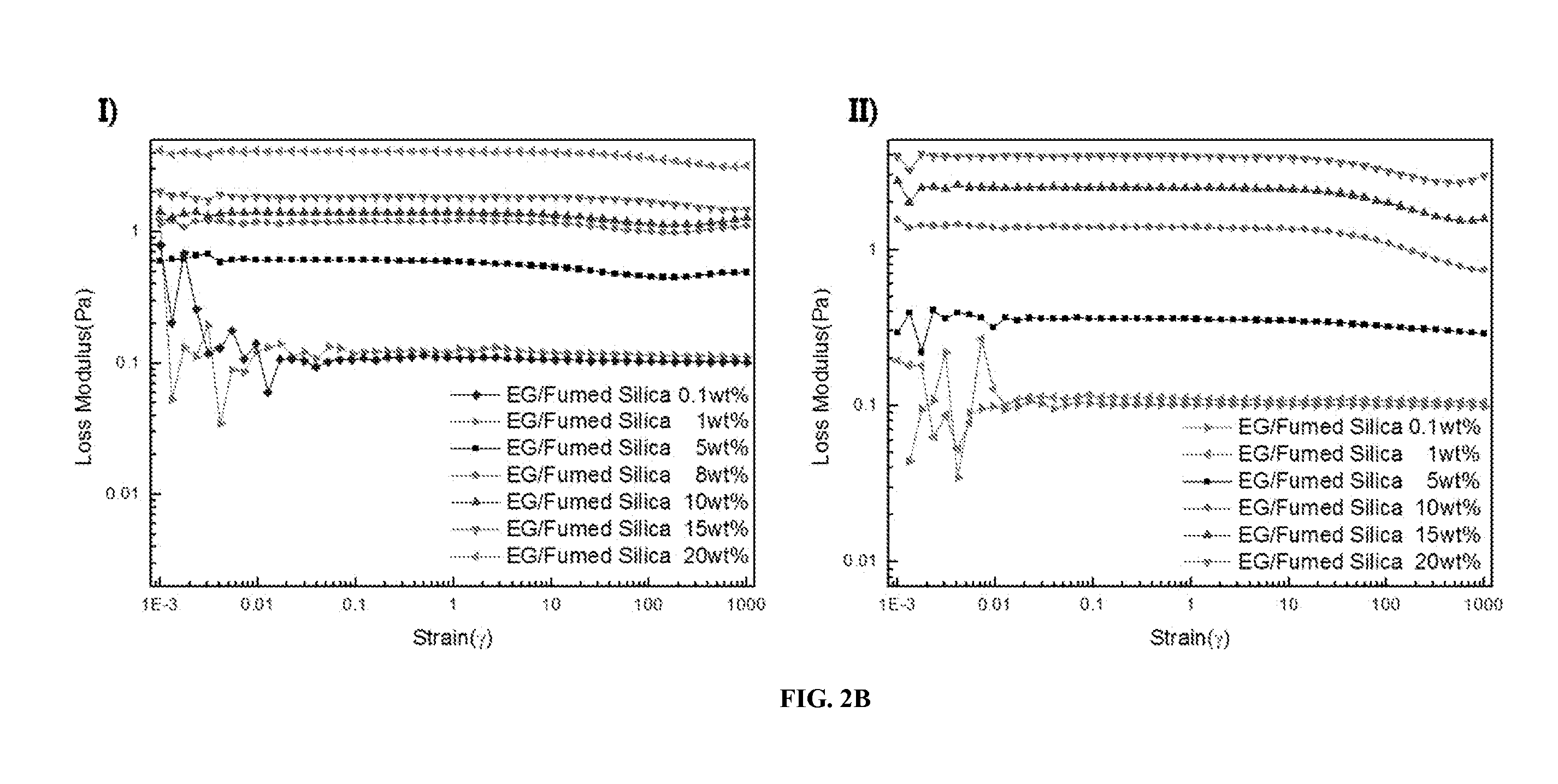

Phase-change suspension fluid composition including fumed silica particles and method for preparing the same

ActiveUS20160130491A1High viscosityIncrease heightOther chemical processesHeat-exchange elementsHigh rateLow frequency band

Disclosed are a suspension fluid and a method for preparing the suspension fluid. Particularly, the suspension fluid is prepared by dispersing fumed silica particles in a solvent that includes one or more compounds selected from the group consisting of ethylene glycol and propylene glycol, and water. The phase-change suspension fluid obtained from the present invention is a shear thickening fluid that have a constant Newtonian behavior at a low rate of shear or a low frequency band, and further have a non-Newtonian behavior as a solid-like suspension at a high rate of shear or a high frequency band due to an increase in viscosity. In addition, the phase-change suspension fluid may reversibly change its phase with vibration of a vehicle, thereby providing advantages of both of the hydro bushes and the solid type bushes.

Owner:HYUNDAI MOTOR CO LTD

A pellicle for lithography

InactiveCN102081299ASemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentLithographic artistDecomposition

A pellicle 10 for lithography includes a pellicle frame 3, a pellicle membrane 1 adhered onto the upper end surface of the pellicle frame 3 and an agglutinant layer 4 formed on the lower surface of the pellicle frame 3 and the agglutinant layer 4 is formed by hardening a curable composition containing a straight chain perfluoro compound having a perfluoro structure in a main chain. The thus constituted pellicle 10 generates only a small amount of a decomposition gas even when it is used for a long time, thereby preventing solid-like foreign materials from separating out on a pattern region of a photomask 5 and can suppress degradation of an the agglutinant agent contained in an agglutinant layer 4 to be used for fixing a photomask 5 to the pellicle frame 3. Further, this pellicle 10 can be easily peeled off from a photomask 5 and replaced with a new one.

Owner:SHIN ETSU CHEM CO LTD

Laser and magnetorheological fluid coupling polishing device

PendingCN110170887AShear resistanceReduced shear resistanceOptical surface grinding machinesGrinding drivesLaser transmitterMagnetorheological fluid

The invention discloses a laser and magnetorheological fluid coupling polishing device. The laser and magnetorheological fluid coupling polishing device comprises a laser transmitter, a laser guide rail, an electromagnet, a polishing wheel, a rotatable support, a laser guide rail sliding block, a bottom seat, a workpiece feeding device and a magnetorheological fluid circulation device. The laser and magnetorheological fluid coupling polishing device adopts coupling effect of magnetorheological fluid and laser for polishing, is high in processing efficiency and processing accuracy, and good inprocessing quality, and easily controls processing conditions. The magnetorheological fluid is changed into solid-like substances under the action of a magnetic field, and the solid-like substances are equivalent to a plurality of flexible grinding heads, and then the flexible grinding heads perform opposite movement relatively to a workpiece under drive of the polishing wheel, and thereby achievegrinding and polishing effects. The laser can transmit heat to the surface of the workpiece through heat conduction, and therefore shear resistance on the surface of the workpiece is reduced, the surface of the workpiece is softened, and polishing efficiency and polishing quality are improved. The workpiece feeding device achieves precise processing for each position on a part in irregular shape.The magnetorheological fluid circulation device achieves cyclic utilization for the magnetorheological fluid. The laser and magnetorheological fluid coupling polishing device is ingenious in design and low in manufacture cost.

Owner:HEBEI UNIV OF TECH

Apparatus and method for using a viscoelastic cleaning material to remove particles on a substrate

ActiveCN102387872ADetergent mixture composition preparationSemiconductor/solid-state device manufacturingPatterned substrateSubstrate surface

The embodiments provide apparatus and methods for removing particles from a substrate surface, especially from a surface of a patterned substrate (or wafer). The cleaning apparatus and methods have advantages in cleaning patterned substrates with fine features without substantially damaging the features on the substrate surface. The cleaning apparatus and methods involve using a viscoelastic cleaning material containing a polymeric compound with large molecular weight, such as greater than 10,000 g / mol. The viscoelastic cleaning material entraps at least a portion of the particles on the substrate surface. The application of a force on the viscoelastic cleaning material over a sufficiently short period time causes the material to exhibit solid-like properties that facilitate removal of the viscoelastic cleaning material along with the entrapped particles. A number of forces can be applied over a short period to access the solid-like nature of the viscoelastic cleaning material. Alternatively, when the temperature of the viscoelastic cleaning material is lowered, the viscoelastic cleaning material also exhibits solid-like properties.

Owner:LAM RES CORP

Method of particle contaminant removal

ActiveUS9159593B2Thin layerEasy to disassembleNon-surface-active detergent compositionsDetergent mixture composition preparationSolid surfaceHigh velocity

Apparatus and methods for removing particle contaminants from a solid surface includes providing a layer of a viscoelastic material on the solid surface. The viscoelastic material is applied as a thin film and exhibits substantial liquid-like characteristics. The viscoelastic material at least partially binds with the particle contaminants. A high velocity liquid is applied to the viscoelastic material, such that the viscoelastic material exhibits solid-like behavior. The viscoelastic material is thus dislodged from the solid surface along with the particle contaminants, thereby cleaning the solid surface of the particle contaminants.

Owner:LAM RES CORP

Building concrete

The invention discloses concrete for a building. The feed additive is prepared from the following raw materials in parts by weight: 80-100 parts of cement, 30-50 parts of river sand, 30-50 parts of gravels, 20-30 parts of fly ash, 5-10 parts of silicon oxide, 20-30 parts of steel fibers, 10-15 parts of a surface enhancer, 8-12 parts of calcium lignosulphonate powder, 8-12 parts of epoxy resin, 6-8parts of acrylic emulsion, 4-6 parts of rubber powder, 1-2 parts of an anti-rust agent, 3-5 parts of auxiliaries and 60-80 parts of water. Compared with the prior art, a certain amount of steel fibers are doped into the concrete, so that the tensile strength, bending resistance, cracking resistance, wear resistance, impact resistance, fatigue resistance, toughness and the like of the concrete canbe improved; the surface reinforcing agent is fully permeated; effective components of the water reducing agent can be quickly subjected to chemical reaction with free calcium in concrete, so that the compactness of the structure is improved, a firm solid like massive rock is formed on the surface layer of the concrete, the strength and the wear resistance of the surface layer of the concrete structure are greatly improved, and the concrete structure is permanently closed, firm, wear-resistant, free of dusting and capable of bearing larger loads.

Owner:安徽虹达道路桥梁工程有限公司

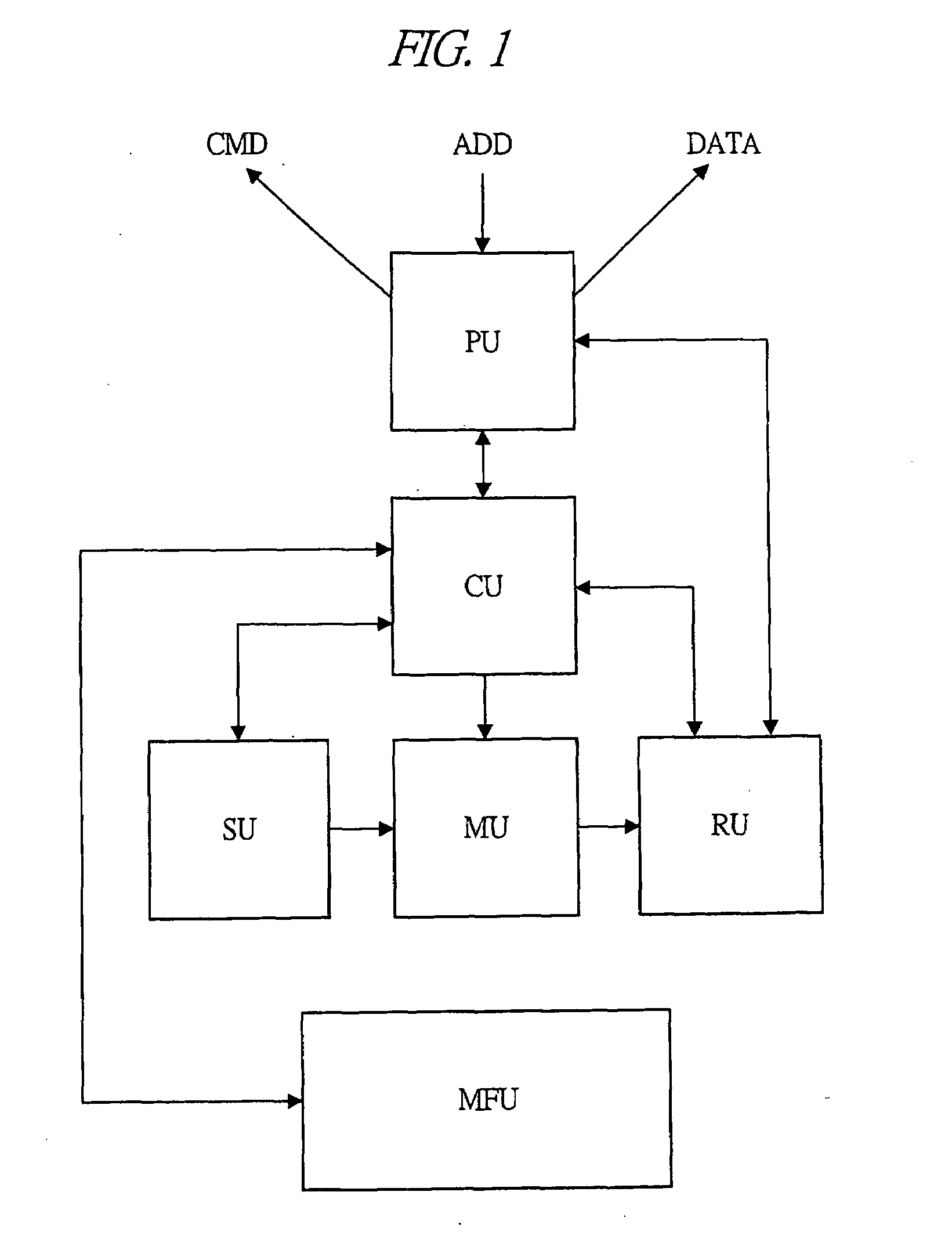

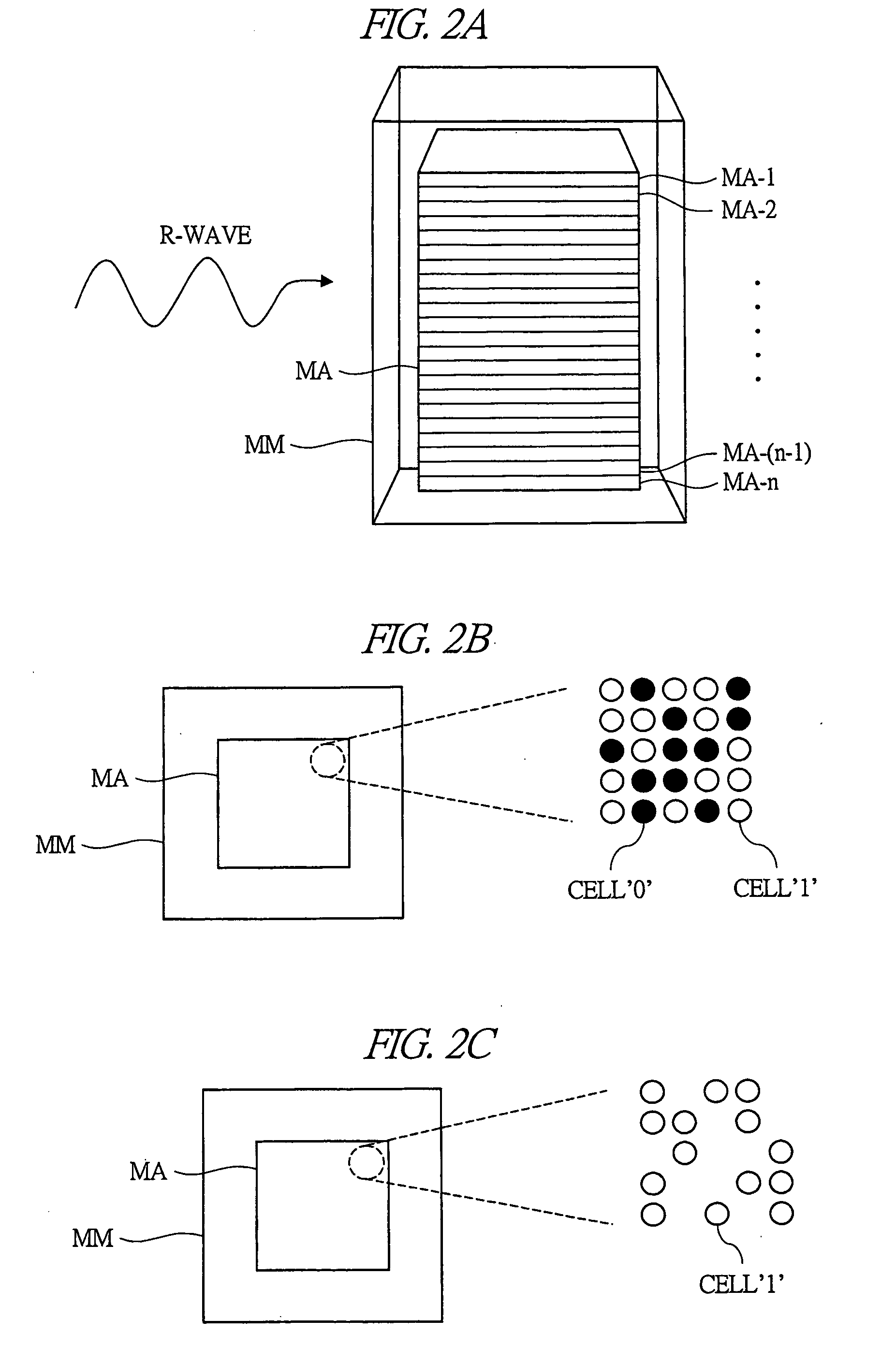

Information memory device and memory medium

InactiveUS20090154304A1Easy to integrateCombination recordingRecord information storageHigh densityThree-dimensional space

An information memory device using an electromagnetic-wave resonance phenomenon is provided to achieve both high density and long-period storage of stored data. Memory cells are three-dimensionally arranged in the inside of a solid-like medium which is not contacted with a surface of the medium, and the memory cell has resonance characteristics to electromagnetic waves depending on the space coordinates of the memory cell. For the medium, a material is selected so that an electromagnetic wave having the resonance frequency of the memory cell. By observing absorption spectra of the irradiated electromagnetic wave or emission spectra after the absorption, three-dimensional space coordinates of the memory cell are calculated.

Owner:HITACHI LTD

Precision machining device for spherical surface of orthopedic implant

PendingCN110340744ARealize automatic polishingHigh polishing precisionGrinding drivesSpherical surface grinding machinesLiquid stateEngineering

The invention discloses a precision machining device for the spherical surface of an orthopedic implant. A polishing body is arranged on a base through a horizontal movement mechanism, a coil is fixedto the polishing body, a polishing groove is formed in the polishing body, magneto-rheological polishing fluid is located in the polishing groove, and a rotating mechanism for clamping and rotating apolished part is arranged above the polishing groove. The horizontal movement direction of the polishing body is consistent with the length direction of the polishing groove. The precision machiningdevice has the beneficial effects that the magneto-rheological polishing fluid is converted into a solid-like form through a magnetic field, the horizontal movement mechanism and the rotating mechanism are simultaneously started, the polished part can relatively move in the horizontal direction while rotating, omni-bearing polishing is carried out, automatic polishing is achieved, as the magneto-rheological polishing fluid is in a liquid state when not collected in the magnetic field, the portion between the side wall of the polishing groove and the polished part can be well filled with the magneto-rheological polishing fluid, after the magneto-rheological polishing fluid is converted into the solid-like state due to the magnetic field change, the magneto-rheological polishing fluid can polish each fine position of the polished part, the polishing precision is greatly improved, and automatic polishing is achieved.

Owner:ZHEJIANG CANWELL MEDICAL DEVICES CO LTD

Method for cleaning petrochemical engineering pipeline with ice slurry

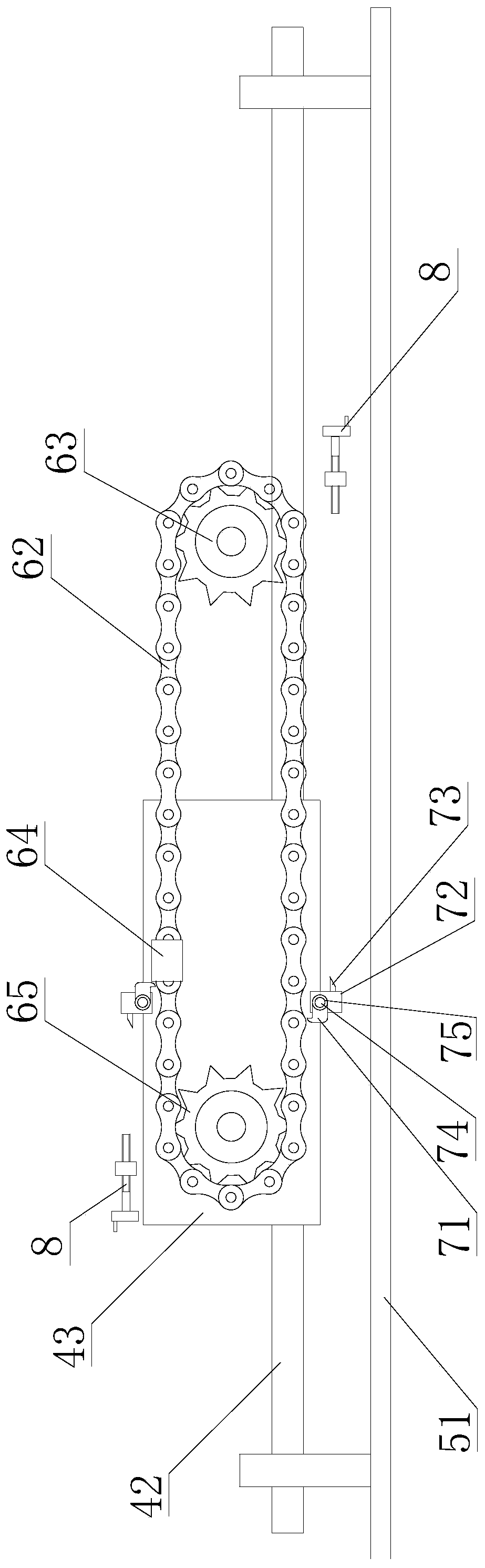

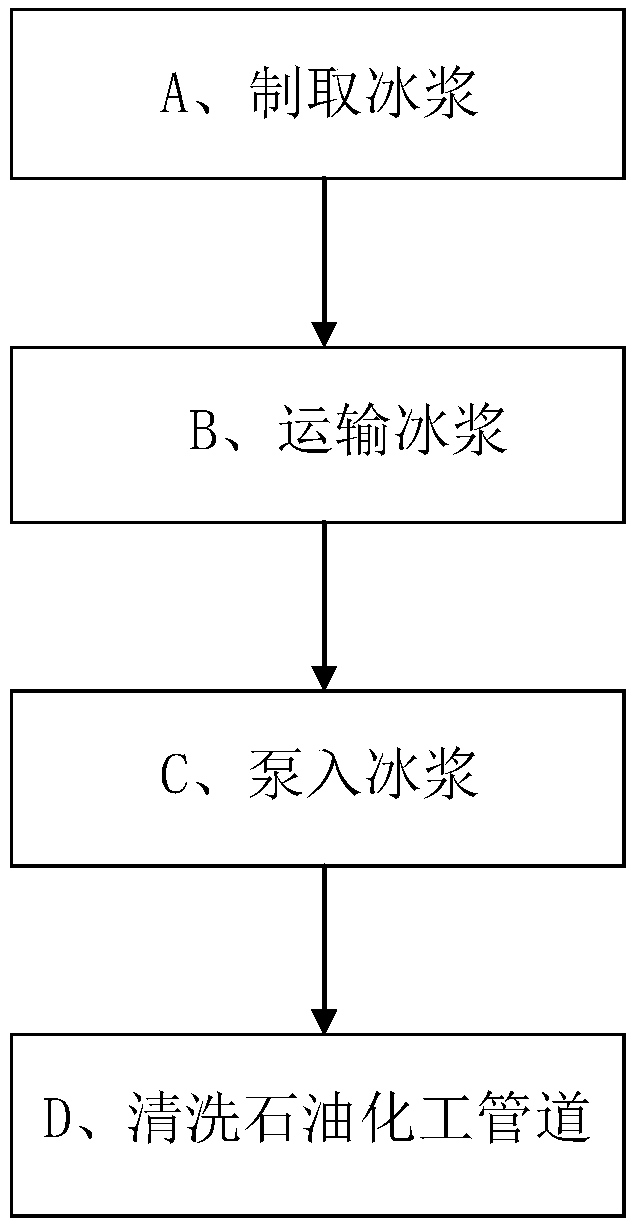

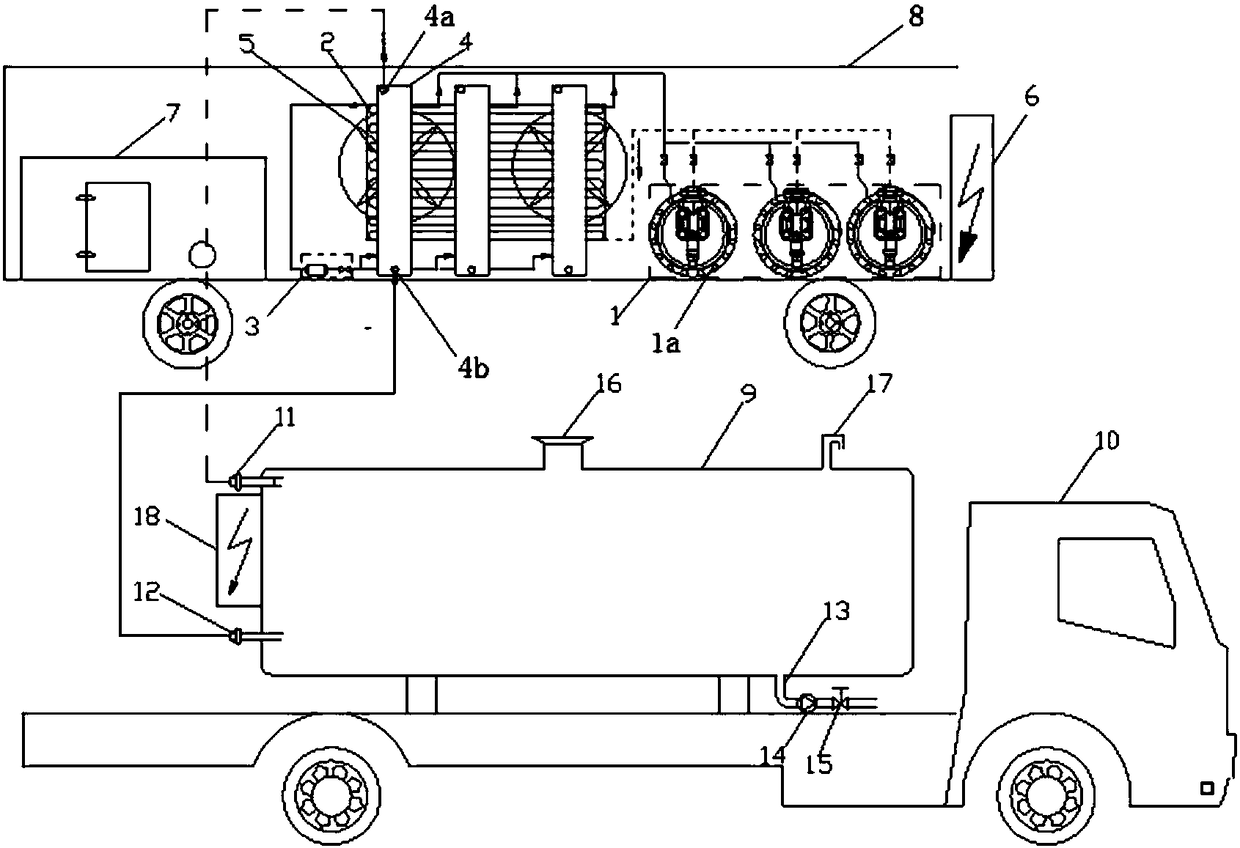

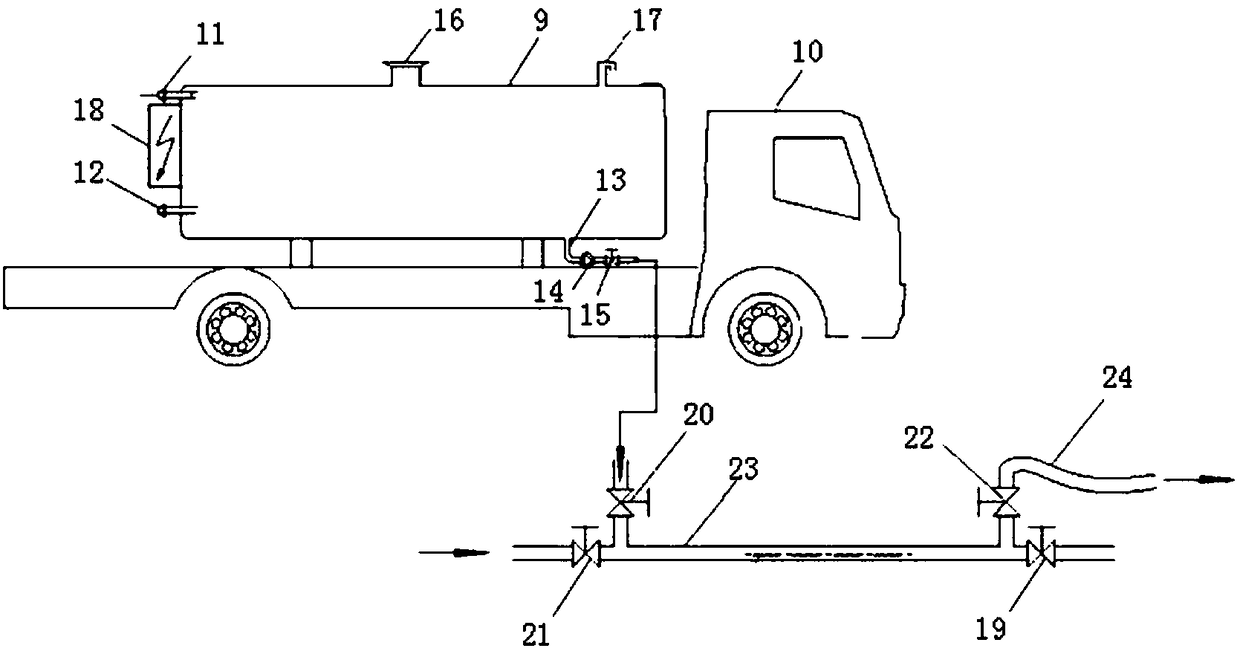

PendingCN108393316AFit tightlyThe appearance of the ice crystal is roundSewer cleaningHollow article cleaningHigh concentrationSlurry

The invention provides a method for cleaning a petrochemical engineering pipeline with ice slurry, and belongs to the technical field of pipeline cleaning methods. The cleaning method includes the steps that A, the ice slurry is prepared, specifically, an ice slurry preparing unit and an ice slurry storing unit are used for preparing the ice slurry in non-working time; B, the ice slurry storing unit containing the prepared ice slurry is conveyed to the to-be-cleaned petrochemical engineering pipeline; C, the high-concentration ice slurry is injected into the to-be-cleaned petrochemical engineering pipeline from a valve port of the petrochemical engineering pipeline by utilizing an ice slurry conveying pump, and the high-concentration ice slurry forms a solid-like ice column in the petrochemical engineering pipeline and has flowability; and D, the high-concentration ice slurry is pushed to flow through the petrochemical engineering pipeline by pressure or power of the ice slurry conveying pump or original fluid in the pipeline, so that the cleaning purpose is achieved. The cleaning method is adopted for cleaning the interior of the pipeline with the ice slurry, no chemical agent isused, and the method is environmentally friendly and safe.

Owner:广州中臣埃普科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com